A kind of vehicle door assembly accuracy detection method

A detection method and technology of assembly accuracy, applied in the direction of measuring device, mechanical measuring device, using mechanical device, etc., can solve the problems of machining and manufacturing error, measurement error, inability to judge out-of-tolerance parts in time, etc., to improve machining accuracy and machining benchmark. unifying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

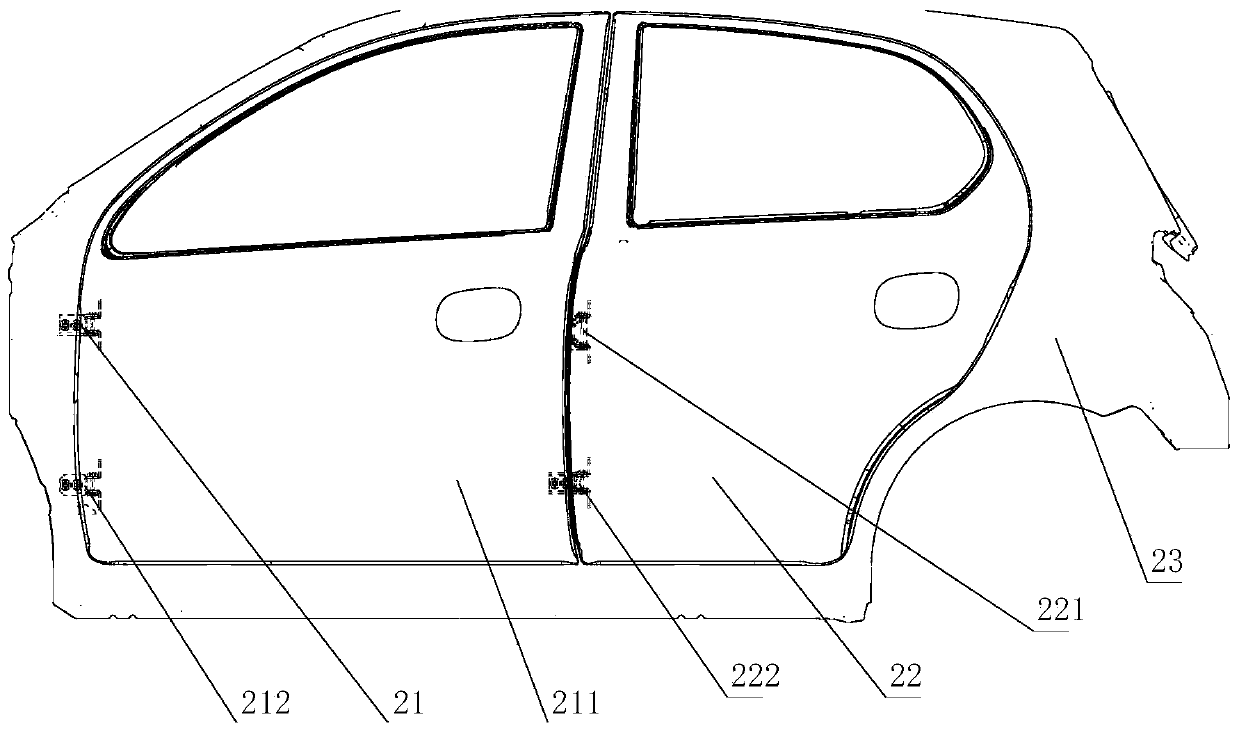

[0060] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. Taking the left door as an example, the right door is symmetrical to it.

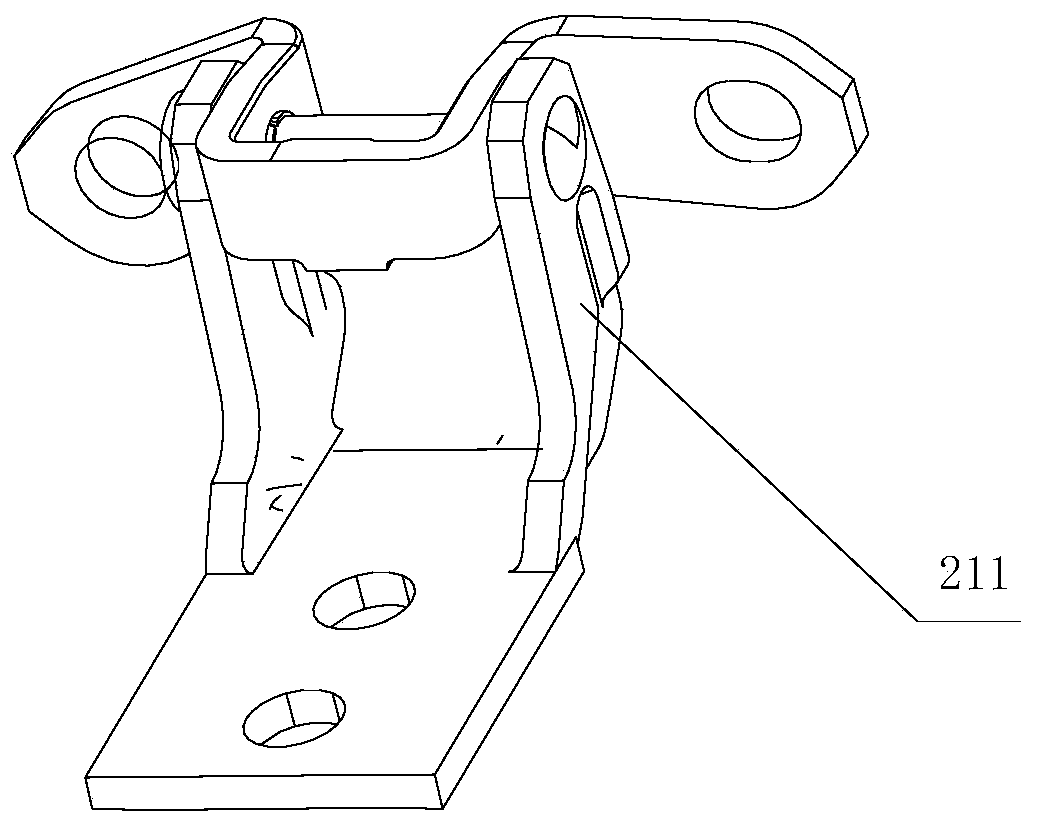

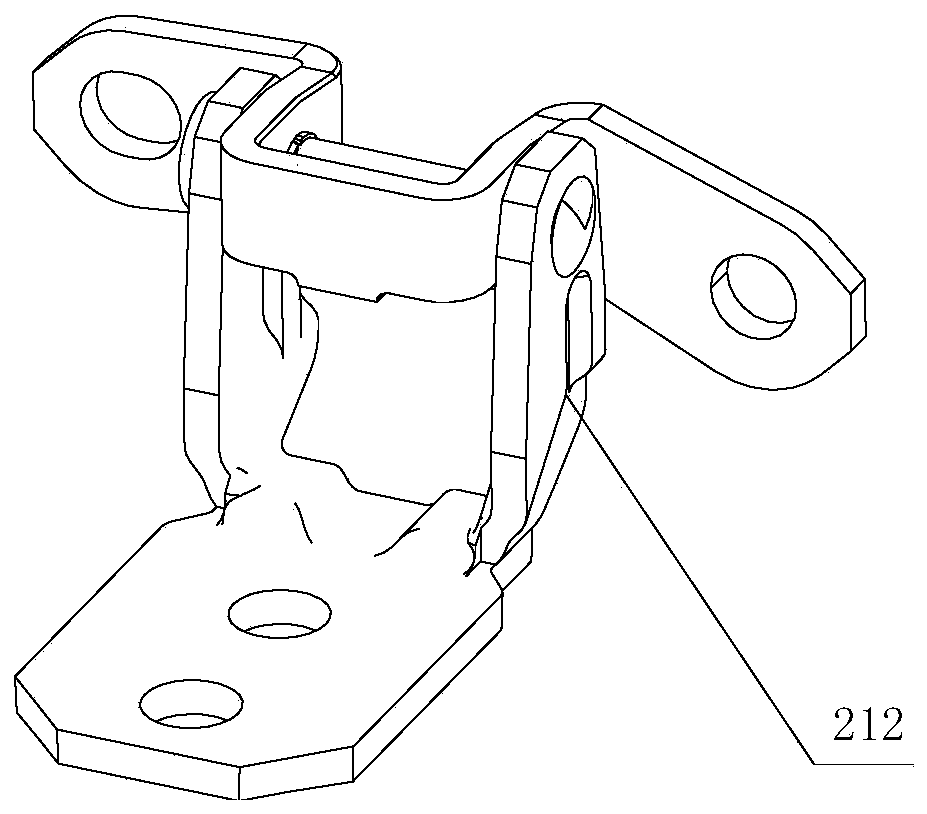

[0061] Such as Figure 1-5 As shown, the door assembly of a four-door automobile includes a front door 21 (left front door) and a rear door 22 (left rear door). The front door 21 is installed on the vehicle body through a front door upper hinge 211 and a front door lower hinge 212. 22 is installed on the vehicle body by the upper hinge 221 of the rear car door and the lower hinge 222 of the rear car door, and the car door hinge parts rely on bolts to be fixedly installed on the side wall and the car door. The door hinge is used as an opening and closing part. When the matching gap and surface difference are out of tolerance during the assembly of the front and rear doors and the body, it is necessary to judge the out-of-tolerance of the eight parts of the front and rear d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com