Clicking press

A technology of press and die, applied in the field of rotary arm die press, can solve the problems of reduced processing quality, not allowed to use the entire area, limited workpiece size, etc., to save time, high quality and consistent quality processing, easy to operate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

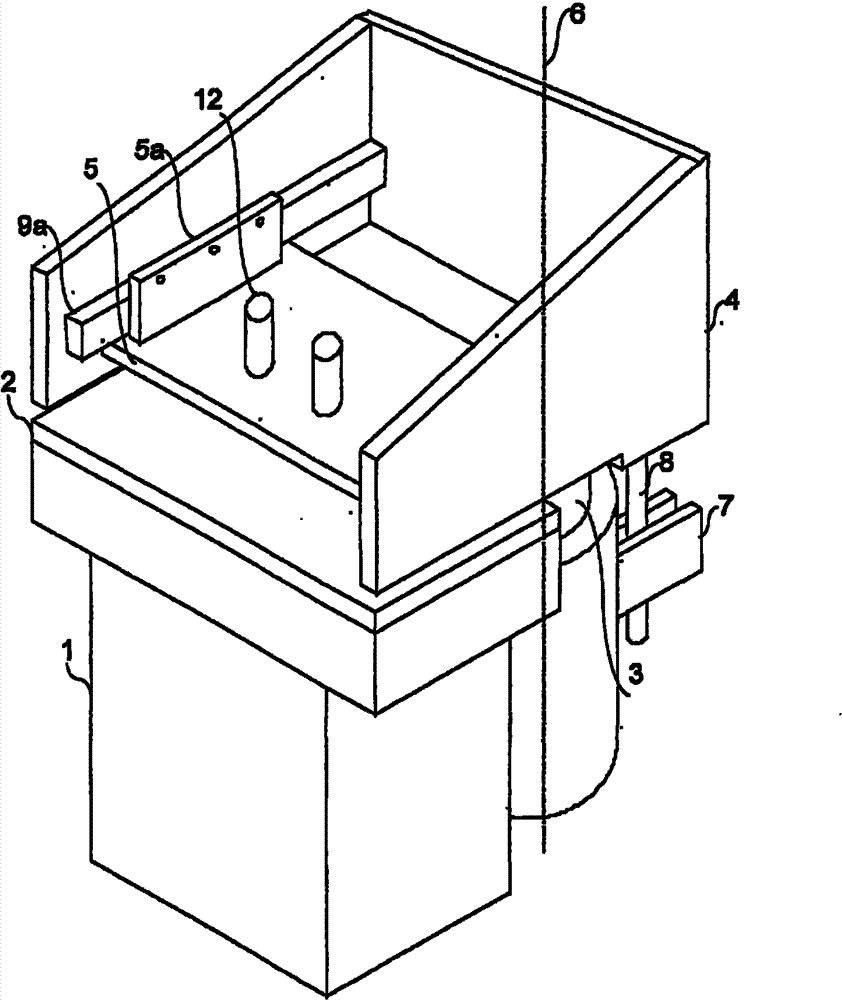

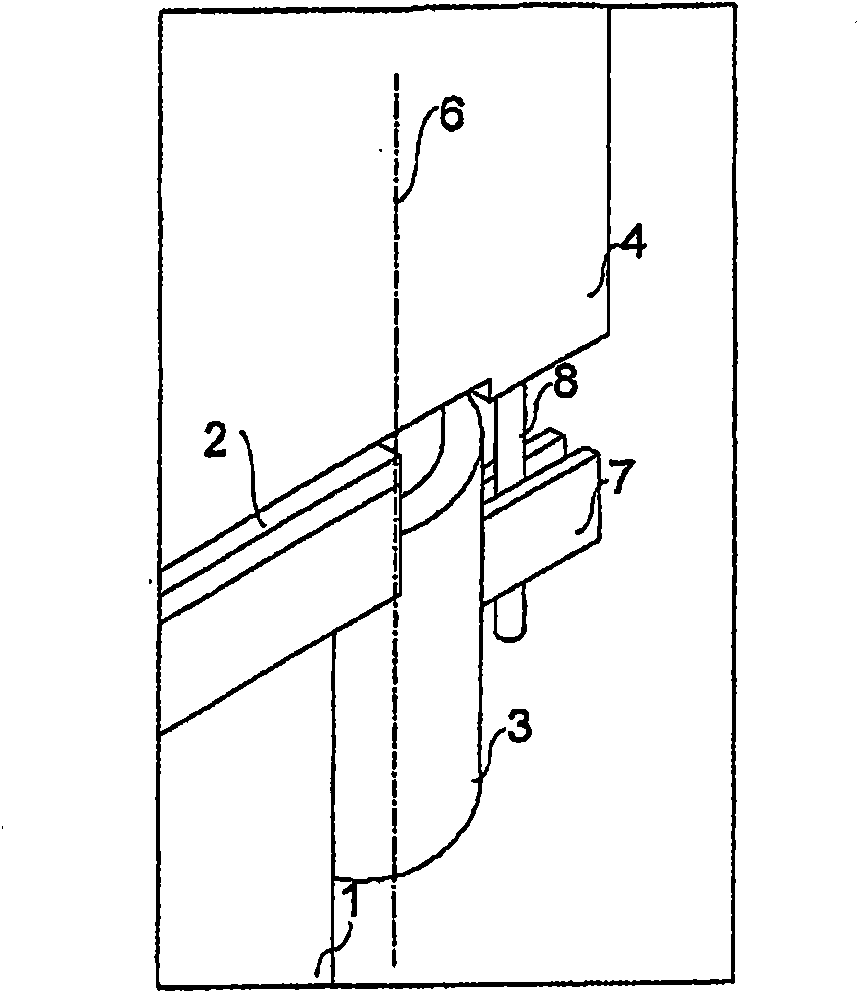

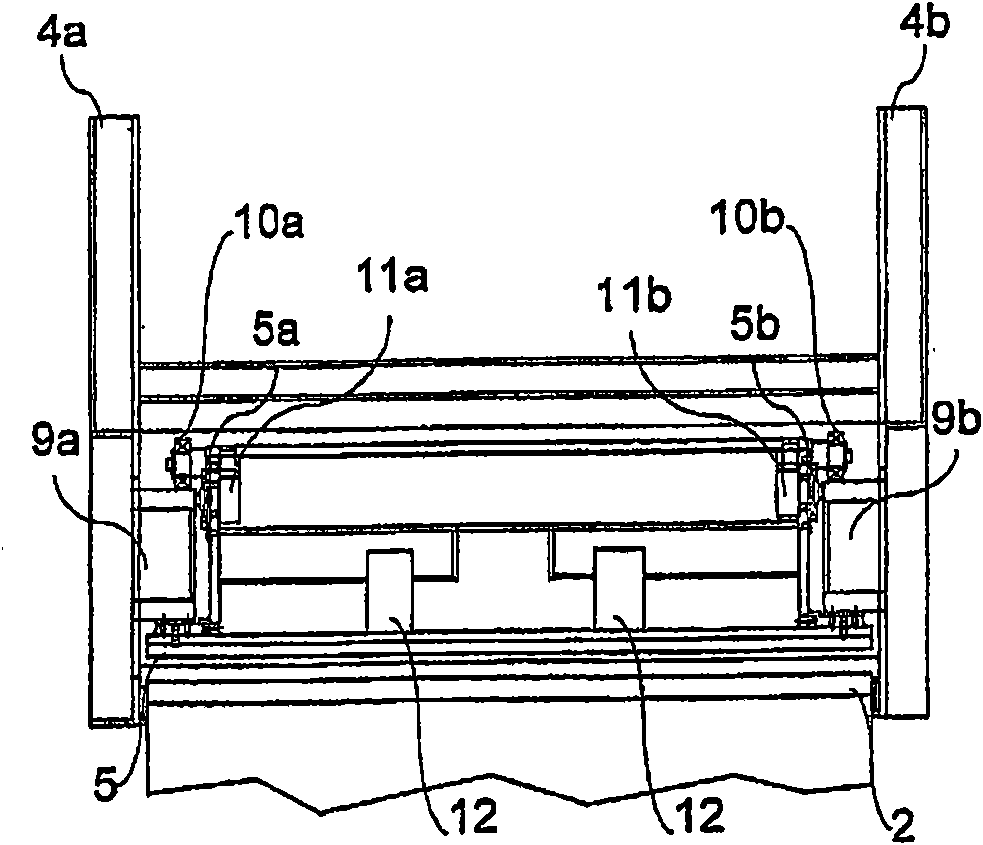

[0014] refer to figure 1 , the die press according to the invention comprises, in a known manner, a base body 1 on top of which a working surface 2 is arranged. This base body 1 has a vertical support 3 on which an arm 4 is fixed so as to support a pressing surface 5 substantially parallel to the working surface 2 . For the punching operation, the support 3 is movable in the vertical direction and is driven by a drive arranged inside the basic body 1 , for example a hydraulic servomechanism. Arm 4 is rotatable relative to base 1 about vertical axis 6

[0015] According to the invention, the die press also comprises blocking means of the arm 4 comprising a first blocking element 7 arranged on the base body 1 and a second blocking element 8 arranged on the arm 4 . The first and second blocking elements are adapted to engage one in the other so as to define an operative position of the arm 4 in which the pressing surface 5 substantially overlaps the working surface 2 . Further...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com