Spherical tube machine tool and machining method thereof

A technology for processing machine tools and spherical tubes, which is applied in the field of workpiece processing, can solve problems such as the inability to meet the requirements for the use of workpieces, poor pressure bearing capacity and sealing effect, and the inability to realize hollow metal balls, so as to improve processing efficiency and processing accuracy, avoid Roller wear, uniform force and consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

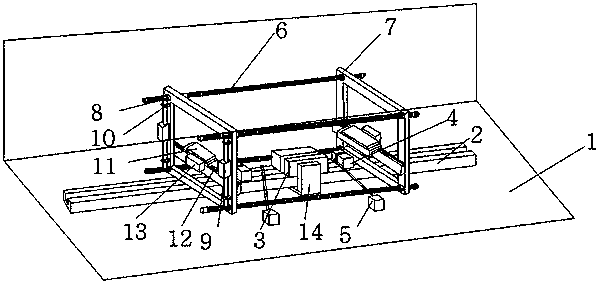

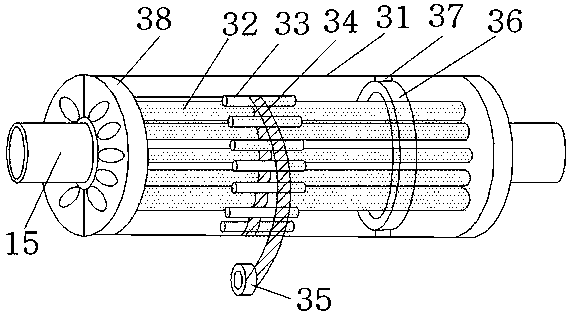

[0040] see figure 1 , a spherical tube processing machine tool, including a frame 1, a guide rail 2 arranged on the frame 1, and a double-ended synchronous mold that is slidably connected to the guide rail 2, and a clamp 3 and two forming molds are also slidably connected to the guide rail 2 Block 4, the clamp 3 is used to clamp the workpiece 15, the forming block 4 is located at both ends of the workpiece 15, and is used to process the external shape of the two ends of the workpiece 15, the frame 1 is provided with a heating device 5, the heating device 5 is a high-frequency induction heater, and a heating ring is arranged on the high-frequency induction heater. The inner diameter of the heating ring is larger than the outer diameter of the workpiece 15, so that the heating ring is conveniently placed outside the workpiece 15, and the heating device 5 can simultaneously heat the workpiece 15 .

[0041] By being provided with forming blocks 4, the two ends of the workpiece 15...

Embodiment 2

[0061] A processing method using the above-mentioned spherical tube processing machine tool, comprising the following steps:

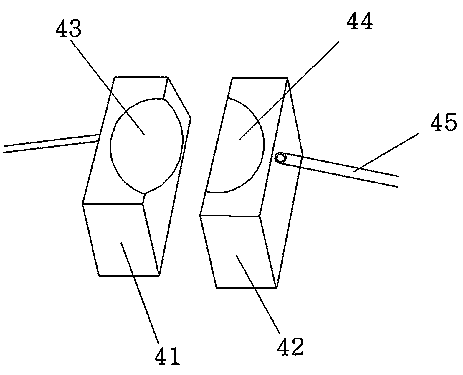

[0062] a), the workpiece 15 is installed, and the specific operation of installing and locking the workpiece 15 to be processed in the cavity is as follows: the left housing and the right housing move backwards with the movement of the support frame 311 under the contraction of the cylinder 39 , so that the left housing and the right housing rotate outward, the top of the fixture 3 forms a gap, the gap communicates with the cavity containing the workpiece 15, the workpiece 15 is installed in the cavity from the gap at the top of the fixture 3, and the two ends of the workpiece 15 Stretch out of the clamp 3; after the cylinder 39 is reset, the left housing and the right housing move towards each other with the movement of the support frame 311, so that the top of the clamp 3 is closed. Direction movement clamps the workpiece 15, detects and corrects the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com