A new method of making a microprism type reflective material mold

A technology of reflective materials and production methods, applied in optics, optical components, instruments, etc., can solve problems such as difficult to meet the intensity of reflected light, harsh processing equipment and technology, difficult adjustment and replacement, etc., to achieve excellent wide-angle, processing method Simple and easy processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

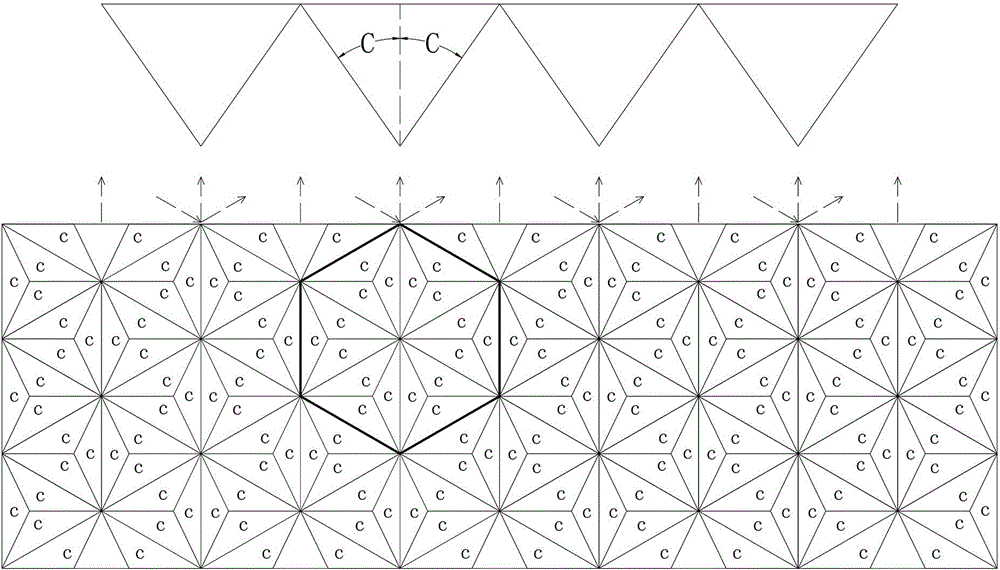

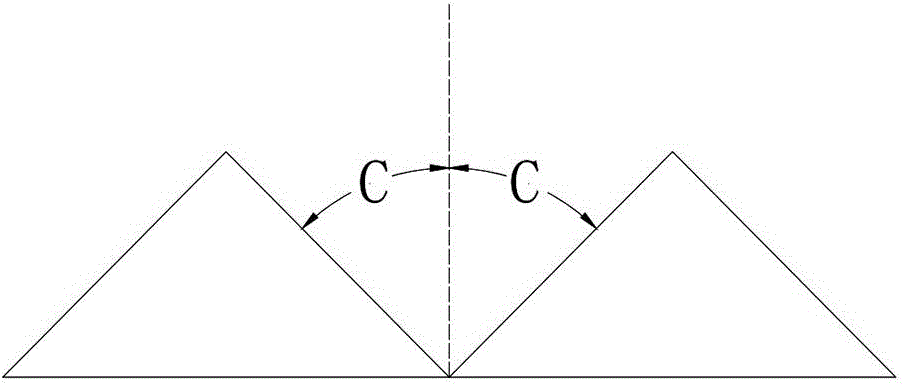

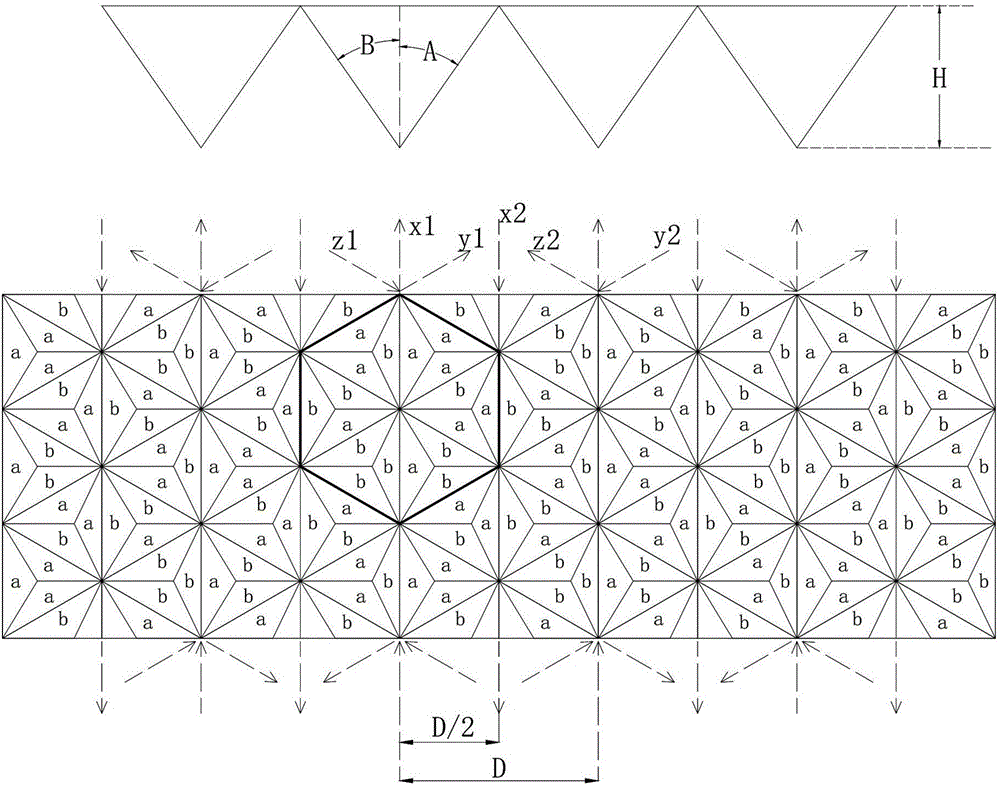

[0032] Such as Figure 3 to Figure 5 Shown, a kind of manufacturing method of novel microprism type reflective material mould, comprises the following steps:

[0033] (a) On a flat substrate, use a tool to cut the substrate in three directions, the angle between the three cutting directions is 60 degrees, the distance D between the cutting lines in the three cutting directions is 300 μm to 500 μm, and the cutting depth H is 60 μm to 110 μm, the tool has two cutting angles A and B with different angles, the cutting angle A is 35.2 degrees to 35.4 degrees, and the cutting angle B is 35.1 degrees to 35.3 degrees;

[0034] (b) The tool is offset by a distance D / 2, and the substrate is cut in a direction opposite to the three cutting directions in step (a), and a microprism type reflective material mold is formed after cutting.

[0035] Specifically, such as image 3As shown, in the step (a), the cutting is performed along the x1 direction first, and the substrate is rotated 60 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com