Method for controlling cutting quantity of spiral bevel gear

A technology of spiral bevel gears and control methods, which is applied in general control systems, control/regulation systems, instruments, etc., and can solve problems such as difficulty in forming mathematical models and complex causes of tooth surface quality problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

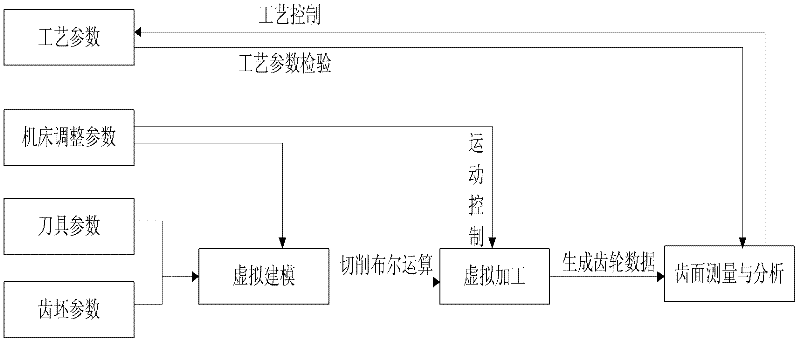

Method used

Image

Examples

Embodiment 1

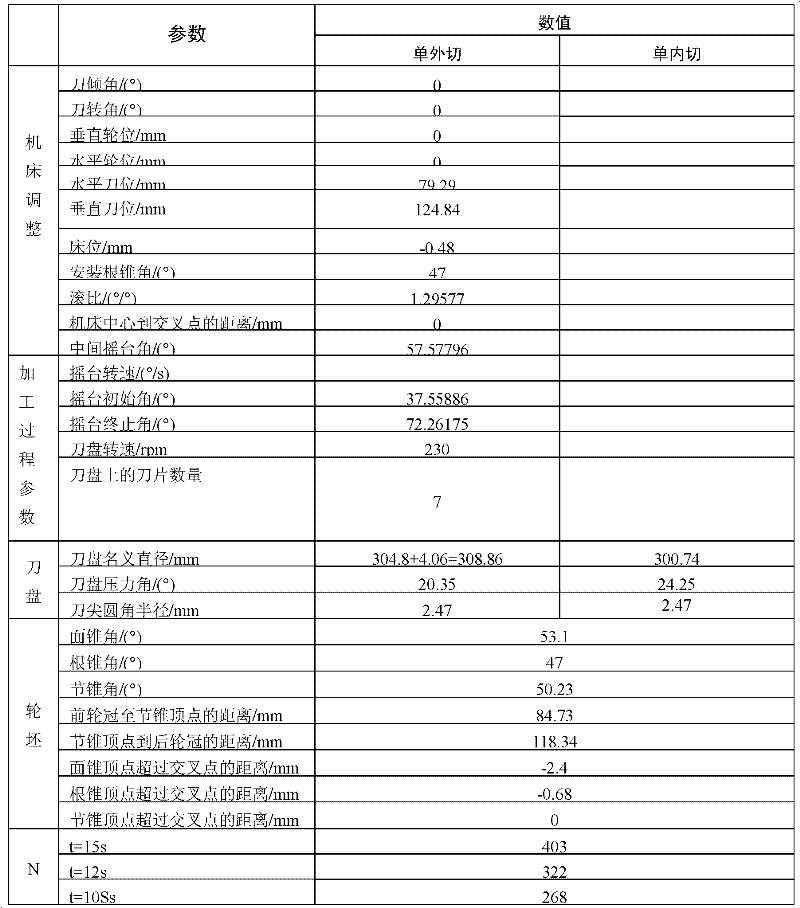

[0043] In this example, when the cutting amount of the high-speed cutting machine tool is less than 0.11 mm, the vibration is small, and the surface finish of the processed tooth surface is high. It is necessary to determine the processing time when the cutting amount is less than 0.11mm. The known parameters are shown in Table 1:

[0044] Table 1 Relevant parameters and calculated values of cutting inserts

[0045]

[0046] In the hobbing process of the spiral bevel gear, a disc milling cutter is used, and the cutter head speed n and the number of blades m are known, and the processing time t and the cradle speed w need to be determined.

[0047] 1) Use the solid modeling in the CAM software Solidworks to establish the model of the blade and the gear blank, determine the reasonable start angle and end angle of hobbing, and calculate the swing angle range of the cradle q=72.26175-37.55886.

[0048] 2) Segment the required time. The cutting time determined in this example...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com