A crop waste crushing and compressing device

A compression device and crop technology, applied in agriculture, agricultural machinery and implements, cutting equipment, etc., can solve the problem of crop waste processing and other problems, and achieve the effect of facilitating post-processing, ensuring safety, and uniform powder particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

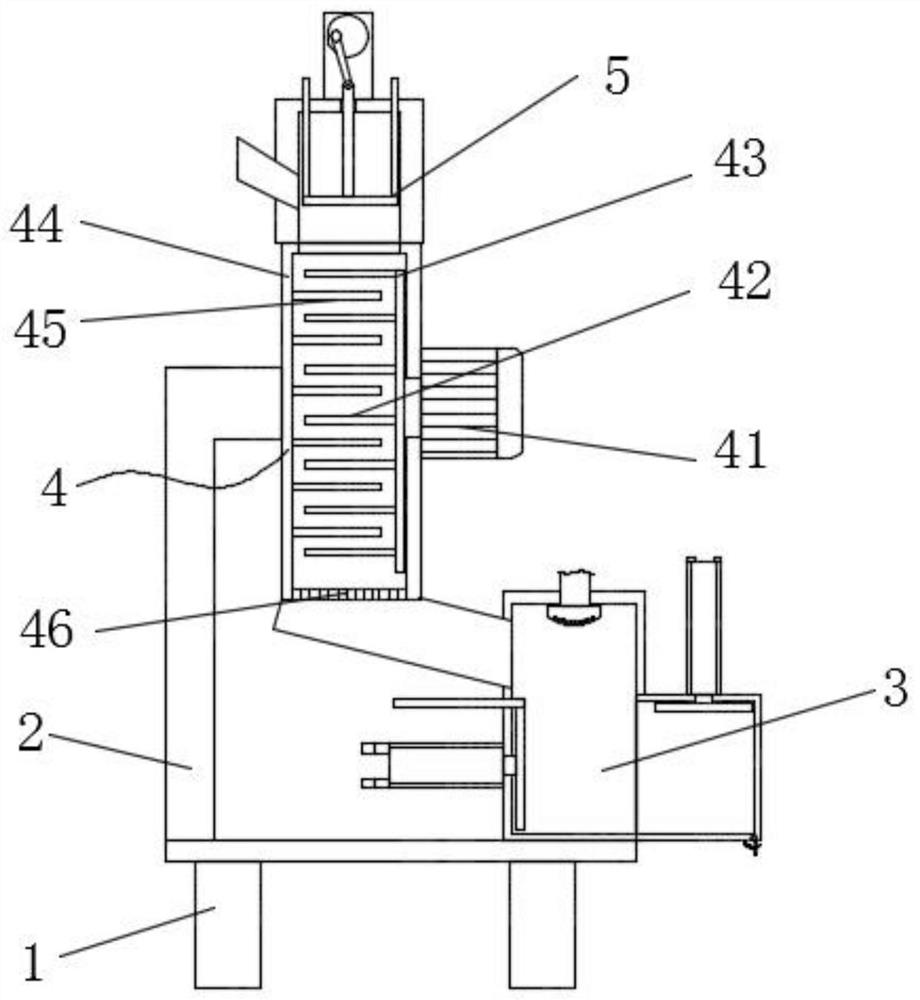

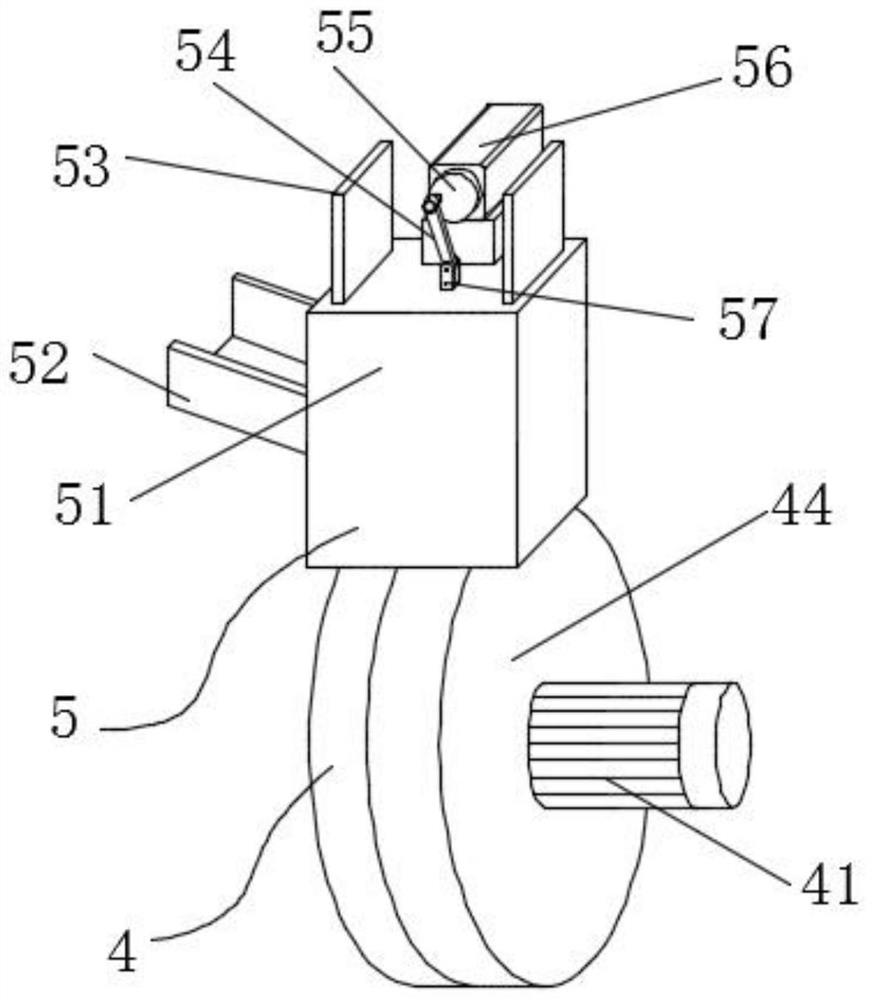

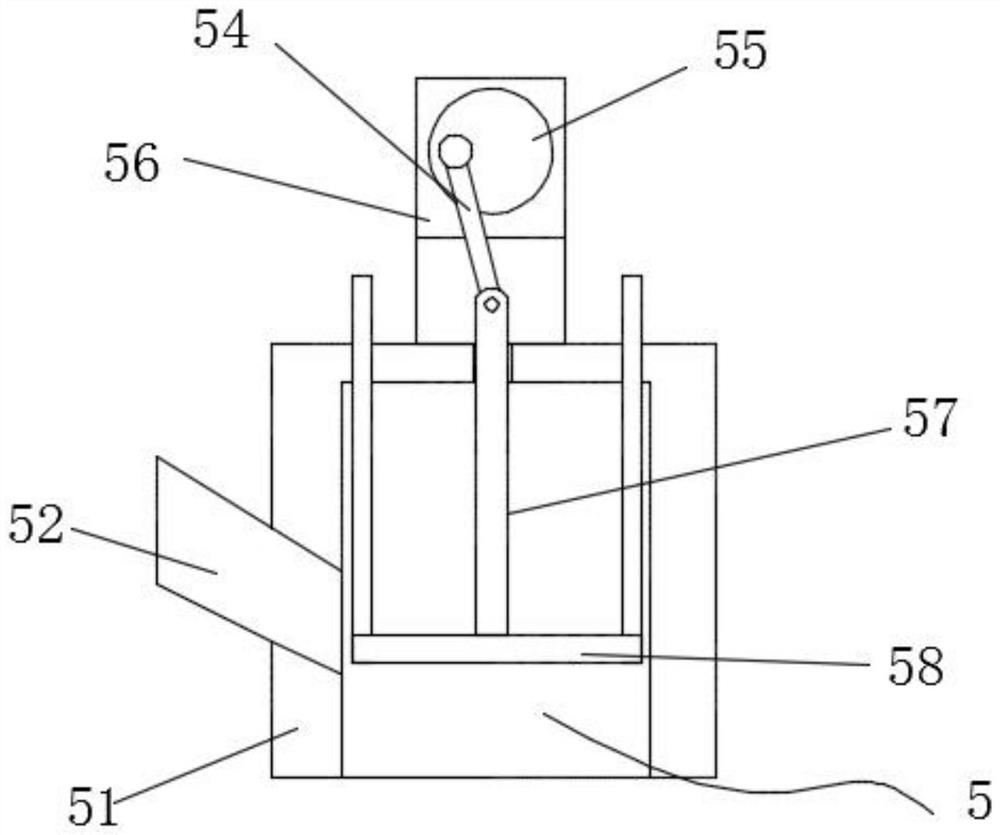

[0033] Such as Figure 1-5 As shown, a crop waste crushing and compressing device includes: a support frame 1, a fixed beam 2, a compression molding structure 3, a crushing structure 4 and a pushing structure 5, the fixed beam 2 is fixed on the top side of the fixed beam 2 by welding, The compression molding structure 3 is installed on the top side of the support frame 1, the crushing structure 4 is fixed on the top end of the fixed beam 2, and the pushing structure 5 is installed on the top side of the crushing structure 4;

[0034] The compression molding structure 3 includes an extrusion cylinder 31, an extrusion plate 32, a parallel baffle 33, a material guide pipe 34, a material storage box 35, a nozzle 36, a push cylinder 37, a push plate 38, a forming box 39, and a limit rod 310, a positioning plate 311, an extruding spring 312 and a discharge door 313, the extruding cylinder 31 is installed at the bottom of one side of the outer wall of the material storage box 35, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com