Multichannel parallel automatic solid phase extraction device

An extraction device and multi-channel technology, applied in the field of multi-channel parallel automatic solid-phase extraction devices, can solve the problem of high price and achieve the effect of consistent sample processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

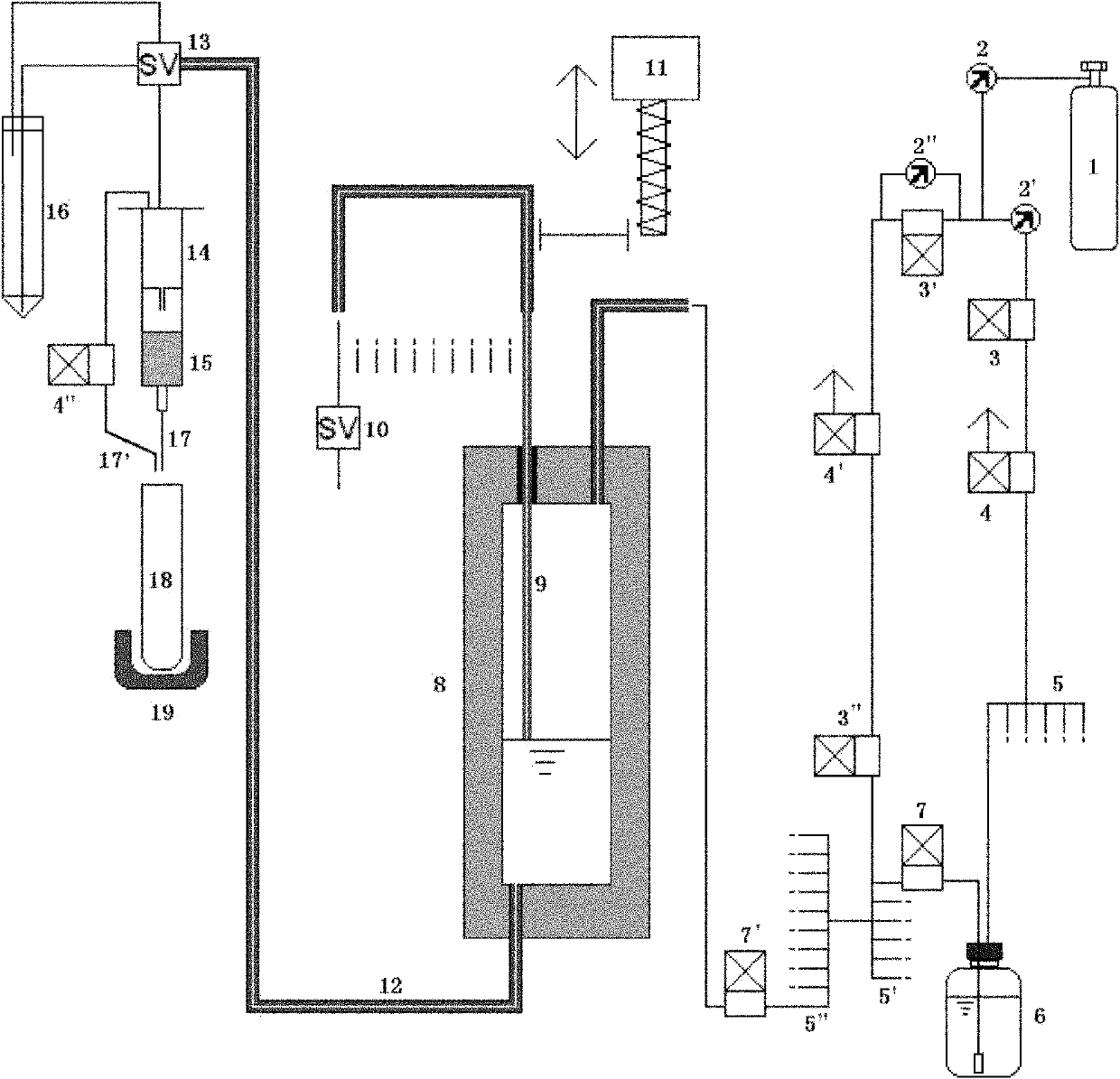

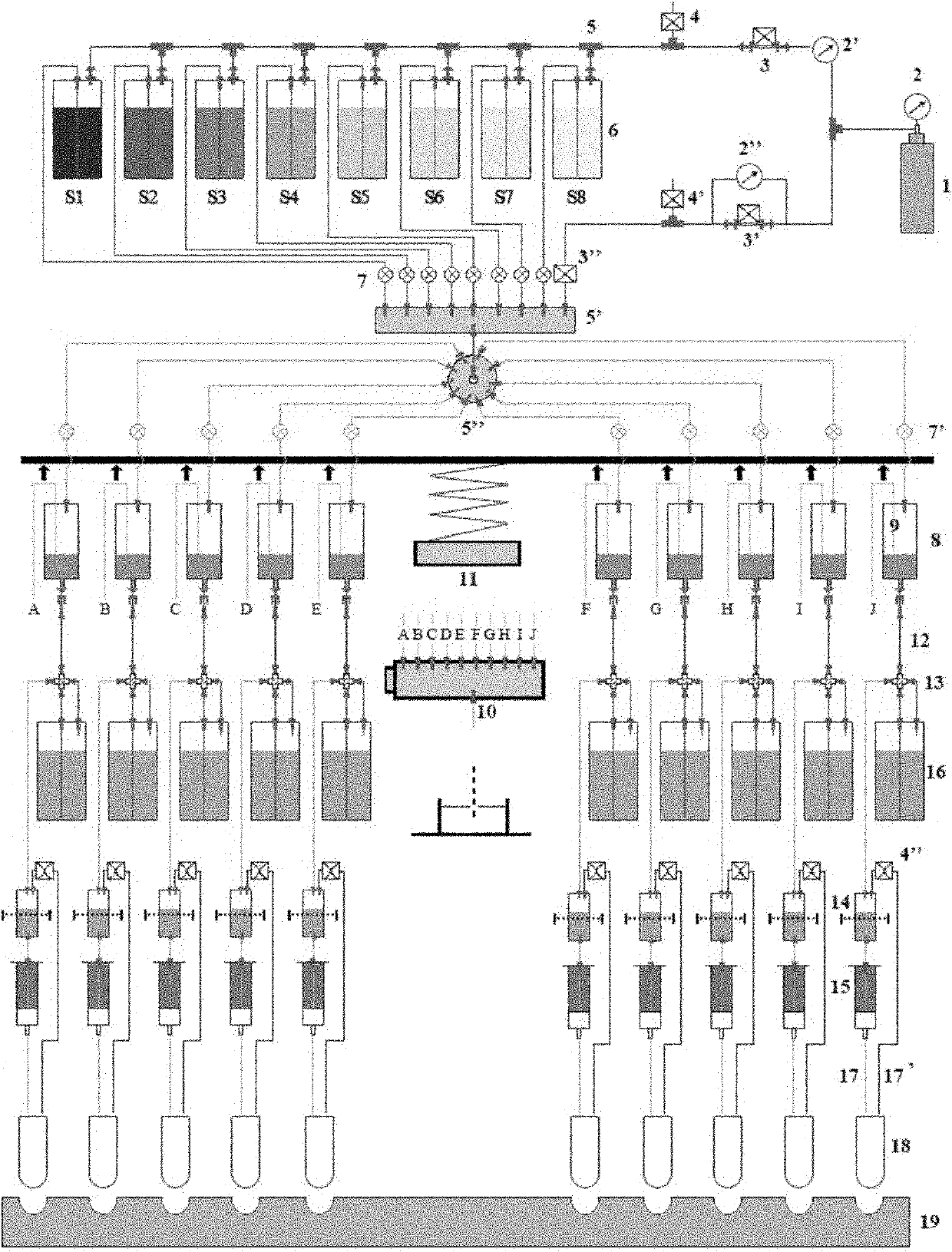

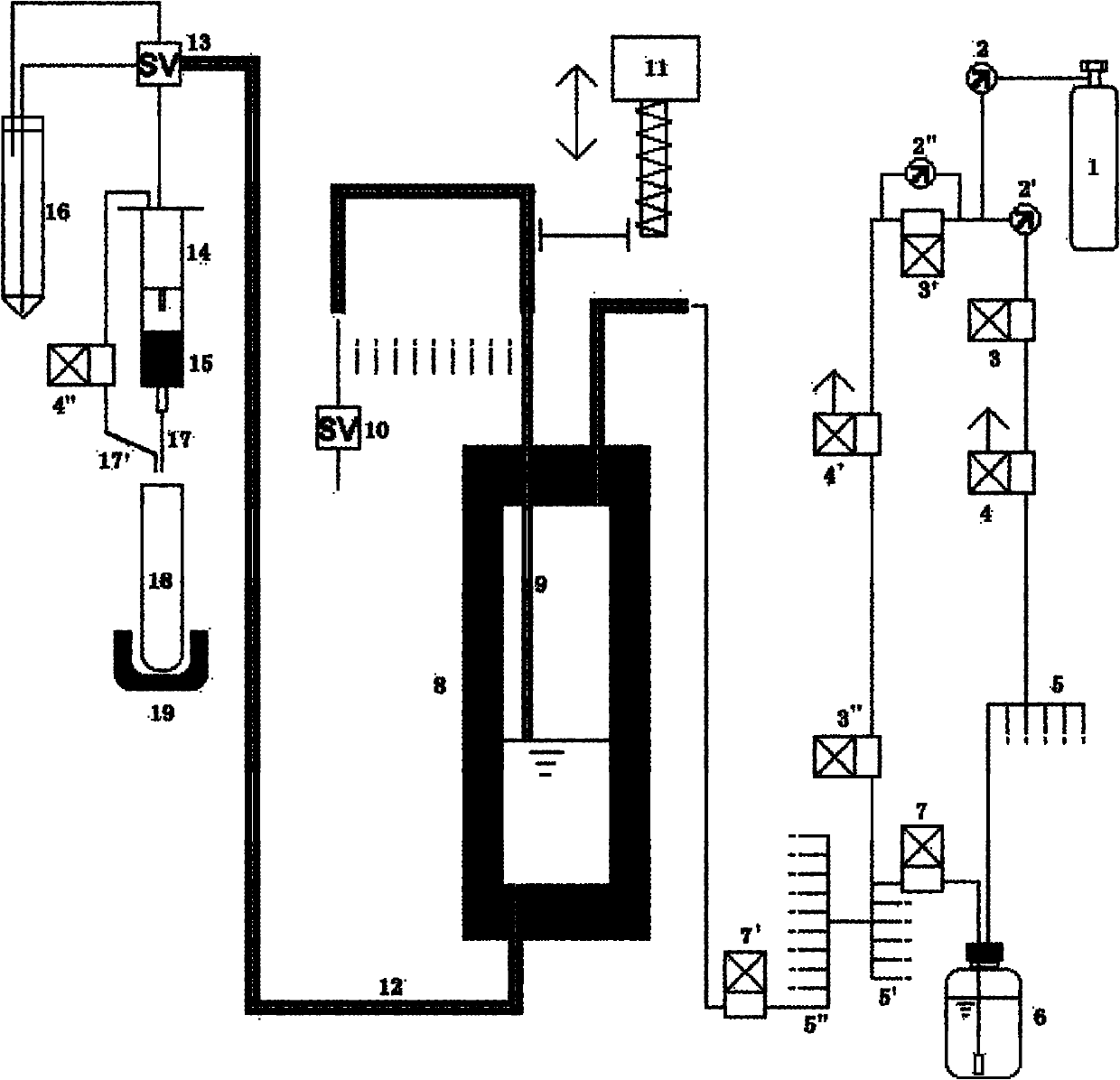

[0024] In order for relevant personnel to better understand the content described in the present invention, the working principle and flow of the present invention will be specifically described below.

[0025] The system is powered by compressed inert gas such as compressed nitrogen in cylinder 1. The pressure output is displayed and controlled by a pressure reducing valve and a pressure gauge. Pressure reducing valve 2 controls the maximum output pressure of the system. Divided into two roads.

[0026] In the first path, the output end of the pressure reducing valve 2' outputs compressed inert gas, which provides power to pressurize the solvent bottle 6, and can fill the quantitative tank 8 with solvent, and the shut-off valve 3 is used as the switch of the gas path. The first distributor 5 has a main road and a plurality of branch roads, the main road is connected behind the shut-off valve 3, and the shunt roads are connected to each pressure-resistant solvent bottle 6 (a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com