A processing device imitating hand-made meatballs

A processing device and meatball technology, which is applied in the direction of processing meat, softening meat by beating, and tenderizing meat, can solve the problems of inability to rebound in time, affect the taste of meatballs, and affect the taste of meatballs, so as to save energy, The effect of uniform processing degree and improved hammering efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

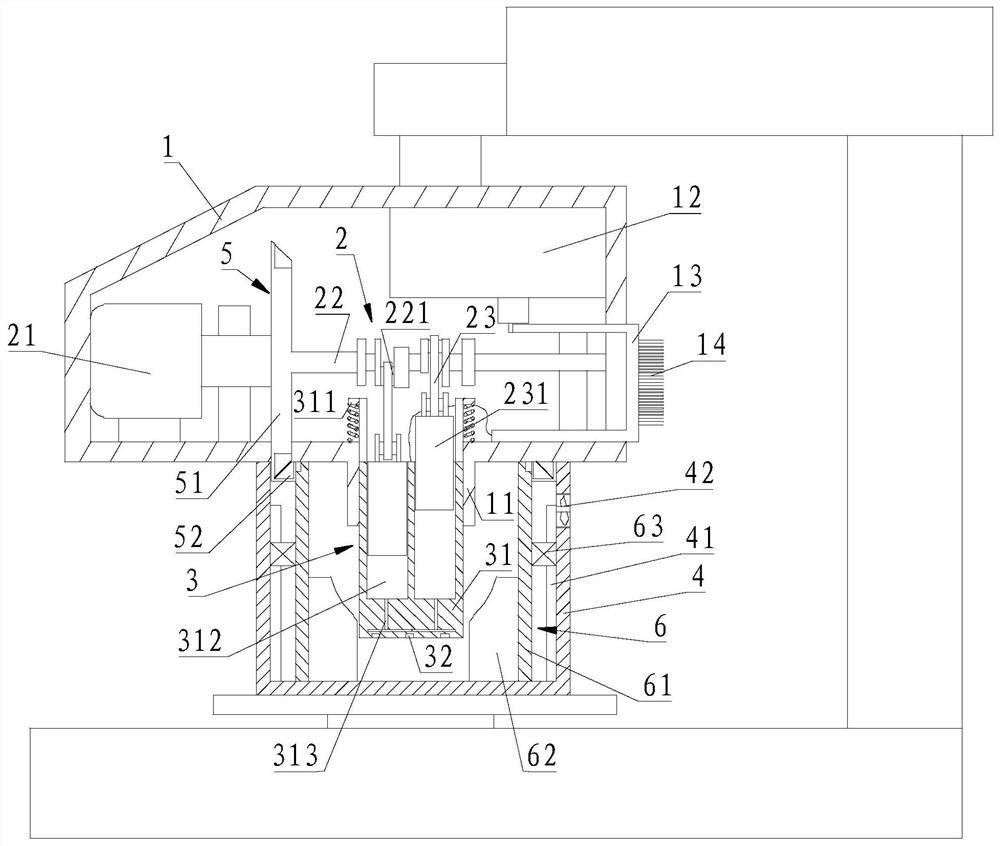

[0051] An imitation hand-beaten meatball processing device, such as figure 1 , including the upper casing 1, the drive assembly 2, the beating assembly 3 and the container 4;

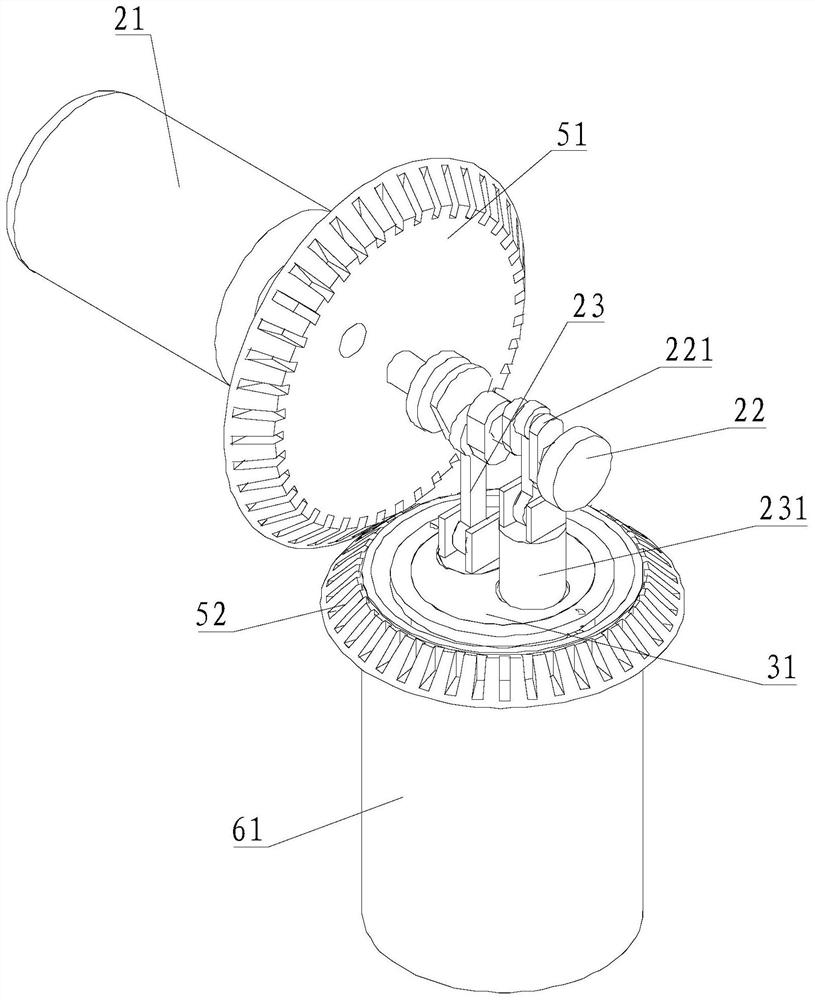

[0052] The drive assembly 2 is arranged inside the upper casing 1, and the drive assembly 2 includes a drive motor 21, a crankshaft 22 and a connecting rod 23. The drive motor 21 is fixedly connected to the interior of the upper casing 1. The power output shaft is fixedly connected to one end of the crankshaft 22, such as figure 2 , the crankshaft 22 is provided with at least two cranks 221 in opposite directions, the number of the connecting rods 23 is consistent with the cranks 221, one end of the connecting rod 23 is rotatably connected with the cranks 221, and the other end is rotatably connected with The slider 231, wherein the crank 221 includes two crank arms and a connecting rod journal that is fixedly connected between the two crank arms and is parallel to the main journal of the crankshaft. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com