Split type hydraulic pile hammer

A hydraulic piling hammer, split-type technology, applied in the direction of sheet pile wall, building, foundation structure engineering, etc., can solve the problems of transfer transportation cost and manufacturing cost increase, hydraulic impact hammer striking efficiency decrease, pile cap production and transportation troubles, etc. , to achieve the effect of reducing volume and quality, reducing manufacturing cost and operating cost, and improving pile sinking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0028] like image 3 , Figure 4 The difference between the split type hydraulic piling hammer shown in this embodiment and the above embodiment (Embodiment 1) is that there is no guide rod sliding sleeve 12 on the lower support frame 9, so there is no Set the center guide rod 10. There are only six guide structures formed by the column guide rods on the rigid body formed by the tup 1 and the tup connecting frame 8 .

Embodiment 3

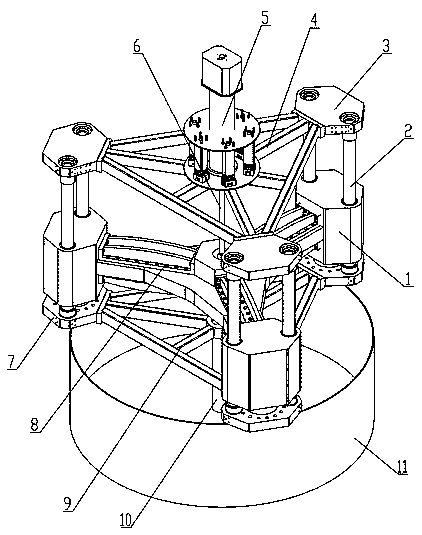

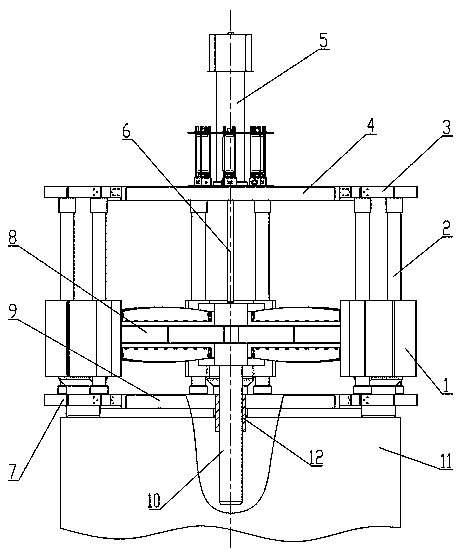

[0030] like Figure 5 , Image 6 The split-type hydraulic piling hammer shown includes three hammer heads 1, which are located on the circumference of the cylinder wall of the circular tubular foundation pile 11, and the three hammer heads 1 are equidistant along the circumference of the cylinder wall. Interval settings. The three hammerheads 1 are respectively fixedly installed on the arm ends of the three outrigger arms of the hammerhead connecting frame 8, so that the three hammerheads 1 and the hammerhead connecting frame 8 form a rigid body. A hydraulic cylinder 5 is fixedly installed on the upper support frame 4 , and several energy accumulators are also arranged around the hydraulic cylinder 5 , and the energy accumulators are all fixedly installed on the upper support frame 4 . Each extended end of the upper supporting frame 4 is fixedly installed with a column 2 respectively. The upper end of the column 2 is fixedly connected with the upper supporting frame 4 throu...

Embodiment 4

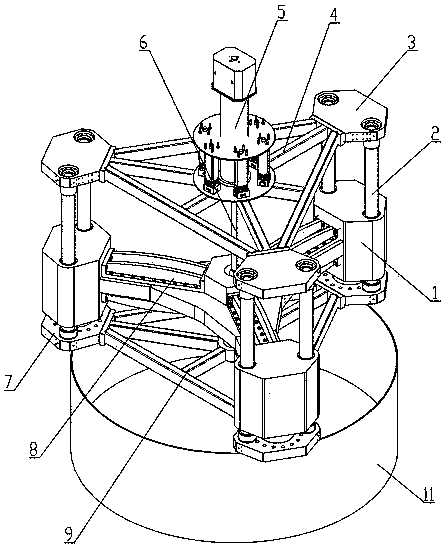

[0035] like Figure 7 , Figure 8 The difference between the split type hydraulic piling hammer shown in this embodiment and the above embodiment (Embodiment 3) is that there is no guide rod sliding sleeve 12 installed on the lower support frame 9, so there is no Set the center guide rod 10. The rigid body formed by the tup 1 and the tup connecting frame 8 has only three guide structures formed by the column guide rods.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com