A kind of water conservancy construction equipment

A construction equipment and water conservancy technology, which is applied in construction, foundation structure engineering, sheet pile walls, etc., can solve the problems of being unable to adapt to various operating environments, environmental pollution, and large vibration, and achieves simple structure, convenient operation, and improved The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

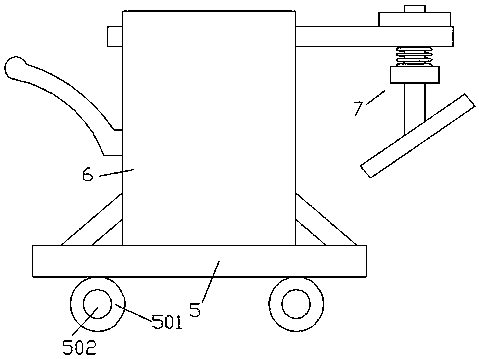

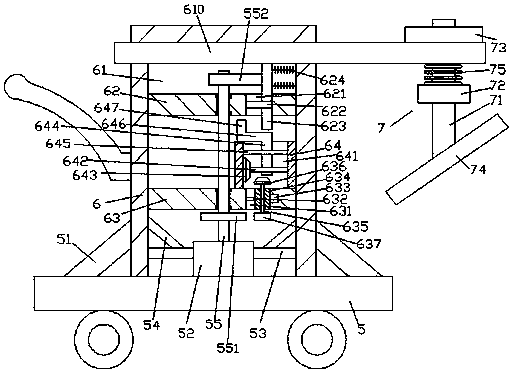

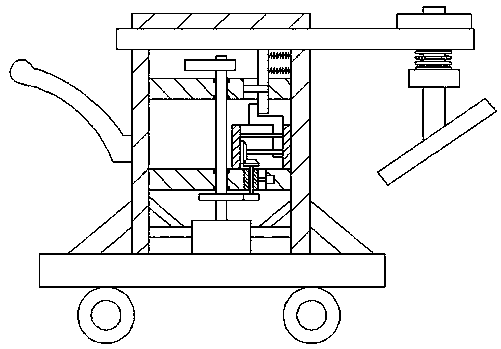

[0021] Such as figure 1 — Figure 4 As shown, a water conservancy construction equipment of the present invention includes a base body 5 and a host 6 fixedly installed on the top of the base body 5, the host 6 is provided with a cavity 61 passing through the bottom surface of the host 6, so The inside of the cavity 61 is provided with a first horizontal beam 62 and a second horizontal beam 63 that are elongated left and right, and the left and right sides of the first horizontal beam 62 and the second horizontal beam 63 are elongated. The tail tips are respectively fixedly connected with the inner walls of the left and right sides of the cavity 61, and the top surface of the base body 5 at the bottom of the cavity 61 is fixedly provided with a first power machine 52 protruding into the cavity 61. The top of a power machine 52 is fitted with a first rotating rod 55 extending upwards, and the top extension of the first rotating rod 55 passes through the second horizontal beam 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com