Generating method of three-dimensional elliptical vibrating cutting optical freeform surface machining path

A technology of elliptical vibration and path generation, which is used in the fields of ultra-precision cutting and difficult-to-machine material cutting, and can solve the problems of in-depth and difficult-to-machine materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

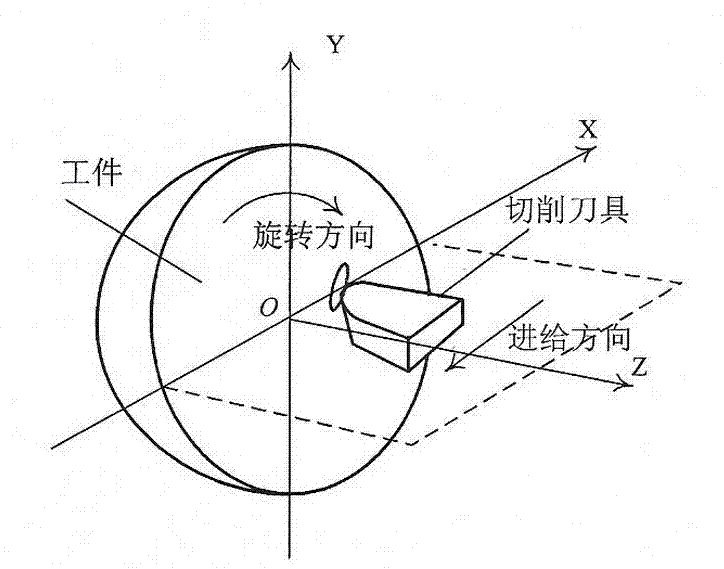

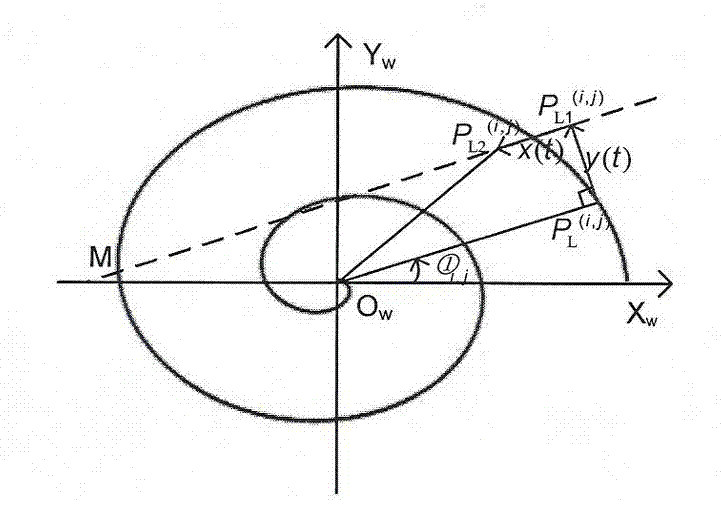

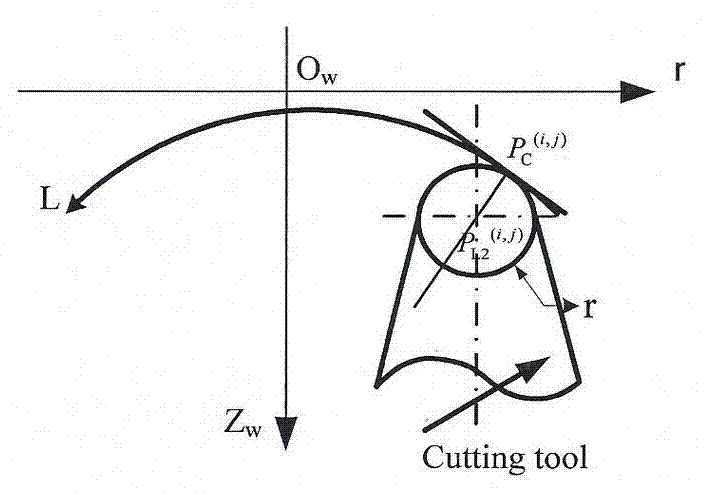

[0024] The expression of the three-dimensional ellipse is shown in formula (1), where, in order to ensure no overcut, the displacement formula of the ellipse in z direction is revised as z(t)=c(1+cos(2πft+ψ z )).

[0025] x ( t ) = a cos ( 2 πft ) y ( t ) = b cos ( 2 πft + ψ y ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com