Diamond super precision lathe free curved surface processing path generation method

A technology of path generation and surface processing, applied in the fields of ultra-precision machining and complex parts manufacturing, it can solve the problem of not providing pre- and post-processing algorithms or modules for free-form surfaces, and achieve the effect of ultra-precision machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

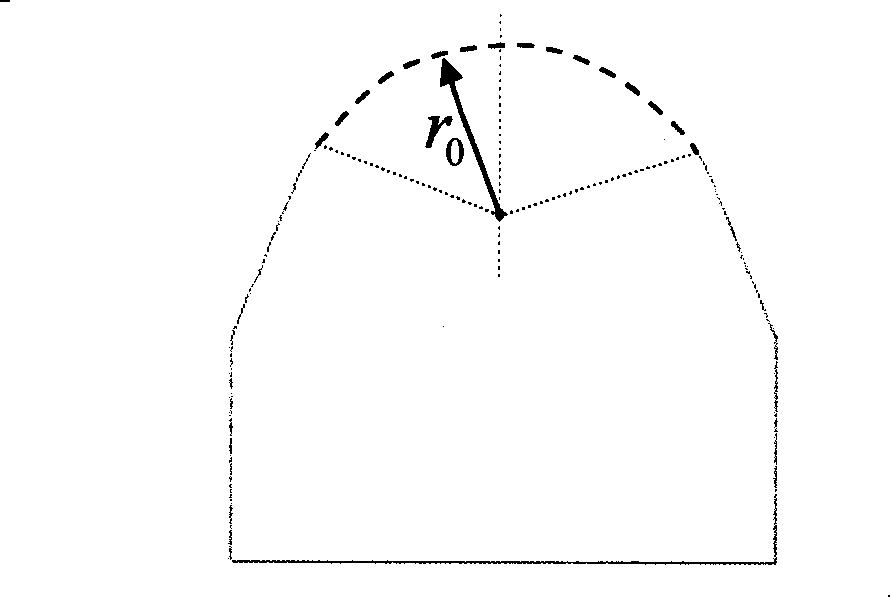

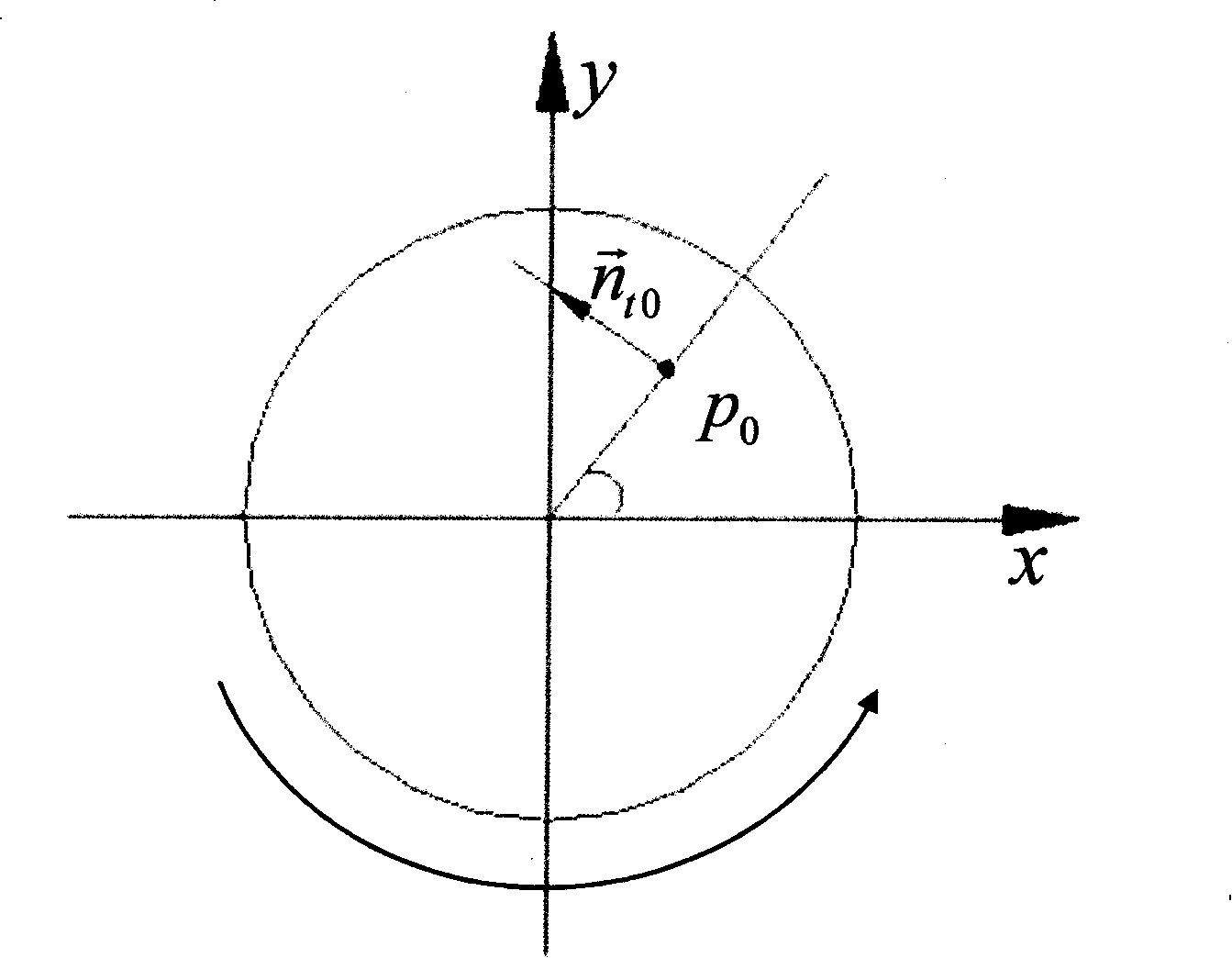

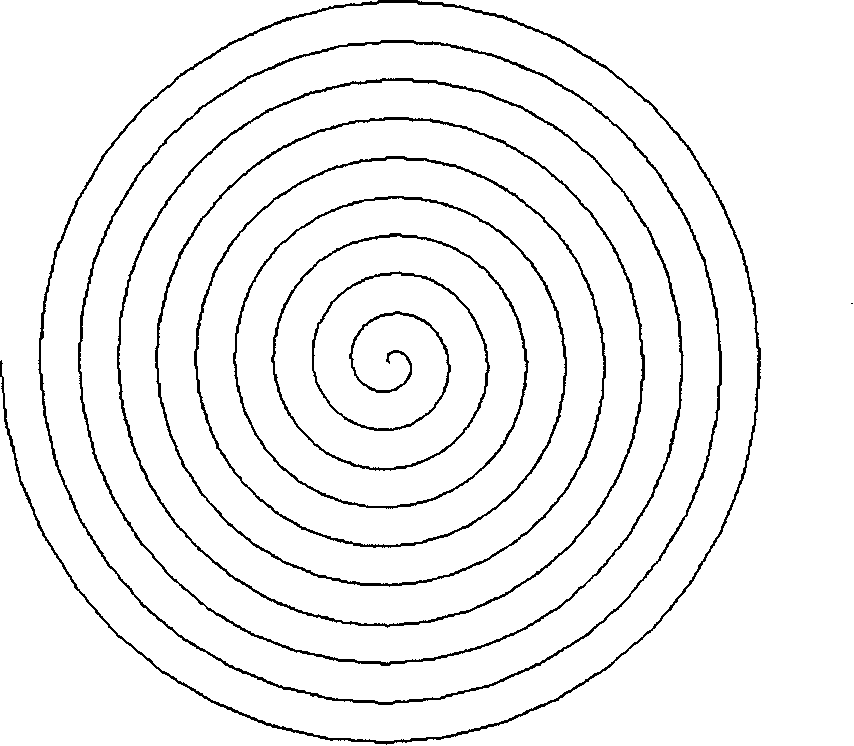

[0024] Ordinary lathes have 2 degrees of freedom. In addition to rotary motion, the spindle can also move along the X-axis, and the turning tool can move along the Z-axis. When the encoding device is installed on the rotating spindle, its rotation angle can be controlled or fed back. Therefore, the lathe has a third degree of freedom, that is, the C axis. Let the coordinates of any point on the machine tool be expressed as Where ρ is the X-axis coordinate, is the C-axis coordinate, and z is the Z-axis coordinate; as long as the rotation angle of the spindle and the feed rate and depth of cut of the turning tool are coordinated and controlled, complex free-form surfaces can be processed. figure 1 is the top view of the diamond turning tool model, and the radius of the tool nose arc on the cutting surface is r 0 . The coordinates of the arc center of the tool nose can control the positioning during the machining process, but the actual machining is performed on the cutting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com