Free hook face prism positioning design and machining method

A technology of curved prism and processing method, which is used in metal processing equipment, manufacturing tools, optical surface grinders, etc., can solve the problems of loss of repeated positioning datum, difficulty in assembly and adjustment, loss and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention are described in detail below, and the embodiments are exemplary and intended to explain the present invention, but should not be construed as limiting the present invention.

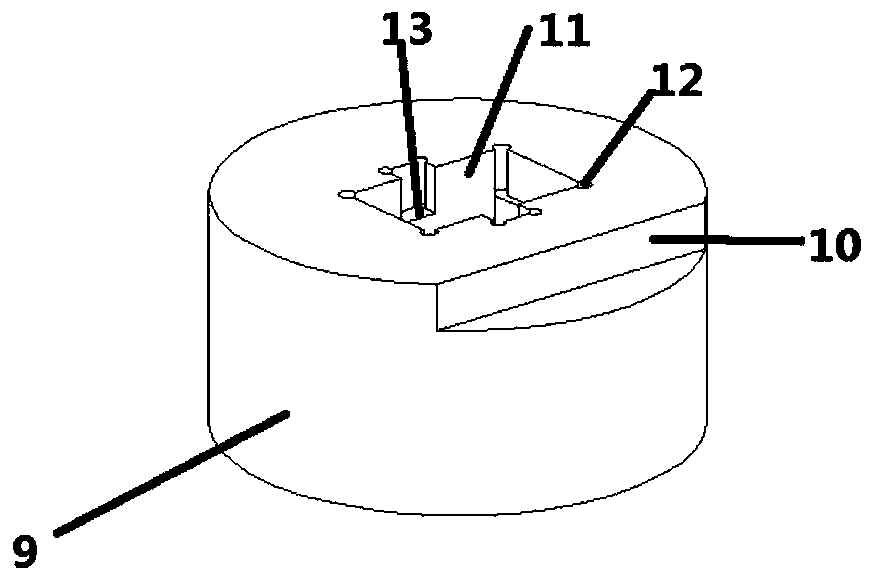

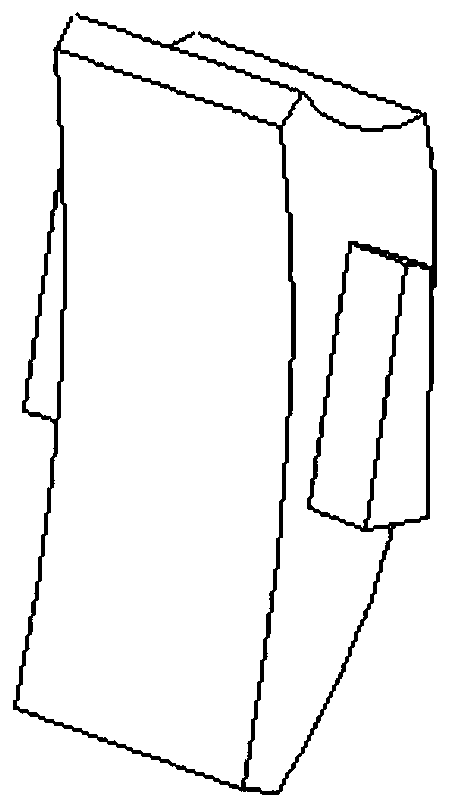

[0025] The invention provides a special tooling for processing special optical elements and a positioning method. The main principle includes symmetrically setting auxiliary reference process tables 2 (two places) on the free-form surface prism blank 1, and designing a special integrated tooling 9 so that the prism blank and the integrated tooling are not separated during the entire grinding, polishing and testing process.

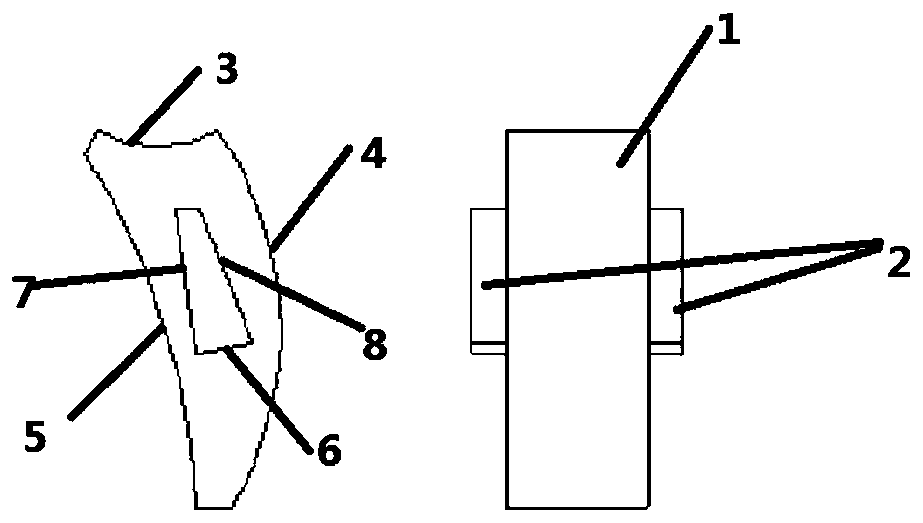

[0026] Such as figure 1 As shown, the free-form surface prism 1 needs to process the free-form surfaces 3, 4, and 5. All three surfaces have angle and shape requirements. The optical coordinate system is used in the optical design, and the coordinate system is converted to the processing in the process of processing. under the coordinate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com