Patents

Literature

128results about How to "Lower fixed costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Secure payment system using a mobile phone, and payment method using same

InactiveUS20140052607A1Avoid contactEffective preventionFinanceProtocol authorisationCredit cardShort Message Service

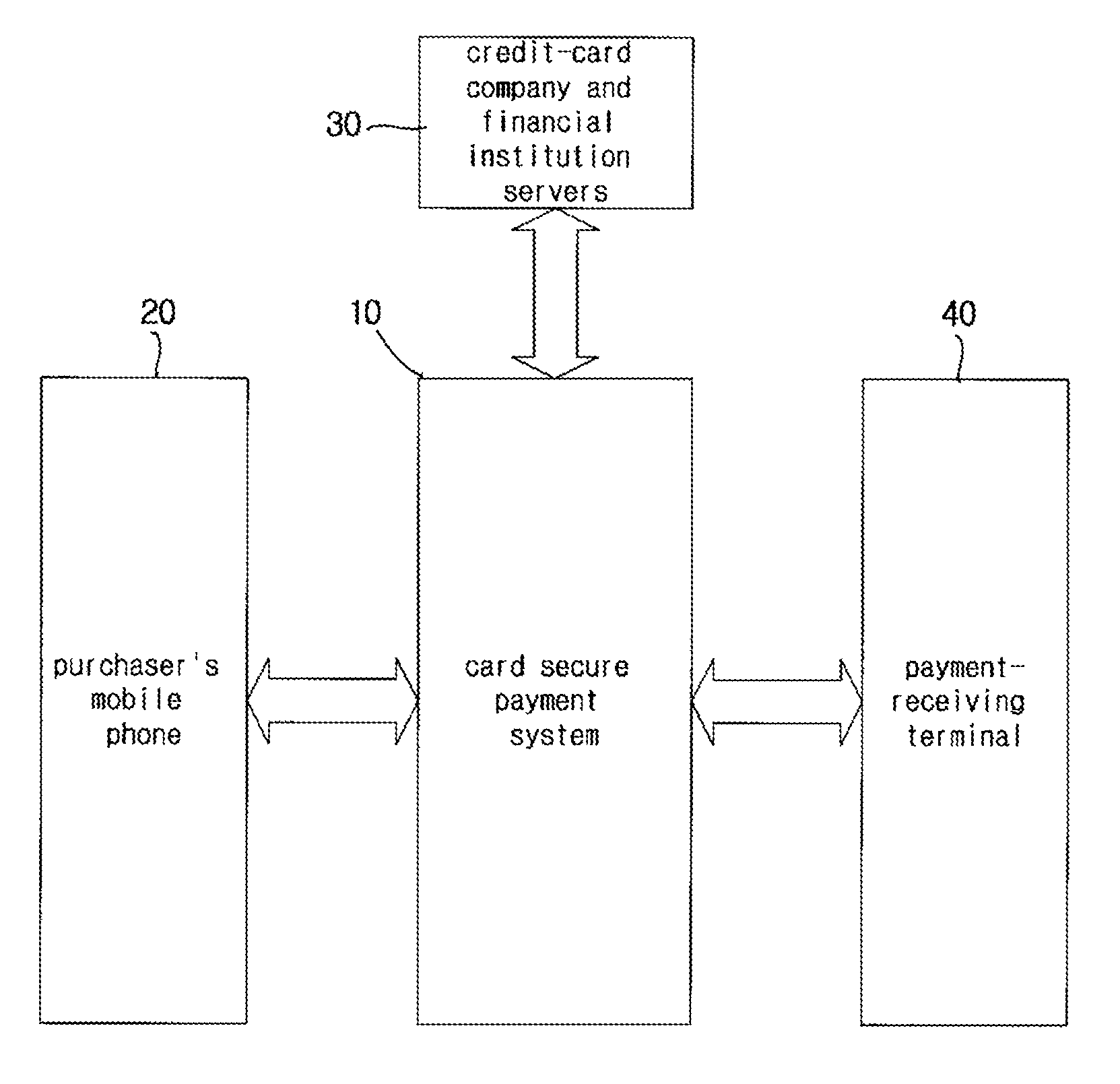

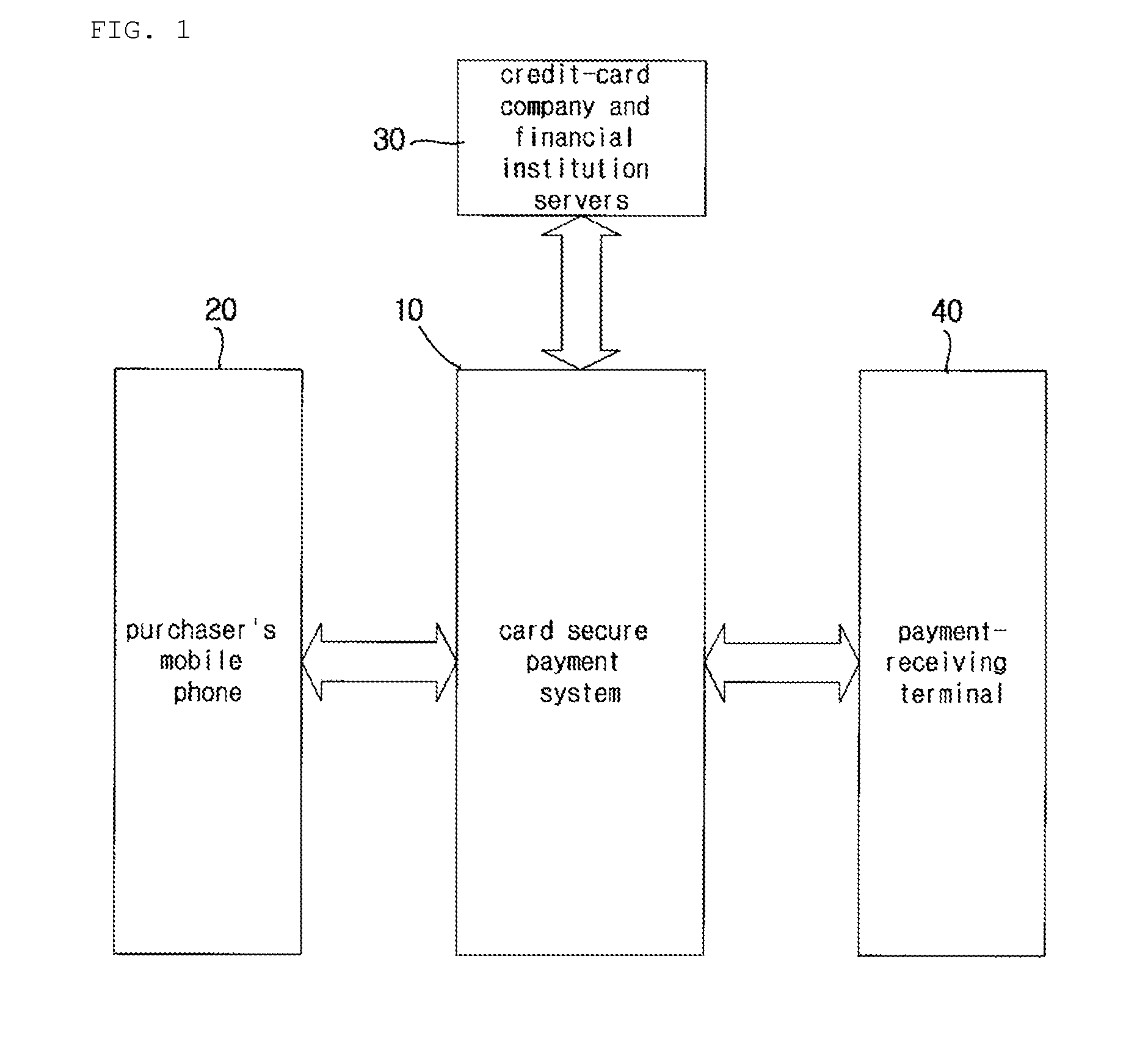

The present invention relates to a secure payment system and method using a mobile phone, wherein a purchaser makes payments using various credit cards and a seller confirms the payments instantly through a payment-receiving terminal, and more particularly, to a secure payment system and method using a mobile phone, wherein: a purchaser accesses a payment system using the mobile phone having a card registered therein and inputs and transmits seller information, a payment, and a password; a payment system recognizes and stores the inputs and extracts necessary information with a view to transmitting same to a credit-card company and a financial institution; and, if approval is granted by the credit-card company and financial institution, an approval number is automatically inputted in a process list of the payment system, and then a short message service (SMS) is simultaneously provided to the mobile phones of the purchaser and of the seller and to a payment-receiving terminal of the seller for payment confirmation.

Owner:PARK GUI SUG

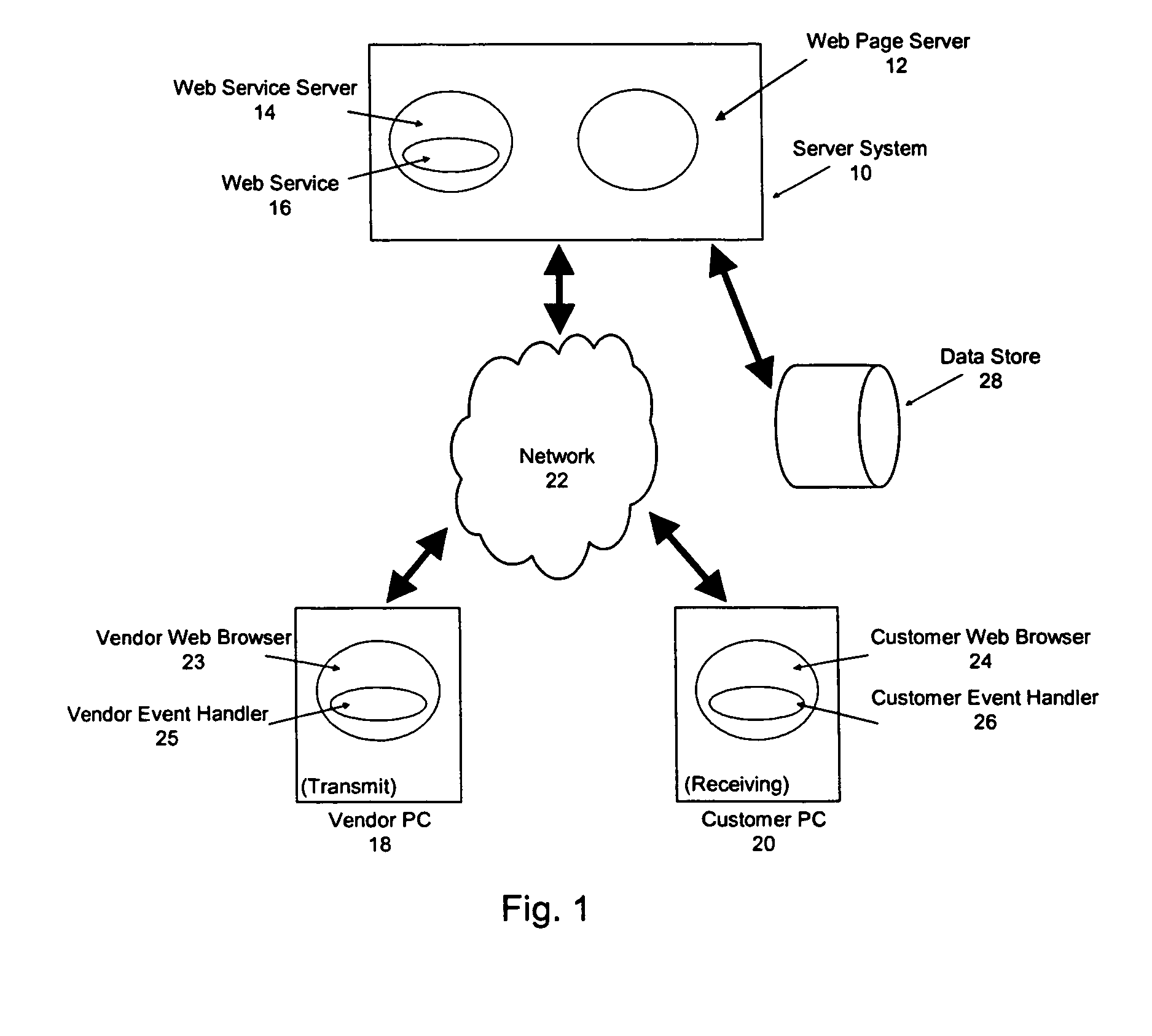

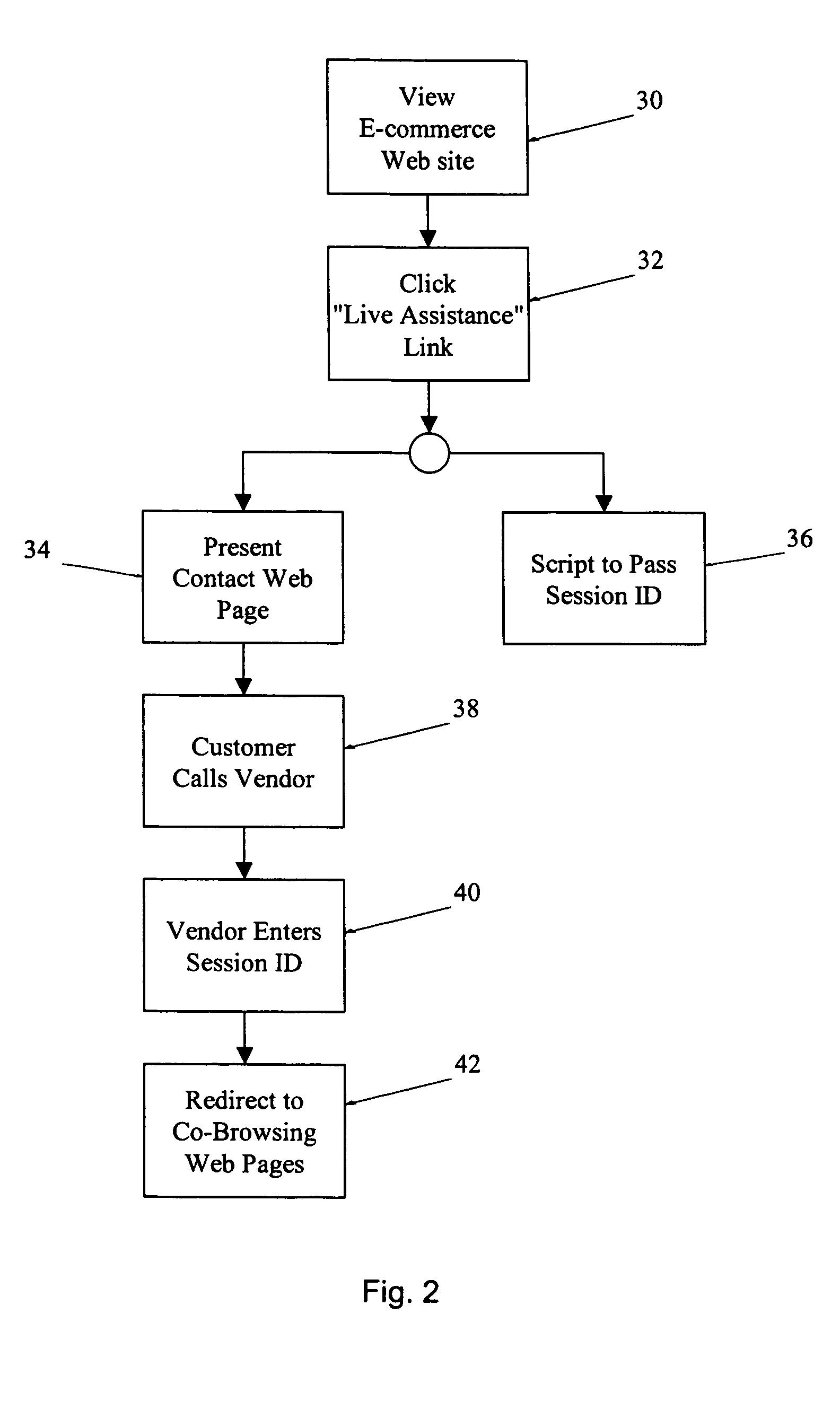

Apparatus and method for remotely sharing information and providing remote interactive assistance via a communications network

InactiveUS8051178B2Reduce overheadIncrease volumeSynchronised browsingMultiprogramming arrangementsWeb siteSoftware

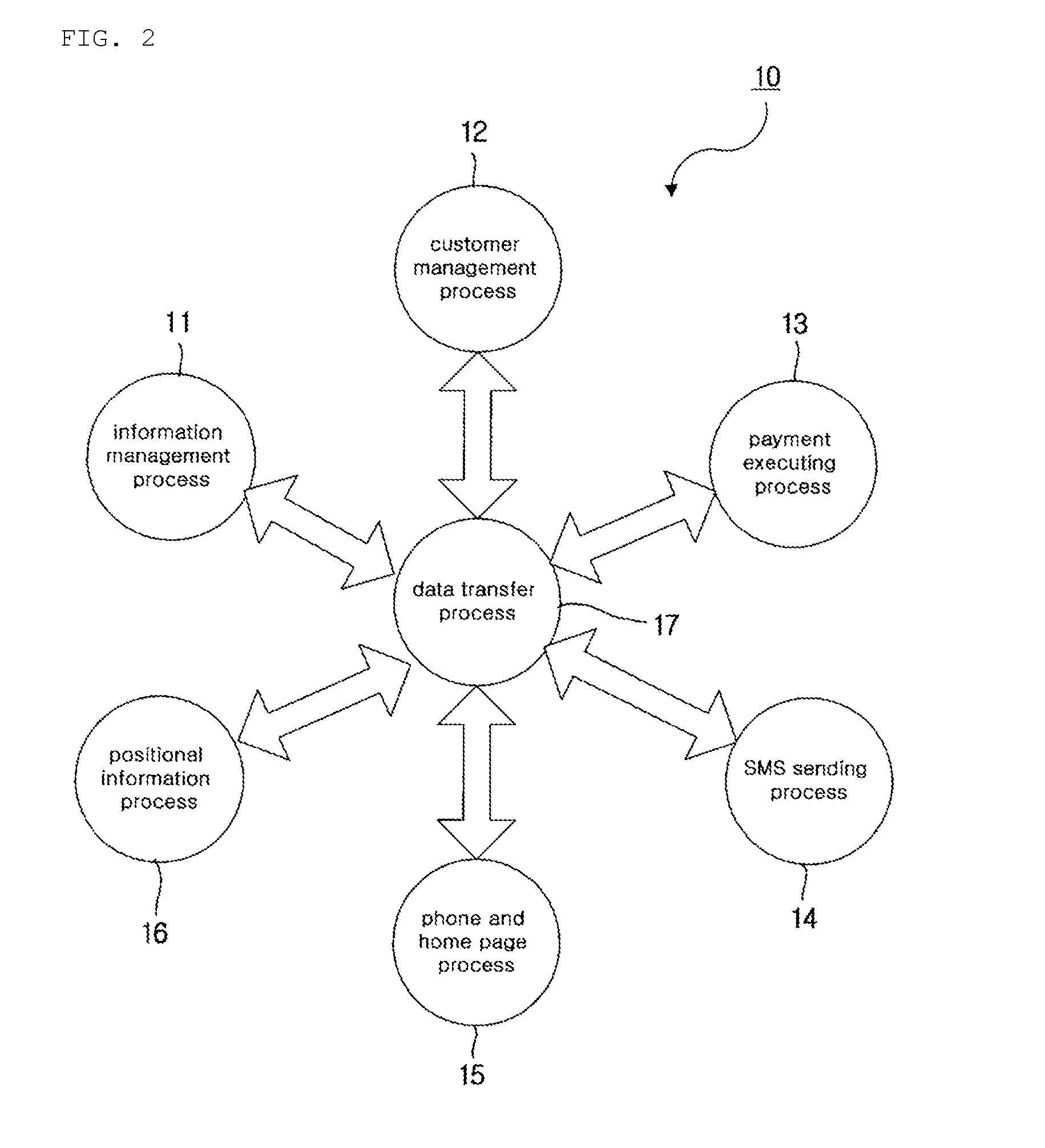

A system for providing collaborative browsing of information and interactive communications on the worldwide web. A customer may use the system for a co-browsing session with a customer assistance representative by simply providing an access number from an accessed web site to the customer service representative. The customer is transparently switched from a normal web site to a co-browsing web site merely by clicking on a button to request assistance. The co-browsing site includes software to periodically poll a server for synchronization purposes.

Owner:BENEFITS TECH

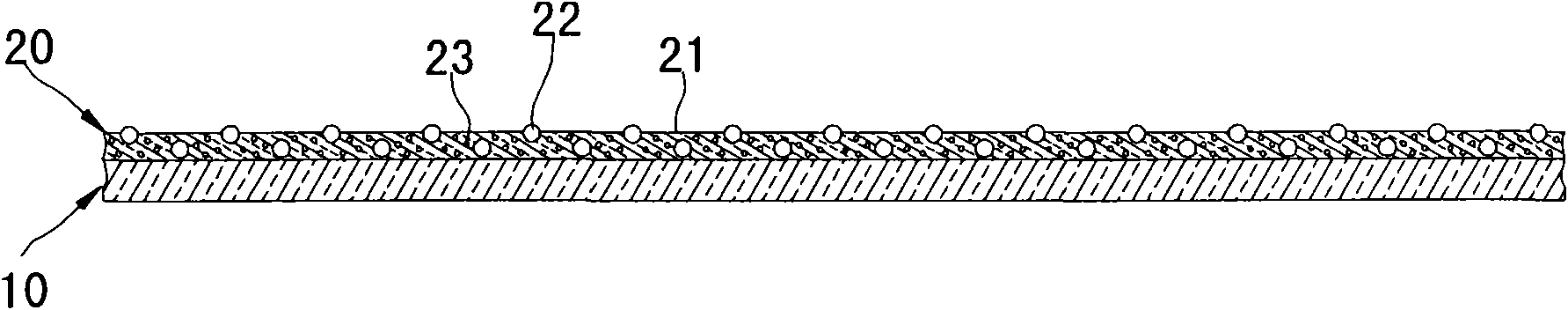

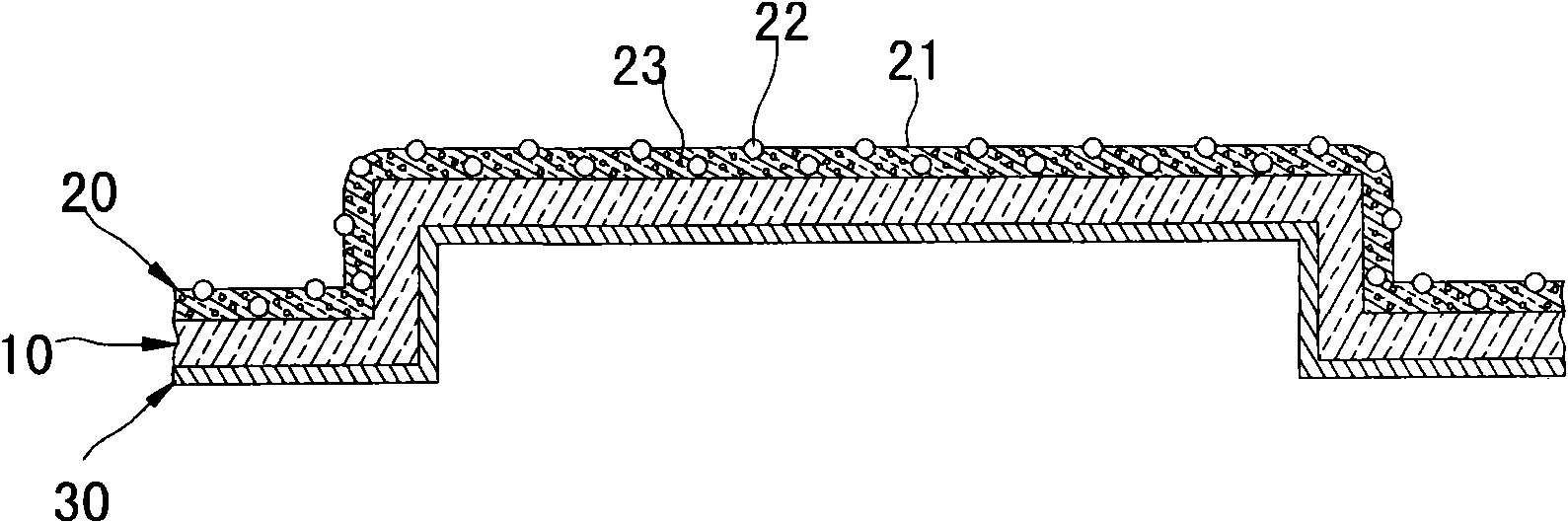

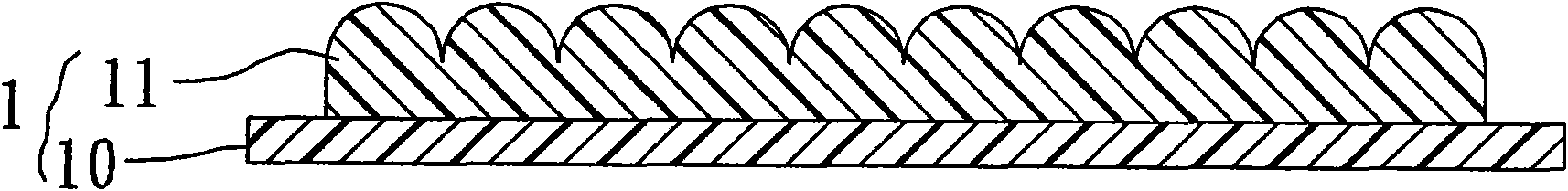

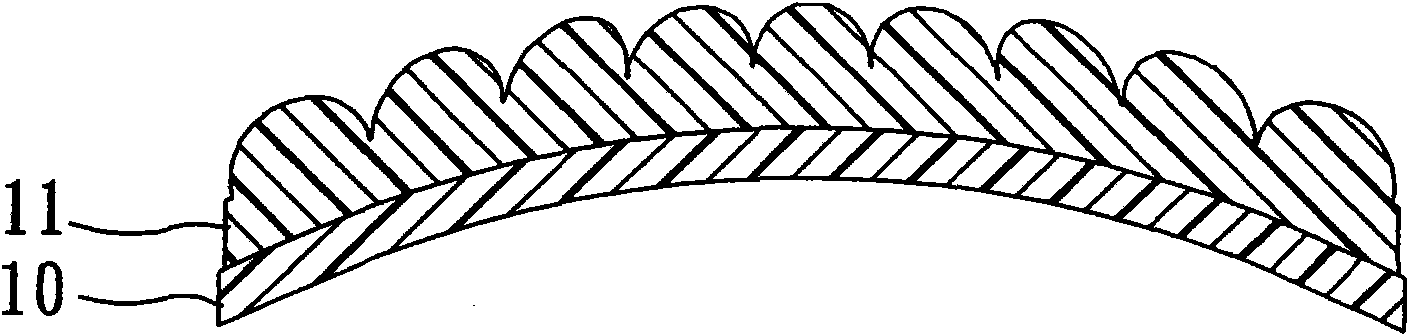

Thin film structure and manufacturing method thereof

ActiveCN101596803AFeel comfortableImprove scratch resistance and abrasion resistanceLiquid surface applicatorsSynthetic resin layered productsUltraviolet lightsThermal treatment

The invention discloses a thin film structure and a manufacturing method thereof for intromode decoration process. The method comprises the steps of coating a coating containing at least two kinds of elastic resin particles on the surface above the thin film, wherein the two kinds of resin particles contains first resin particles for increasing the fluffy feeling and second resin particles for increasing the scratch and abrasion resistances, then forming an ink layer on the surface below the thin film and molding the thin film into a predetermined shape through thermal treatment, molding and laminating a plastic base material under the ink layer in the form of injection molding, and finally hardening the coating by using ultraviolet light. Hereby, the thin film has fluffy feeling as well as scratch and abrasion resistances.

Owner:ENTIRE TECH CO LTD

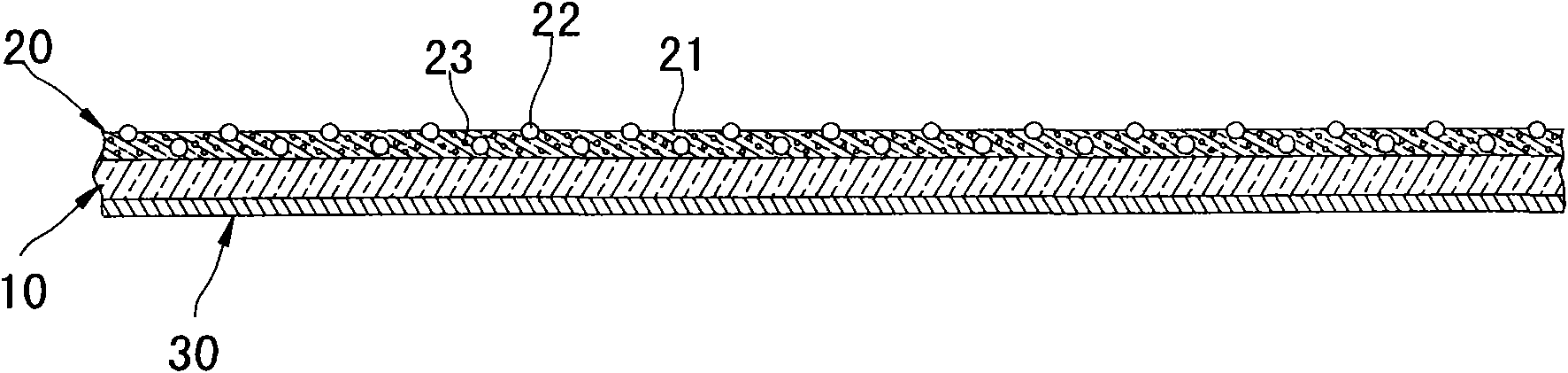

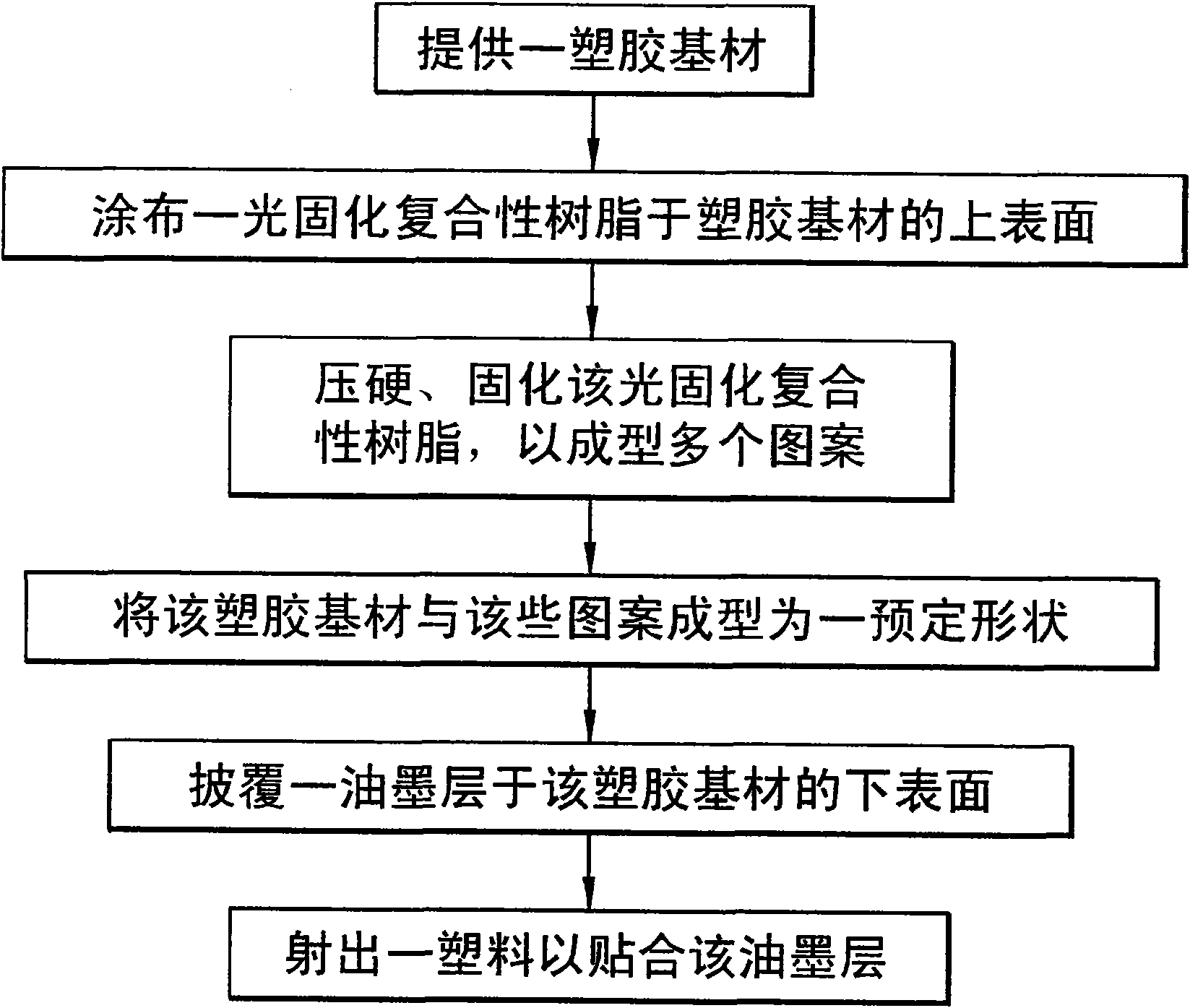

Manufacture method of light-cured composite film

ActiveCN101941353AExcellent surface scratch resistance and wear resistanceAvoid cosmetic damageSynthetic resin layered productsSpecial ornamental structuresComposite materialPrinting ink

The invention discloses a manufacture method of a light-cured composite resin film, comprising the following steps of: (1) providing a plastic substrate, light-cured composite resin, a printing ink layer and plastic, wherein the plastic substrate is provided with an upper surface and a lower surface; (2) coating the upper surface of the plastic substrate with the light-cured composite resin; (3) impressing and solidifying the light-cured composite resin to form a plurality of patterns; (4) forming the plastic substrate and the plurality of patterns; (5) coating the printing ink layer on the lower surface of the plastic substrate; and (6) ejecting and attaching the plastic on the printing ink layer.

Owner:ENTIRE TECH CO LTD

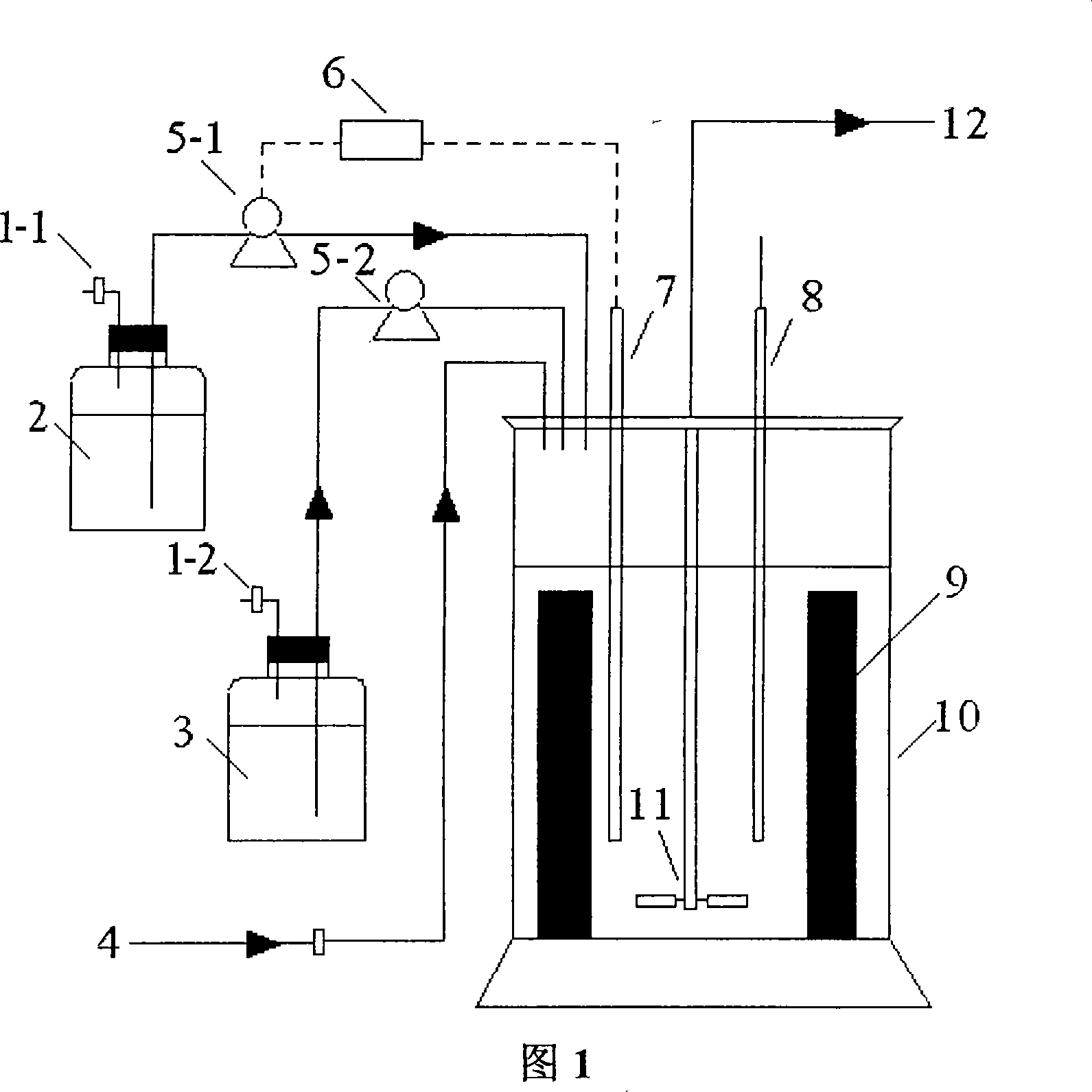

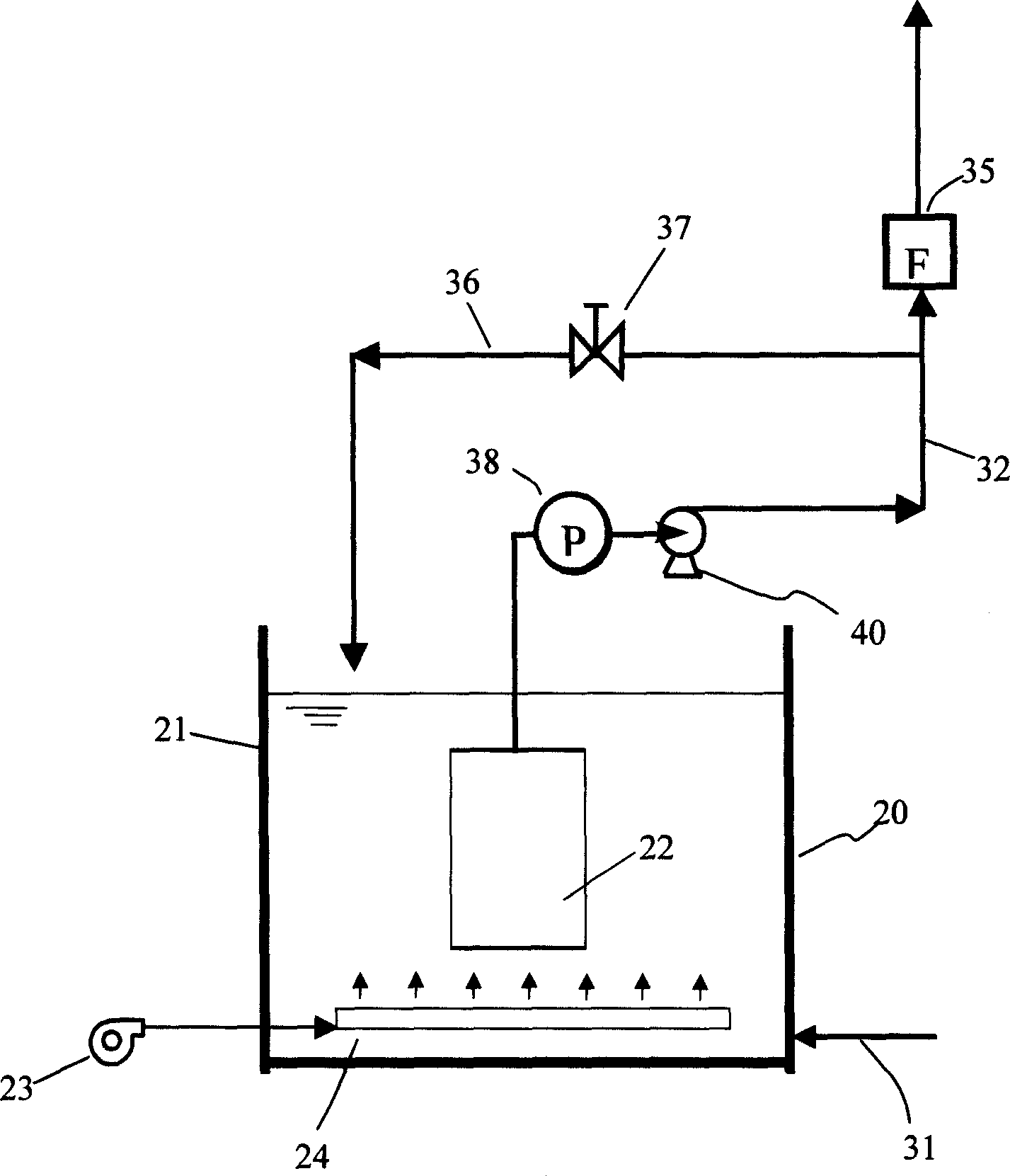

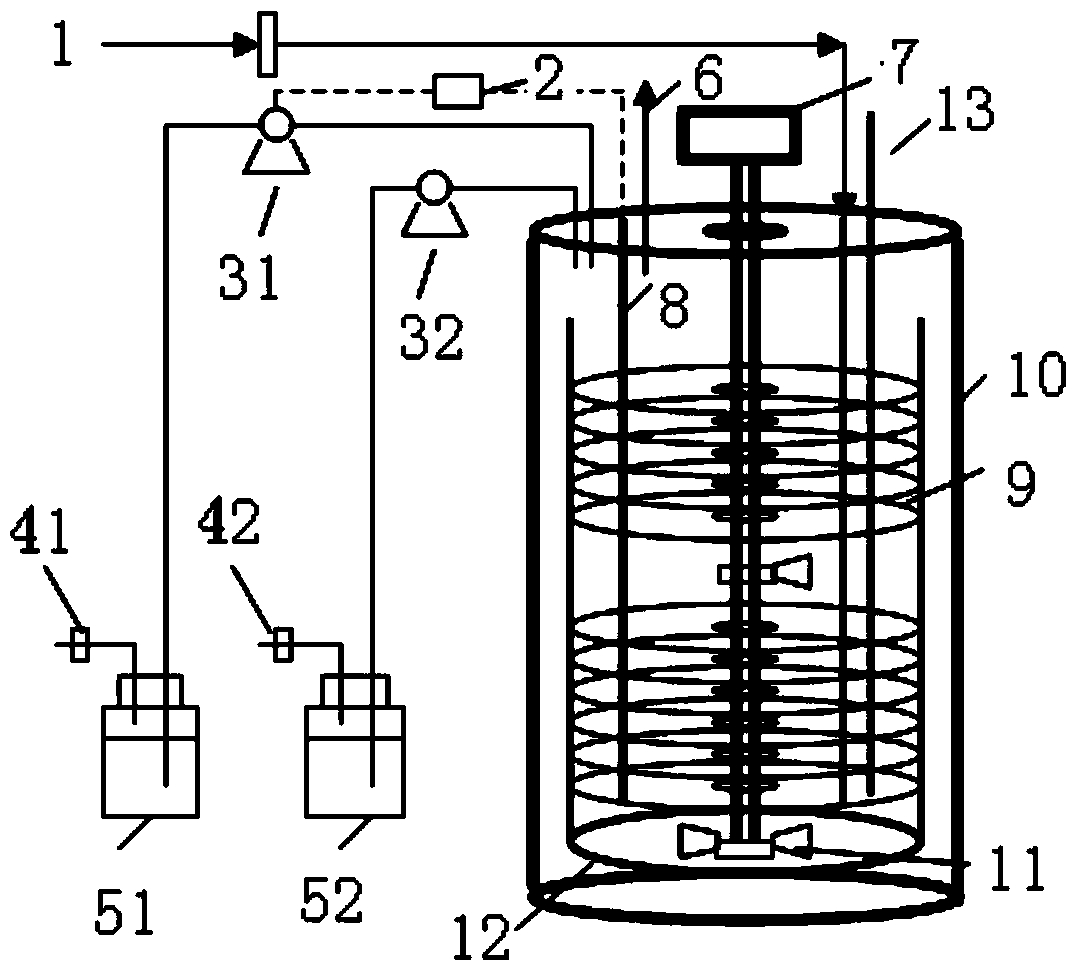

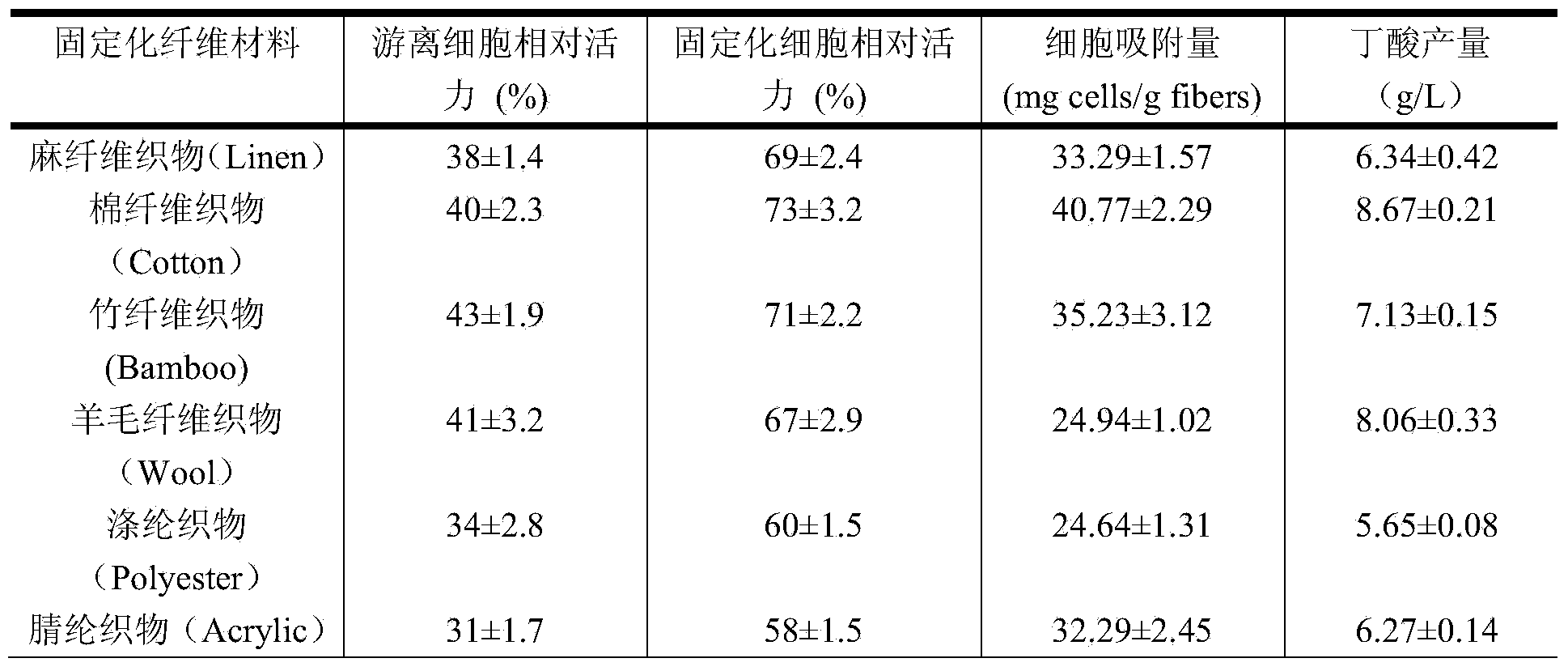

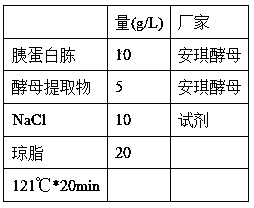

Immobilized fibrous bed bioreactor for fermentation productions of ethylformic acid, butyric acid and succinic acid

ActiveCN101182456AImprove utilizationKeep aliveBioreactor/fermenter combinationsBiological substance pretreatmentsFiberPropanoic acid

The invention relates to an immobilized fibrous bed reactor for fermentation production of propionic acid, butyric acid and amber acid. The reactor mainly comprises a reactor (10), fiber material (9), a stirring device (11), a pH automatic control device and a feeding device. The invention is characterized in that the fiber material (9) is fixed in the reactor (10), which is used as carrier for cell immobilization; the pH automatic control device and the feeding device are connected with the reactor (10); the stirring device (11) is suspended in an inner part of the reactor (10). The reactor is used to produce propionic acid, butyric acid and amber acid with high production efficiency and stable batch production. And the device has the advantages of cheap immobilization material, simple arrangement and convenient operation, which are suitable for the industrial production of propionic acid, butyric acid or amber acid.

Owner:NANJING TECH UNIV

Technique method of immobilized candida antarctica lipase B

InactiveCN101575594AReduce dosageHigh immobilization efficiencyOn/in organic carrierZymogenOrganic solvent

The invention relates to a technique method of immobilized candida antarctica lipase B, which adopts an organic solvent as an immobilizing medium and realizes the immobilization of lipase in microaqueous phase. The technique method comprises the following steps of: (1) pretreatment of resin; (2) preparation of immobilized enzyme: the pretreated resin is added into a reactor and an organic medium is added; and after standing, then zymogen solution is added according to the mass ratio of the candida antarctica lipase B and the resin, which is equal to 1:60-1:100; the reactor is sealed and then arranged in a shaking bath with constant temperature of 25-35 DEG C for 1h-3h; after vacuum freezing and drying, the immobilized candida antarctica lipase B is prepared. The method for preparing the immobilized enzyme has low consumption of resolvase and high immobilization efficiency and avoids the considerable waste of resolvase caused by an aqueous-phase absorption method, thereby reducing immobilization cost; a carrier has low price and is easily obtained; furthermore, the method has simple technique, mild condition, low loss in enzyme activity and enzyme activity recovery rate of 83.3 percent.

Owner:HEBEI UNIV OF TECH

Organic waste water treaitng magnetic field and supersonic wave method

InactiveCN1344685AIncrease concentrationPrevent or reduce recombinationWater/sewage treatment with mechanical oscillationsWater/sewage treatment by magnetic/electric fieldsCavitationVolumetric Mass Density

In a water treating reactor, industrial organic waste water or domestic sewage is irradiated with supersonic wave and magnetic field simultaneously. The supersonic wave has a frequency range of 16 kHz to 10 MHz and a strength of 0.1-12 W / sq cm. The magnetic flux density is 0.008-2 T, and the combined irradiation time is over 5 min. The present invention utilizes magnetochemical effect to prevent and reduce the recombination of OH and H free radical pair produced in supersonic cavitation and this raise greatly the supersonic treatment effect of waste water. The method of the present invnetion is easy to control, high in efficiency and low in power consumption, and may be used widely.

Owner:南京大学环境学院

Process for producing hydrogen peroxide

InactiveUS20020141935A1Increase heightCapital costPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesHydrogenBoiling point

Process for producing hydrogen peroxide The invention relates to a process for producing hydrogen peroxide by the cyclic anthraquinone process. According to the invention, the rate of oxidation of a hydrogenated working solution containing a tetrahydroanthrahydroquinone derivative is increased if the oxidation is carried out in the presence of a secondary amine. Preferably a slightly water-soluble secondary amine having a boiling point of at least 150° C., in a quantity of 0.001 to 2 mol per mol of tetrahydro compounds, is used.

Owner:DEGUSSA AG

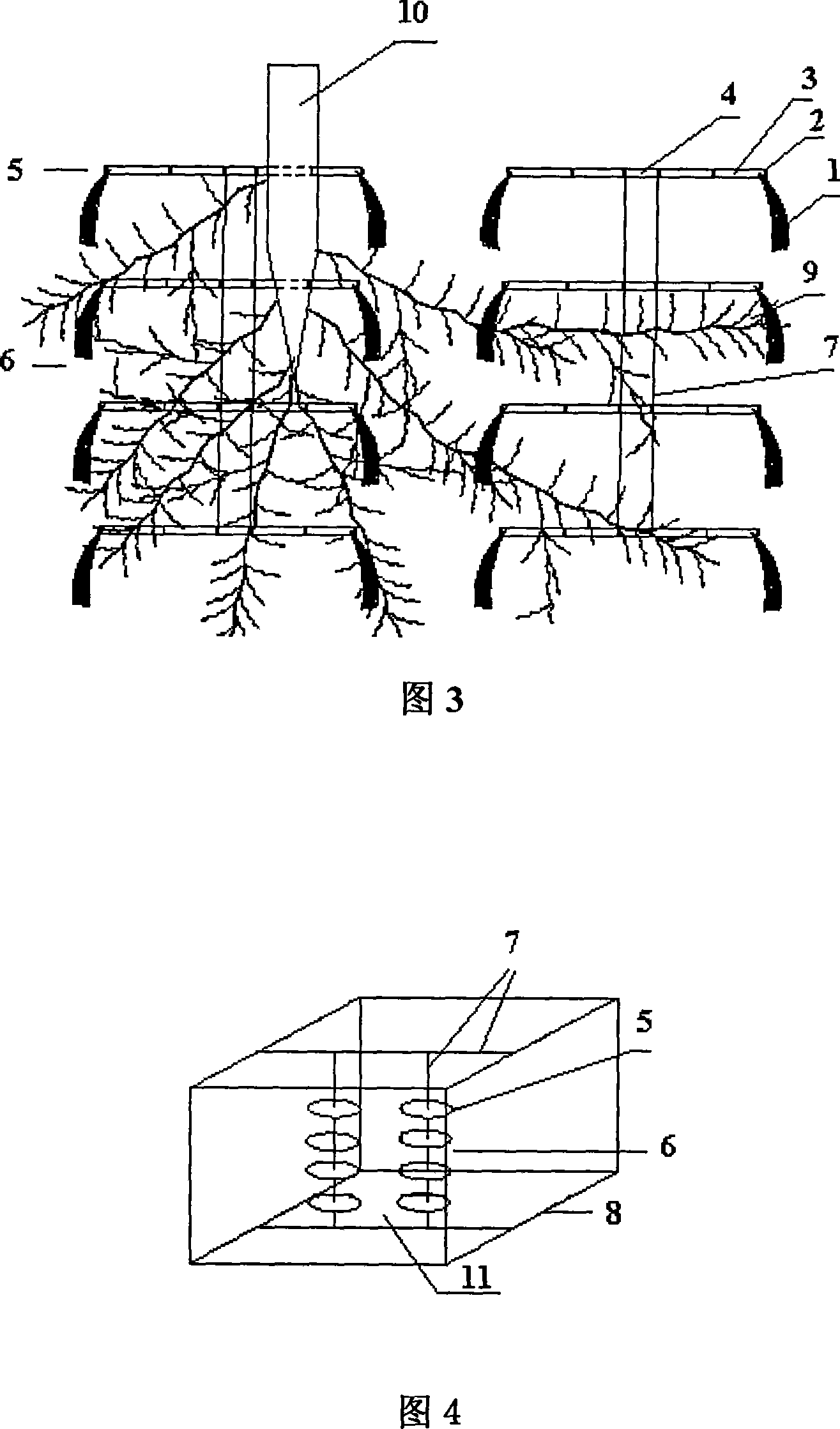

Method for fixing plants in water

InactiveCN101096282AAchieve fixationEasy to fixCultivating equipmentsSoilless cultivationFiberPlant roots

The invention discloses a plant fixing method in the water body in the plant fixing and environmental protective technical domain, which comprises the following steps: adopting present combined filling piece as substrate to fix the plant; placing the plant in the combined filling piece immersed in the water body directly; entangling the two and three graded beard roots and the fiber of the combined filling piece tightly; fixing the plant on the combined filling piece directly. The invention has fastened fixing, light-weight substrate, large contact area of water body and plant root and good fluidity of water among root, which is fit for fixing plant in the water body to harness water quality.

Owner:EAST CHINA NORMAL UNIV

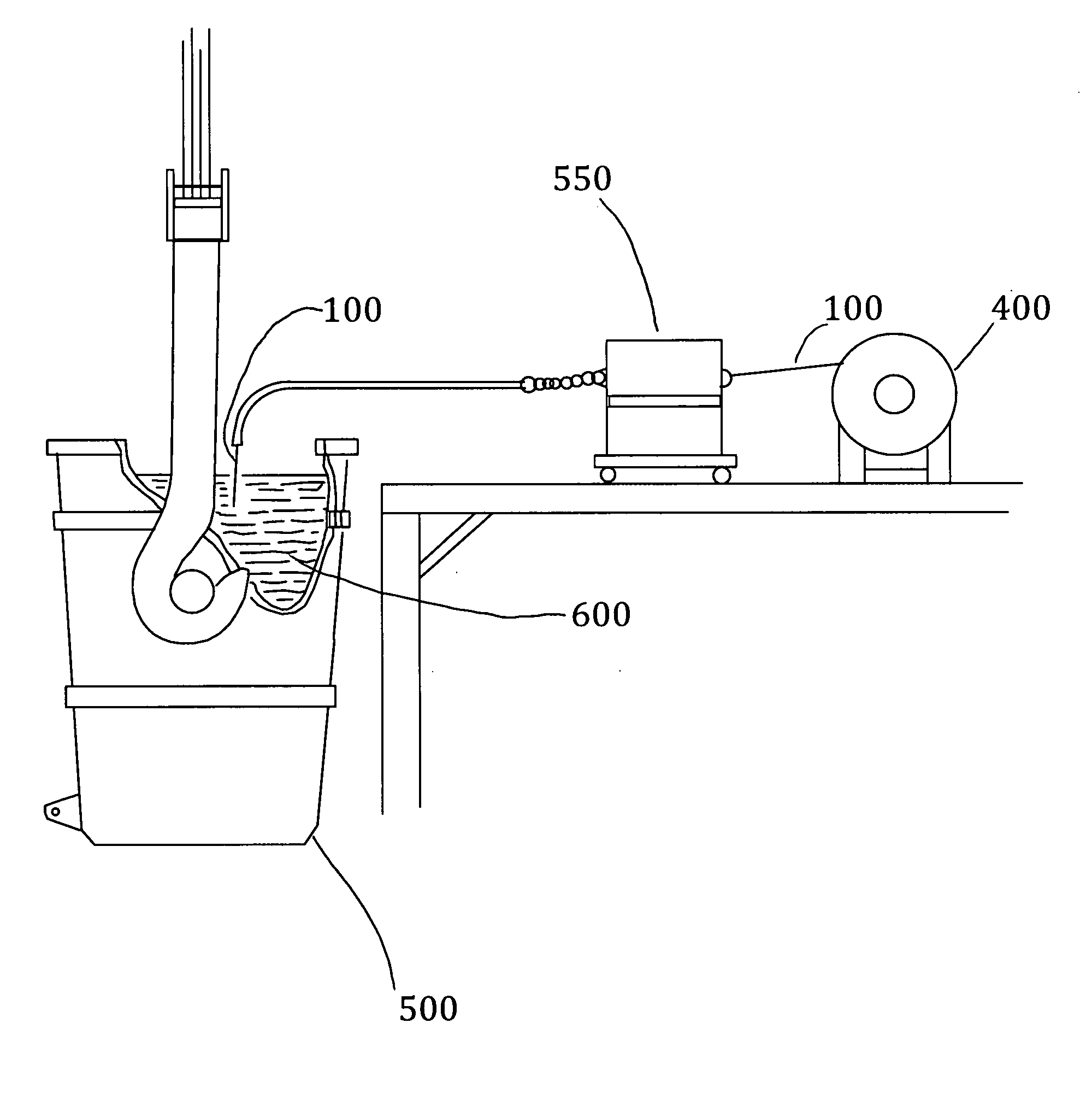

Composition and process for improved efficiency in steel making

ActiveUS20120024112A1Clogging of nozzle be eliminatePrecise controlHearth type furnacesOxideControl manner

A method for reducing tundish and ladle nozzle clogging in a steel making process by introducing an additive into molten steel containers used in steel making at predetermined times. The additives introduced are oxides of iron which contain between 10% and 30% of oxygen by weight. By adding the oxides of iron in a controlled manner using a cored wire apparatus, clogs in tundish or ladle nozzles in the steel making process are avoided and the steel flows more smoothly with less interruptions due to clogged nozzles. A preferred embodiment uses oxides of iron contained in a cored wire which can be introduced at a predetermined rate and readily mix with molten steel, provide better distribution of dissolved oxygen in the steel to oxidize inclusions, and facilitate removal of the inclusions before the inclusions can cause nozzle clogging.

Owner:DRESSEL TECH

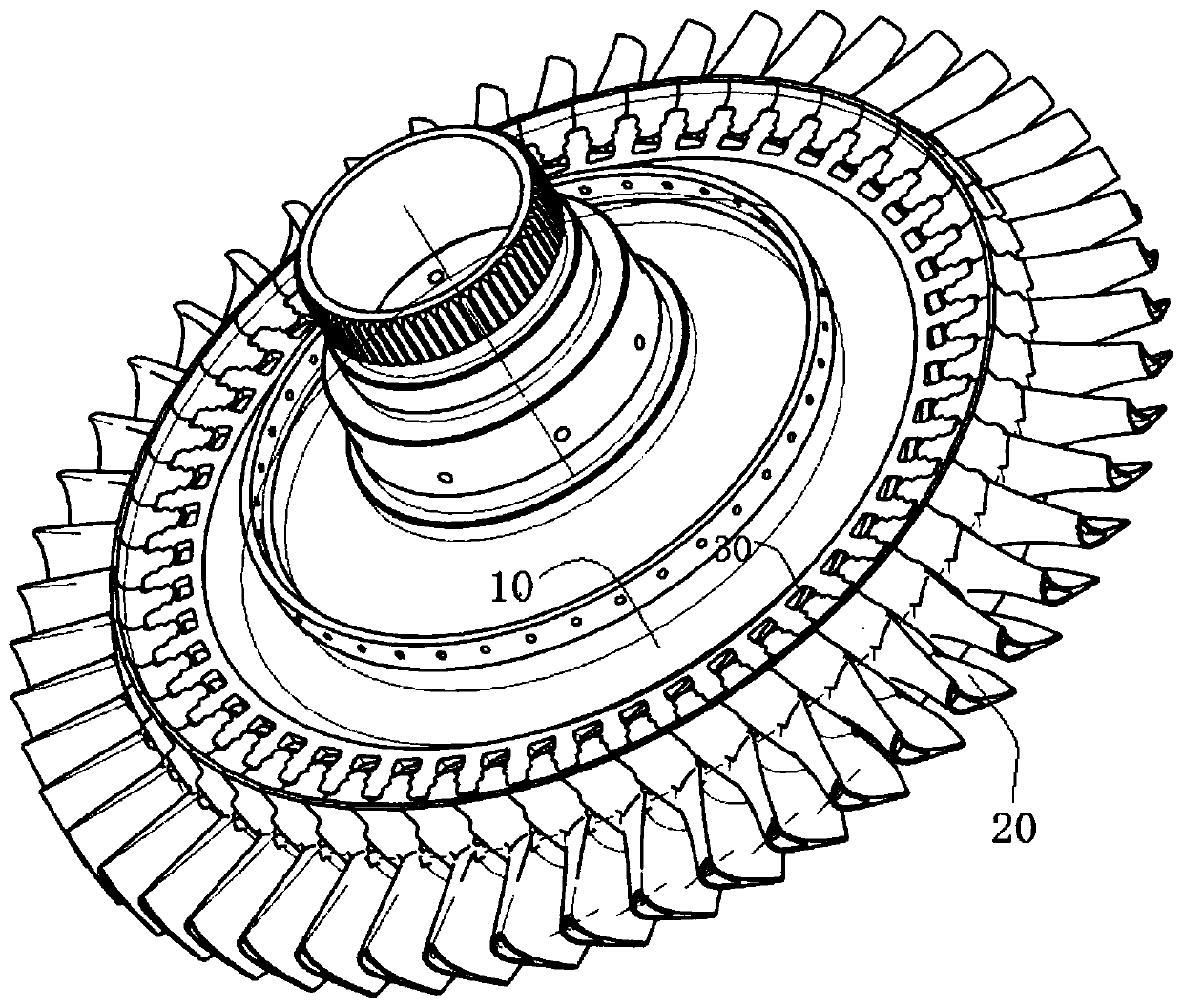

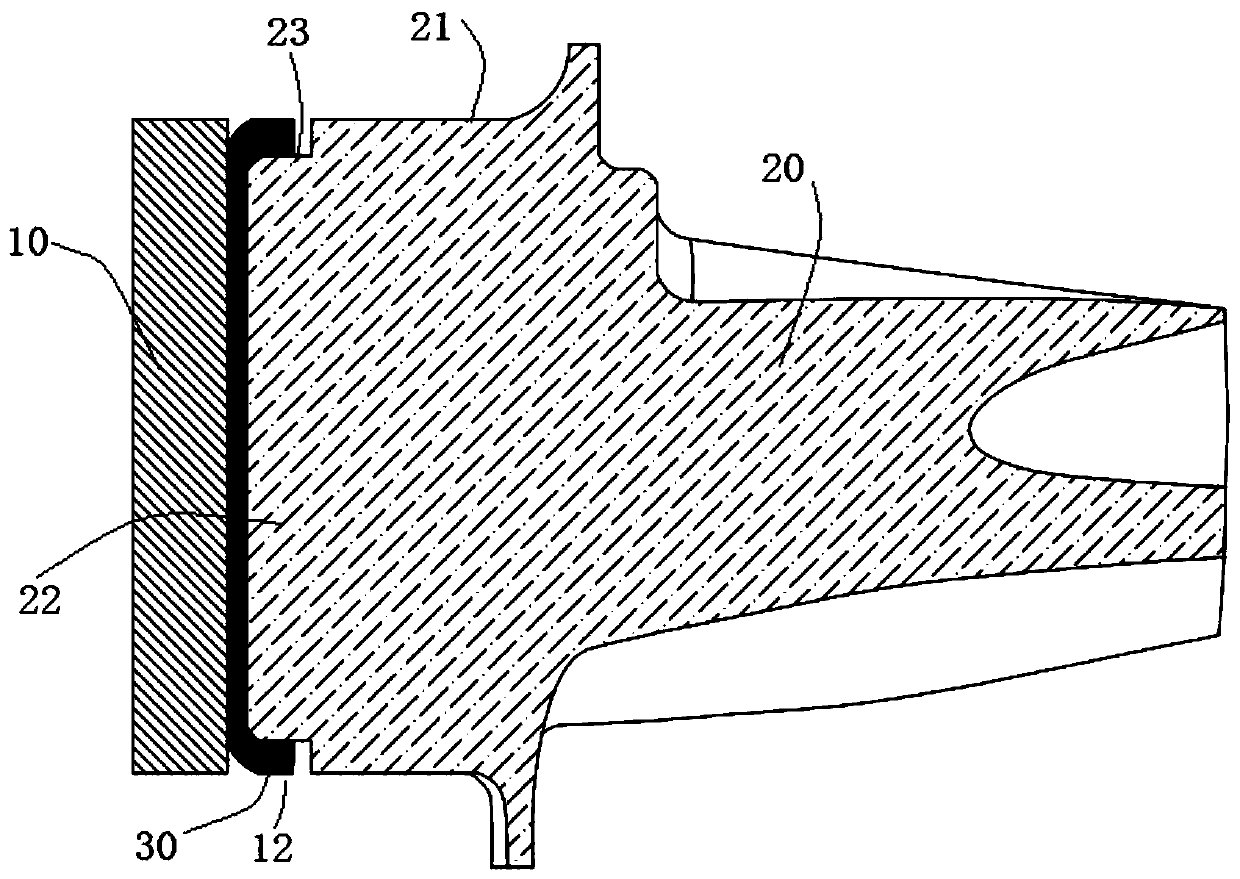

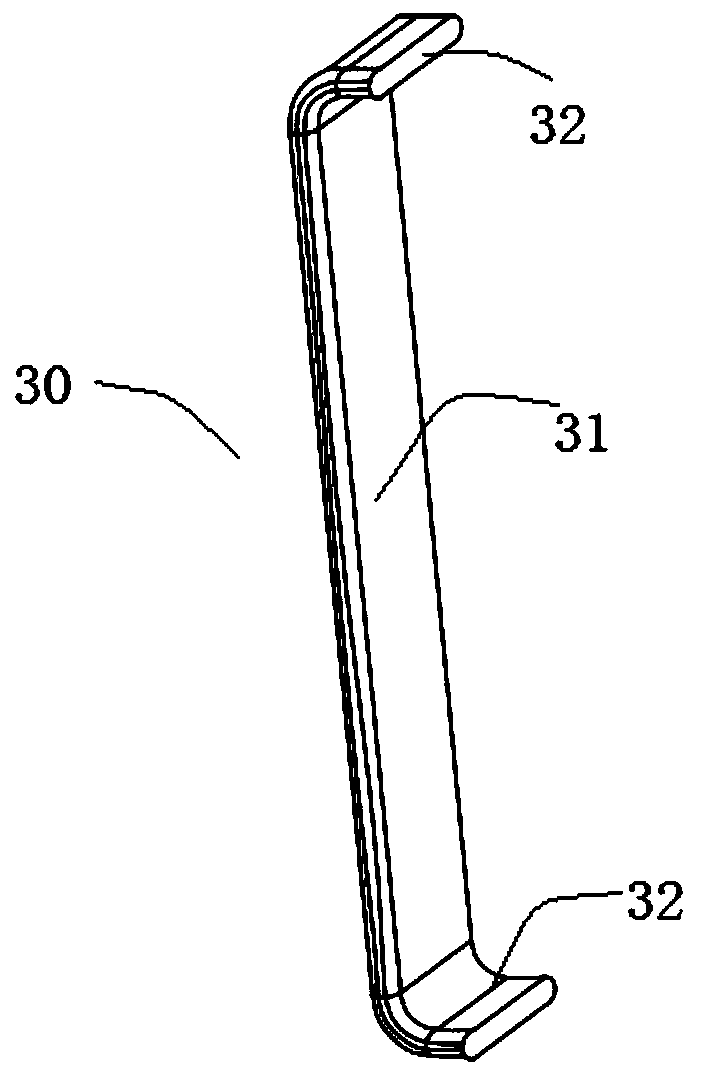

Turbine disc and blade locking mechanism for turboprop engine

PendingCN111472845AReduce processing timeImprove production efficiencyBlade accessoriesMachines/enginesTurbineTurboprop

The invention discloses a turbine disc and blade locking mechanism for a turboprop engine. The turbine disc and blade locking mechanism comprises a turbine disc and a plurality of blades which are uniformly distributed at the periphery of the turbine disc, wherein mortise structures are uniformly distributed at the periphery of the turbine disc; each mortise structure is composed of a first mortise at the outer side and a second mortise at the inner side, and the first mortise communicates with the second mortise; the root parts of the blades are provided with tenon structures; each tenon structure is composed of a first tenon and a second tenon on the end part of the first tenon; the first tenons are embedded into the first mortises; the second tenons are embedded into the second mortises, and are locked and fixed through blocking plates embedded between the second tenons and the seond mortises. According to the turbine disc and blade locking mechanism for the turboprop engine disclosed by the invention, the blades are matched with the turbine disc though the tenons and the mortises, so that only the locking plates need to insert and bend, and therefore, operations are simple; andmoreover, the turbine disc and blade locking mechanism is novel in design, is simple and convenient in assembly, is high in practicability, is excellent in stable performance, and can be widely applied to turbines of various functions.

Owner:上海尚实航空发动机股份有限公司

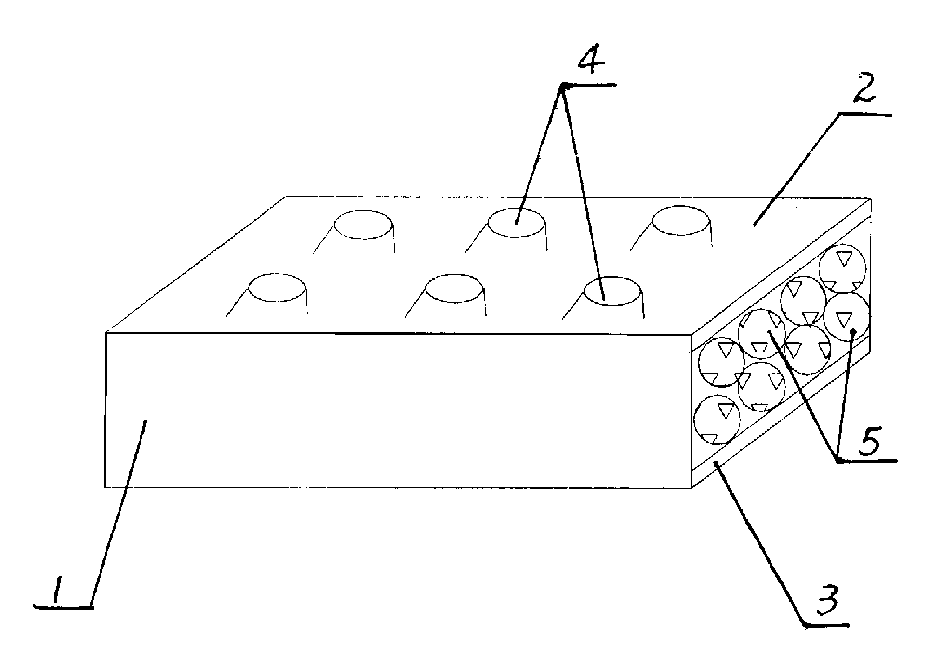

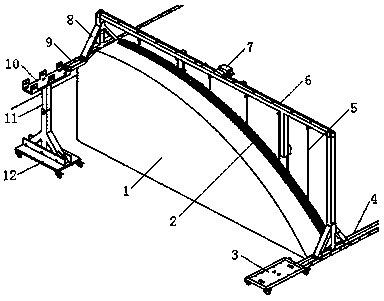

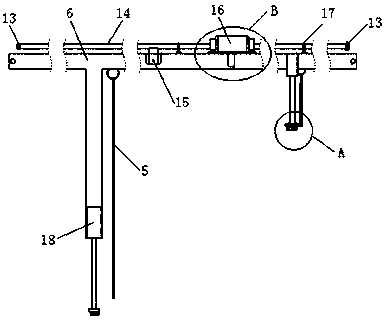

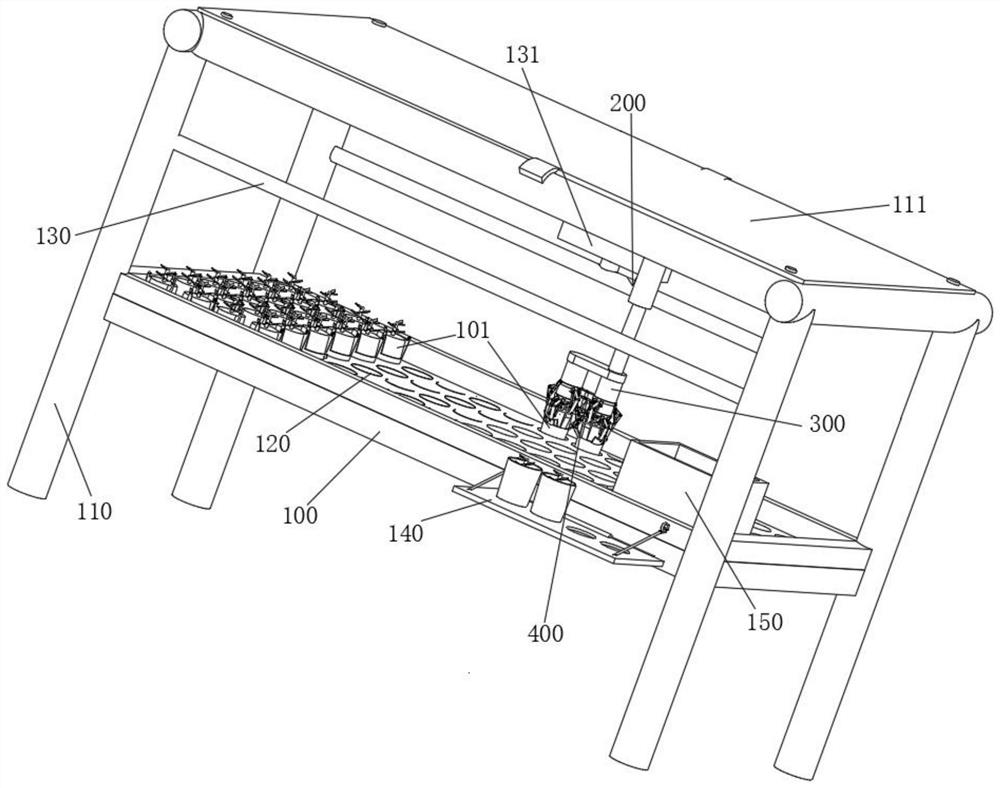

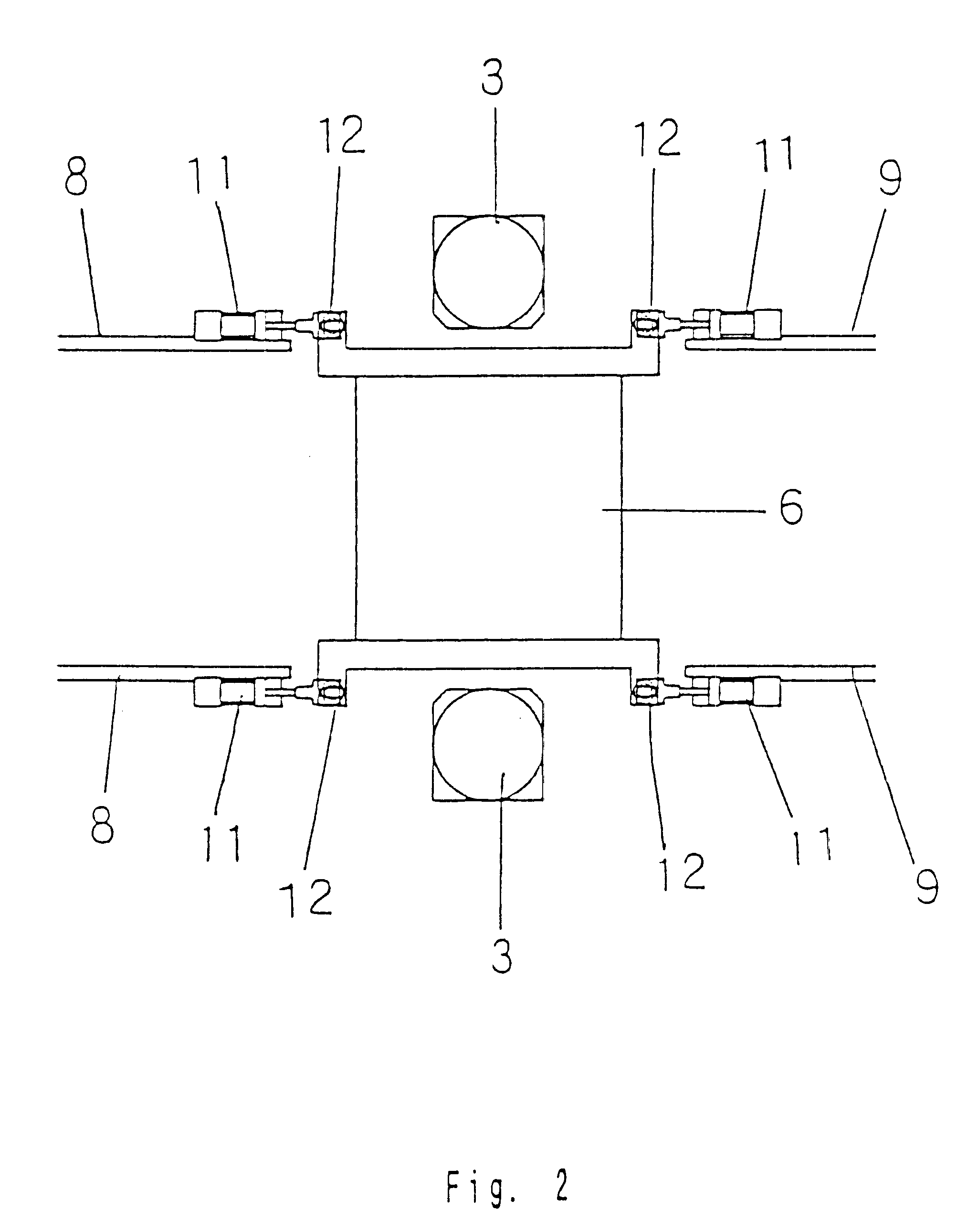

Shed-replaceable self-propelled sunlight greenhouse film washing device

PendingCN108435615ARealize the shed change operationImprove mobilityClimate change adaptationCleaning using toolsGreenhouseDaylight

The invention relates to a shed-replaceable self-propelled sunlight greenhouse film washing device. The shed-replaceable self-propelled sunlight greenhouse film washing device comprises a greenhouse (1); the greenhouse (1) is fixedly provided with a front rail (4) and a rear rail (9) correspondingly in the length direction of the greenhouse; the front rail (4) and the rear rail (9) are each internally provided with a movable supporting seat (8); a movable beam (6) which is positioned at the upper portion of the greenhouse (1) and in the width direction of the greenhouse (1) is fixedly arrangedbetween the supporting seats (8); and a washing device (2) is fixedly arranged below the movable beam (6). The shed-replaceable self-propelled sunlight greenhouse film washing device provided by theinvention is low in cost, can operate in a shred replaceable manner, reduces labor investment as far as possible, alleviates the labor intensity, meets the requirements of farmers for washing the greenhouse and improves the illumination intensity requirements inside the greenhouse.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

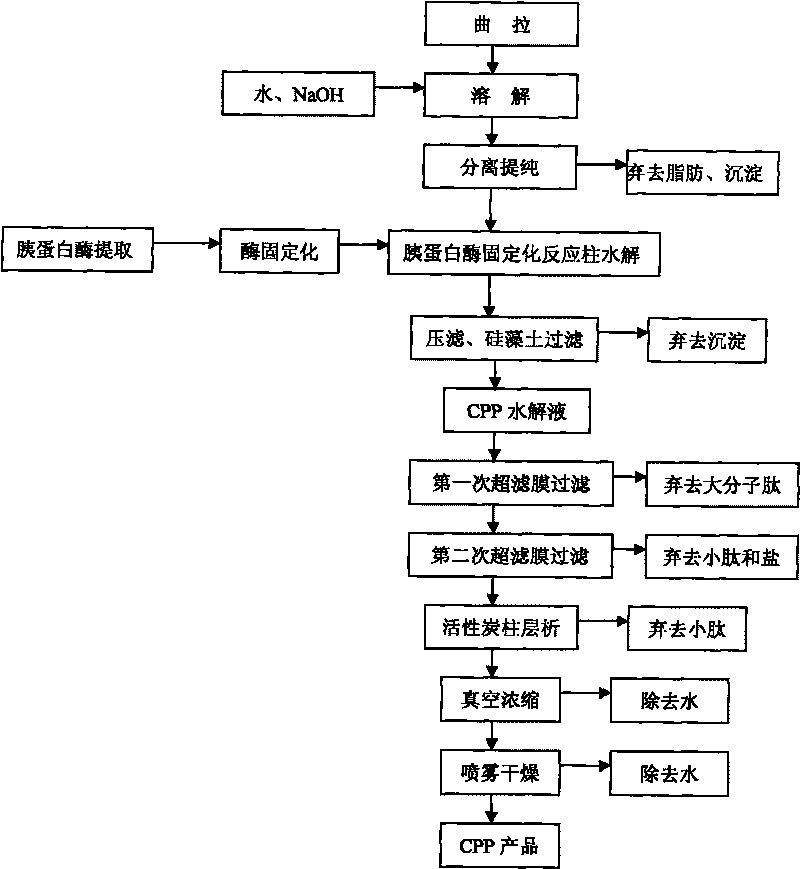

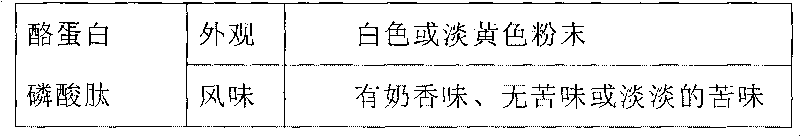

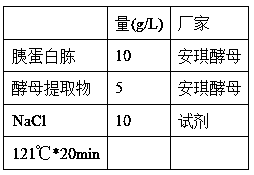

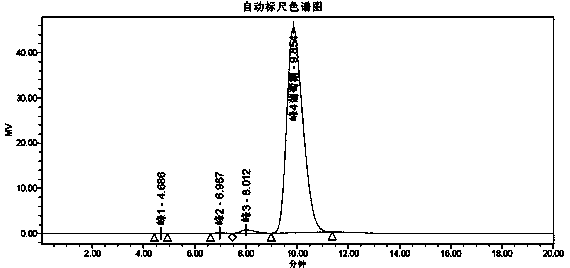

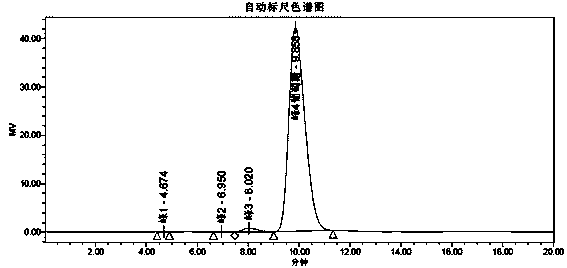

Casein phosphopept continuous production process by adopting immobilized enzyme hydrolysis crude cheese and ultrafiltration membrane separation method

The invention relates to a casein phosphopept continuous production process by adopting an immobilized enzyme hydrolysis crude cheese and ultrafiltration membrane separation method, comprising the following steps: a. extraction of tryptase; b. preparation of tryptase immobilized reaction column; c. crude cheese hydrolysis; d. separation and purification of the casein phosphopept (CPP) with an ultrafiltration membrane; e. column chromatography of CPP ultrafiltrate. The process has rational design, strong operability, short production process, high concentration of intermediate products and low production energy consumption; the main separation and purification processes are carried out at normal temperature, the evaporation capacity is less in the drying process, the energy consumption in the production can be greatly reduced, and the cost is saved; the product is obtained by vacuum concentration and spray drying, the main ingredient of the product is micromolecule bioactive polypeptides, the polypeptide with 2000-6000 of molecular weight accounts for more than 45 percent of the polypeptides.

Owner:甘南州科瑞乳品开发有限公司

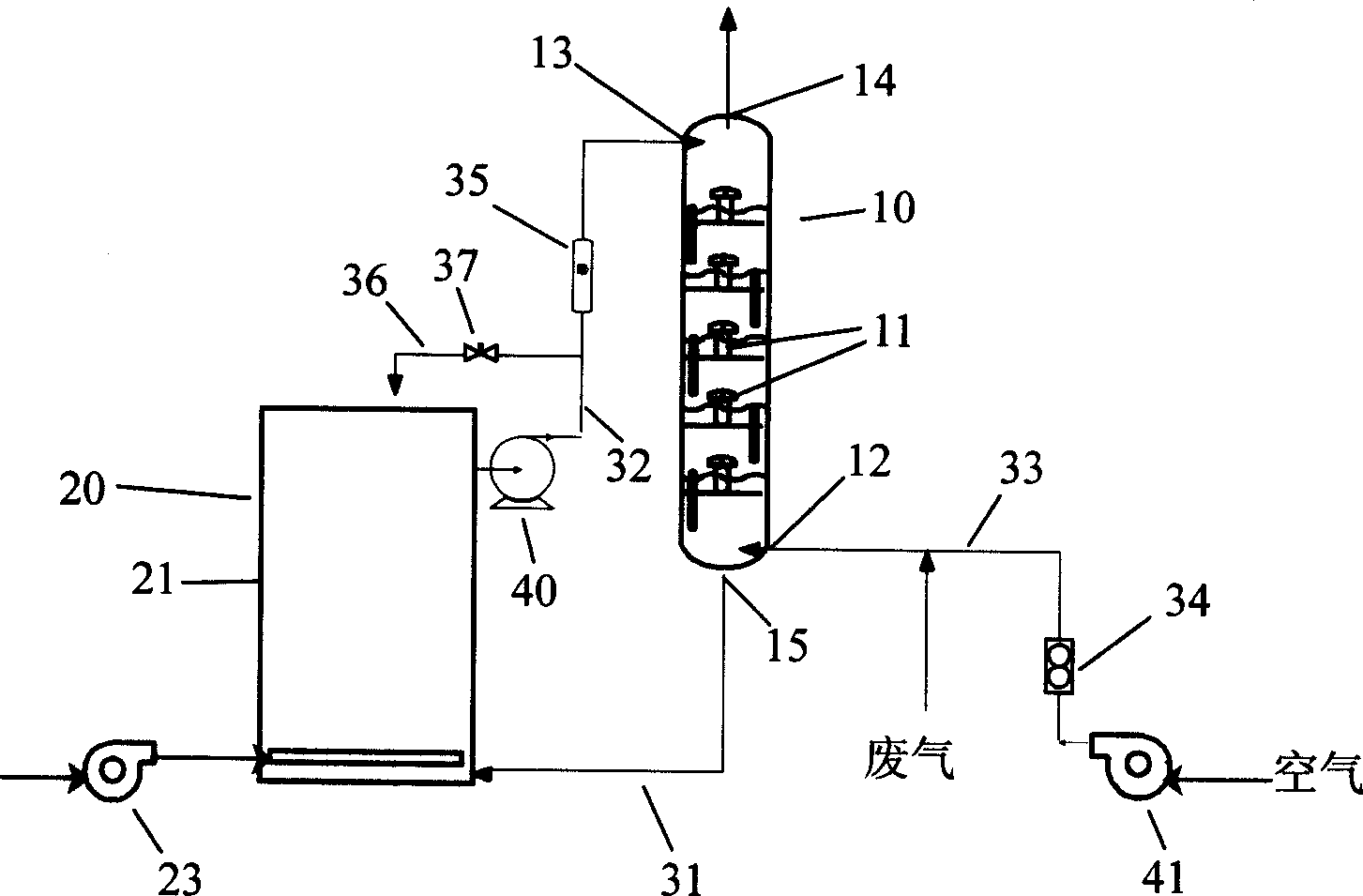

Waste gas treatment equipment employing scrubber and membrane bioreactor and method thereof

ActiveCN1864810AIncrease concentrationHigh volume efficiencySemi-permeable membranesDispersed particle separationExhaust fumesEnvironmental engineering

The invention discloses a method for treating waste gas containing organic matter and odour substance, which employs washing tower and film-separated biological reactor to remove organic and odour matter from waste gas. The waste gas contact with washing liquid in washing tower, the organic and odour matter are adsorbed and removed by washing liquid, and the waste washing liquid is introduced into film-separated biological reactor for treatment. The treated water containing low content of suspended solid is recycled to washing tower for reuse.

Owner:IND TECH RES INST

Monocrystal silicon wafer polishing process capable of obtaining high polishing rate

ActiveCN102962756ASpeed up thermal motionAccelerated corrosionPolishing machinesEngineeringForeign market

The invention relates to a monocrystal silicon wafer polishing process capable of obtaining a high polishing rate. In a coarse polishing process, an American Dupont SR330 coarse polishing solution is adopted, and diluted by pure water according to the ratio of 1:20 to 1:40; the flow is 23.5-24.5 L / min; a Rohm and Haas SUBA600 polishing pad is adopted; and the coarse polishing process comprises the following three steps: 1, using a coarse polishing solution to polish for 10 s, the rotating speed of a big disk being 23-27 rpm, the rotating speed of a central guide wheel being 48-52 rpm, and the pressure being 47-53 kPa; 2, using a coarse polishing solution to polish for 7-13 min, the rotating speed of the big disk being 38-42 rpm, the rotating speed of the central guide wheel being 78-82 rpm, and the pressure being 100-200 kPa; and 3, using pure water to polish for 40 s, the rotating speed of the big disk being 23+ / -27 rpm, the rotating speed of the central guide wheel being 48-52 rpm, and the pressure being 47-53 kPa. The polished section processed by the process has the removal rate up to 1.83-2.09 micron / min, which is far higher than the average level of 1 micron / min in the industry, and meanwhile, and has the pass percent up to more than 90% stably. The improvement of the productivity of the polished section can reduce the fixed cost, thereby meeting the requirements of domestic and foreign markets.

Owner:ZHONGHUAN ADVANCED SEMICON MATERIALS CO LTD +1

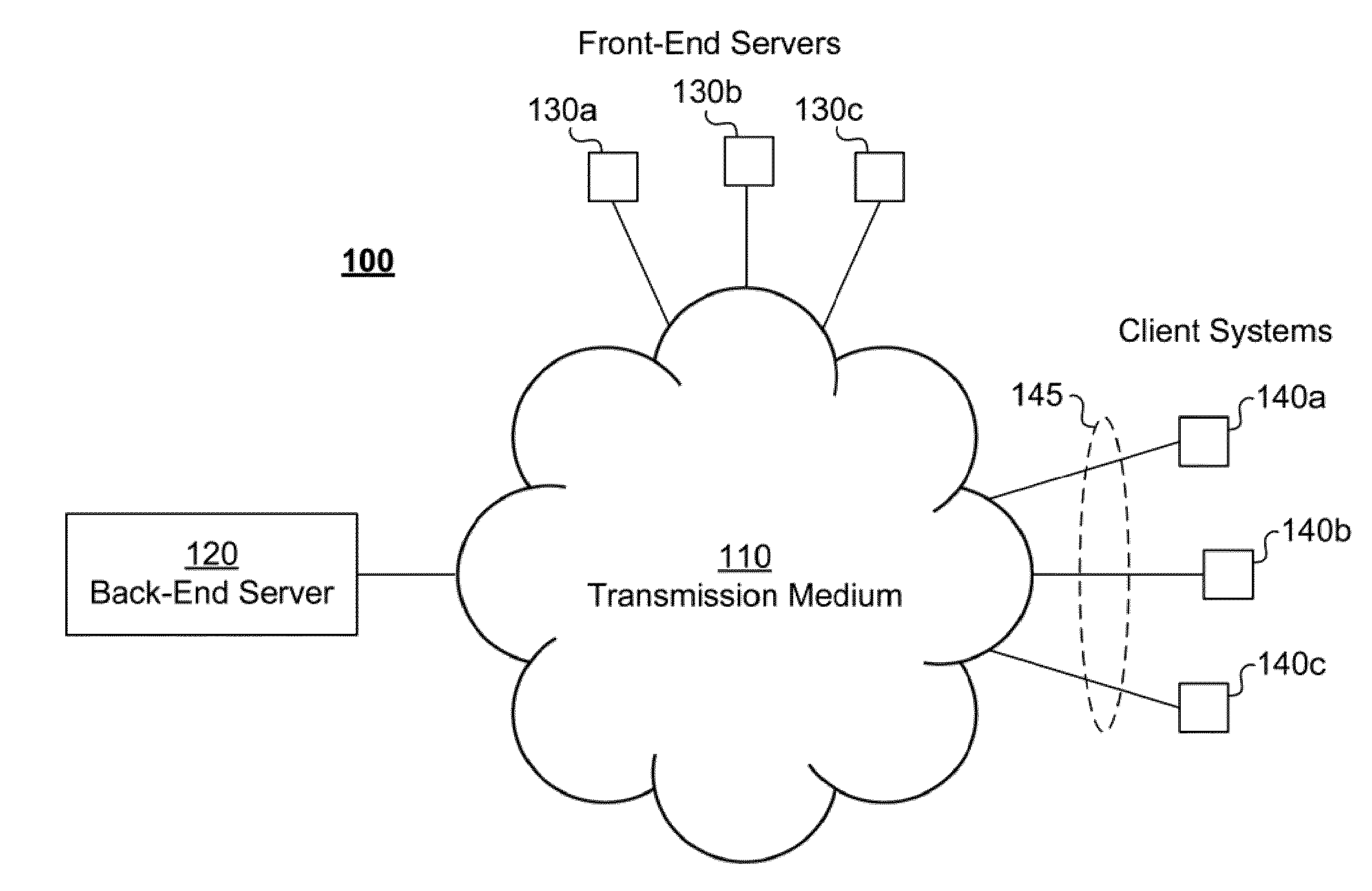

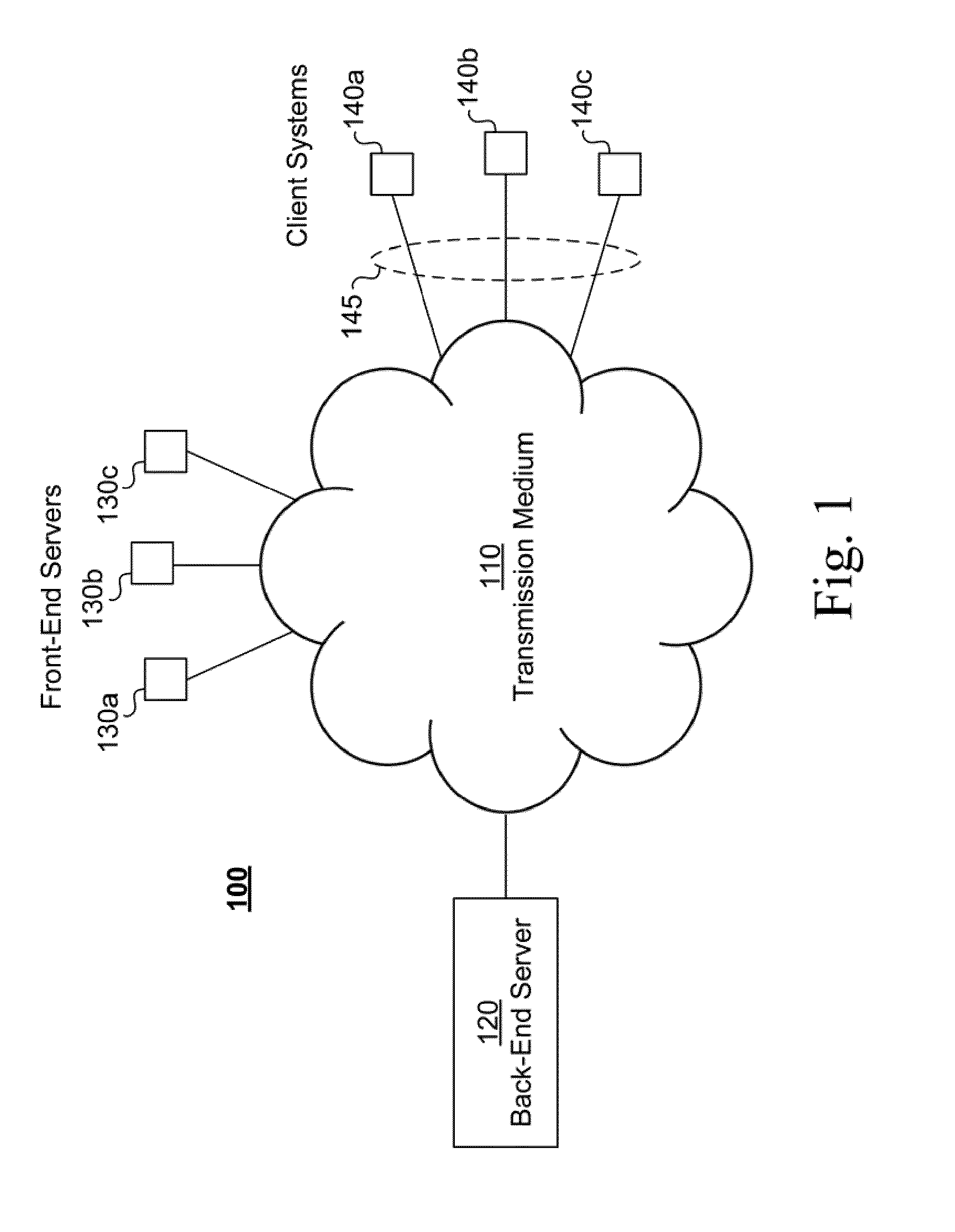

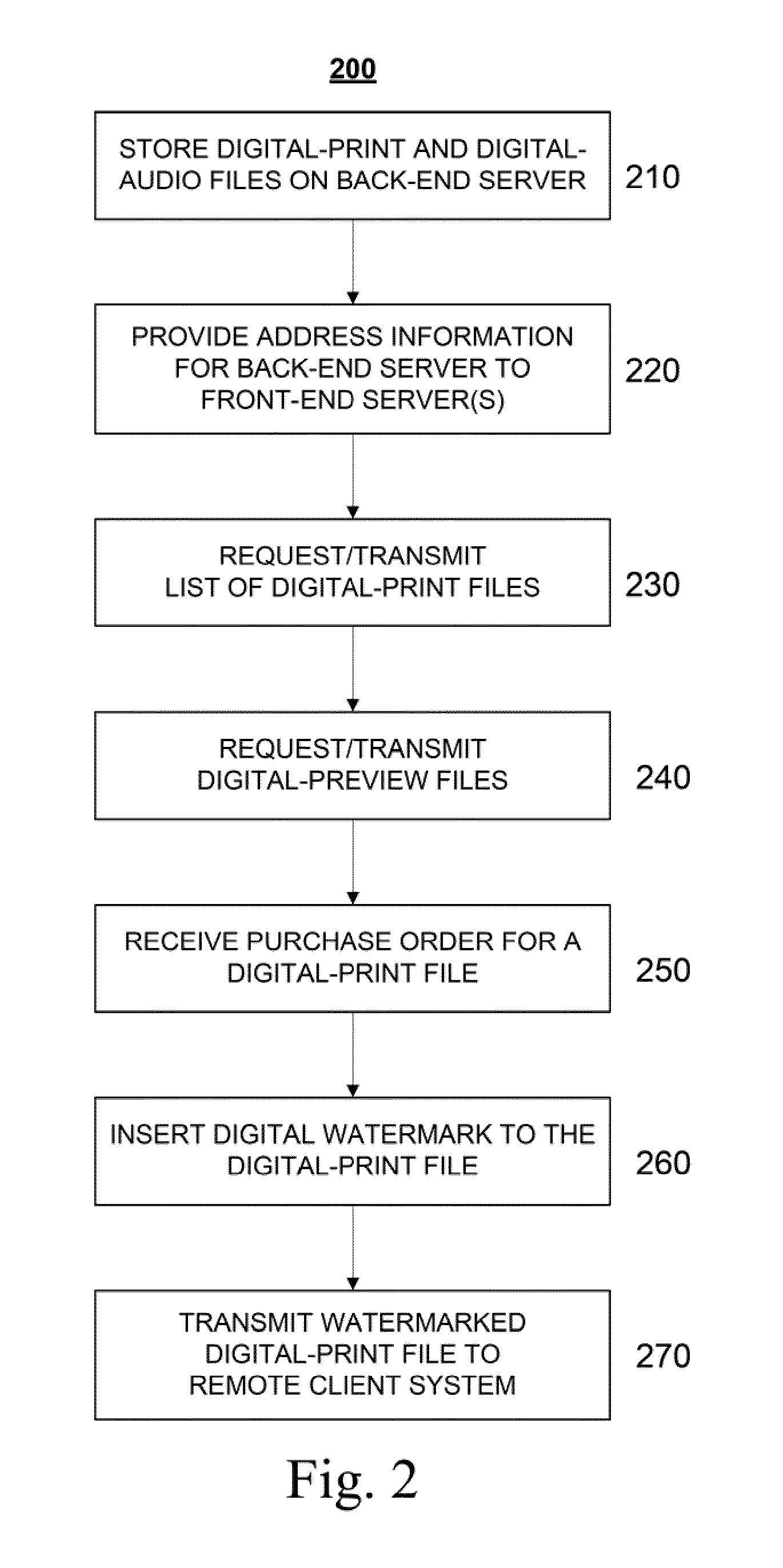

Method and System for Electronic Publishing and Distribution of Printed Sheet Music

InactiveUS20110203004A1Low costLess royalty revenueDigital data processing detailsAnalogue secracy/subscription systemsApplication programming interfaceBack end server

Described are methods and systems, including computer program products, for distributing printed sheet music. The method includes storing a set of one or more digital-print files and a set of one or more digital-audio files in a computer-readable storage medium on a back-end server. Each digital-print file includes sheet music information associated with one of the digital-audio files. Each, digital-print file and digital-audio file is associated with one or more audio identifiers. An application programming interface (API) is provided for client systems remote from the back-end server to retrieve a list of the set of one or more digital-print files and to preview the digital-audio and digital-print files. A purchase order is received for the first digital-print file from the remote client system using the API. A digital watermark is inserted into the first digital-print file. The watermarked digital-print file is transmitted to the remote client system.

Owner:ZIERING ERIC

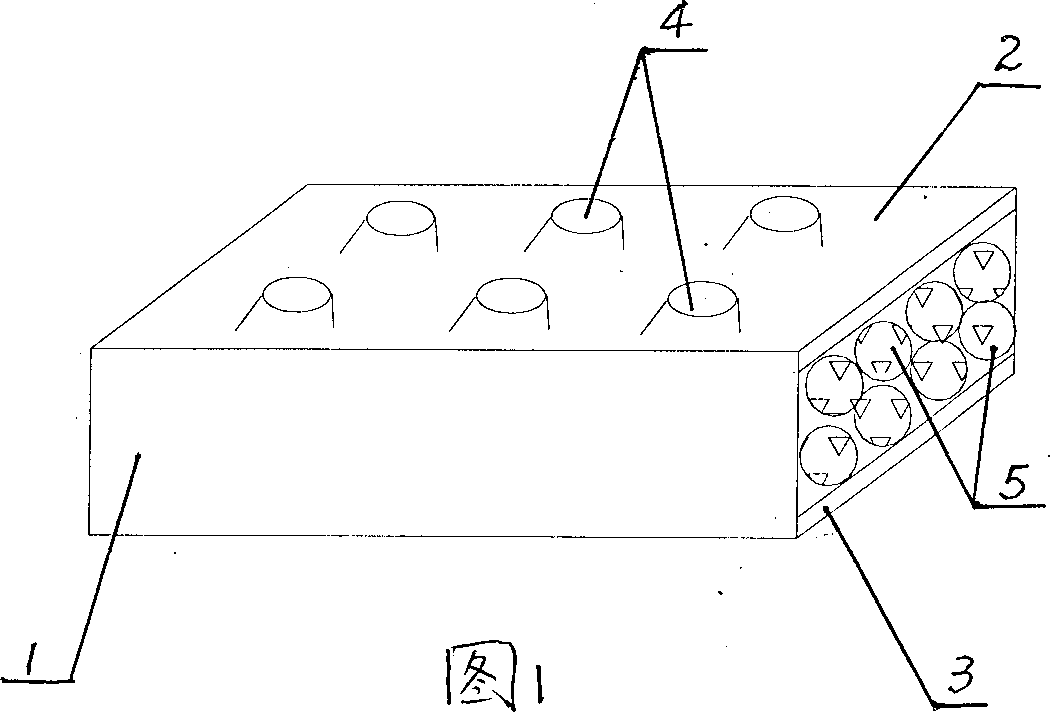

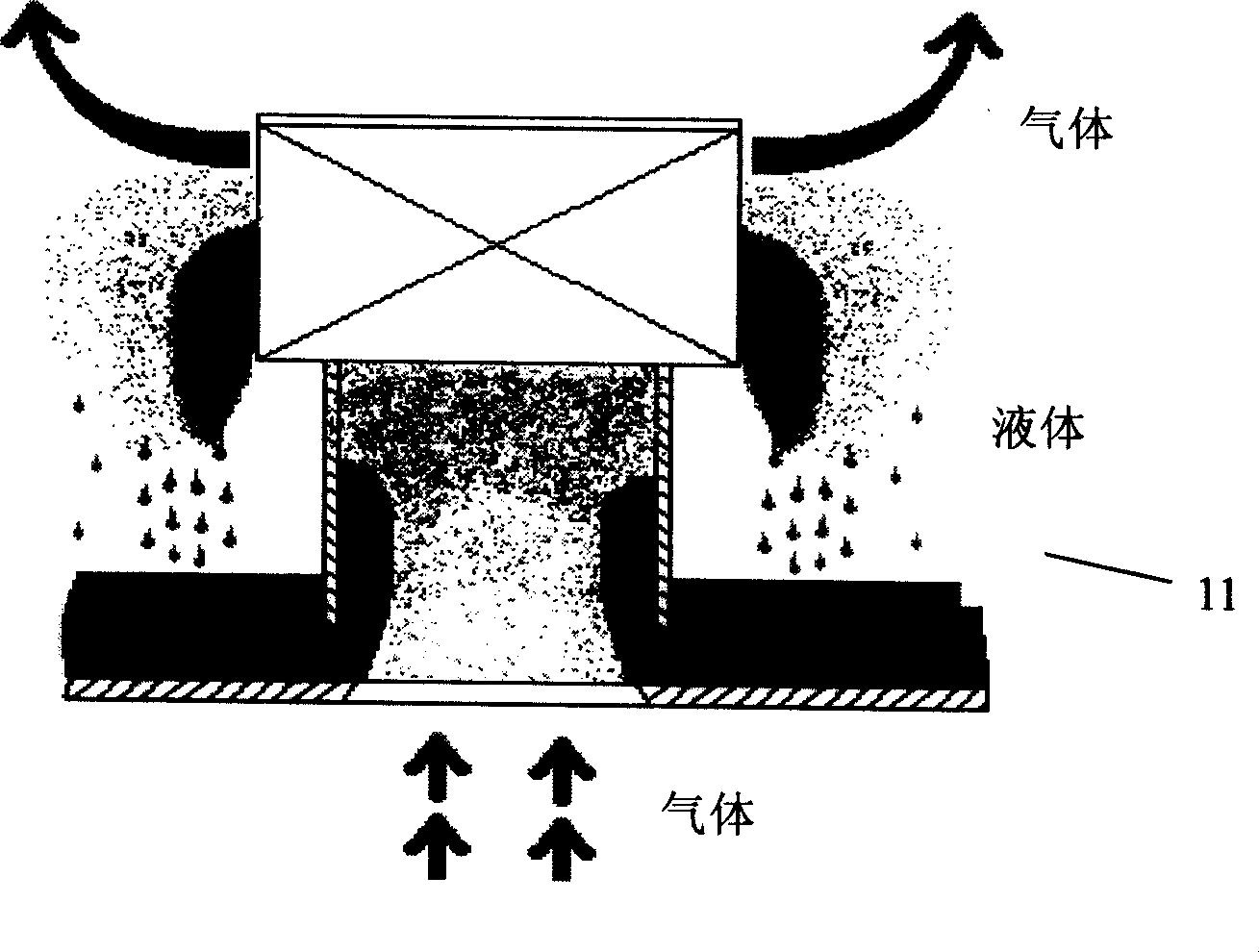

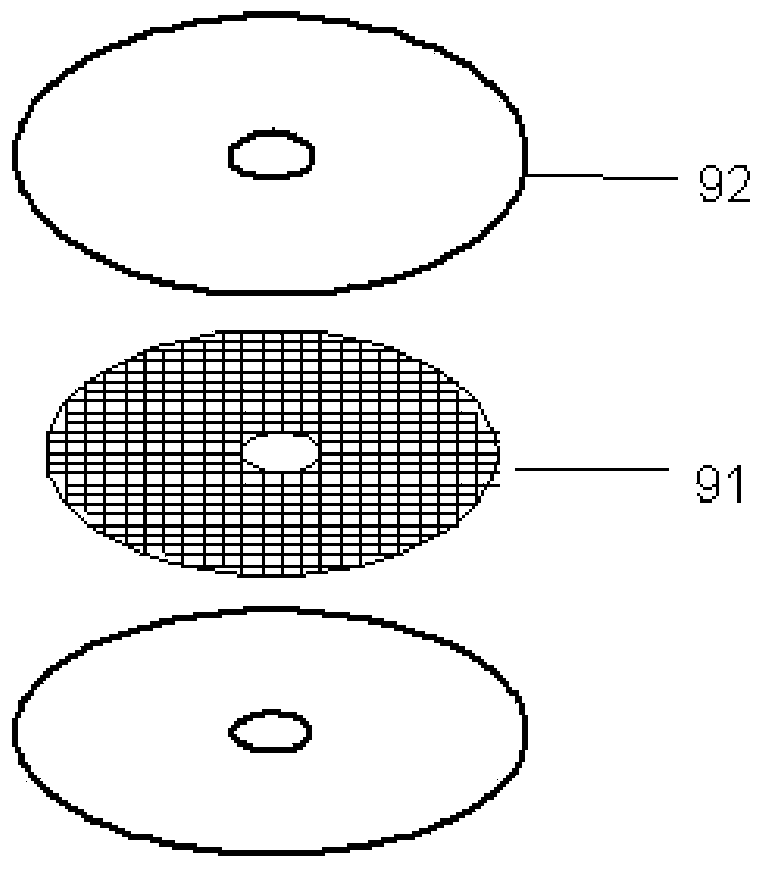

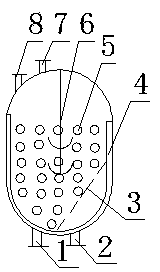

Built-in disc fibrous bed reactor for fermenting production of butyric acid

InactiveCN103642680AReduce the chance of infectionIncrease profitBioreactor/fermenter combinationsBiological substance pretreatmentsAutomatic controlProcess engineering

The invention discloses a built-in disc fibrous bed reactor for fermenting production of butyric acid. The reactor comprises a reactor body, a stirring device, a pH automatic control device and a material supplying device, and further comprises a composite disc type fibrous structures which are fixedly arranged in the reactor body at intervals as cell immobilization carriers, wherein the pH automatic control device and the material supplying device are respectively connected to the reactor body; the stirring device is arranged in the reactor body; the stirring device is free from being in contact with the composite disc type fibrous structures; each composite disc type fibrous structure comprises a disc type stainless steel net and immobilization fibrous materials; the immobilization fibrous materials cover both upper and lower surfaces of the disc type stainless steel nets. Equipment utilization rate of the built-in disc fibrous bed reactor is high and the immobilization fibrous materials are cheap; the reactor is high in acid production strength and stable in repeated batch production when used for producing the butyric acid, and is suitable for industrial production.

Owner:ZHEJIANG UNIV OF TECH

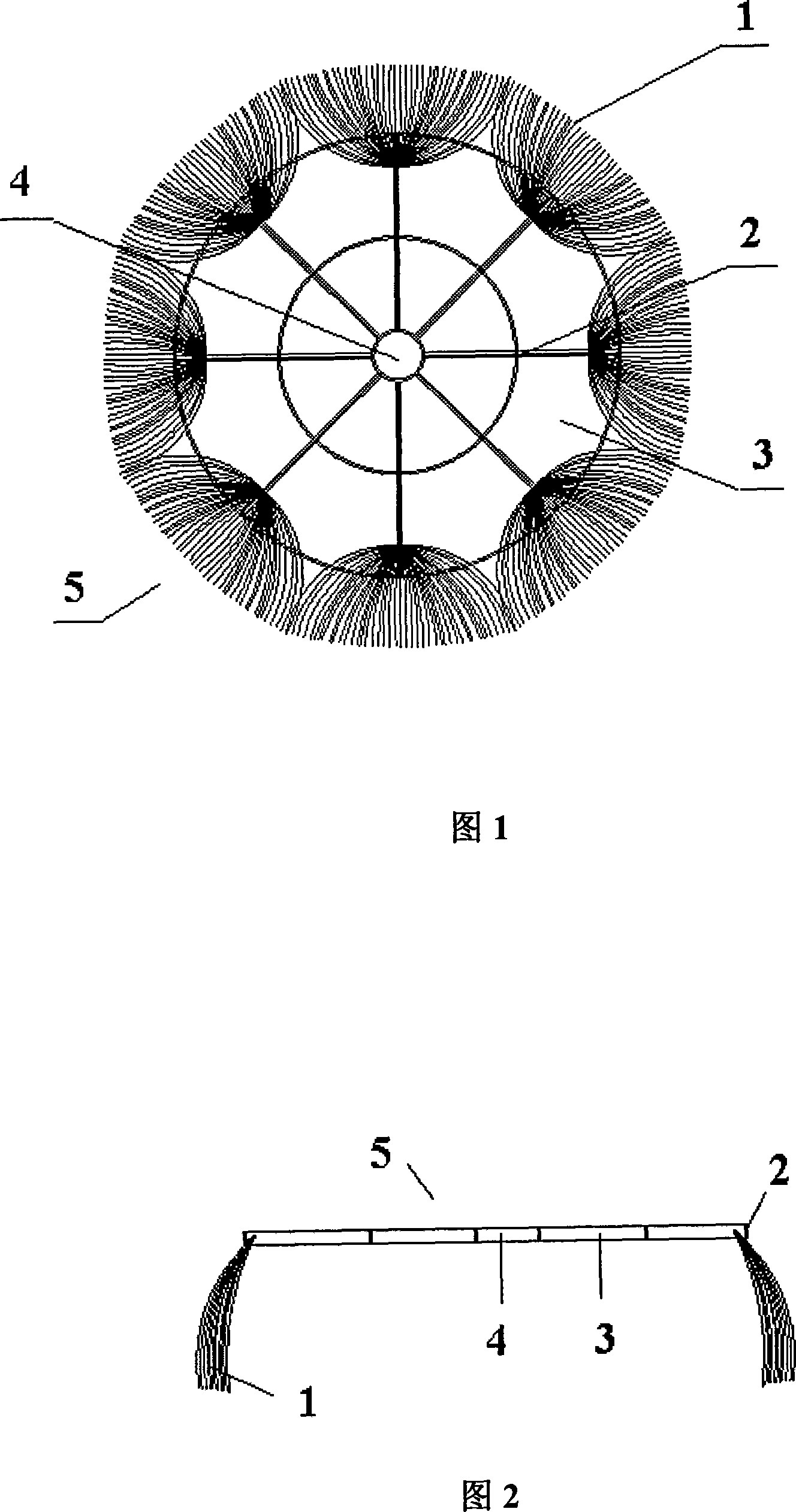

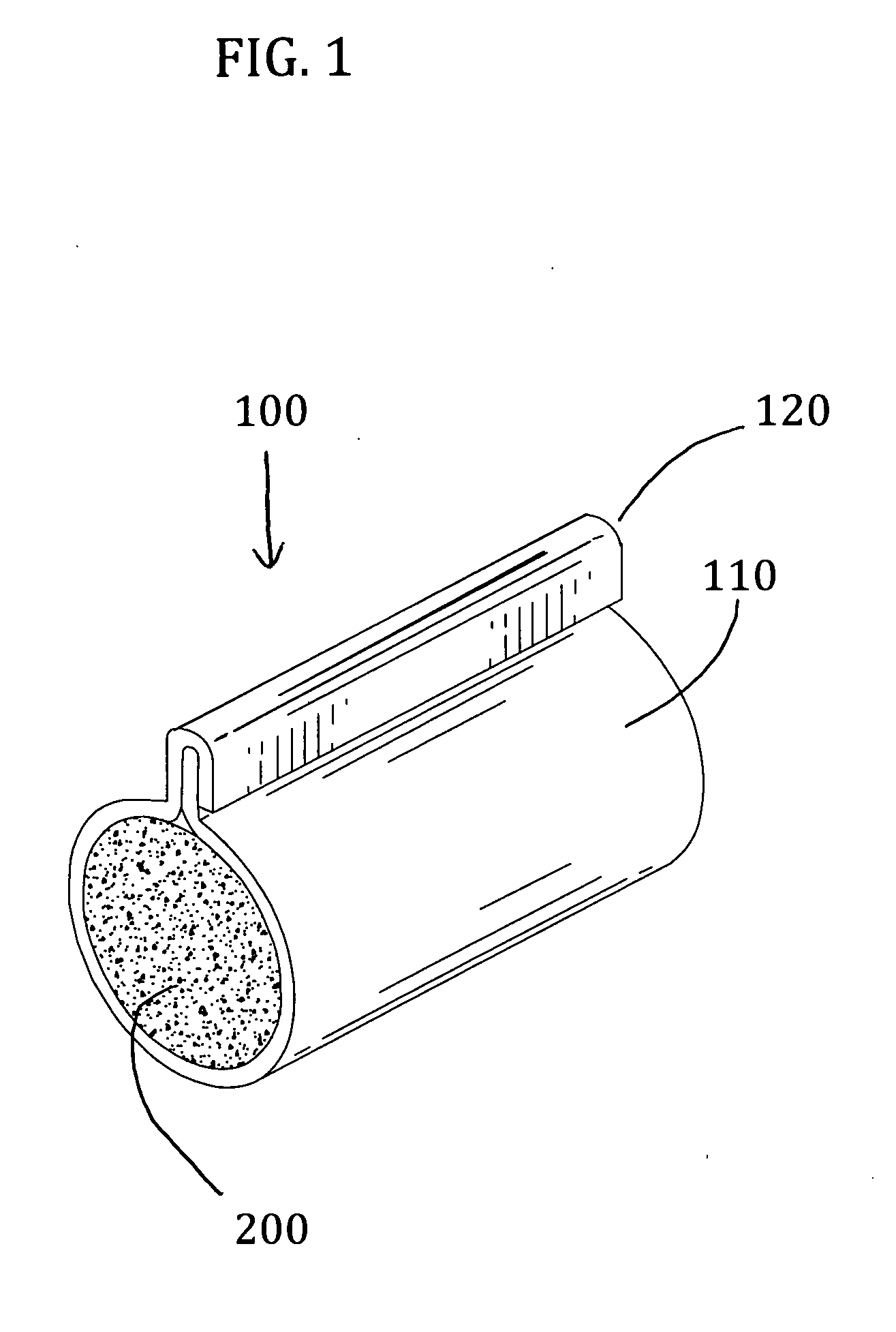

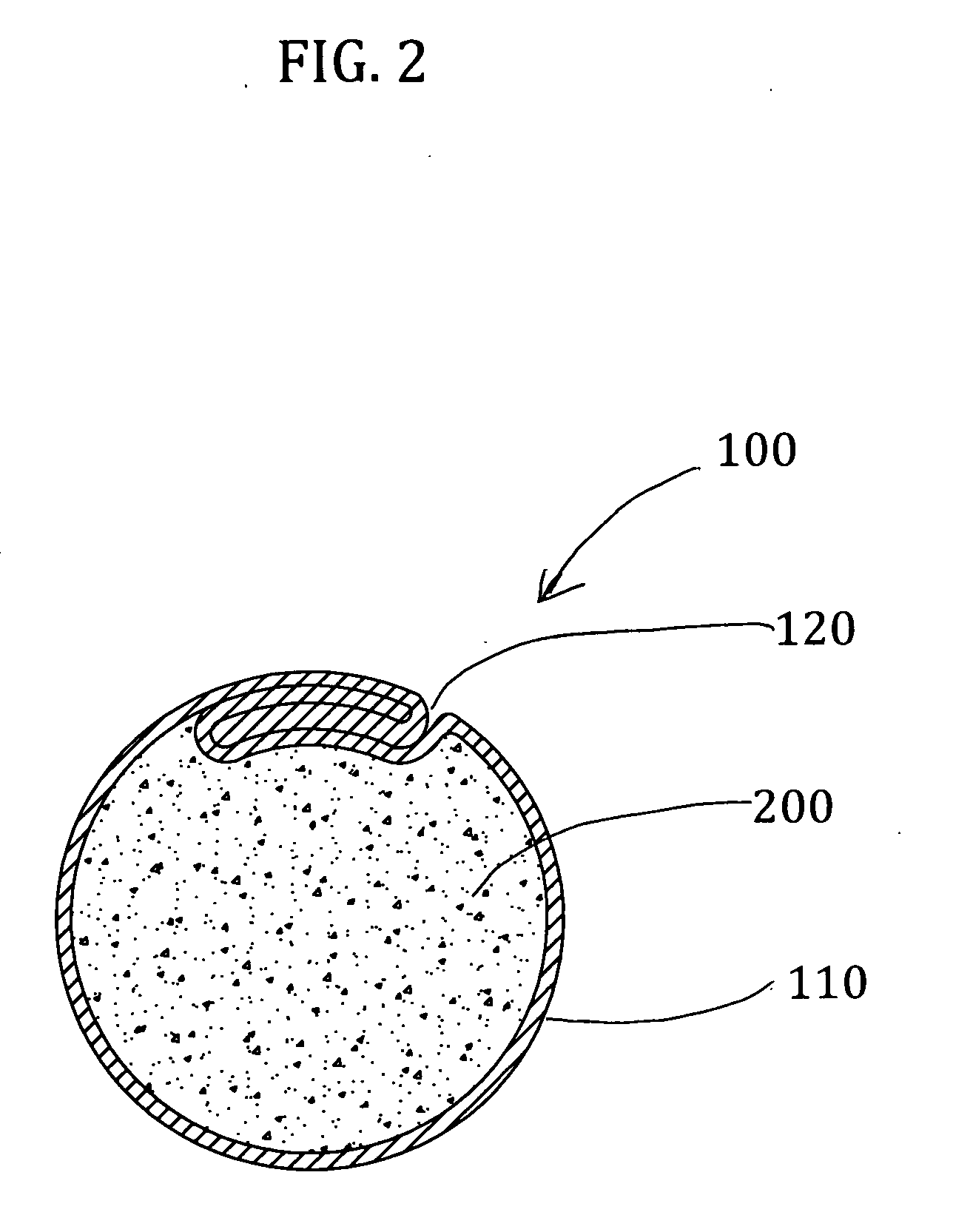

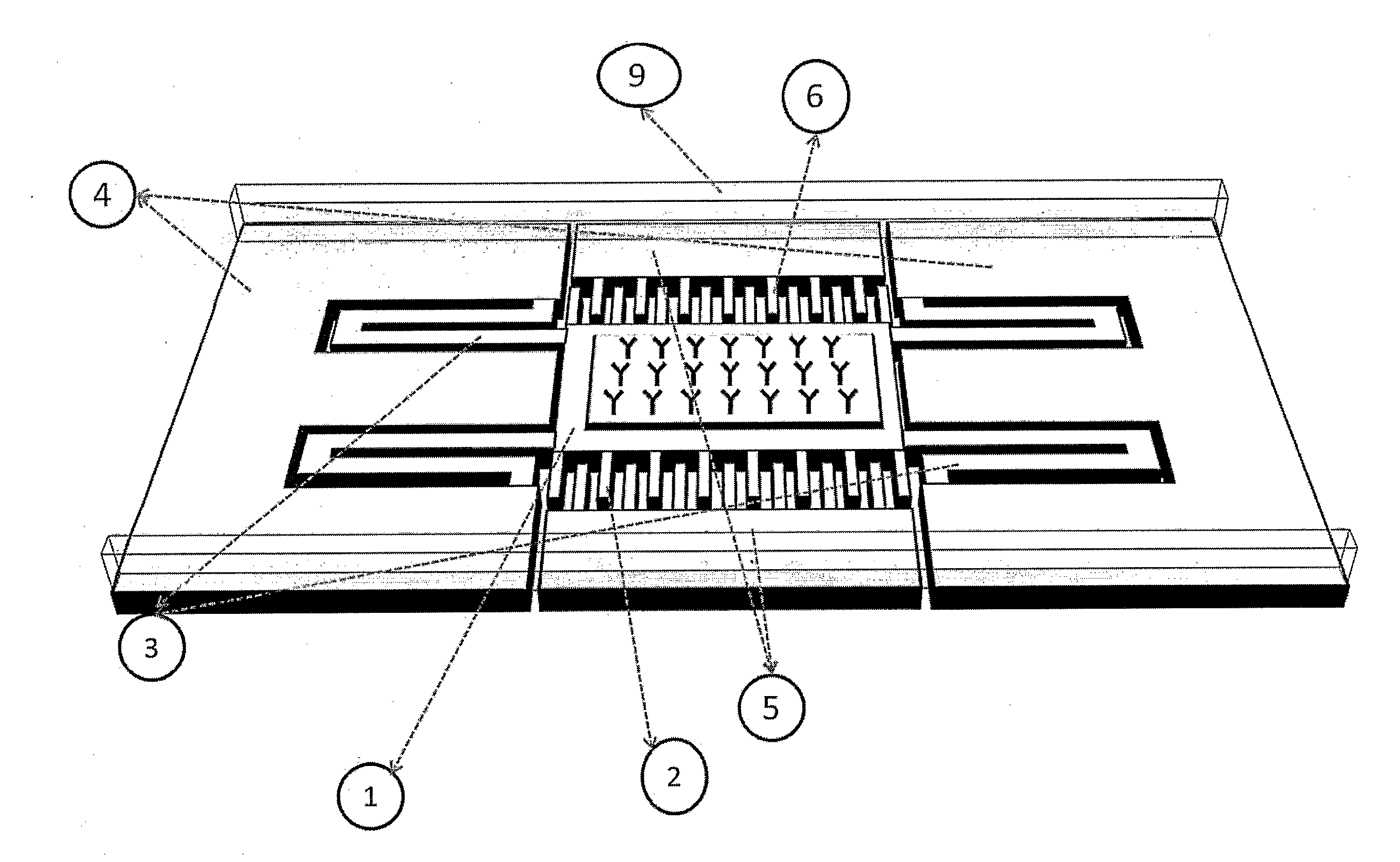

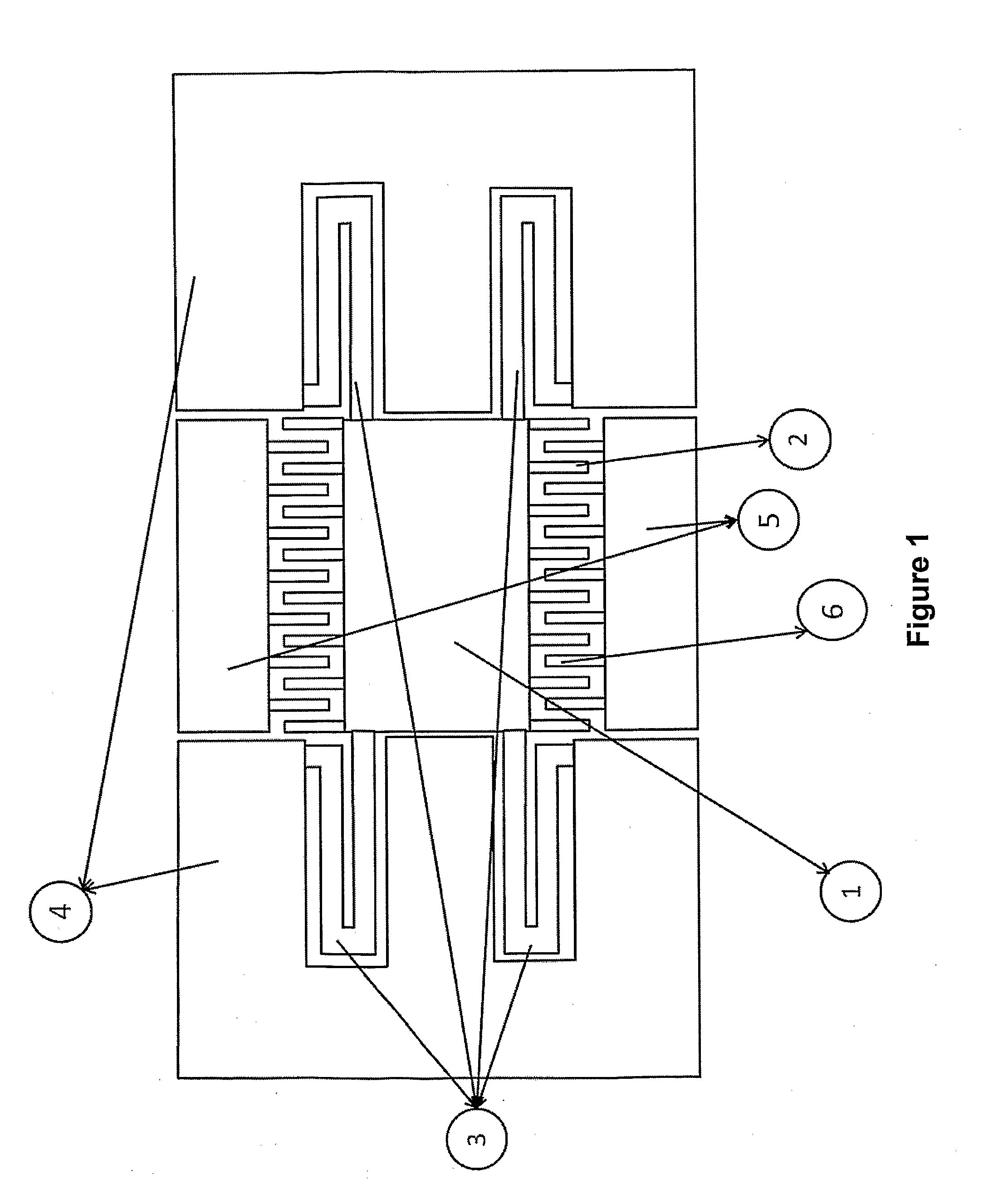

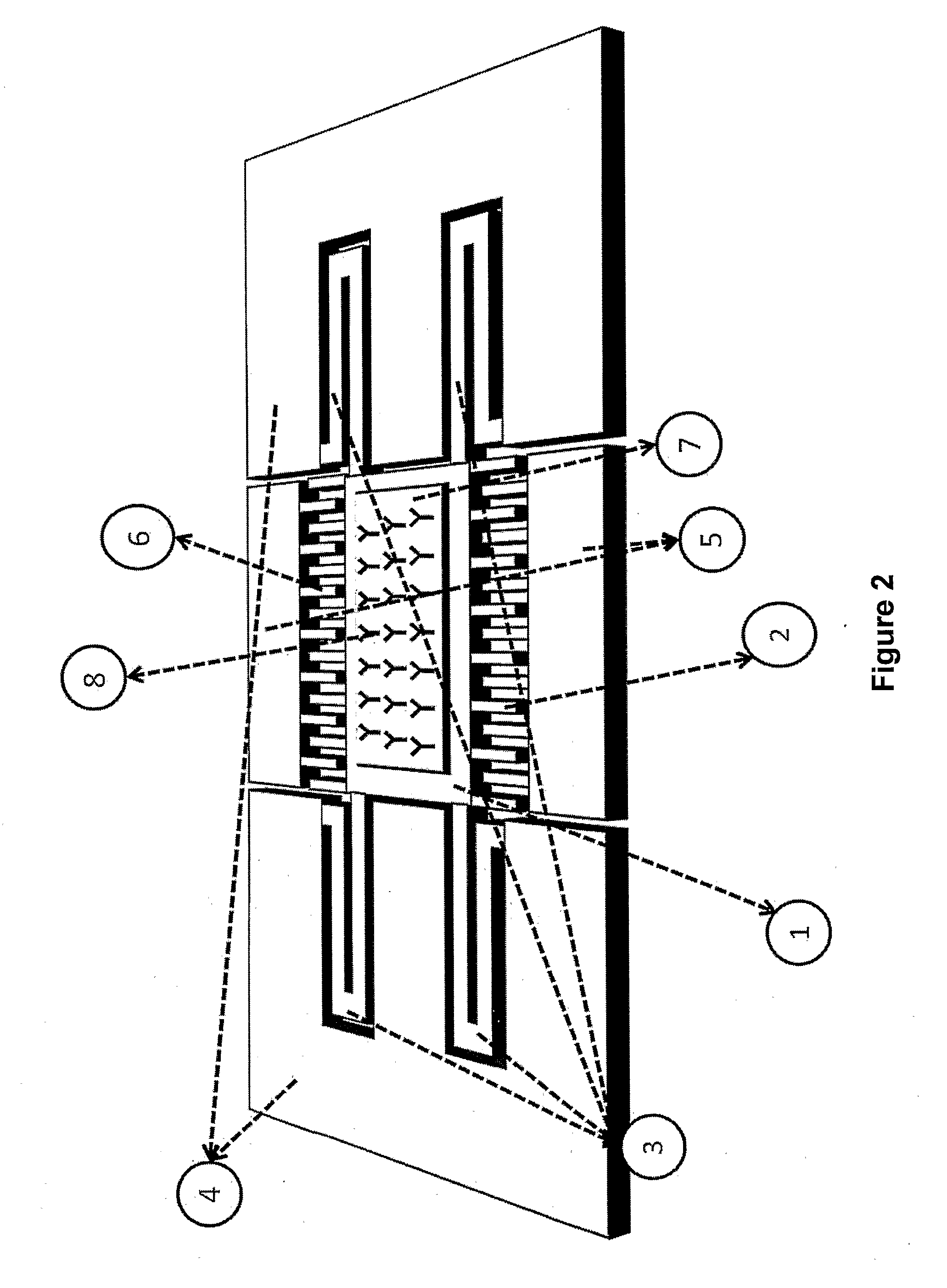

Microfluidic-channel embeddable, laterally oscillating gravimetric sensor device fabricated with micro-electro-mechanical systems (MEMS) technology

ActiveUS20120148448A1Easy to produceHigh quality factorAnalysing fluids using sonic/ultrasonic/infrasonic wavesWeighing apparatus using elastically-deformable membersBiological cellAnalyte

Laterally oscillating gravimetric sensing device embeddable under micro-fluidic channels and fabricated with micro-electro mechanical systems (MEMS) technology, which detects biological cells and analytes by measuring the change of mass attached on its surface is composed of four main groups, namely a resonator that can be placed onto the basis of the channel, components of the resonator bio-activation, a micro fluidic channel, and the microfabrication techniques, and its main components are the proof mass (1), comb fingers fixed to proof mass (2), folded spring beams (3), channel floor and mechanical soil (4), stationary electrodes (5), comb fingers attached to the stationary electrodes (6), golden film deposited onto the mass (7), immobilized biologic recognition molecules (8), and micro fluidic channel placed on resonator structure (9).

Owner:MIKROBIYOSISTEMLER ELECTRONICS SAN & TIC AS

Bionic process for preparing silicon oxide nano-microcapsule immobilized enzyme

The invention provides a bionic process for preparing silicon oxide nano-microcapsule immobilized enzyme. According to the method, enzyme is coated in liposome nano-microcapsules; with the liposome nano-microcapsules as a template, under the effect of an inducing agent poly dimethyl diallyl ammonium, tetramethyl orthosilicate hydrolysate is dehydrated on the surface of liposome, such that a silicon oxide shell layer is formed. Direct contact of enzyme and a silicon precursor is completely avoided, such that a purpose for maintaining relatively high activity of the immobilized enzyme is realized. Also, with the liposome nano-microcapsules as the template, preparation of the silicon oxide nano-microcapsules with controllable morphology can be realized. Finally, the liposome template is removed by using a low-concentration surfactant octyl polyethylene glycol phenyl ether. With the immobilized enzyme preparation method provided by the invention, an embedding rate can reach approximately 50%, such that problems of free enzyme severe wasting and immobilization cost increasing of a sol-gel method are avoided. The reaction mainly involves water phase, such that the reaction is safe and non-polluting. The preparation process is simple, and conditions are mild. An enzyme activity recovery rate is up to 71.8%.

Owner:HEBEI UNIV OF TECH

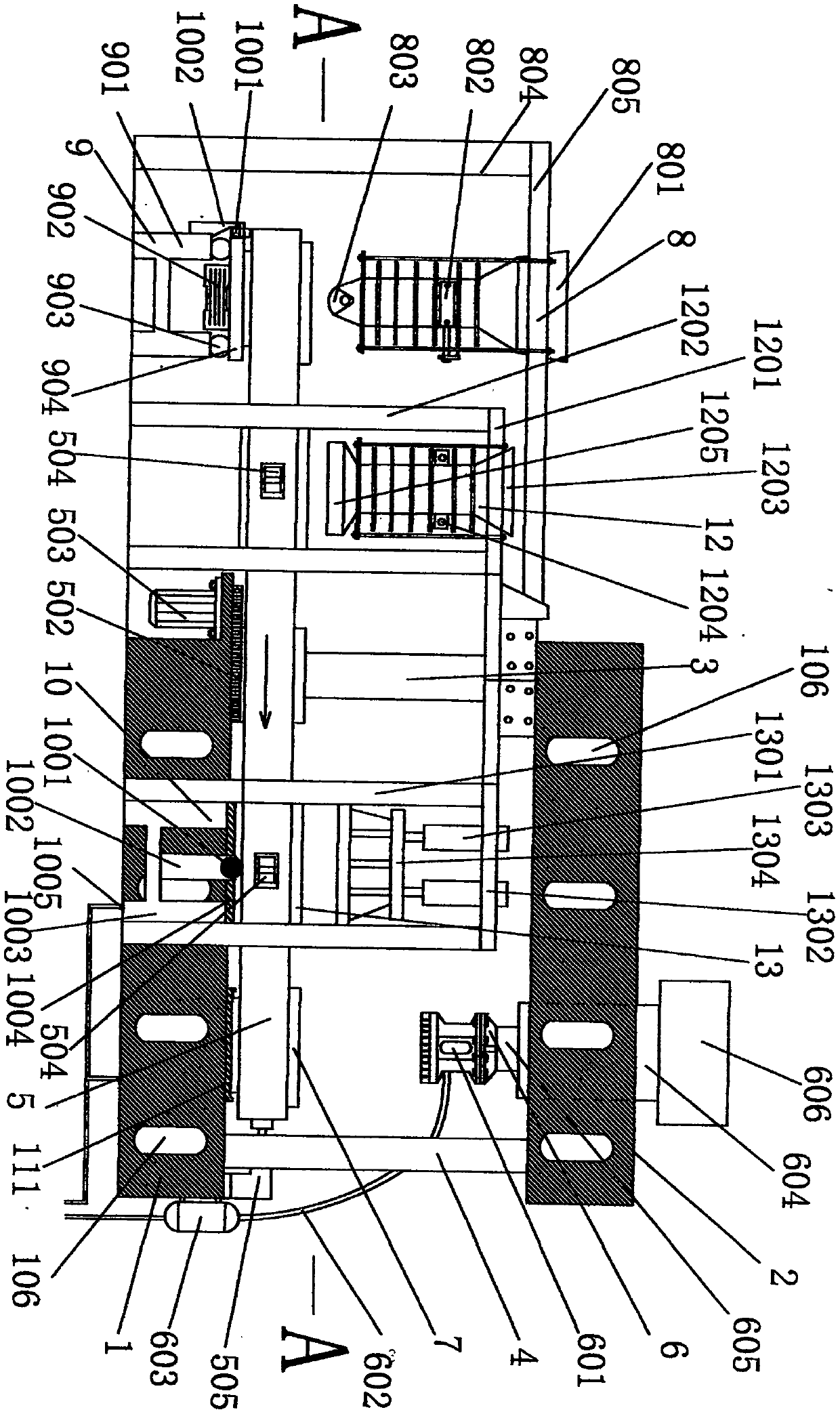

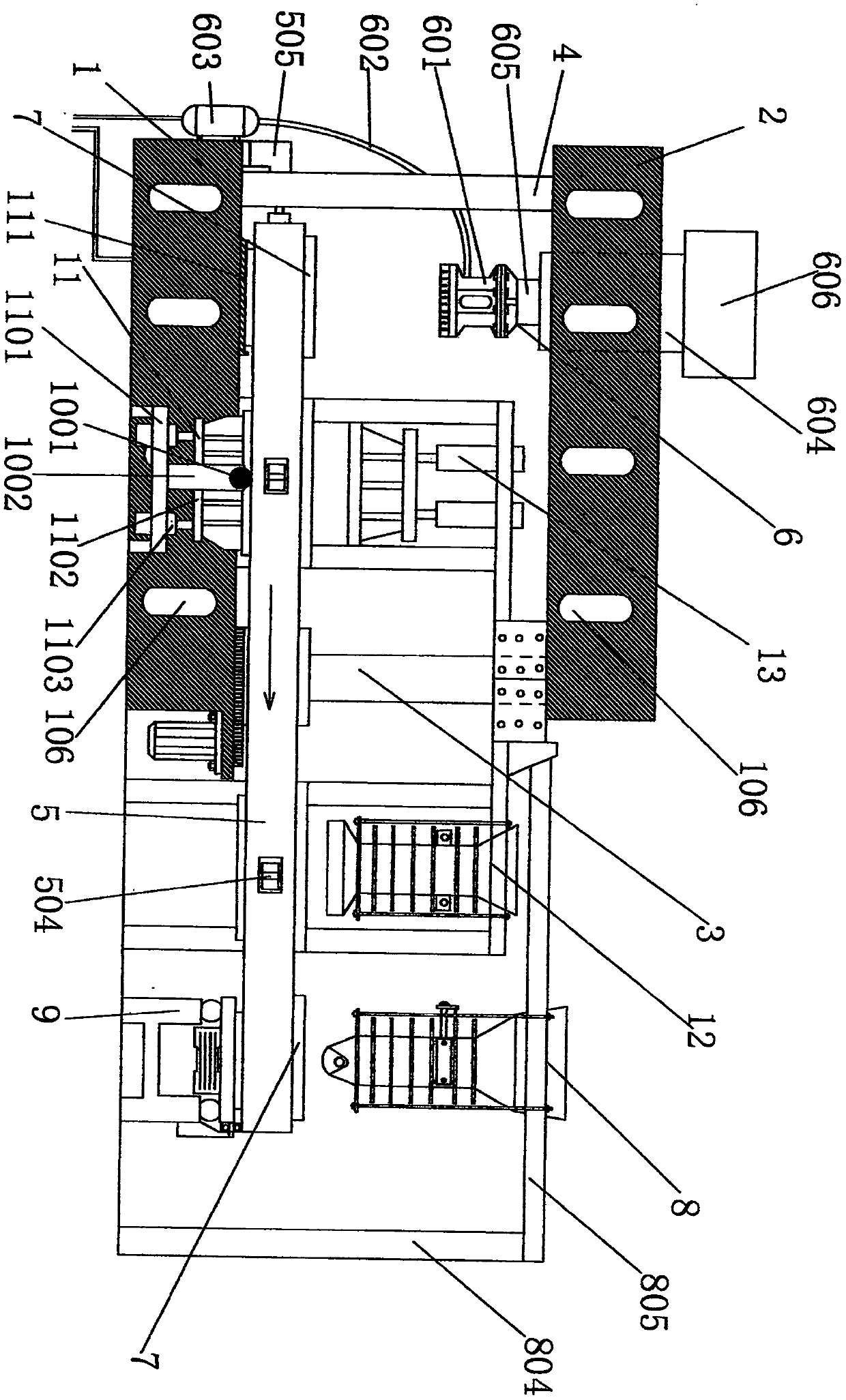

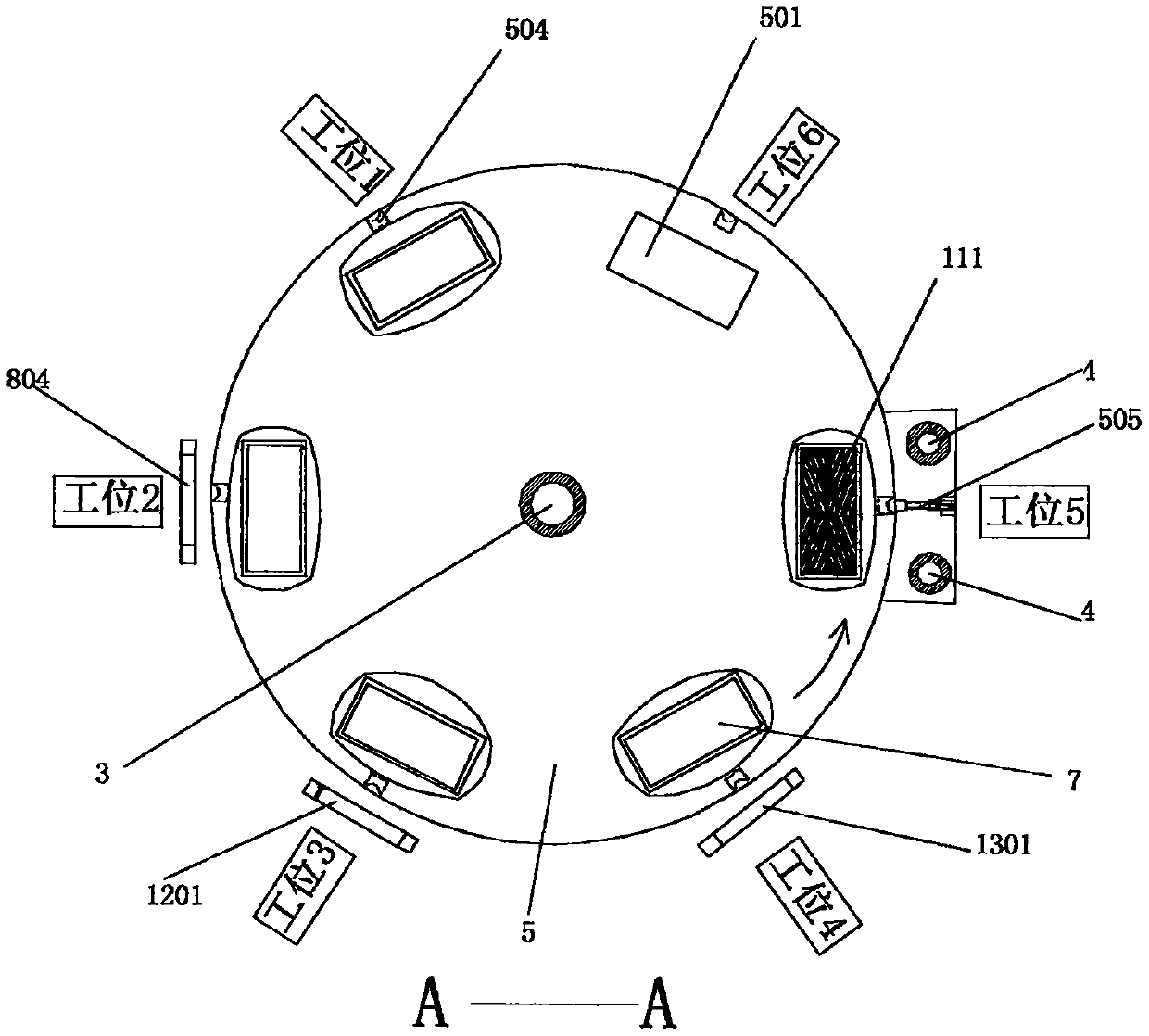

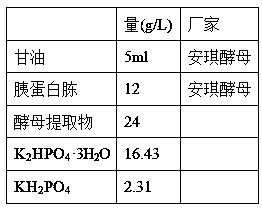

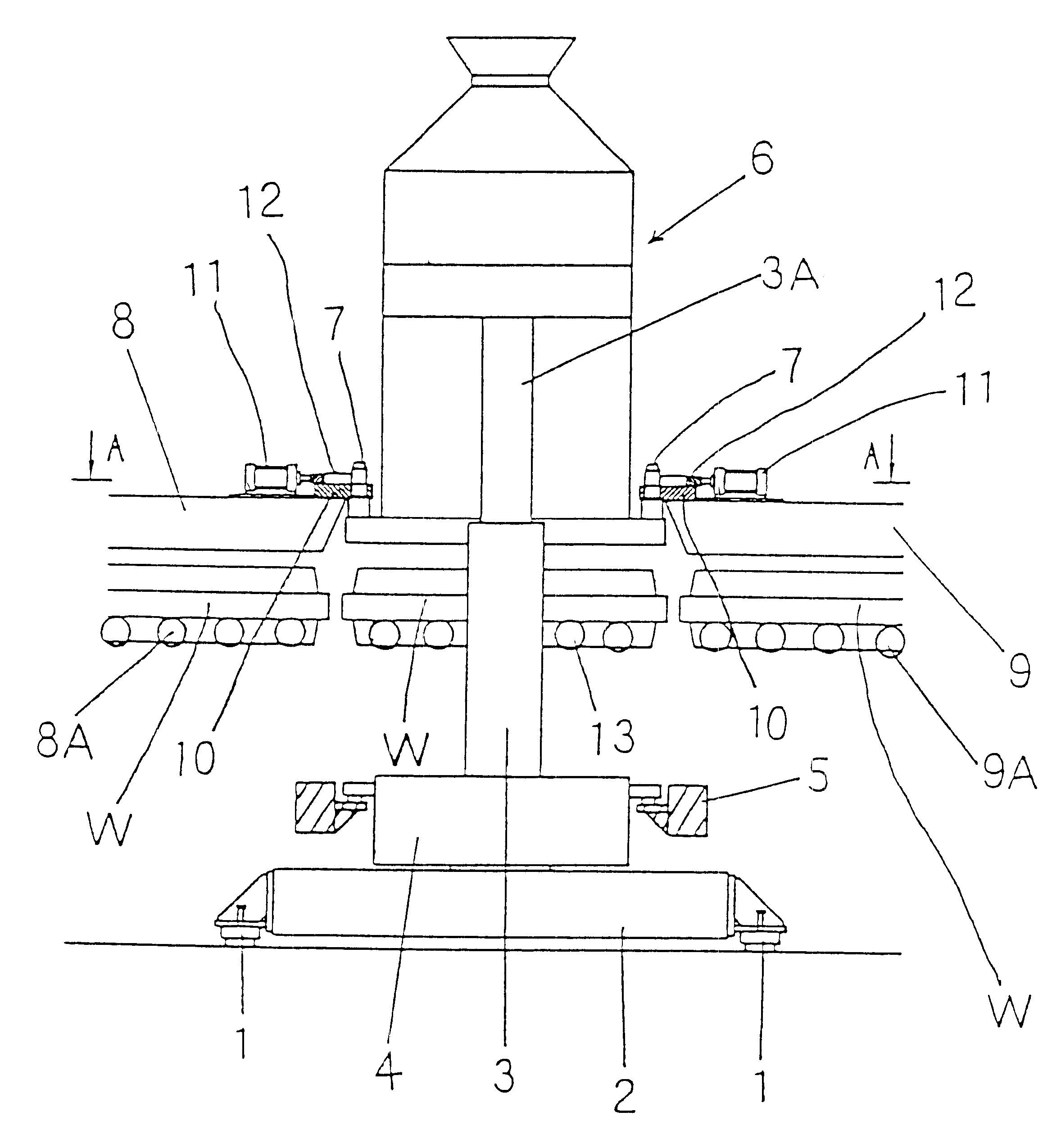

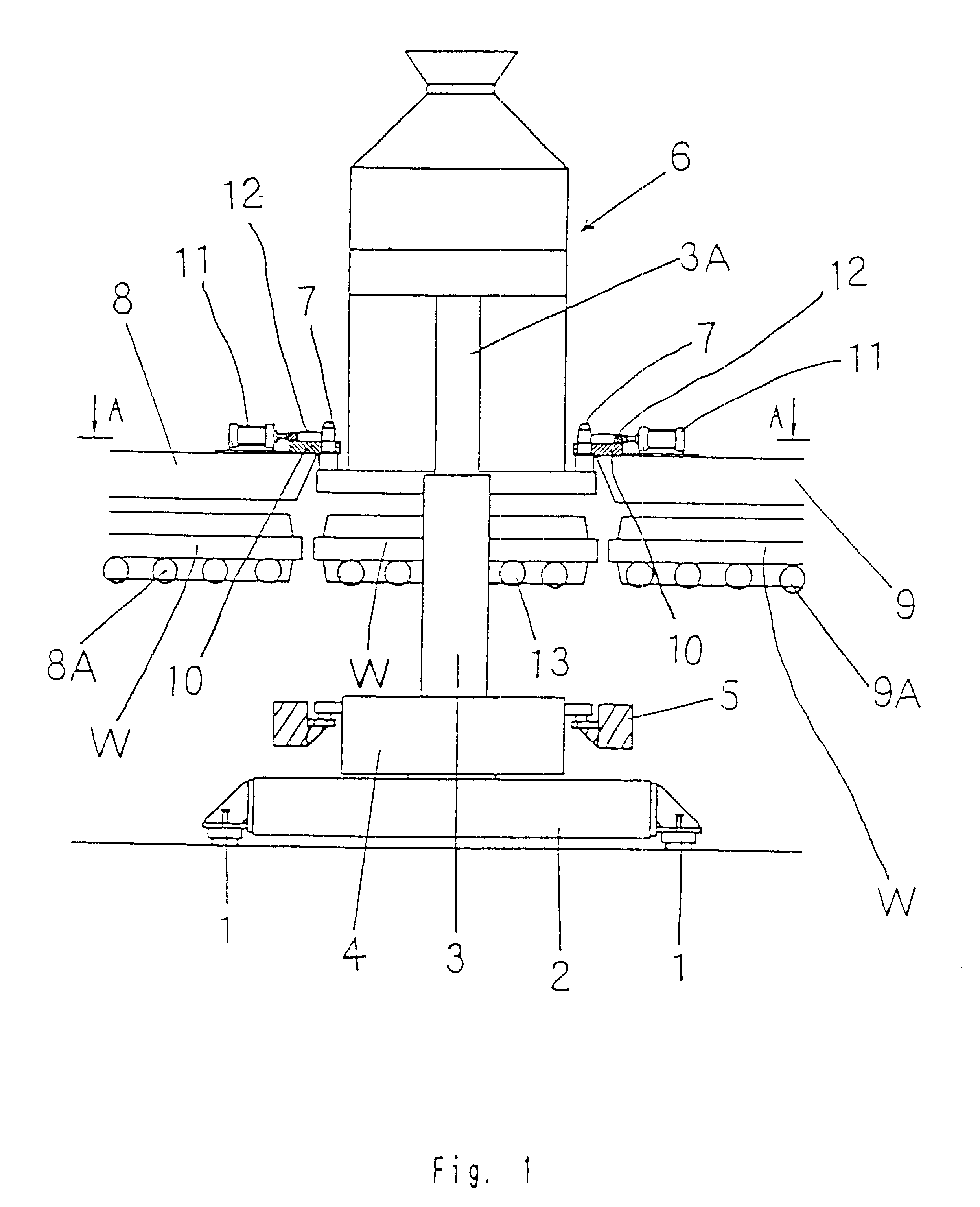

Wet-process six- station molding device for high-strength concrete product

PendingCN110385781AChange the way of beingHigh strengthDischarging arrangementCeramic shaping plantsHigh strength concreteCircular disc

The invention discloses a wet-process six-station molding device for a high-strength concrete product. The wet-process six-station molding device for the high-strength concrete product is characterized by comprising a box-type lower beam 1, a box-type upper beam 2, an independent fixed column 3, dual vertical columns 4, a rotating disc 5, an upper die head component 6, lower die boxes 7, backing material metering devices 8, a vibrating platform 9, a supporting platform 10, a demolding device 11, facing material metering devices 12 and prepressing devices 13, wherein the independent fixed column 3 and the dual vertical columns 4 are separately positioned at two ends of the box-type lower beam 1 and the box-type upper beam 2; the upper die head component 6 is arranged on the right side of the box-type upper beam 2; the backing material metering device 8 provided with the vibrating platform 9 below is connected with the left end of box-type upper beam 2; the supporting platform 10 and thedemolding device 11 are separately positioned on two sides of the box-type lower beam 1; the prepressing devices 13 are arranged right above the supporting platform 10; the facing material metering devices 12 are positioned between the backing material metering devices 8 and the preressing devices 13; and the rotating disc 5 provided with the six lower die boxes 7 is concentric to the dual vertical columns 4, and is positioned above the box-type lower beam 1, the vibrating platform 9, the supporting platform 10 and the demolding device 11.

Owner:通榆加亿科技有限公司

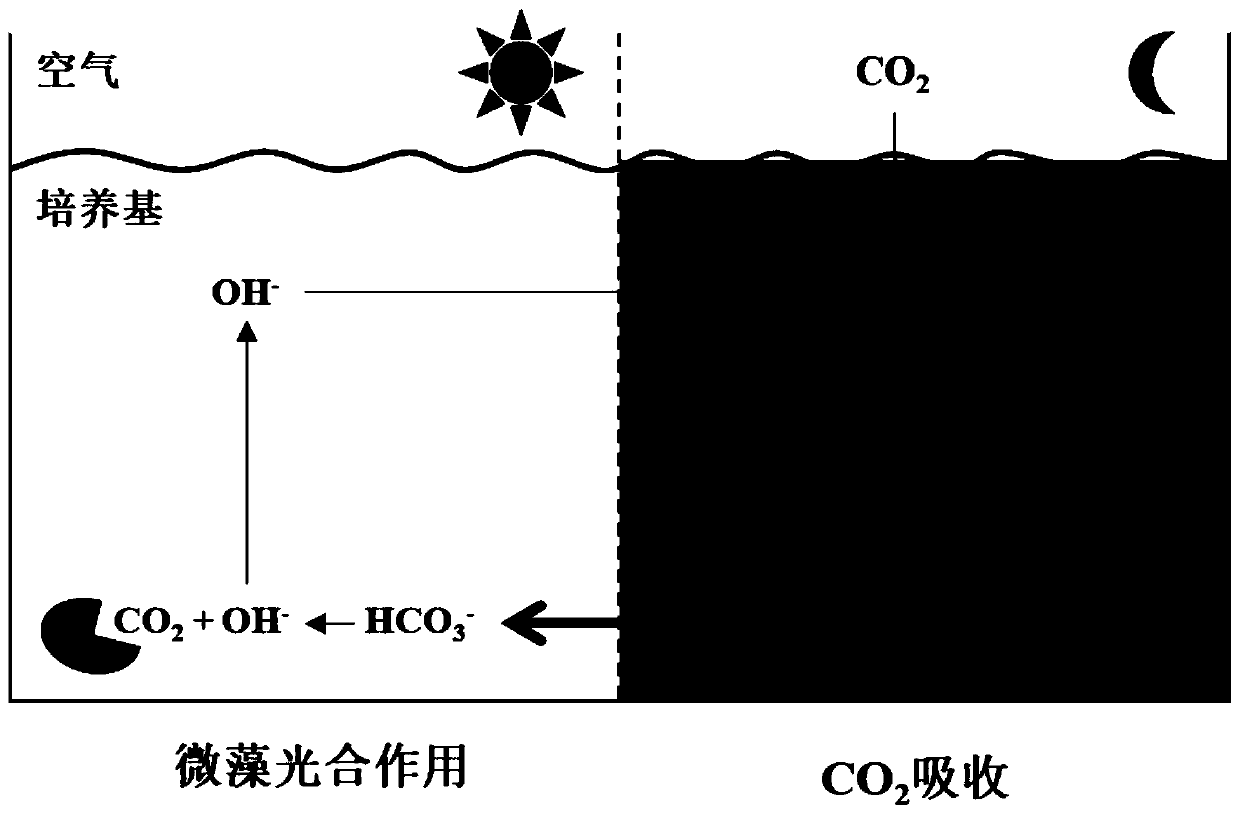

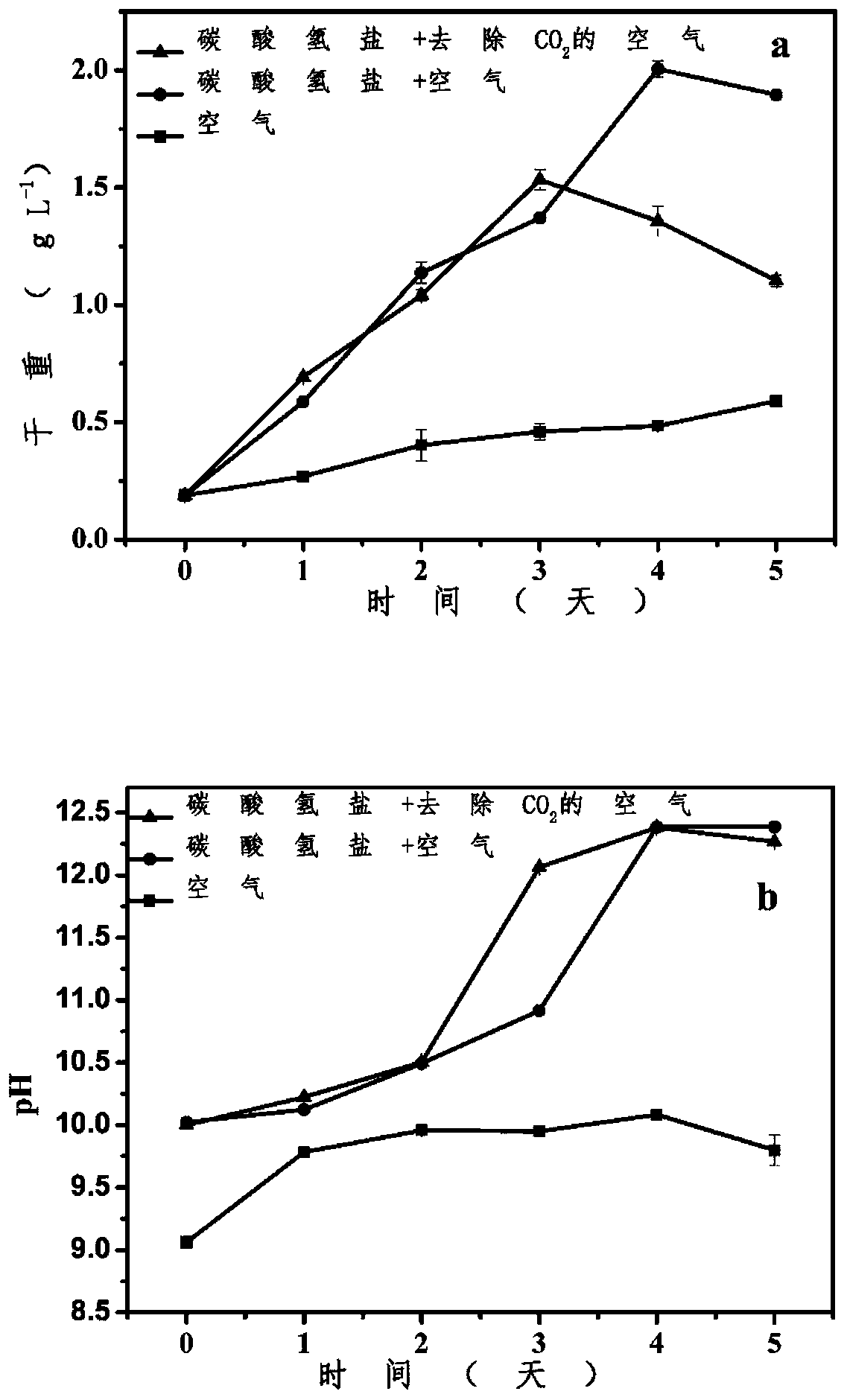

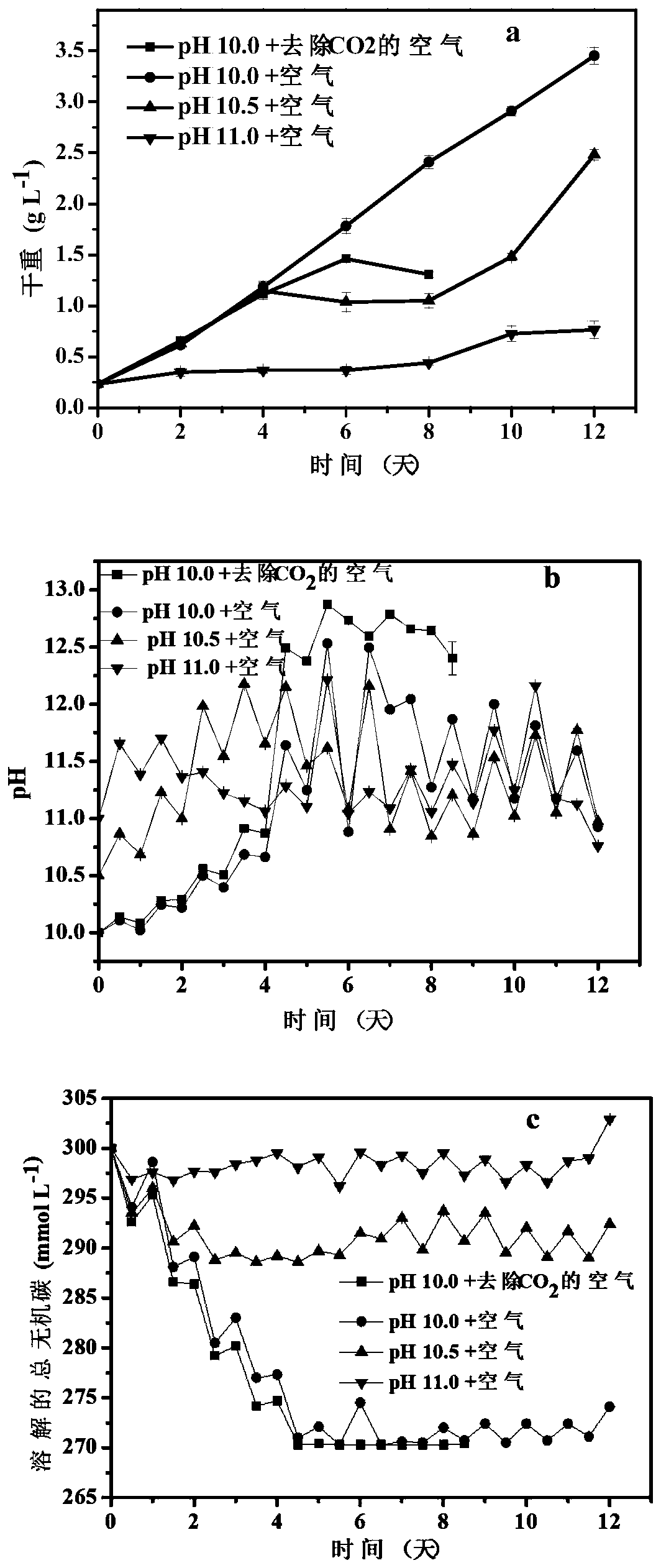

Method for efficiently capturing and utilizing CO2 from air based on microalgae biotechnology

PendingCN111151119AEfficient growth processHigh Inorganic Carbon ConcentrationGas treatmentBacteriaBiologyCulture mediums

The invention relates to the technical field of carbon emission reduction based on a biotechnology, and provides a method for efficiently capturing and immobilizing CO2 from air based on a microalgaebiotechnology under an extreme alkaline condition. A prepared culture medium contains high-concentration bicarbonate, the pH value is higher than 10.0, low-concentration CO2 in the air is efficientlyabsorbed, the absorbed CO2 is stored in a high-concentration carbonate form to form a carbon pool, and therefore a sufficient carbon source is provided for microalgae growth when illumination is sufficient. According to the technology, CO2 in the air is continuously absorbed day and night, a large number of carbon sources is prepared for efficient growth of microalgae in advance when sunlight is sufficient in the daytime, the natural rhythm is better met, and efficient fixation and utilization of CO2 in the air are achieved. More importantly, the energy of air compression and transportation inthe process can be completely provided by natural energy. Therefore, the method can reduce the biomass production cost and the CO2 immobilization cost of the microalgae at the same time, and has great application potential.

Owner:DALIAN UNIV OF TECH

Floating type wind driven generator

InactiveCN1963186AIncrease heightMaintain stabilityMachines/enginesWind motor combinationsWind drivenHelium

The floating matrix structure of an aerogenerator aims to solve the low investment return, low utilization of wind, unstability in upper altitude of existing pillar type aerogenerator, with large scale helium baloon floating in the air and diagonally fastened with steel cable in multi azimuth. A wind driven generator is loaded on the steel cabe between the baloon and the ground, so as to improve the wind utilization height to 100-300 meters, with investment within 300 RMB / kw and excellent stability.

Owner:杨贻方

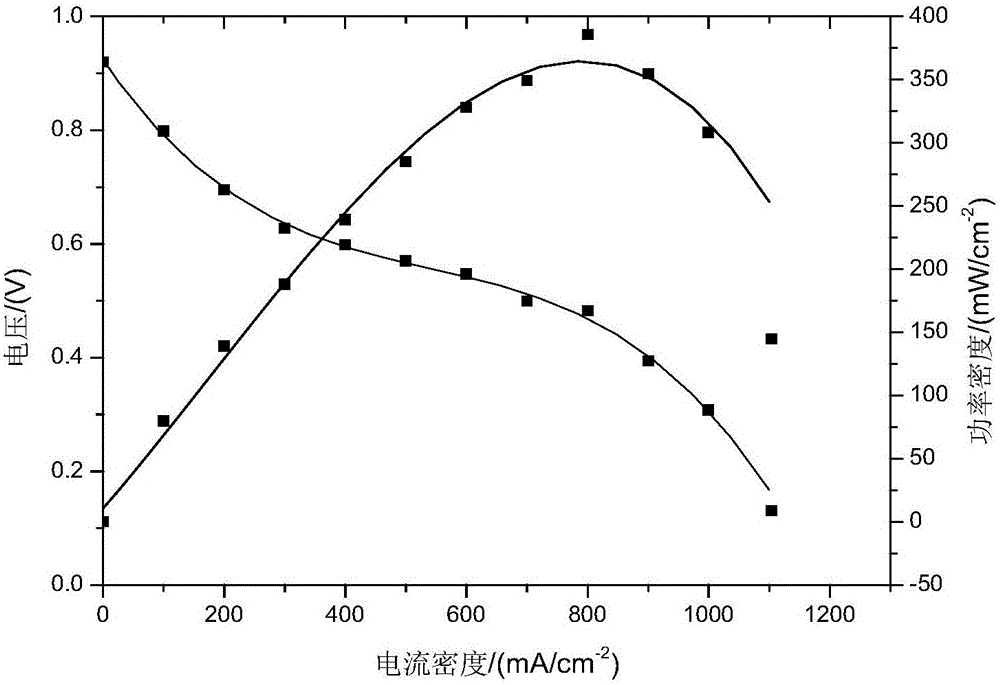

Production method of bipolar membrane electrode

ActiveCN105932316AHighly integratedLower fixed costsFinal product manufactureFuel cellsSolventIon exchange

The invention discloses a production method of a bipolar membrane electrode. A membrane electrode assembly for a fuel battery is produced from a bipolar polymer ion exchange solution and an organic polymer skeleton material. The production method comprises the following steps: forming a proton exchange layer or an oxyhydrogen ion exchange layer on the organic polymer skeleton material at a certain temperature through directly using a raw material slurry prepared by using a polymer and a solvent according to a certain ratio, mixing the cation exchange solution or anion exchange solution with a certain amount of a catalyst to obtain an anode catalyst slurry or a cathode catalyst slurry in order to make the bipolar membrane electrode assembly formed by the anode catalysis layer / the proton exchange layer / the oxyhydrogen ion exchange layer / a cathode catalysis layer; and combining a diffusion layer and the membrane electrode assembly to form the complete membrane electrode product. The method has the advantages of high integration level, agile operation, low cost and excellent product.

Owner:广东喜玛拉雅氢能科技有限公司

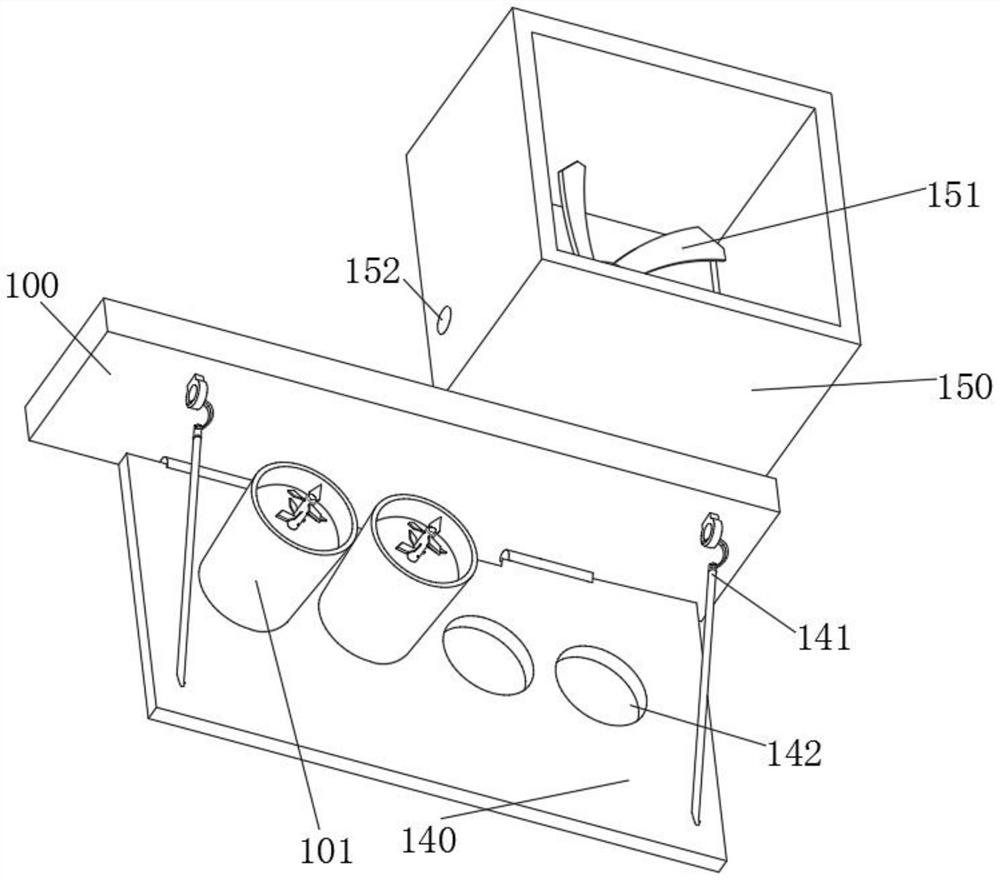

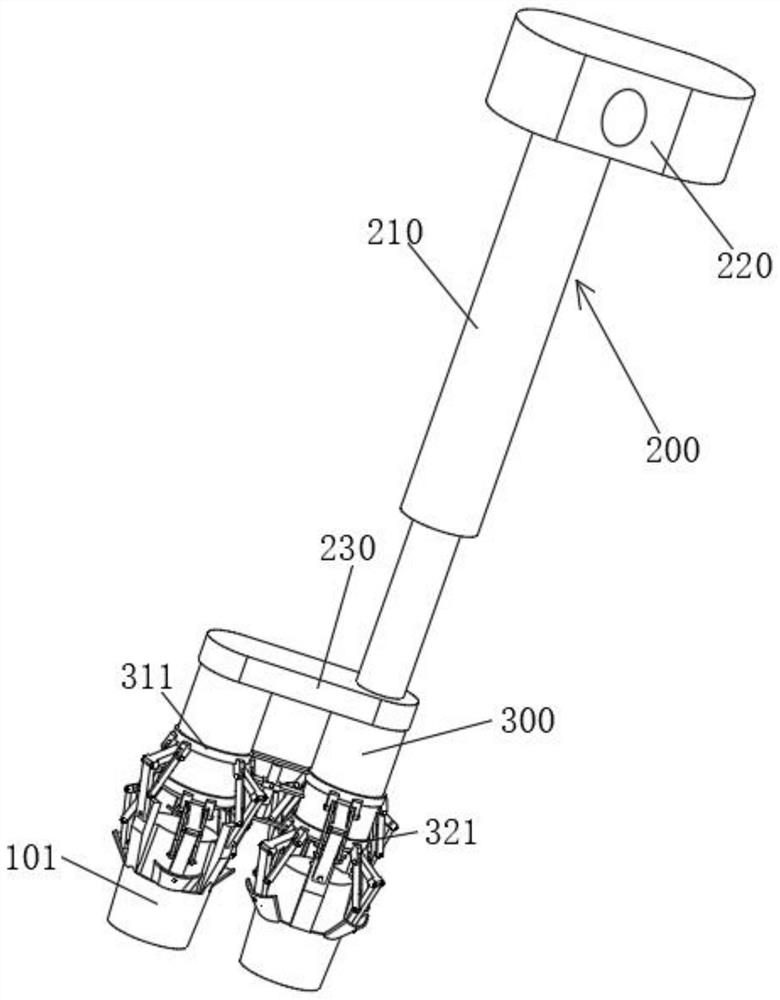

Soilless culture planting device for lettuce

InactiveCN112544426AAvoid disrupting growthReduce dosageProgramme-controlled manipulatorGripping headsLactucaNutrition

The invention relates to the technical field of soilless culture, in particular to a soilless culture planting device for lettuce. The soilless culture planting device comprises a culture bed, a transmission assembly, a mechanical arm and a mechanical claw cooperation assembly. According to the soilless culture planting device, a nutrition pot is placed in a clamping groove of a rotating plate, ahorizontal moving frame in the transmission assembly pushes a first air cylinder and the mechanical arm to move through a driving assembly, a pot body of the nutrition pot is clamped and fixed througha first mechanical clamp and a second mechanical clamp on the mechanical arm, and a paper wall part of the nutrition pot is broken through a second mechanical claw, so that the lettuce seedling culture external environment is fully opened, lettuce root system growth is prevented from being damaged, and the nutrient solution irrigation dosage is reduced; and the bottom end of the second mechanicalclaw on the mechanical arm is connected with a multipurpose mechanical finger and a mold in a screwed manner, so that pit digging and soil leveling work of fine sand on the culture bed can be automatically completed, and the labor intensity of workers and the fixing cost of soilless culture are further reduced.

Owner:张宁

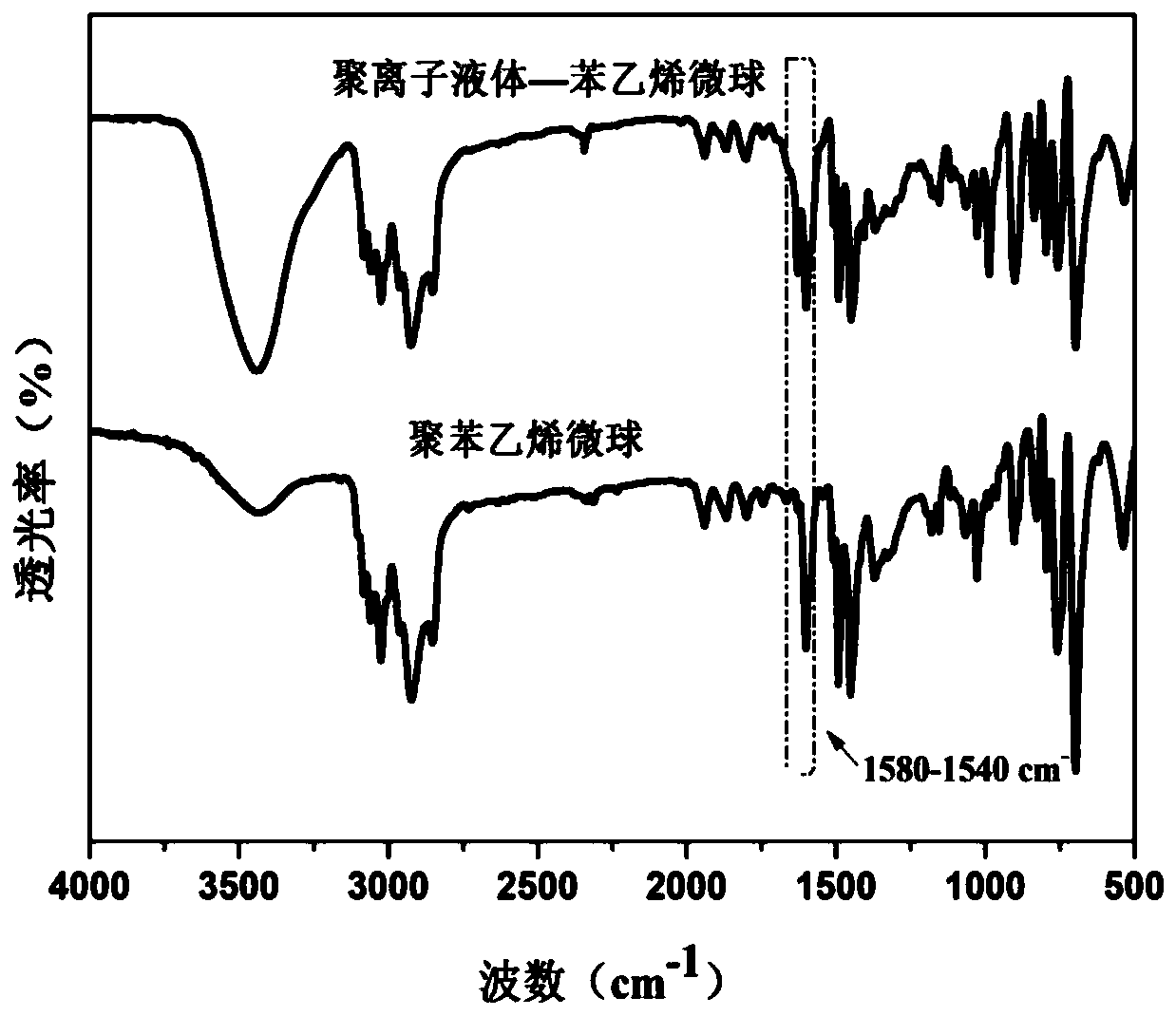

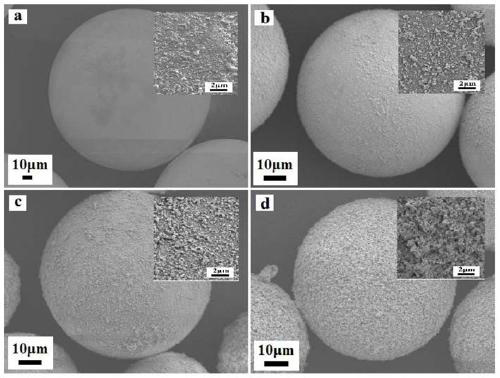

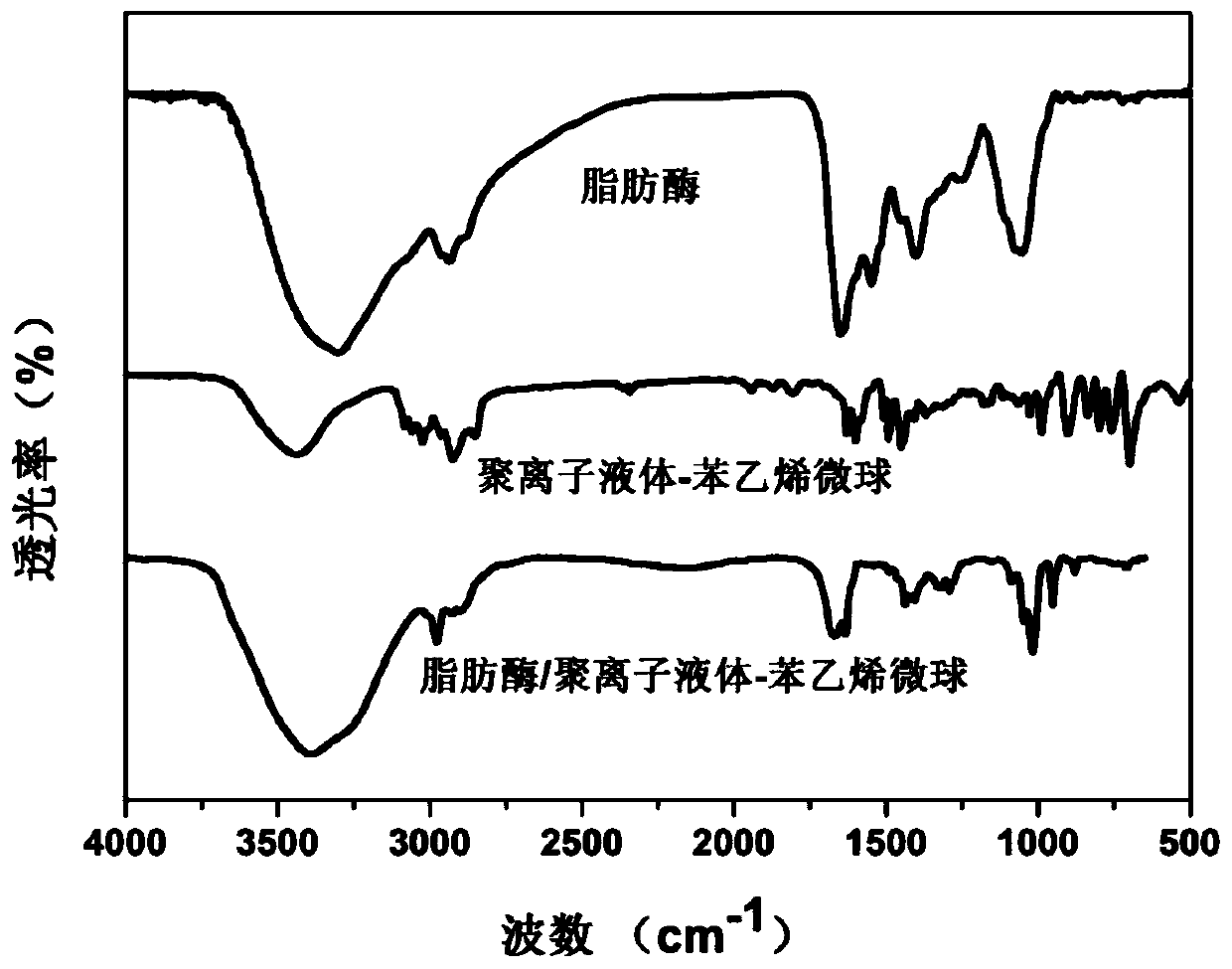

Lipase/polyion liquid-styrene microsphere/hydrogel catalytic material as well as preparation method and application thereof

ActiveCN111285951APrevent falling offEasy to separateHydrolasesOn/in organic carrierMicrosphereBiological organism

The invention relates to a lipase / polyion liquid-styrene microsphere / hydrogel catalytic material as well as a preparation method and application thereof, and belongs to the field of enzyme immobilization. The preparation method comprises the steps: performing polymerization reaction on styrene and imidazolium bromide to form polyion liquid-styrene microspheres; dispersing the polyion liquid-styrene microspheres into a lipase solution, immobilizing lipase onto the polyion liquid-styrene microspheres through physical adsorption to obtain lipase / polyion liquid-styrene microspheres, and carrying out secondary immobilization on the lipase / polyion liquid-styrene microspheres in hydrogel. The obtained catalytic material is environment-friendly and non-toxic, is easy to separate from a reaction system, and can be recycled, so that the catalytic material has a wide application value in various fields such as biocatalysis and food industry.

Owner:DALIAN POLYTECHNIC UNIVERSITY

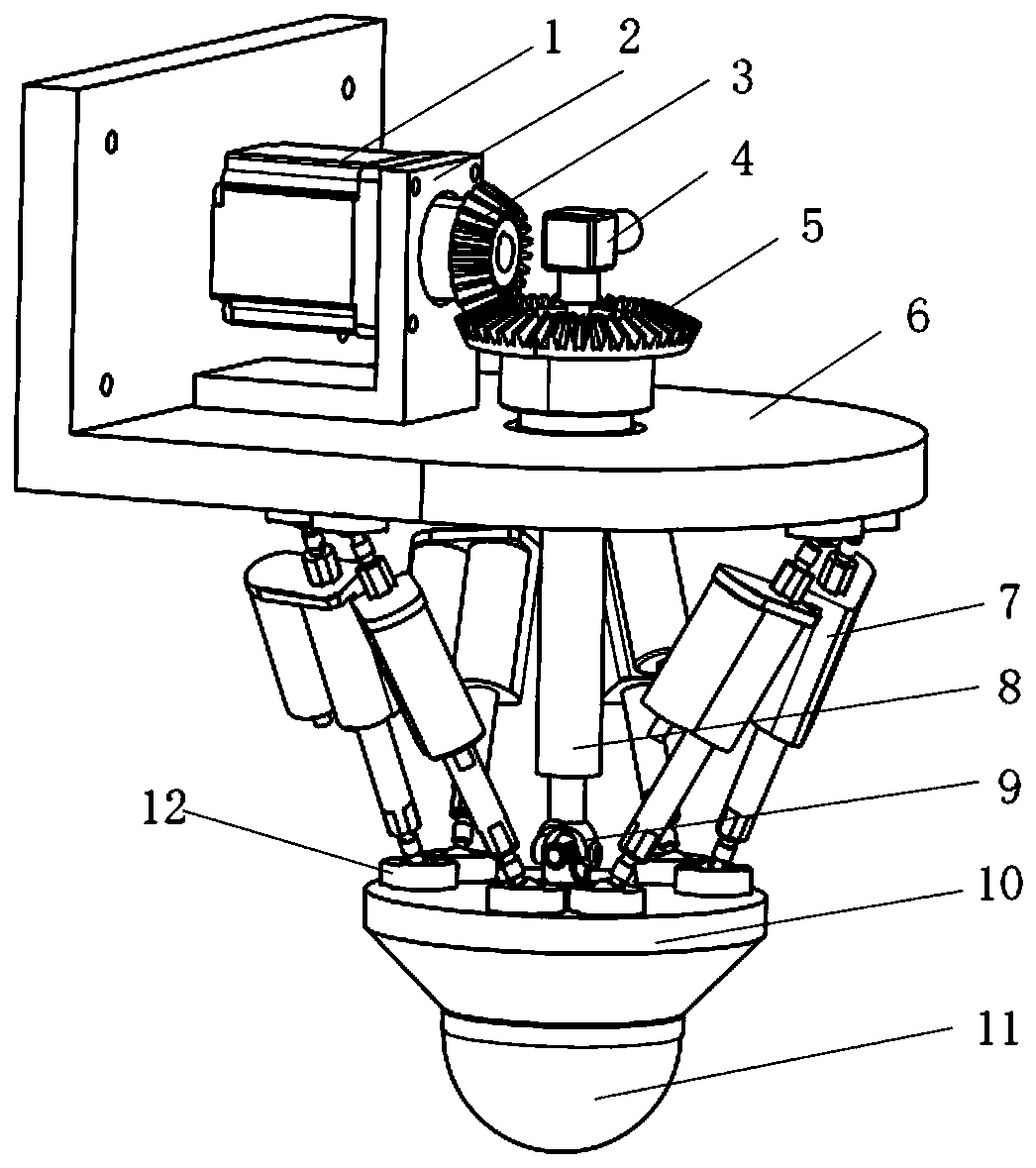

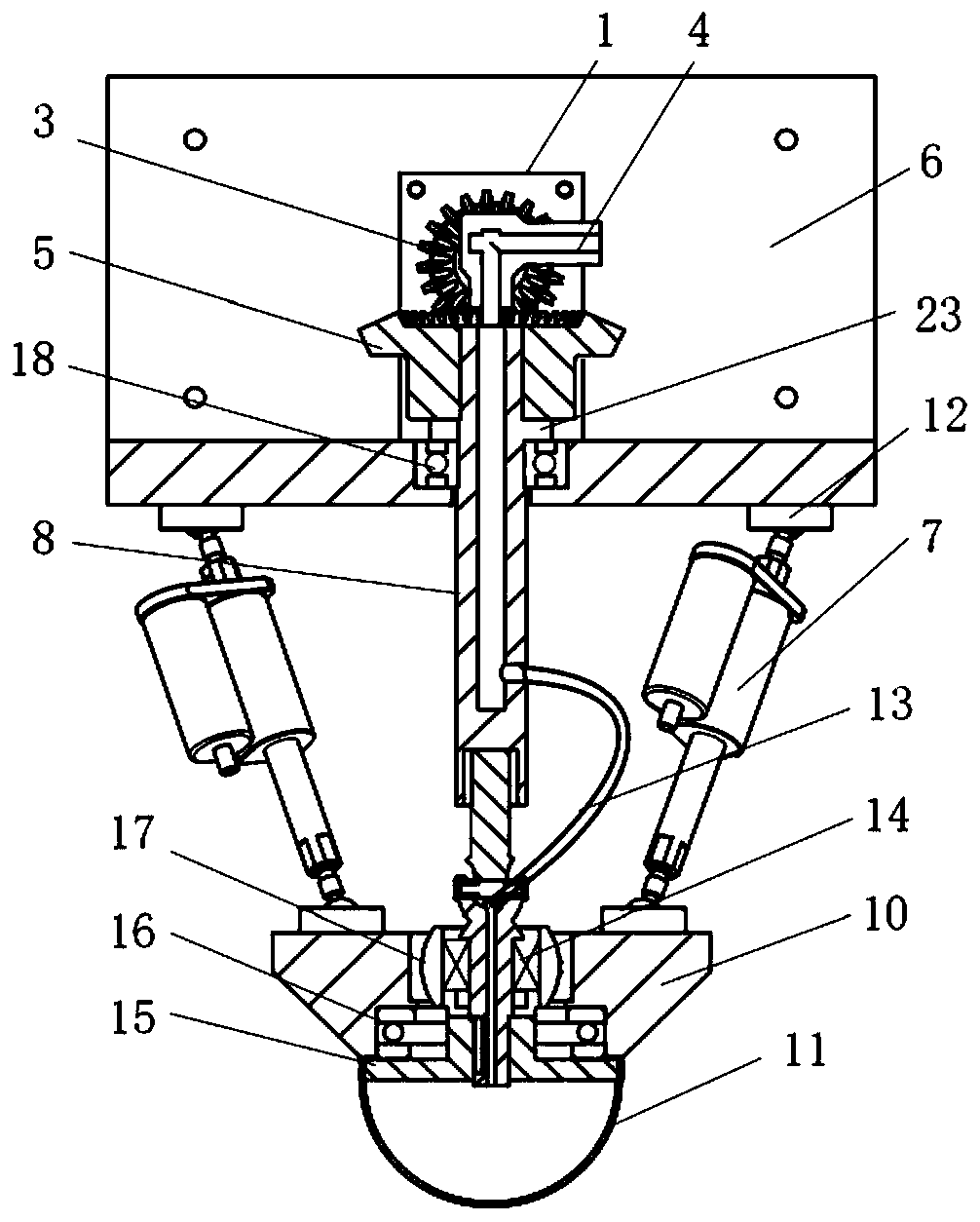

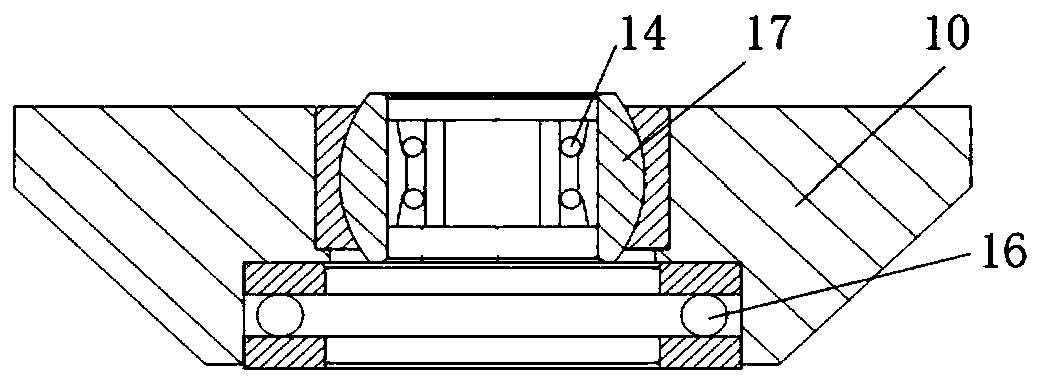

Self-inclined airbag polishing device

ActiveCN110919519AReduce dependenceLower fixed costsPolishing machinesGrinding machine componentsNumerical controlLinear motion

The invention discloses a self-inclined airbag polishing device. The self-inclined airbag polishing device is characterized in that an inclined base performs two-dimensional rotating inclination around a ball bearing rotating center through adjusting a telescopic quantity of an electric push rod mounted between a mounting base and the inclined base; through inclination of the inclined base, a toolbase and an airbag tool head are also inclined, and a machining axis of the airbag tool head is overlapped with a normal of a point to be machined; three linear motion shafts of a numerical control machine tool are shifted, so that the rotating center of the inclined base of the device is overlapped with the normal of the point to be machined, the distance from the point to be machined is a certain value, and an airbag is contacted with the machined point; and through control of the rotating speed of the airbag tool head and internal air pressure, the removal of materials on optical surfacesis realized. The device can realize two-dimensional inclination of the tool head, only needs the numerical control machine tool to possess three orthogonal linear motion shafts to realize tracking ofnormals of optical non-spherical surfaces or free curved surfaces, reduces dependence on a five-axle numerical control machine tool or a precise machine hand, reduces fixed cost investment, and is a low-cost and high-precision optical non-spherical surface and free curved surface machining device.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

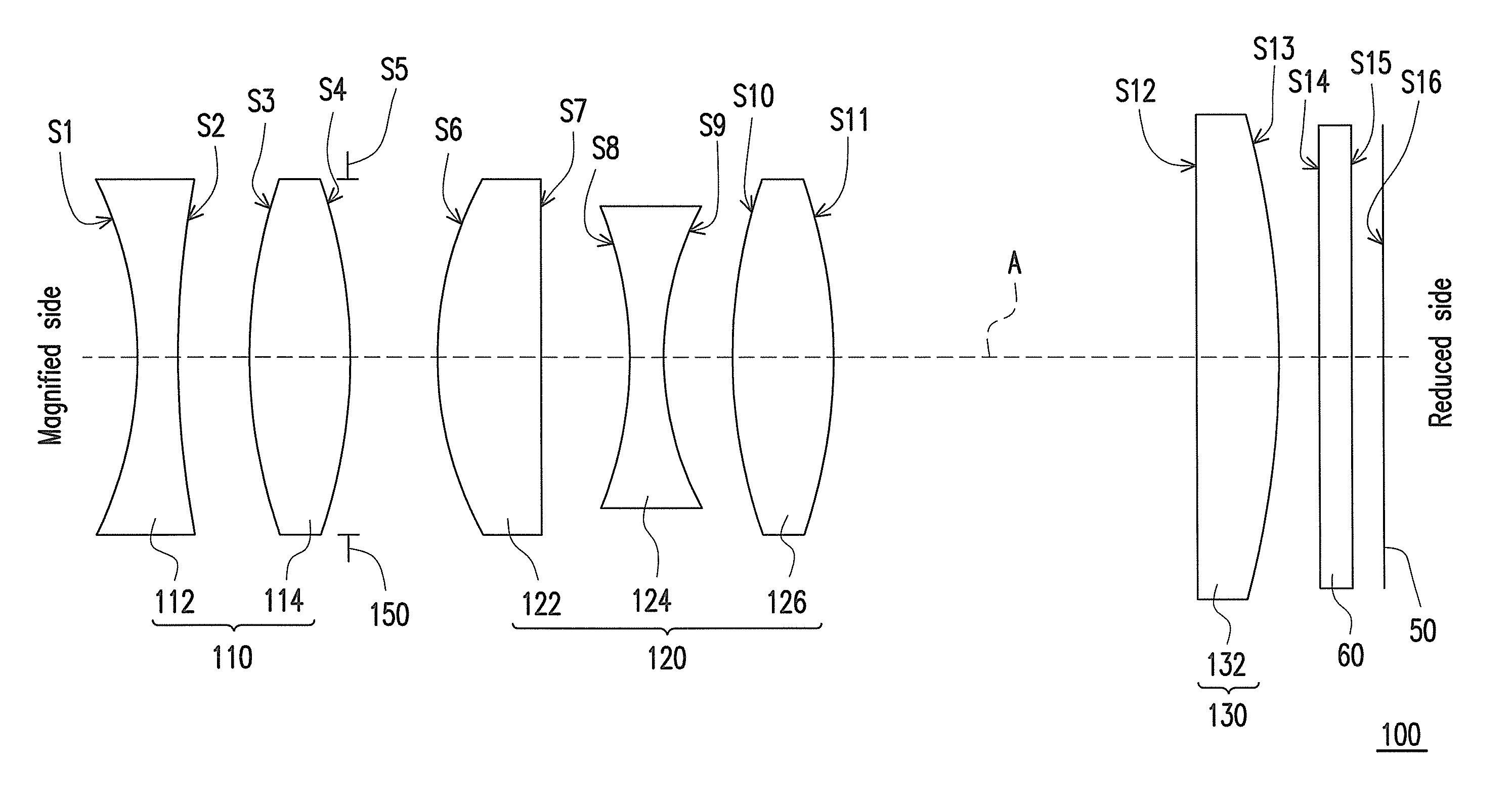

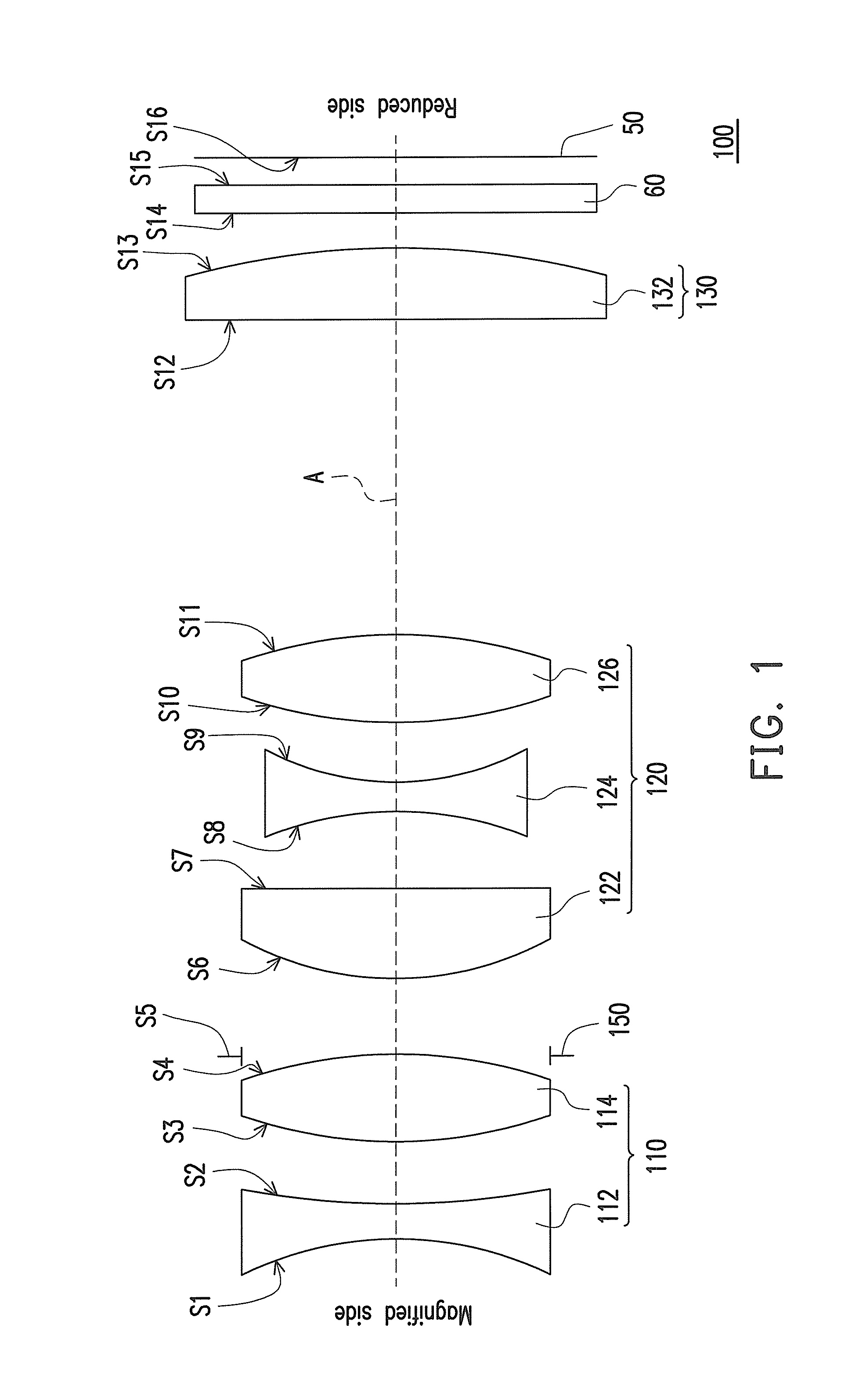

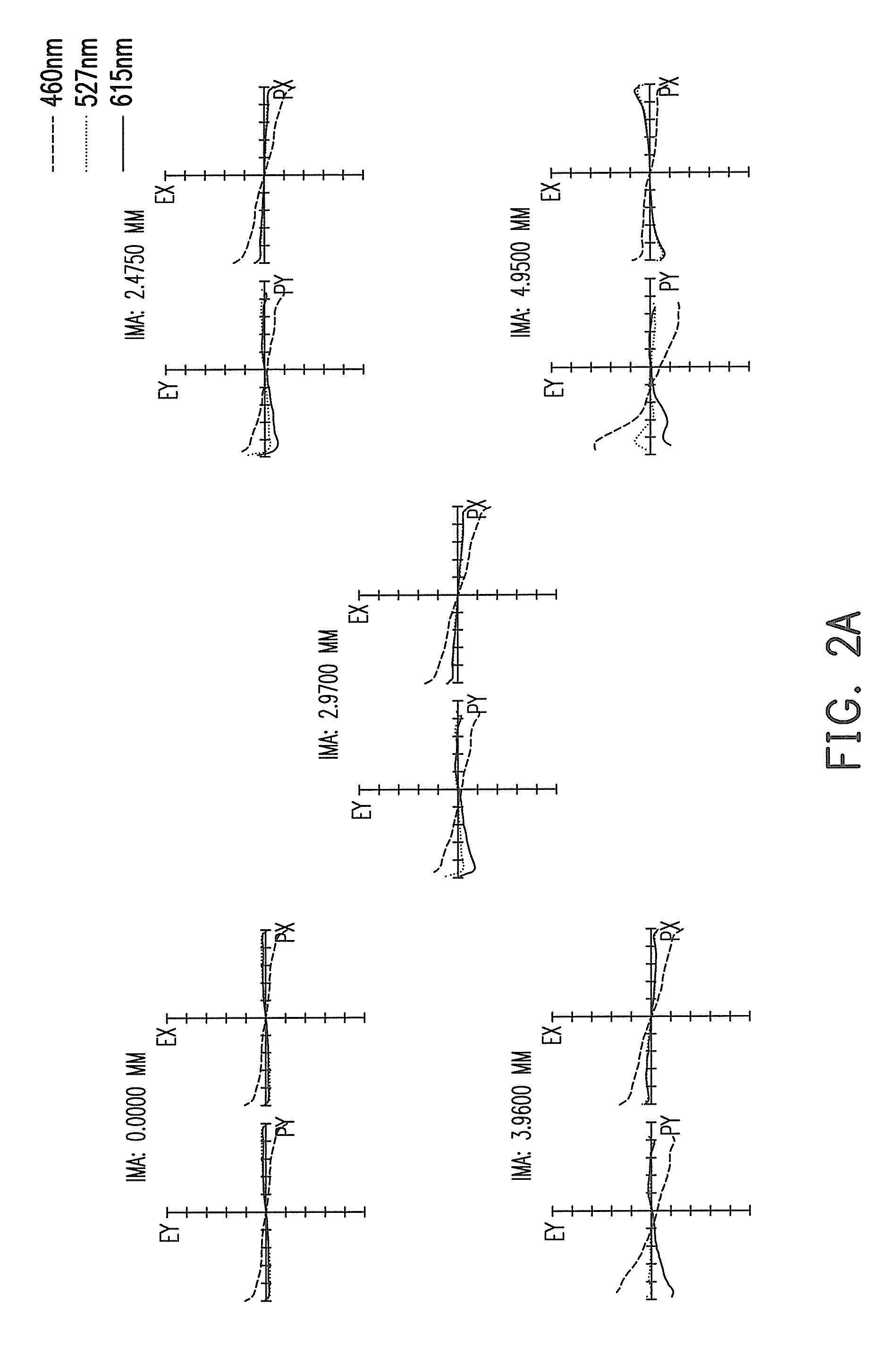

Fixed focal length lens

A fixed focal length lens including a first lens group, a second lens group, and a third lens group arranged in sequence from a magnified side towards a reduced side is provided. The first lens group has a positive refractive power, and includes a first lens and a second lens arranged in sequence from the magnified side towards the reduced side. Refractive powers of the first lens and the second lens are respectively negative and positive. The second lens group has a positive refractive power, and includes a third lens, a fourth lens, and a fifth lens arranged in sequence from the magnified side towards the reduced side. Refractive powers of the third lens, the fourth lens, and the fifth lens are respectively positive, negative, and positive. The third lens group has a positive refractive power, and includes a sixth lens. A refractive power of the sixth lens is positive.

Owner:YOUNG OPTICS

Method for immobilizing L-amino acid deaminase

InactiveCN109022412ALow costLower fixed costsBacteriaMicroorganism based processesCellulose bindingEnzyme catalysis

The invention belongs to the field of biotechnology, and relates to a method for immobilizing L-amino acid deaminase; a cellulose binding domain (CBD) gene fragment is connected a 3' or 5' end of an L-amino acid deaminase (LAAD) gene fragment by a short DNA strand; the L-amino acid deaminase is fused with a cellulose binding domain and combined with microcrystalline cellulose for immobilizing, because the microcrystalline cellulose is cheap and easy to obtain, the immobilization cost is low, and the specificity of the immobilizing process plays an enzyme purifying role, so that enzyme catalysis by-products are very few, and fixed L-AAD-CBD can be used multiple times due to low cost and has a large industrial application value.

Owner:浙江正硕生物科技有限公司

Molding equipment for framed sand molds

InactiveUS6474400B1Reduce stepsLower fixed costsPig casting plantsMoulding toolsEngineeringMechanical engineering

Owner:SINTOKOGIO LTD

Method and application of immobilized glucoamylase by using sodium alginate silicon dioxide hybridized gel

InactiveCN104195128AReduce fixed costsImprove stabilityBioreactor/fermenter combinationsBiological substance pretreatmentsMolecular biologyEnzymatic hydrolysis

The invention belongs to the technical field of immobilized enzymes, and in particular relates to a method of immobilized glucoamylase by using sodium alginate silicon dioxide hybridized gel, and a method for saccharifying the obtained immobilized glucoamylase to produce glucose. According to the method, the sodium alginate silicon dioxide hybridized gel is adopted to embed a saccharified enzyme so as to immobilize the enzyme, by virtue of most appropriate proportioning of silicon dioxide and sodium alginate, the defects that in a conventional embedding method, a substrate is not easy to contact with the enzyme, or enzyme molecules are easy to drop off, and the like, are overcome, the immobilization cost of the saccharified enzyme is lowered, the stability of the saccharified enzyme which is immobilized by using the embedding method is improved, and the production pollution is reduced. In addition, due to design of immobilized saccharified enzyme hydrolysis starch reaction equipment, functions of stirring a reaction liquid and separating the saccharified enzyme from the reaction liquid are achieved, and thus the immobilized saccharified enzyme can be repeatedly used.

Owner:SHANDONG XIWANG SUGAR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com