Method and application of immobilized glucoamylase by using sodium alginate silicon dioxide hybridized gel

A technology of sodium alginate and silicon dioxide, applied to biochemical equipment and methods, fixed on/in organic carriers, specific-purpose bioreactors/fermenters, etc., can solve the problem of loss of catalytic activity and contamination, Changes in the advanced structure of enzyme proteins, increasing immobilization costs, etc., to achieve the effects of reducing immobilization costs, saccharification costs, and protein content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1. Preparation of sodium alginate silica hybrid gel immobilized glucoamylase:

[0041] (1) Prepare 25ml of sodium alginate solution with a mass concentration of 2.0% (w / w) as liquid A for use after disinfection, and prepare 25ml of sodium silicate solution with a concentration of 1.5% (w / w) with sterile water and use a concentration of 30% The above acetic acid is adjusted to pH5.6-7.0 as B liquid for subsequent use;

[0042] (2) Mix liquid A and liquid B evenly to form liquid C, add 0.12 g of glucoamylase into solution C and stir for 10-30 minutes to obtain liquid D;

[0043] (3) The D solution after mixing is dripped into the calcium chloride solution with a mass concentration of 3% by a peristaltic pump through a 10ml syringe needle to form glucoamylase immobilized microsphere particles, soaked in the calcium chloride solution for 3 hours; then use distilled water Wash the microspheres and put them in a 4°C refrigerator for later use.

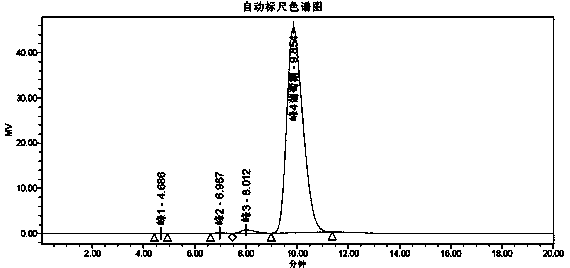

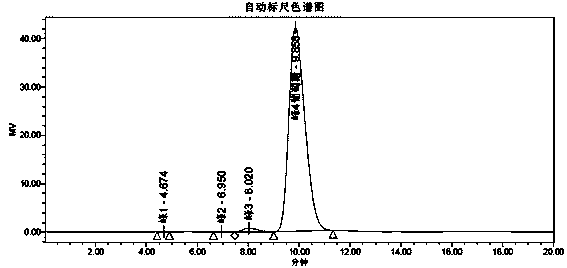

[0044] 2. The starch liquefa...

Embodiment 2

[0062] 1. Preparation of sodium alginate silica hybrid gel immobilized glucoamylase

[0063] (1) Prepare 4 liters of sodium alginate solution with a mass concentration of 1.8% (w / w) as liquid A for use after disinfection, and use sterile water to prepare 3.9 liters of sodium silicate solution with a mass concentration of 1.6% (w / w) Adjust the pH to 5.6-7.0 with hydrochloric acid and use it as liquid B for later use;

[0064] (2) Mix liquid A and liquid B evenly to form liquid C, add 15.3 g of glucoamylase into the scale of solution C and stir for 10-30 minutes to obtain liquid D.

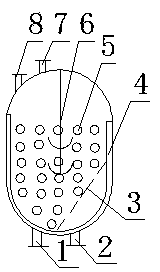

[0065] (3) The D solution after mixing is dripped into the calcium chloride solution with a mass concentration of 4% by a peristaltic pump through a disc equipped with multiple syringe needles to form glucoamylase immobilized microsphere particles, soaked in the calcium chloride solution 3 hours; then wash the microspheres with distilled water and put them in a refrigerator at 4°C for later use.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com