Patents

Literature

32results about How to "Avoid cosmetic damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

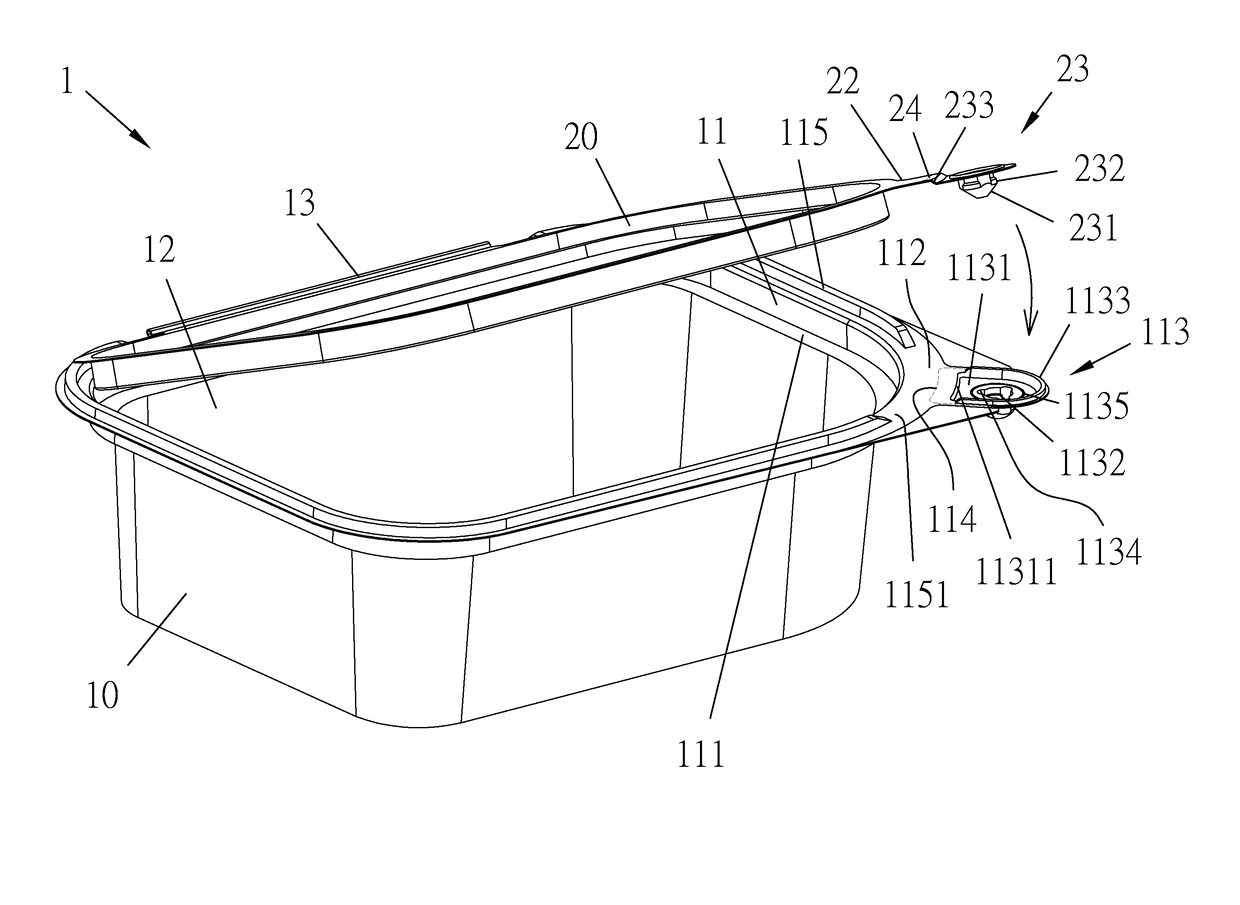

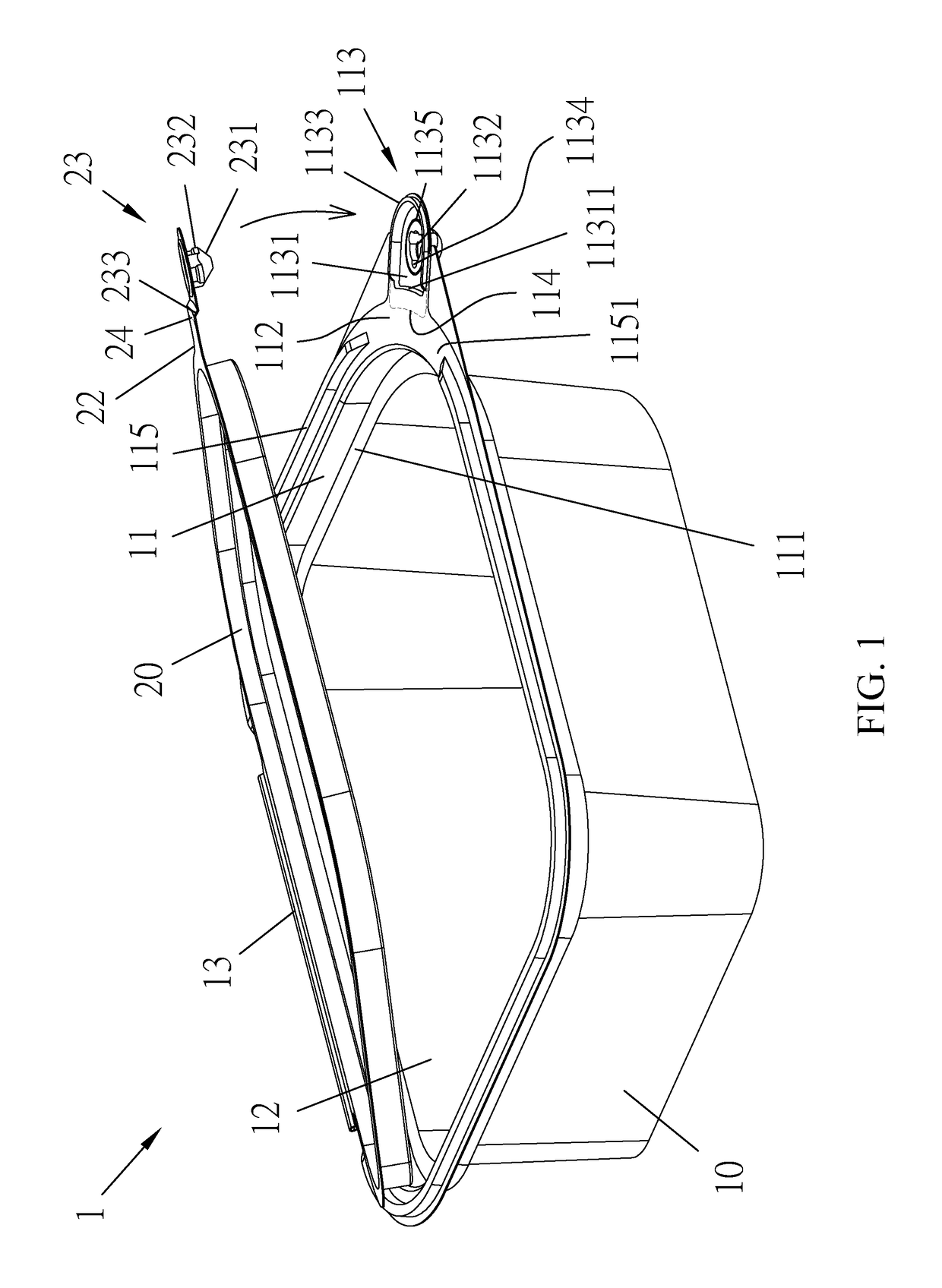

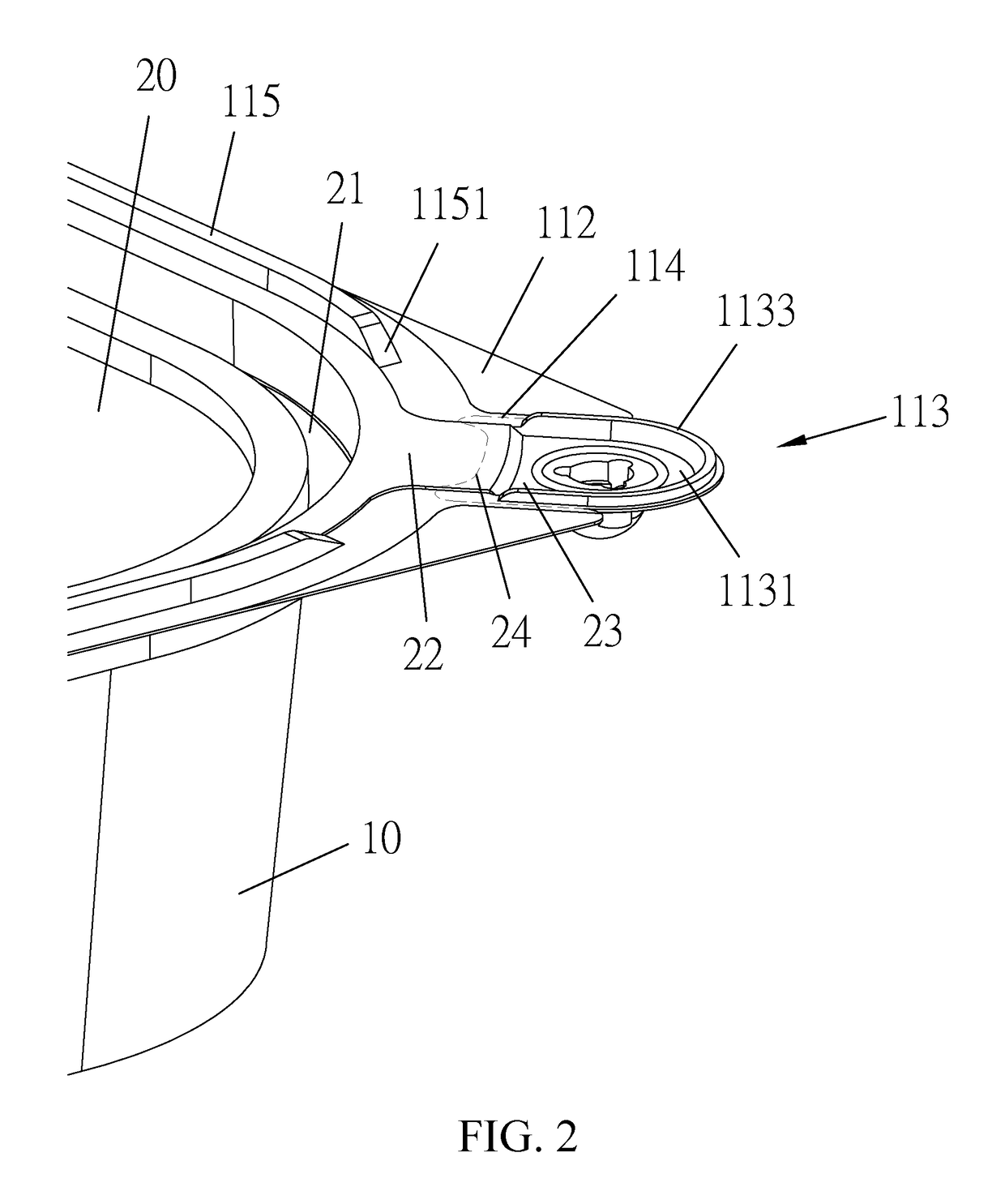

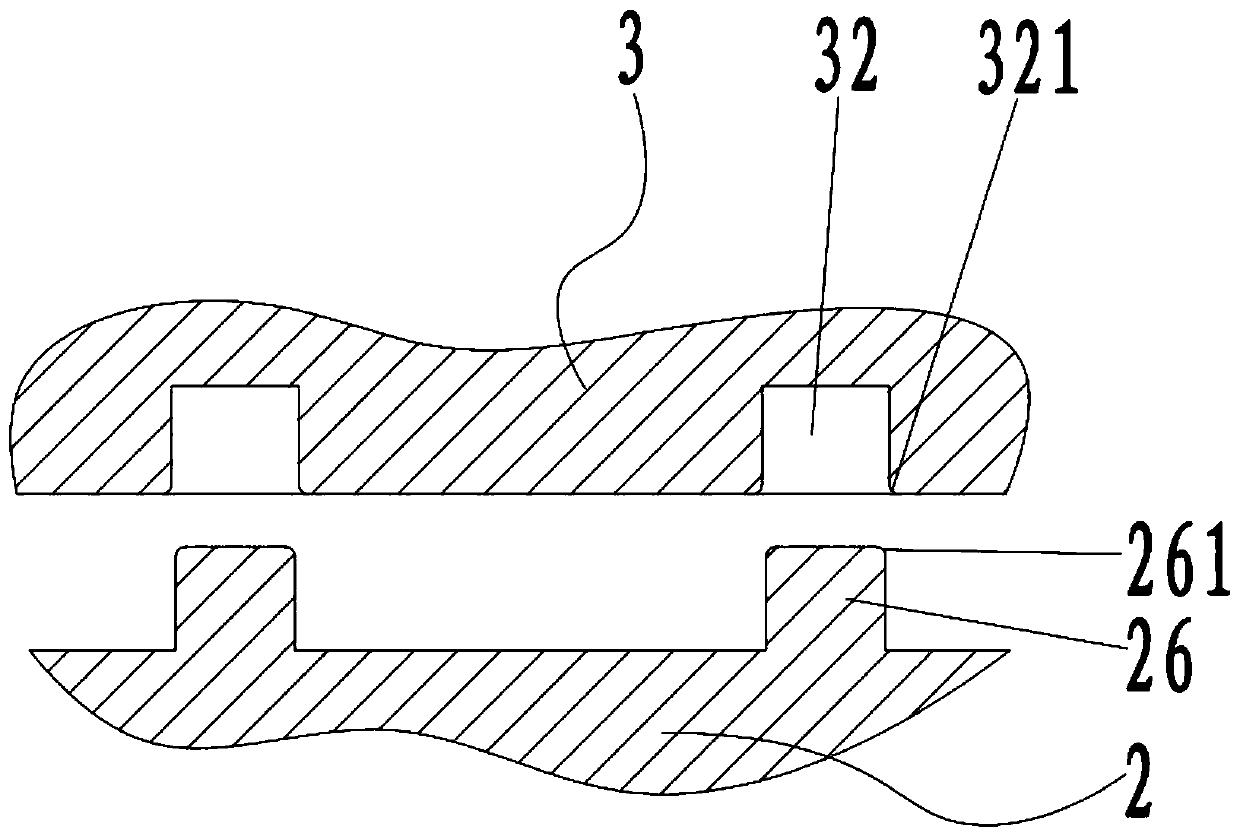

Tamper-evident container

A tamper-evident container generally includes a tray having an opening with a step section formed around the opening and including a first protrusion section that is provided with a first coupling unit with a first perforation line formed therebetween. The first coupling unit includes a coupling trough. A cover includes a concave groove having a bottom and an outside surface engageable with the step section to close the opening. The cover includes a second protrusion section and a second coupling unit between which a second perforation line is formed and projecting beyond the first perforation line. The second coupling unit has a coupling member receivable in and engageable with the coupling trough. Tearing off the first and second perforation lines allows the first and second coupling units to detach from the tray and the cover, respectively with the second protrusion section projecting outside the tray for easy gripping.

Owner:SOUTH PLASTIC IND

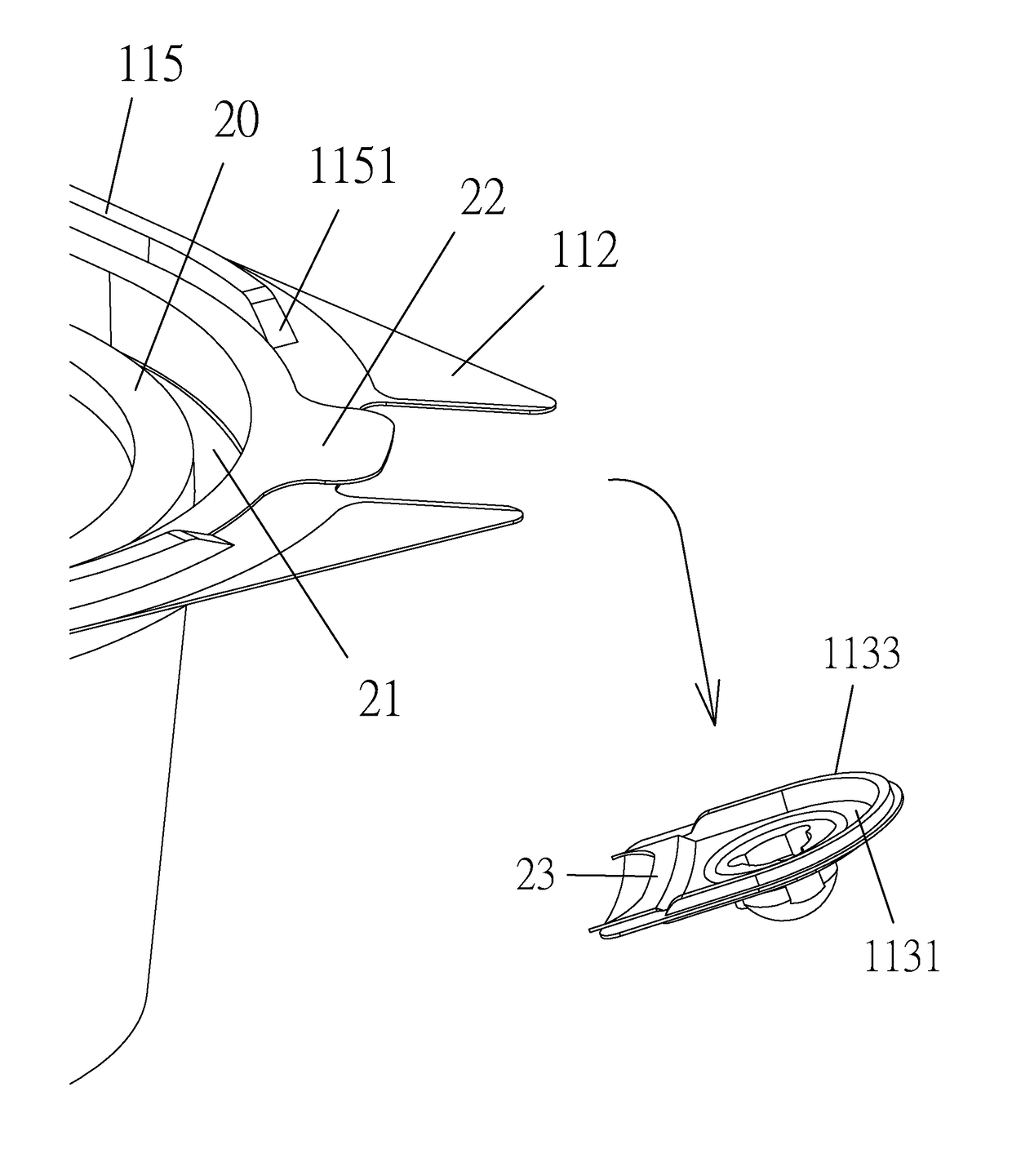

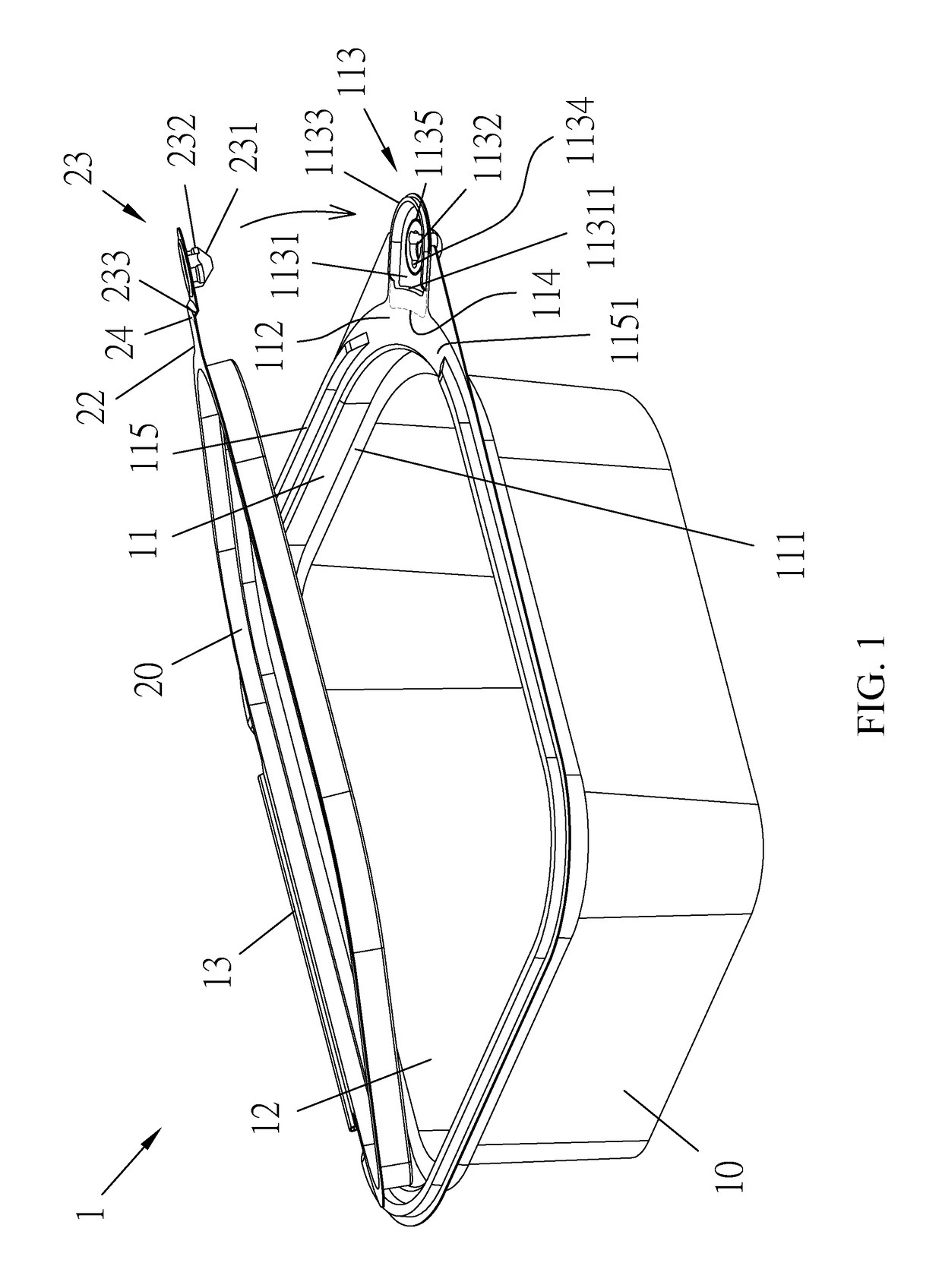

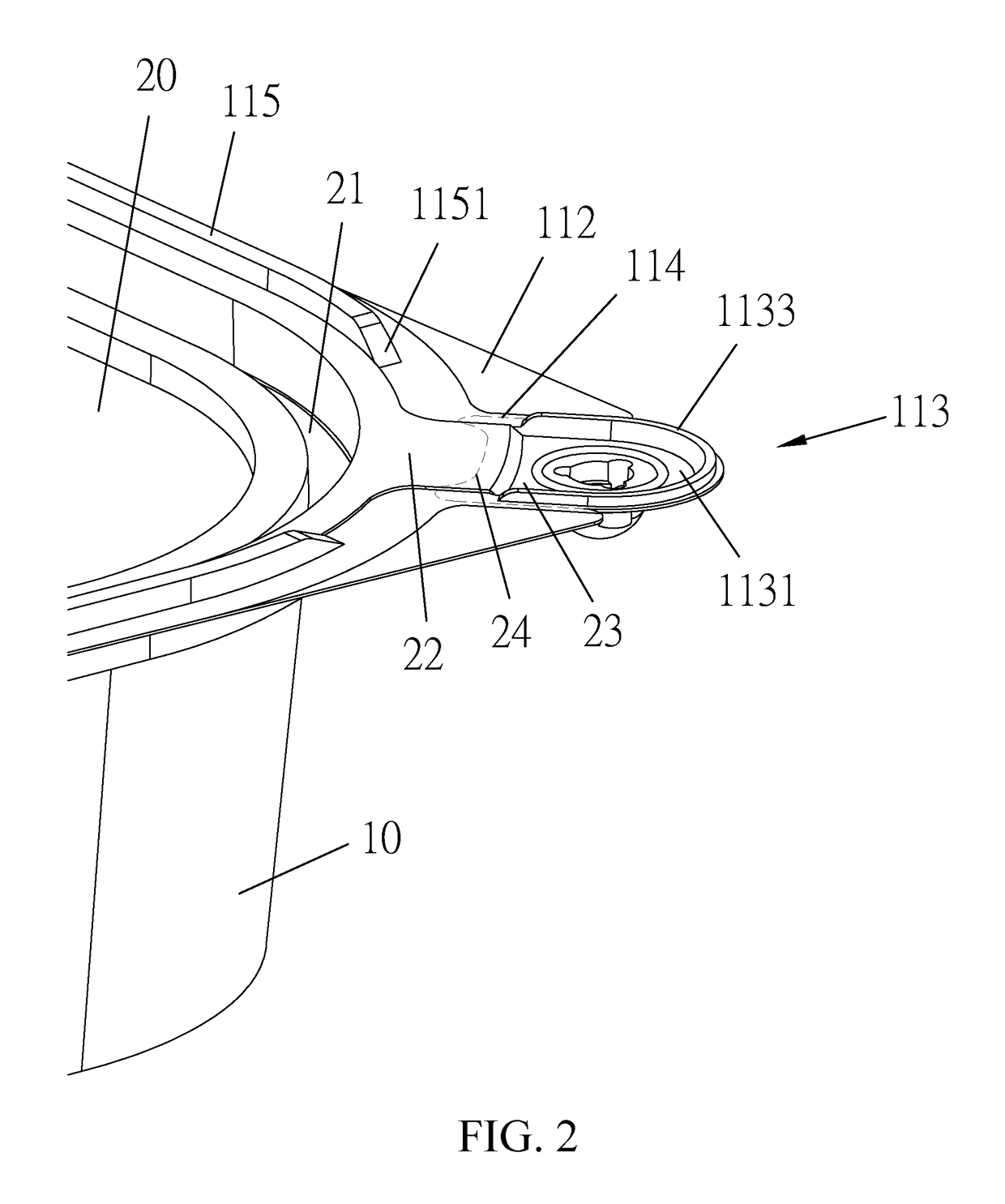

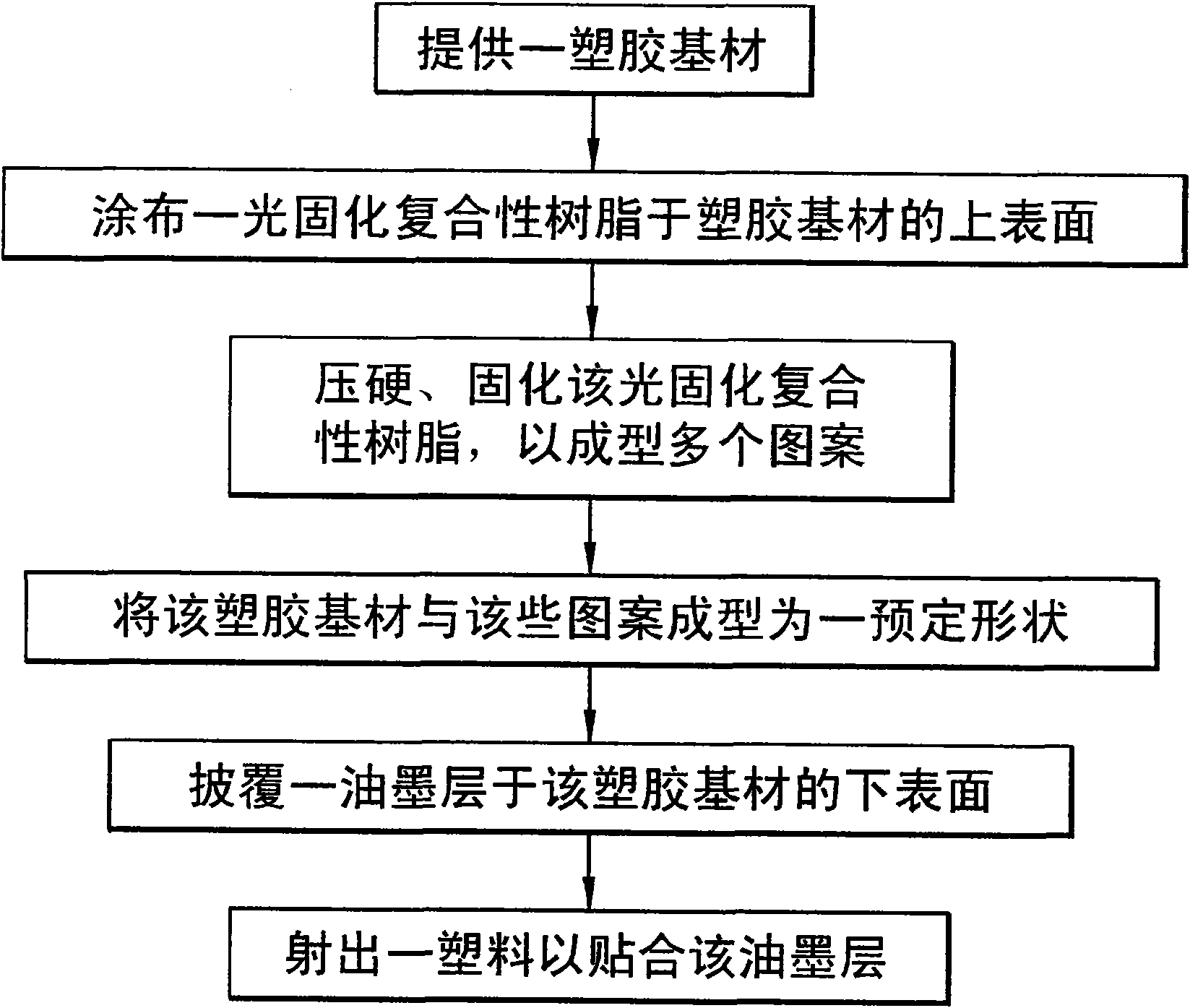

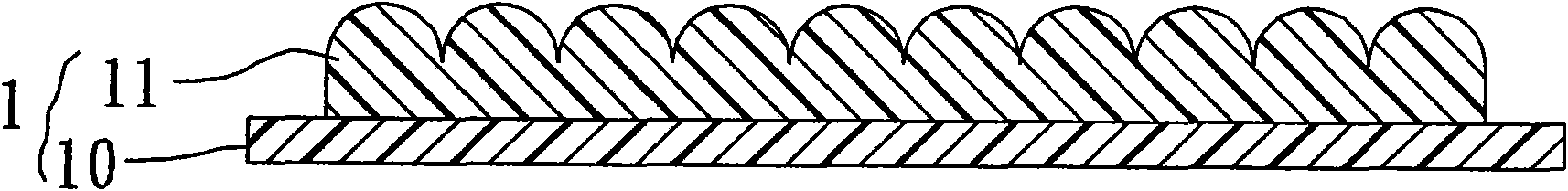

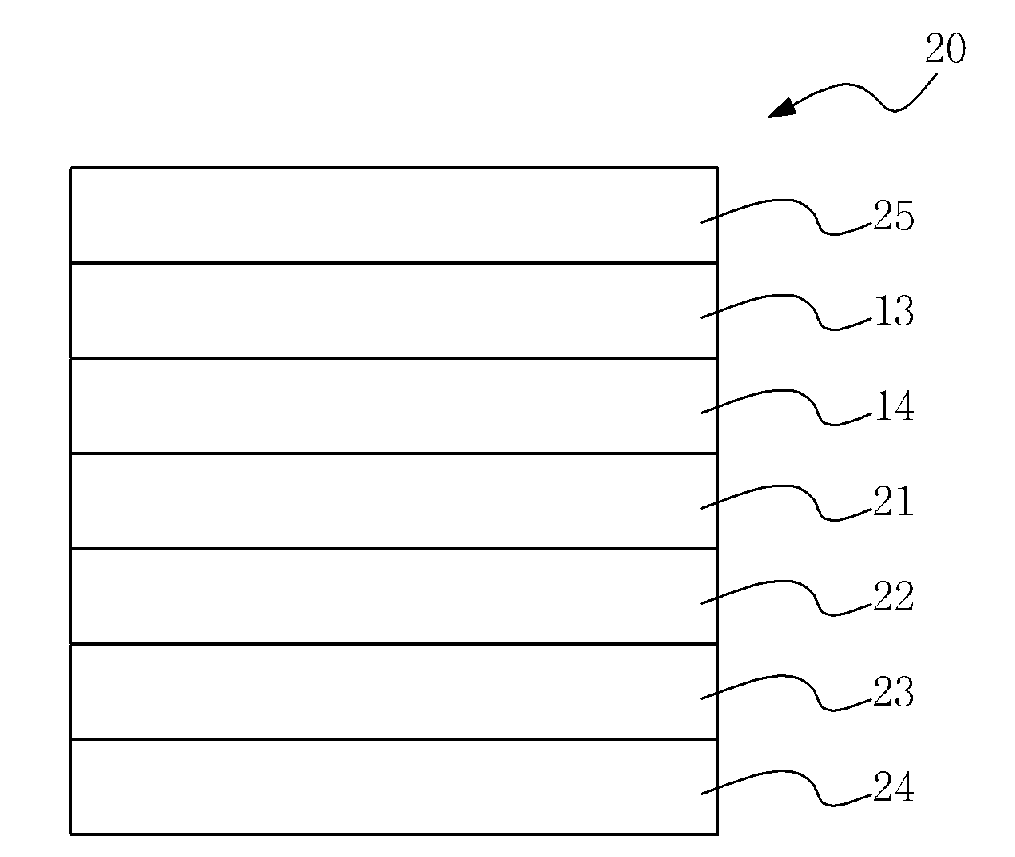

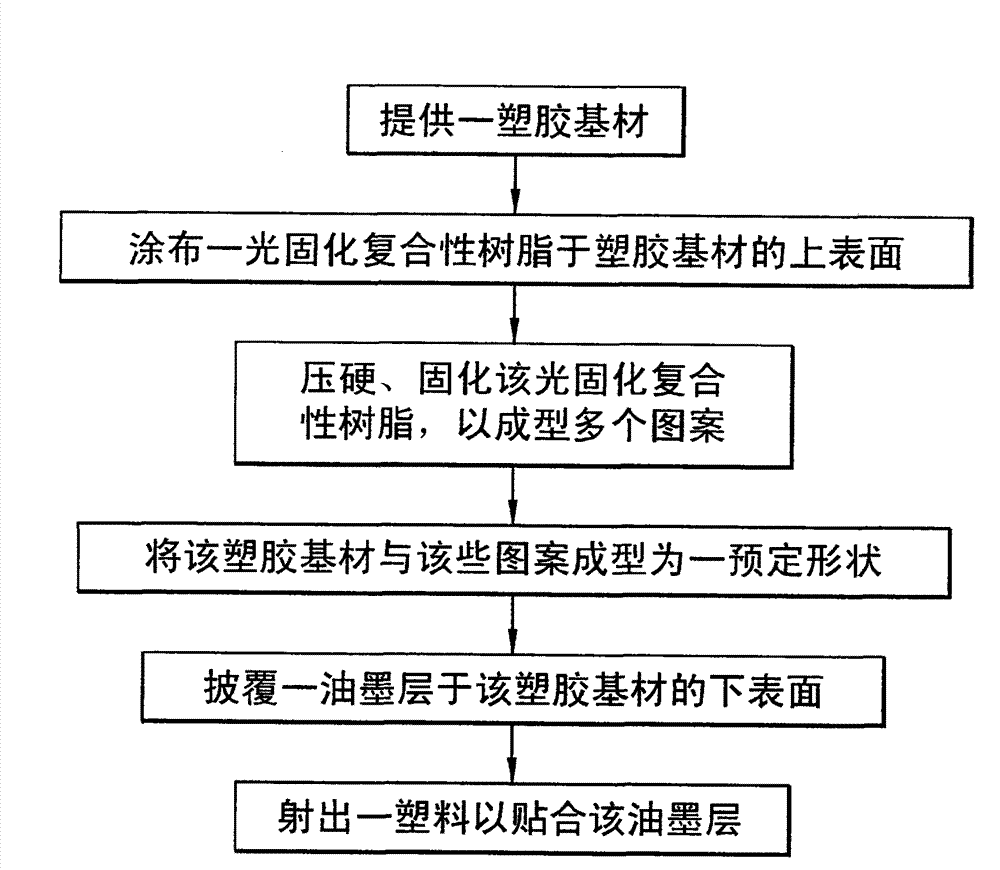

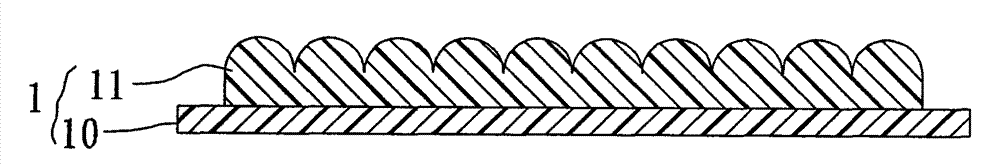

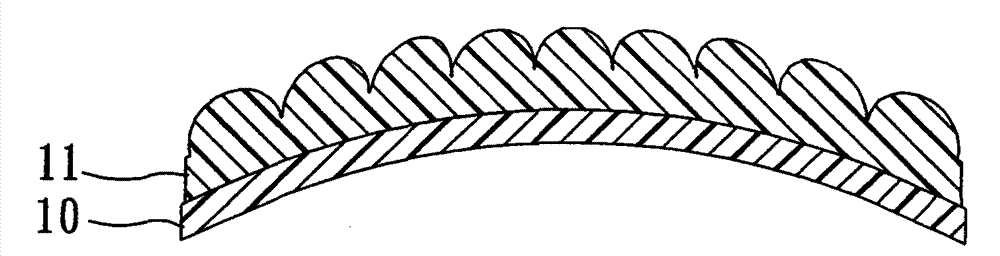

Manufacture method of light-cured composite film

ActiveCN101941353AExcellent surface scratch resistance and wear resistanceAvoid cosmetic damageSynthetic resin layered productsSpecial ornamental structuresComposite materialPrinting ink

The invention discloses a manufacture method of a light-cured composite resin film, comprising the following steps of: (1) providing a plastic substrate, light-cured composite resin, a printing ink layer and plastic, wherein the plastic substrate is provided with an upper surface and a lower surface; (2) coating the upper surface of the plastic substrate with the light-cured composite resin; (3) impressing and solidifying the light-cured composite resin to form a plurality of patterns; (4) forming the plastic substrate and the plurality of patterns; (5) coating the printing ink layer on the lower surface of the plastic substrate; and (6) ejecting and attaching the plastic on the printing ink layer.

Owner:ENTIRE TECH CO LTD

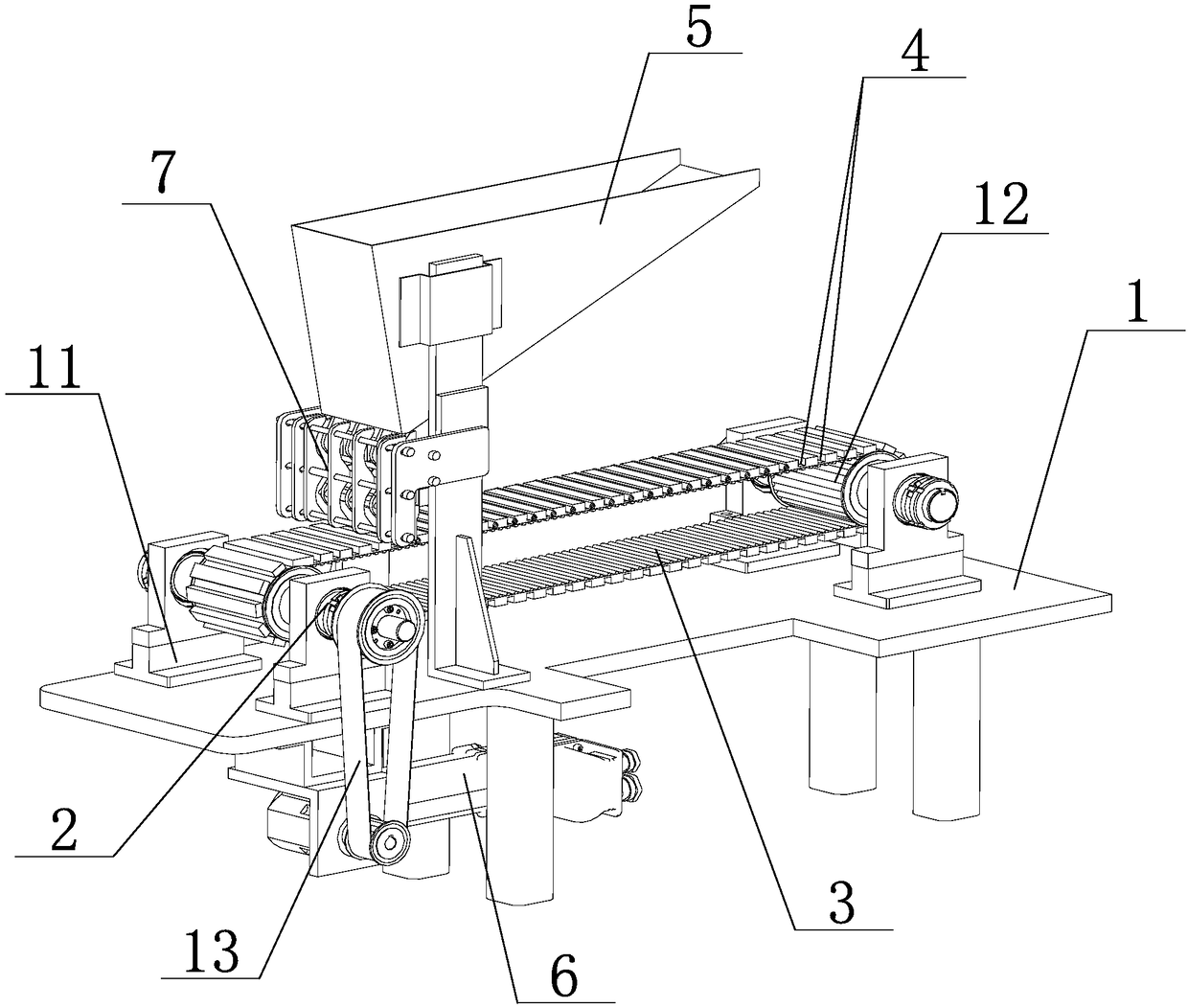

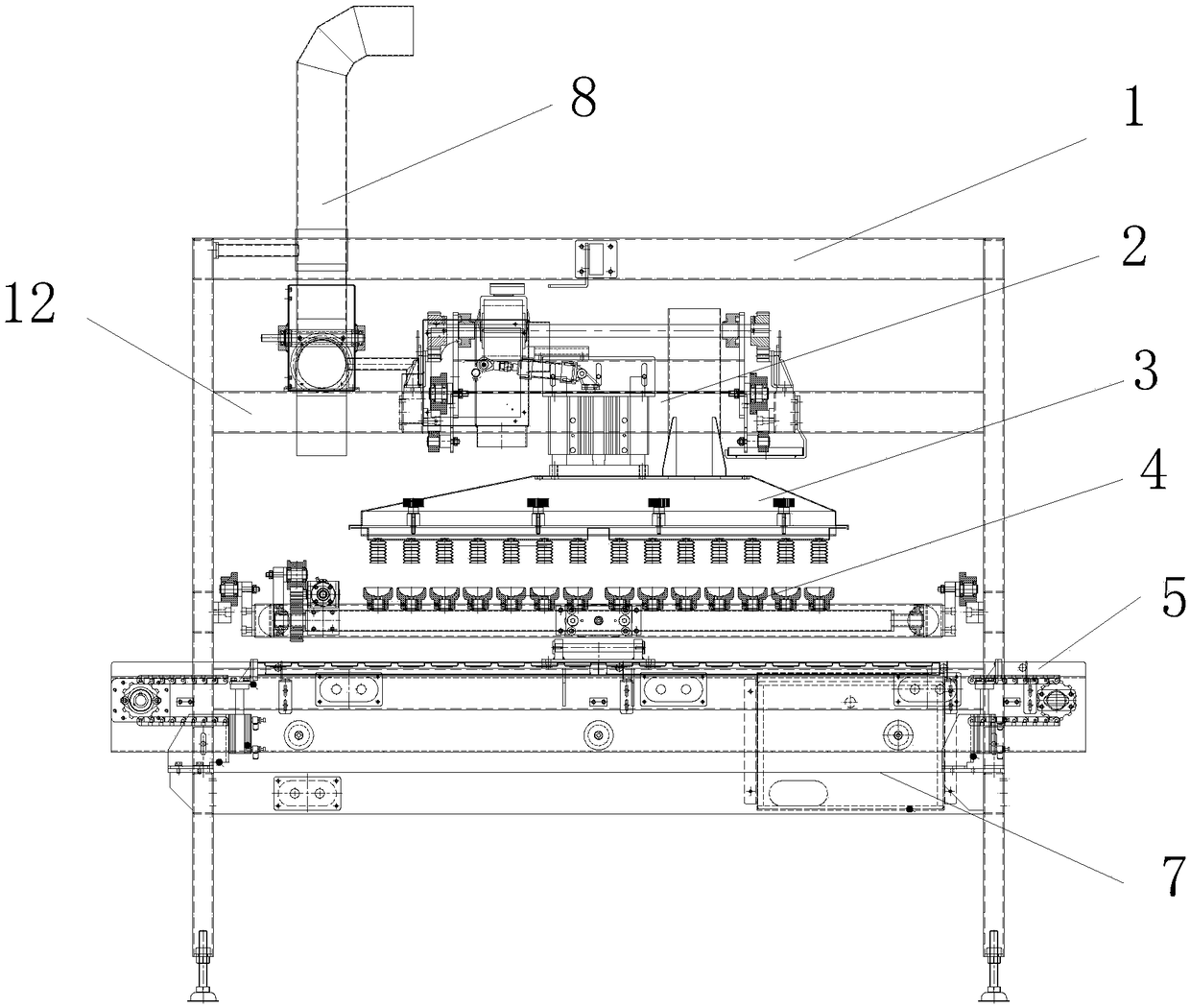

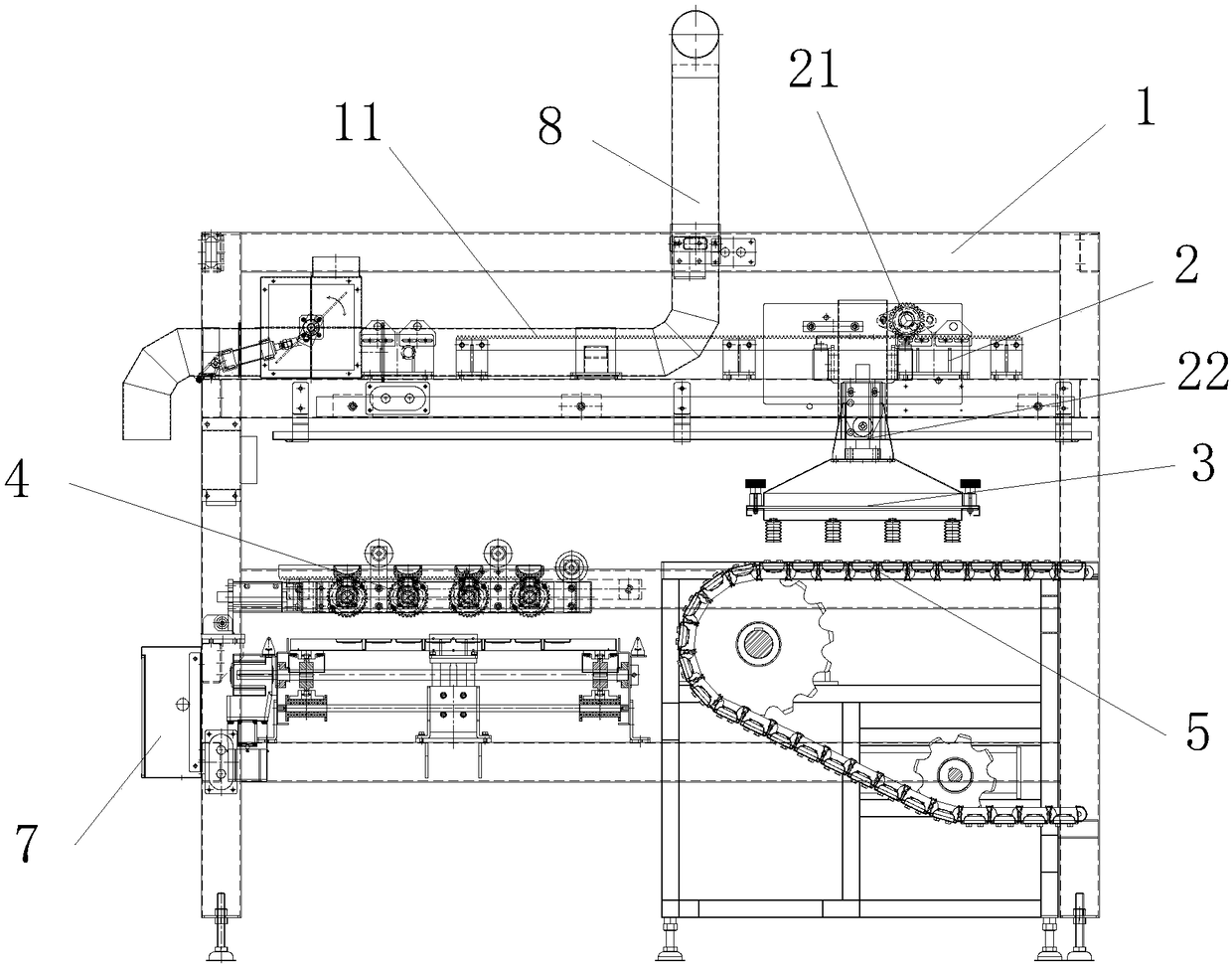

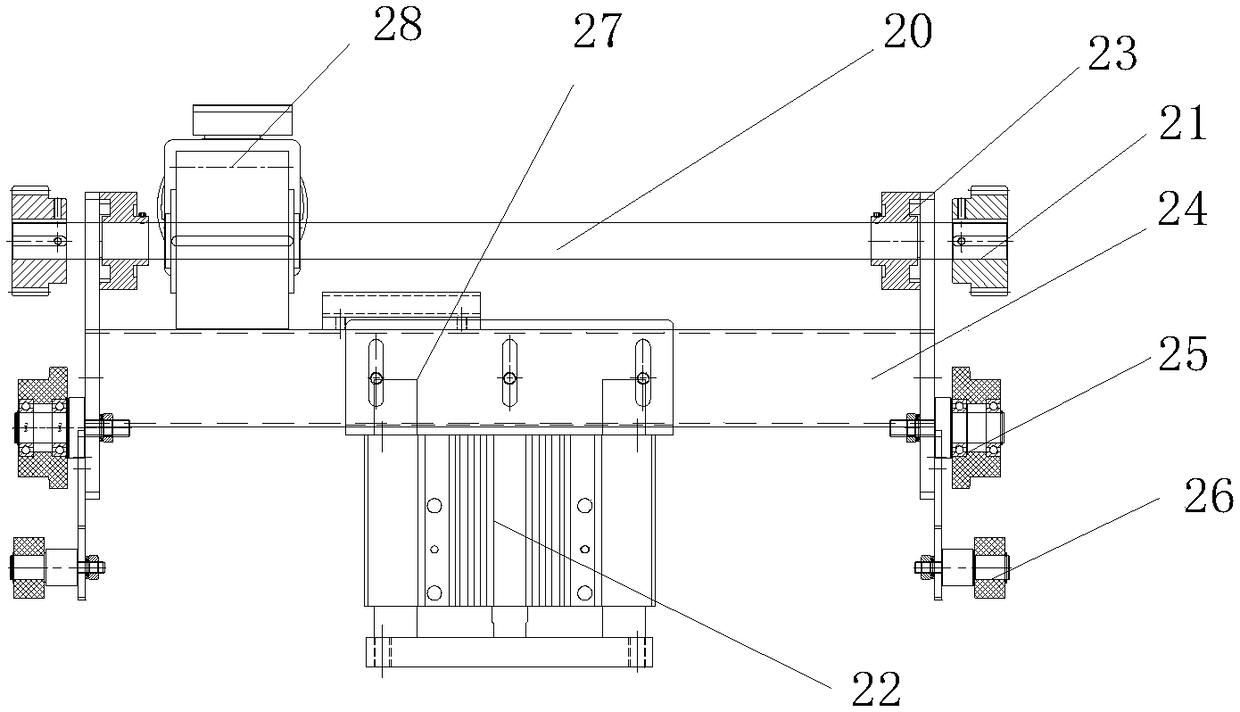

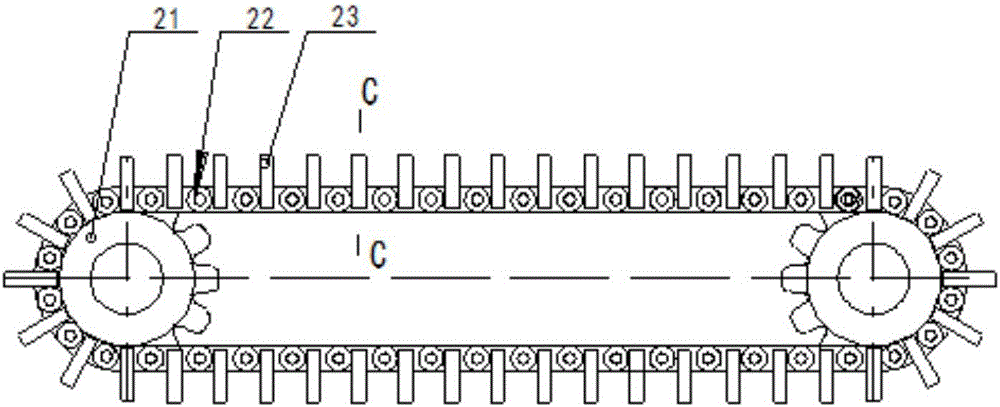

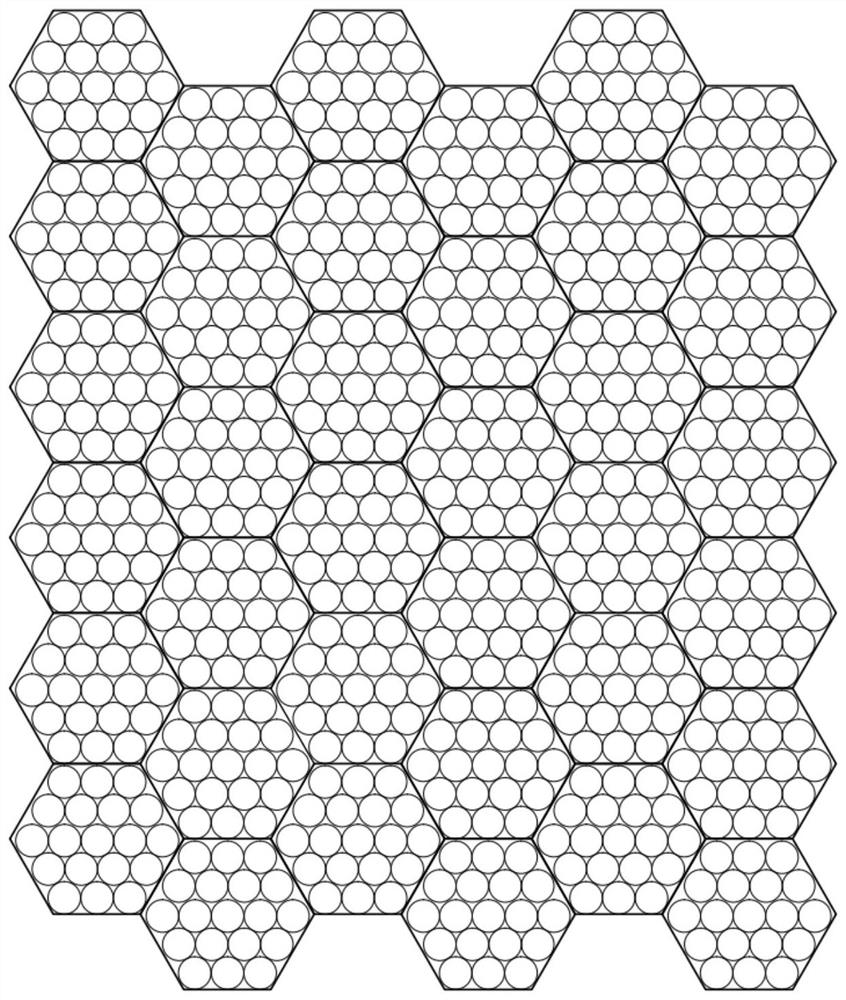

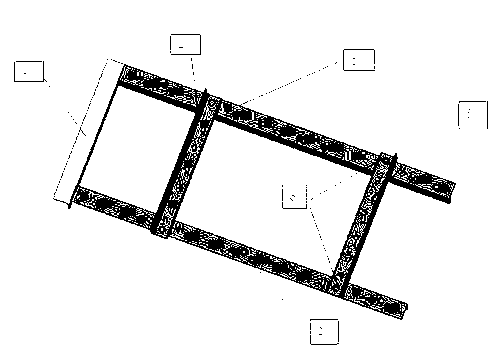

Rapid cylinder bar ranking device

The invention discloses a rapid cylinder bar ranking device. The rapid cylinder bar ranking device comprises a workbench. The workbench is provided with two transmission devices. A synchronous belt isarranged between the two transmission devices in a sleeving manner. The two transmission devices can be driven by a power device to drive the synchronous belt to move. Ranking grooves are formed in the upper surface of the synchronous belt in the motion direction of the synchronous belt at equal intervals. The ranking grooves are perpendicular to the motion direction of the synchronous belt. A feeding hopper is arranged above the synchronous belt. The bottom of the feeding hopper is provided with a long groove, wherein one thin and long cylinder bar is only allowed to pass through the long groove at the same time due to the width of the long groove, and the long groove is parallel to the ranking grooves. According to the ranking device, through cooperation of discharging grooves and the synchronous belt, rapid cylinder bar ranking is achieved, the running simulating synchronous belt is adopted, the reasonable mechanical mechanism is designed, rapid and reliable sequential ranking of cylinder bars can be effectively guaranteed, meanwhile, friction can be reduced as much as possible, and appearance damage is avoided.

Owner:CHINA SOUTH IND GRP AUTOMATION RES INST

Tamper-evident container

ActiveUS9828149B2Avoid cosmetic damageFreshness is lostContainer/bottle contructionLidsCouplingEngineering

A tamper-evident container generally includes a tray having an opening with a step section formed around the opening and including a first protrusion section that is provided with a first coupling unit with a first perforation line formed therebetween. The first coupling unit includes a coupling trough. A cover includes a concave groove having a bottom and an outside surface engageable with the step section to close the opening. The cover includes a second protrusion section and a second coupling unit between which a second perforation line is formed and projecting beyond the first perforation line. The second coupling unit has a coupling member receivable in and engageable with the coupling trough. Tearing off the first and second perforation lines allows the first and second coupling units to detach from the tray and the cover, respectively with the second protrusion section projecting outside the tray for easy gripping.

Owner:SOUTH PLASTIC IND

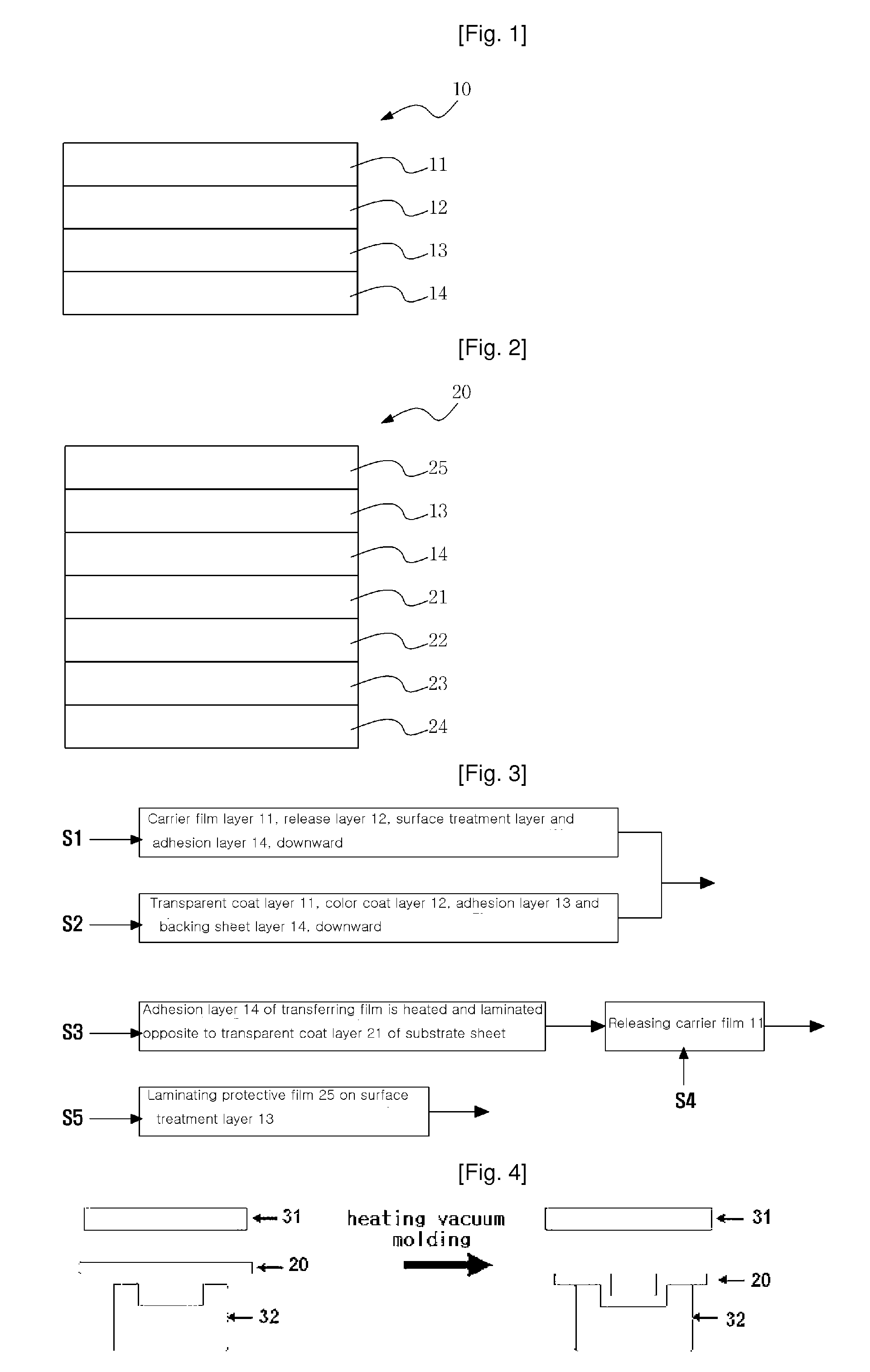

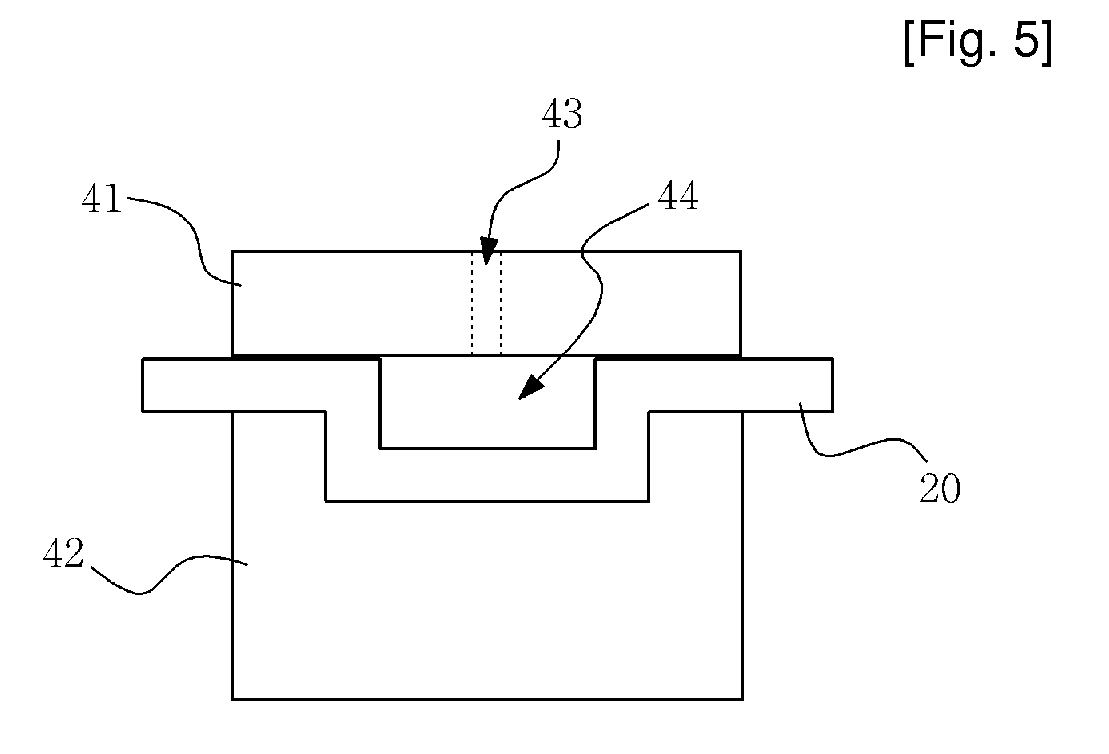

Transferring films, multilayered sheets and manufacturing methods thereof

InactiveUS20100047543A1Excellent surface hardnessExcellent scratch resistance and moldabilityDecorative surface effectsSynthetic resin layered productsVinyl acetateEngineering

The present invention relates to a transferring film for manufacturing a decorative laminate sheet having an excellent weatherability, scratch resistance and moldability, a laminate sheet manufactured therefrom and a method for manufacturing thereof. The transferring film and the laminate sheet of the present invention combine an excellent scratch resistance and thermo-formability, since a surface treatment layer comprising a modified acrylic resin and vinyl acetate is formed thereon, and thus may be effectively applied to protect and decorate plastic molded articles such as household appliances, furniture and automobile parts, especially, molded articles having a three-dimensional complicated shape.

Owner:LG CHEM LTD

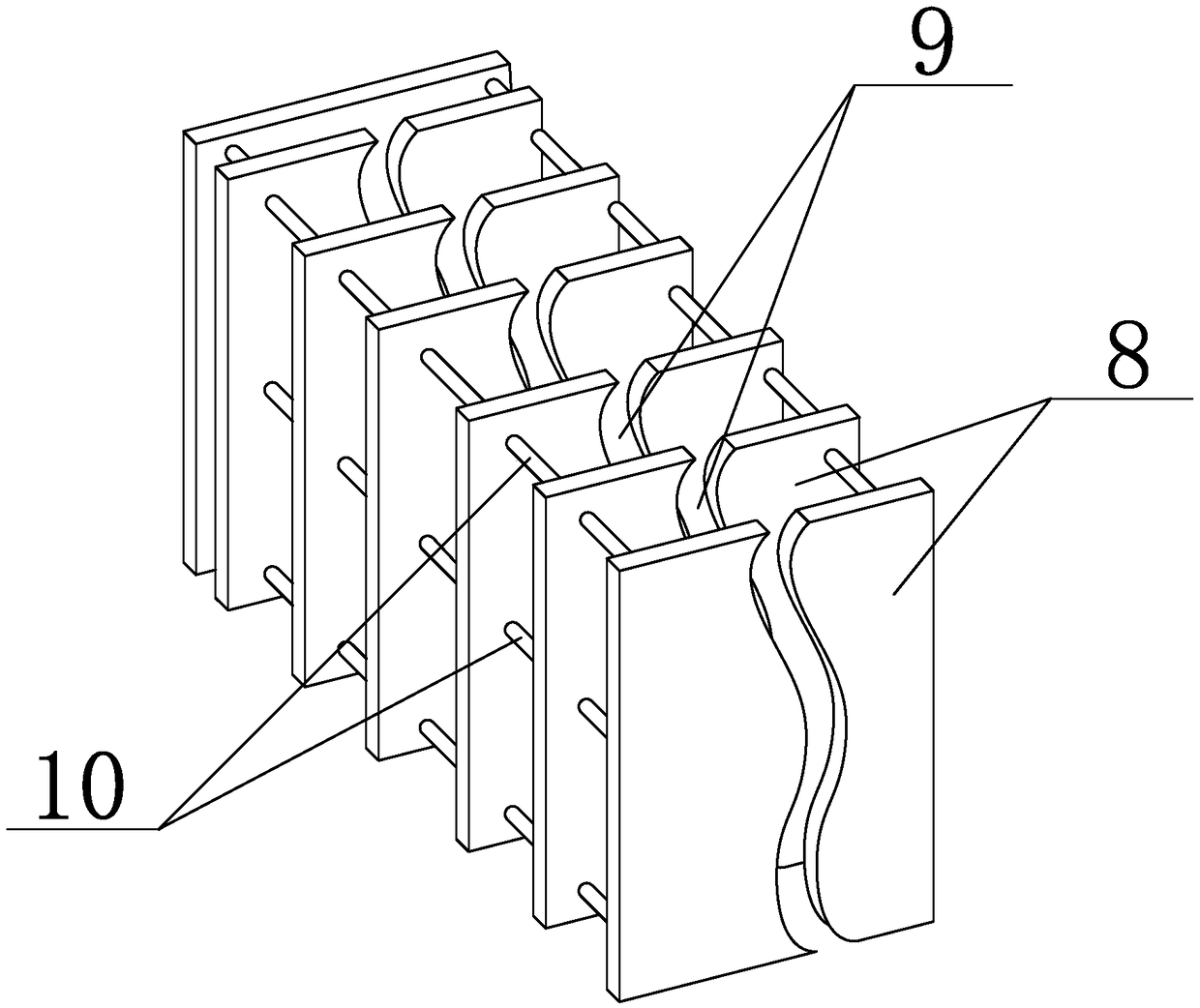

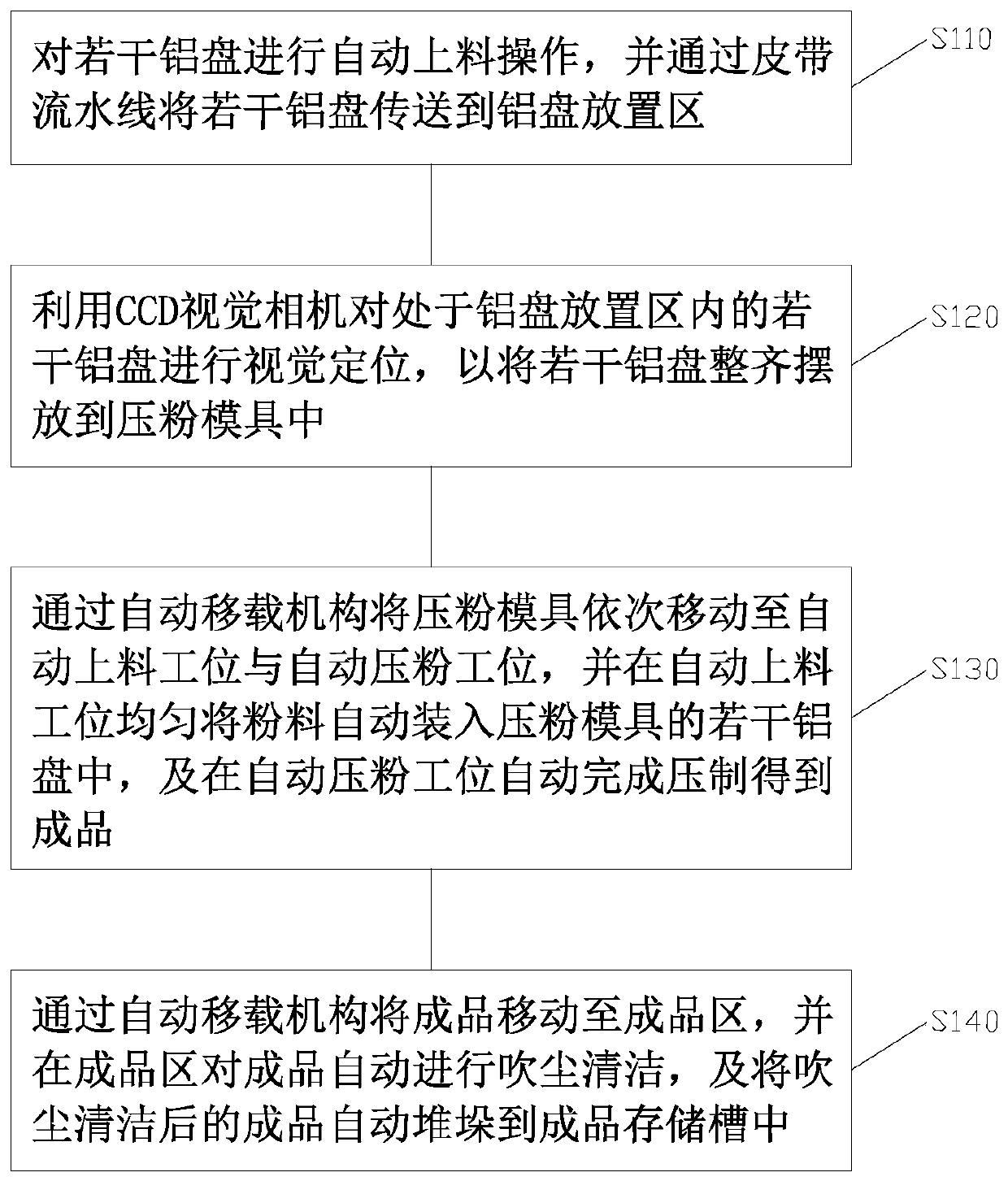

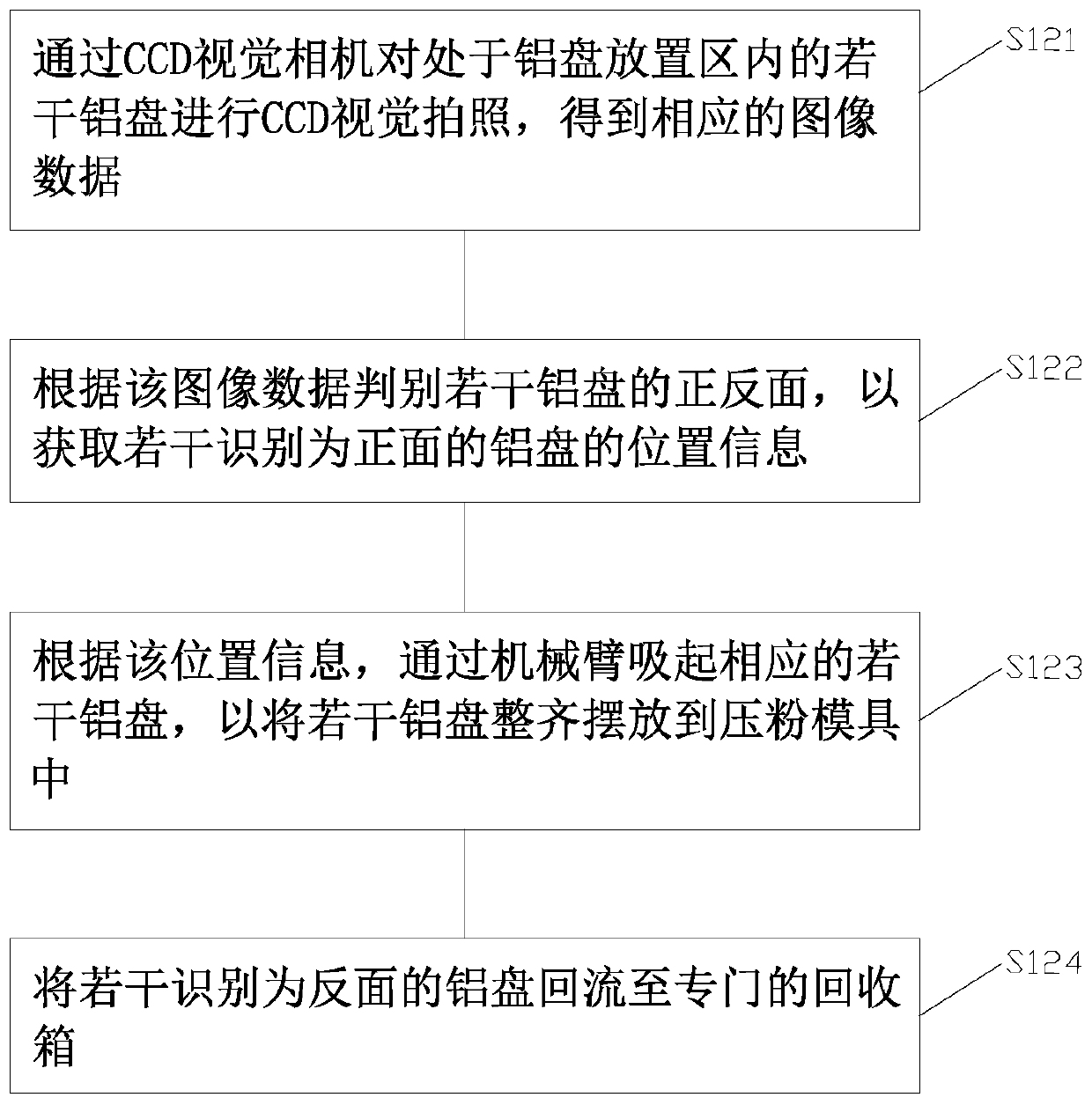

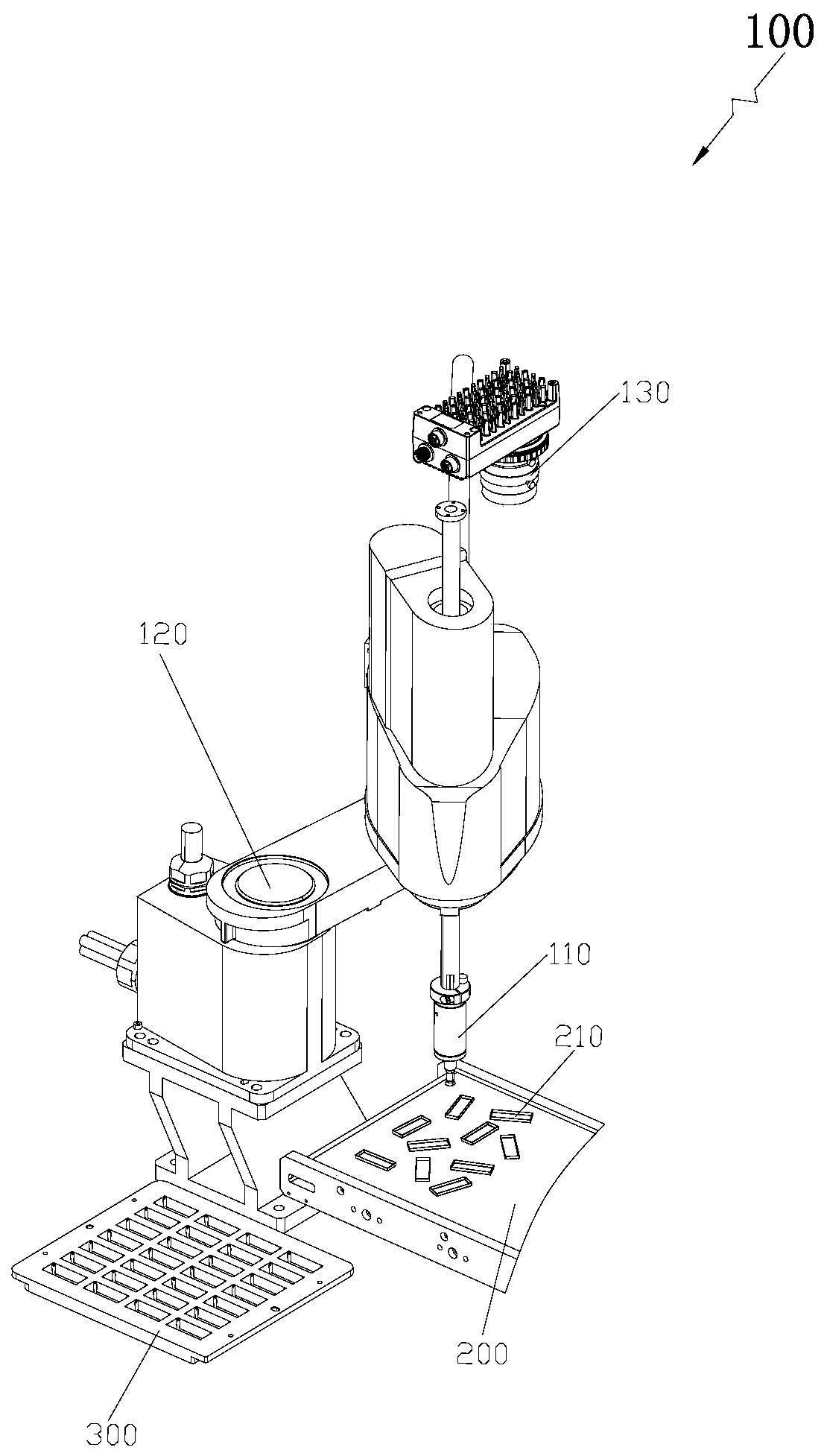

Automatic powder pressing method

InactiveCN111113993AAvoid cosmetic damageAvoid residual contaminationShaping pressCosmetic industryVisual positioning

The invention discloses an automatic powder pressing method and belongs to the technical field of powder pressing equipment. The automatic powder pressing method comprises the following steps that a CCD visual camera is utilized for carrying out visual positioning on a plurality of aluminum discs in an aluminum disc containing area, and the aluminum discs are placed in a powder pressing mold in order; and the powder pressing mold is moved to an automatic feeding station and an automatic powder pressing station in sequence through an automatic transferring mechanism, powder is evenly and automatically contained in the aluminum discs in the powder pressing mold at the automatic feeding station, pressing is automatic completed at the automatic powder pressing station, and finished products are obtained. According to the technical scheme, the technical problems that the whole powder pressing production process of box-packed cosmetics of the cosmetic industry in the prior art is manually completed or semi-automatically achieved, and consequently the labor intensity is large, and the overall efficiency is not high can be effectively solved.

Owner:SHENZHEN HUIDACHENG INTELLIGENT TECH CO LTD

Method for installing electrical reserved wire box in secondary structure wall

InactiveCN108695794AScientific and reasonable designEasy to implementElectrical apparatusMaterial resourcesCement mortar

The invention discloses a method for installing an electrical reserved wire box in a secondary structure wall, and the method is characterized in that the method comprises the following steps: a, marking a center position and bottom position of the wire box in the secondary structure wall according to the layout of the electrical wire box after the construction of a civil engineering secondary structure wall; b, making an opening in the secondary structure wall according to the center position of the wire box in the secondary structure wall and the size of the wire box; c, making a template; d, placing the wire box into the opening in the wall after the plastering of the periphery of the wire box, enabling the template to be attached to the secondary structure wall, fixing the periphery through bolts to guarantee that a central line of the template and a bottom line of the template coincide with the center position in the wall body, and timely removing a die after the initial setting of cement mortar. According to the invention, the method is scientific and reasonable in installation steps and design of the reserved wire box, is simple in implementation, is high in operability, guarantees the installation and elevation of the wire box, guarantees that the mouth of the box is aligned with the wall surface after the plastering of the wall, reduces the rework rate, saves the manpower and material resources, and reduces the engineering cost.

Owner:MCC5 GROUP CORP SHANGHAI

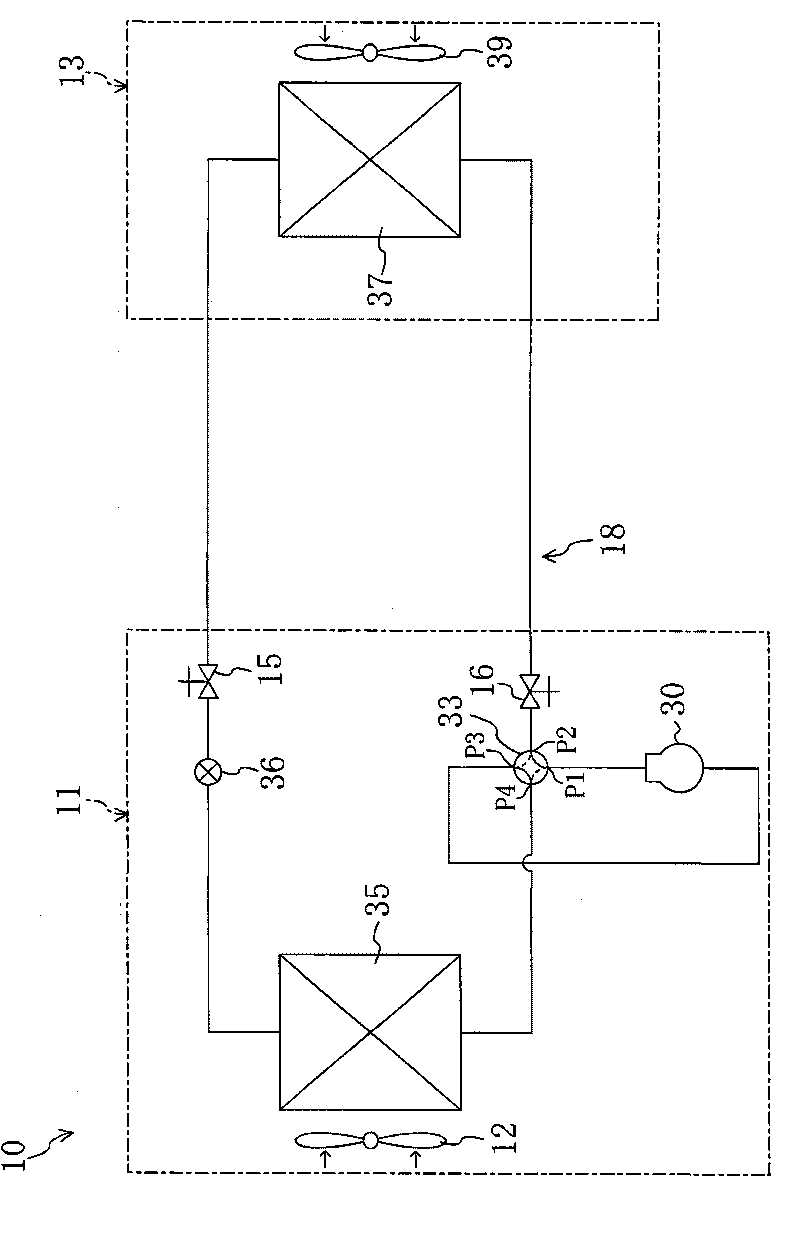

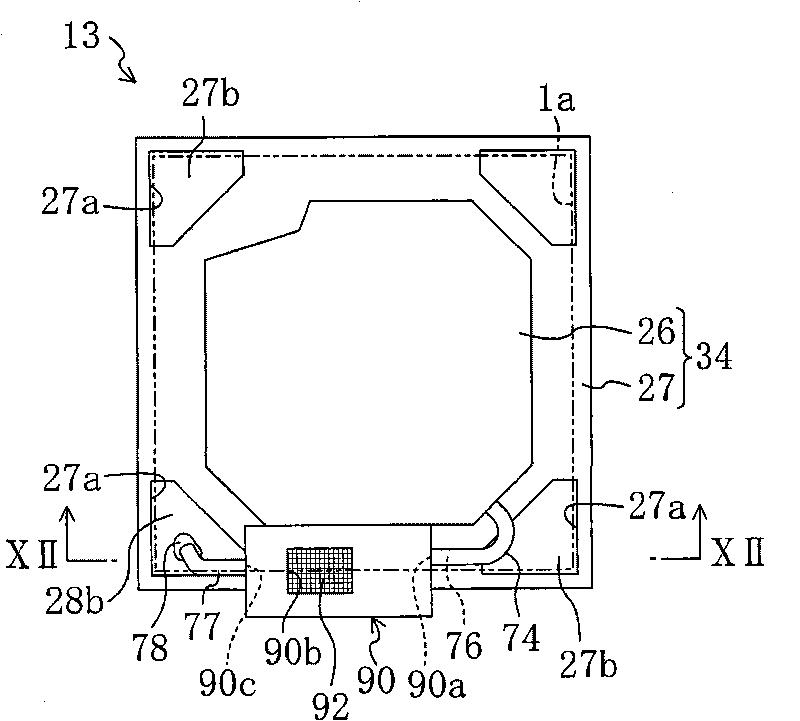

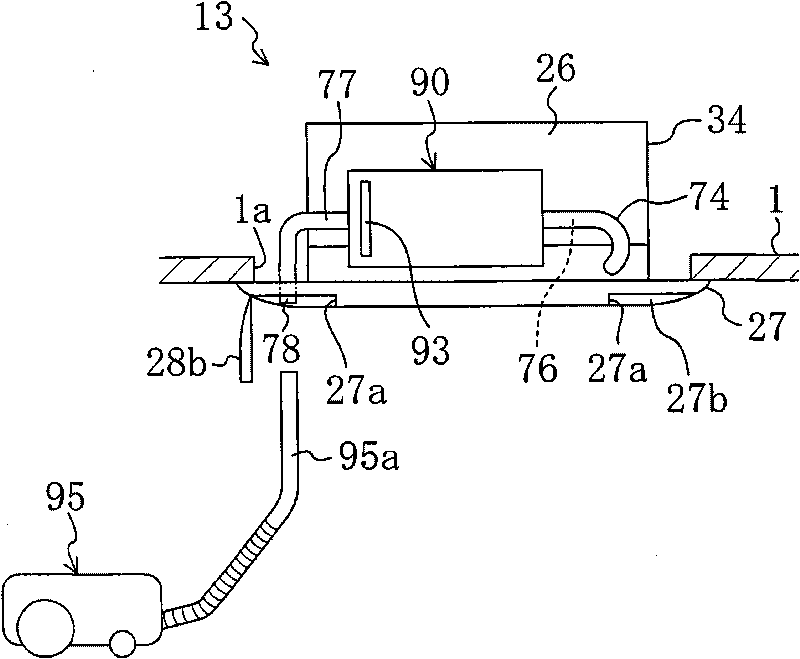

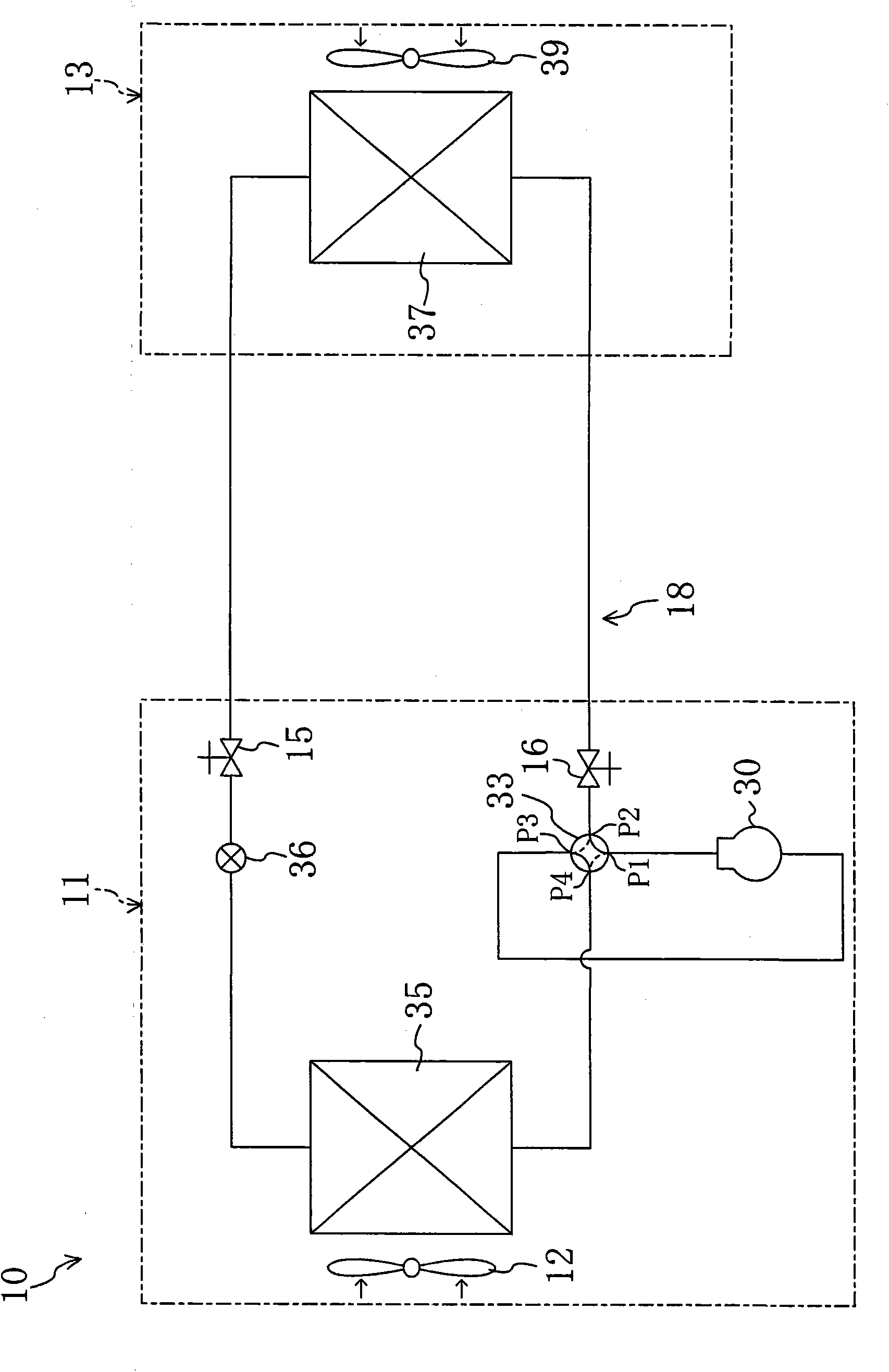

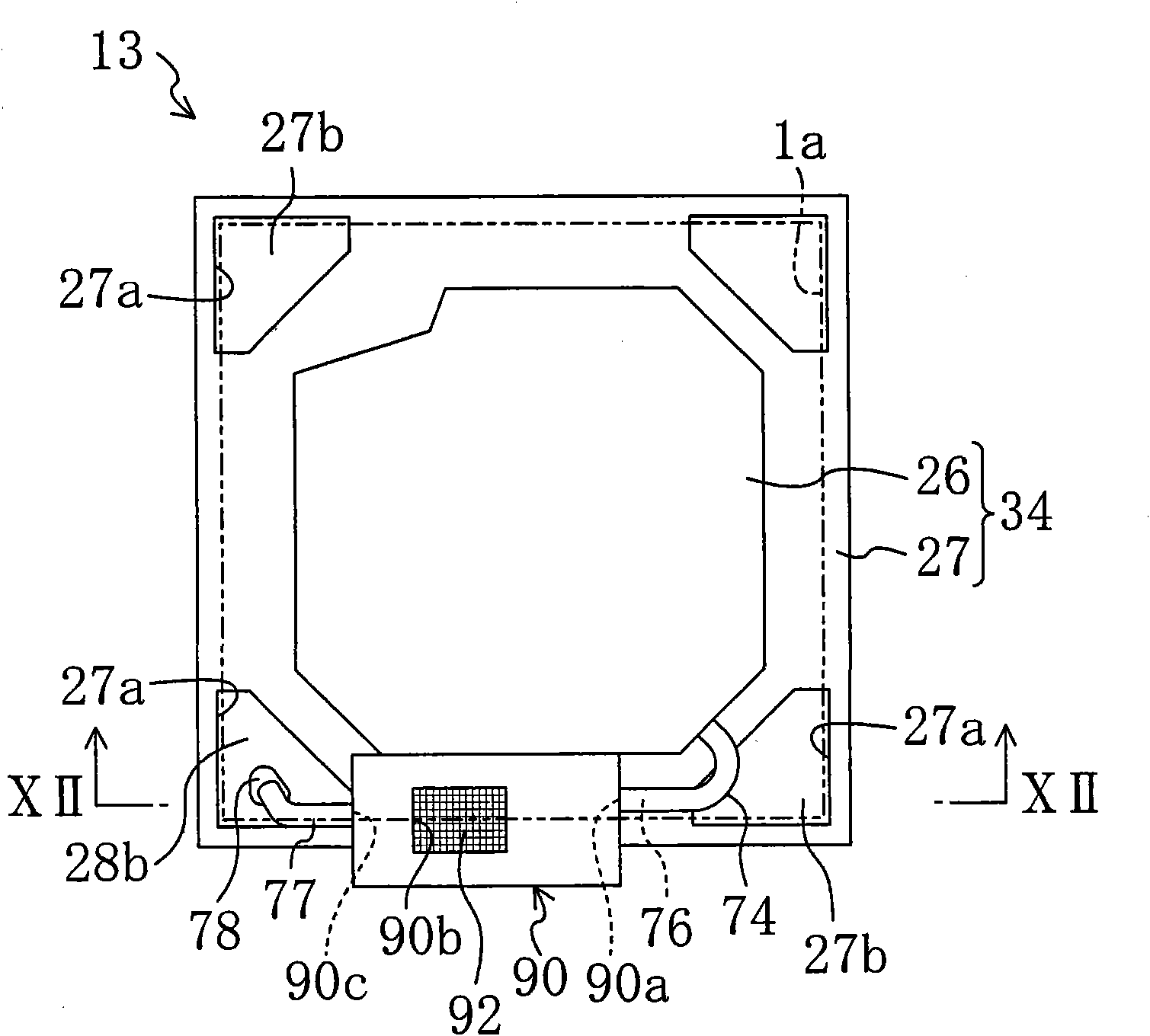

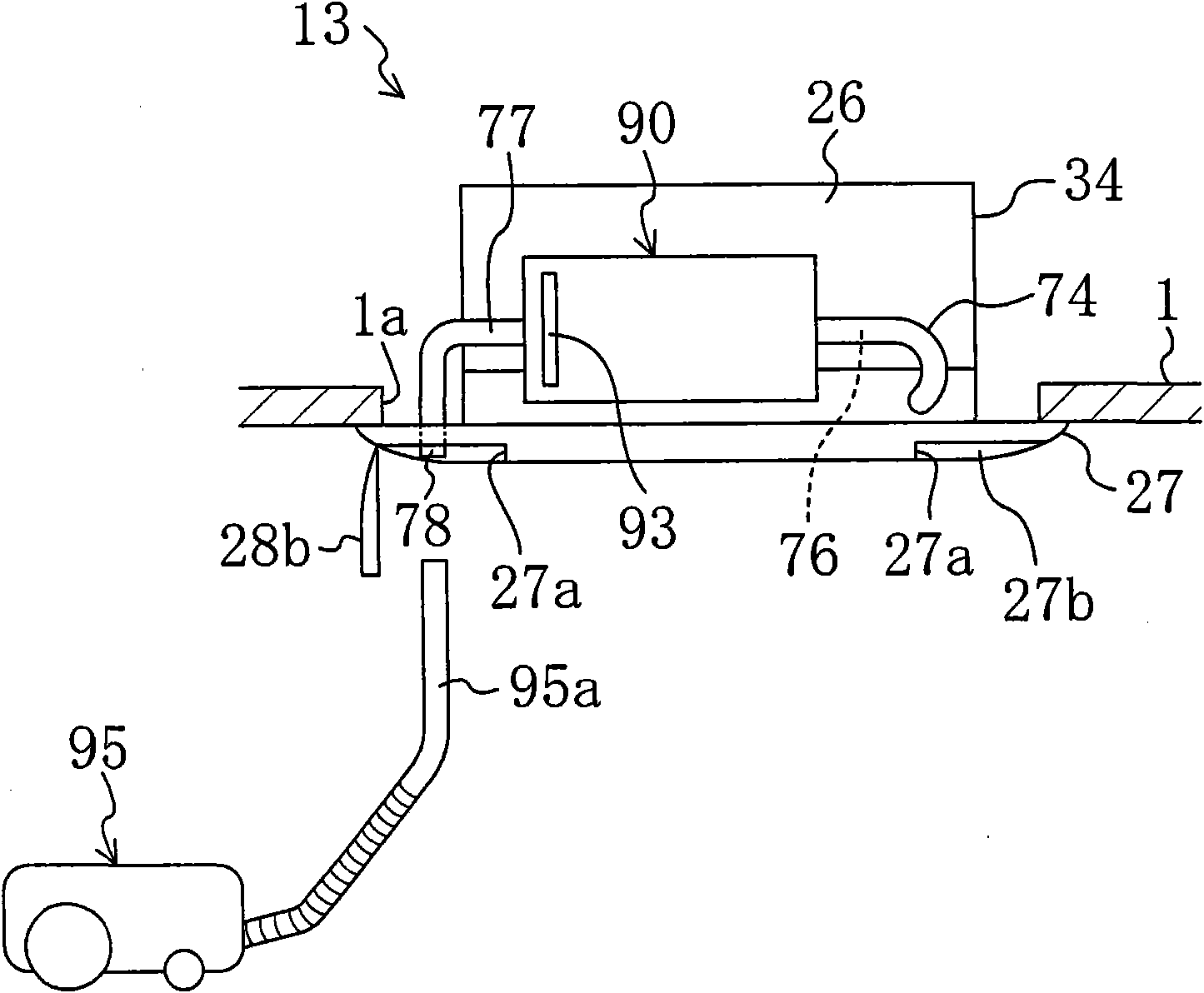

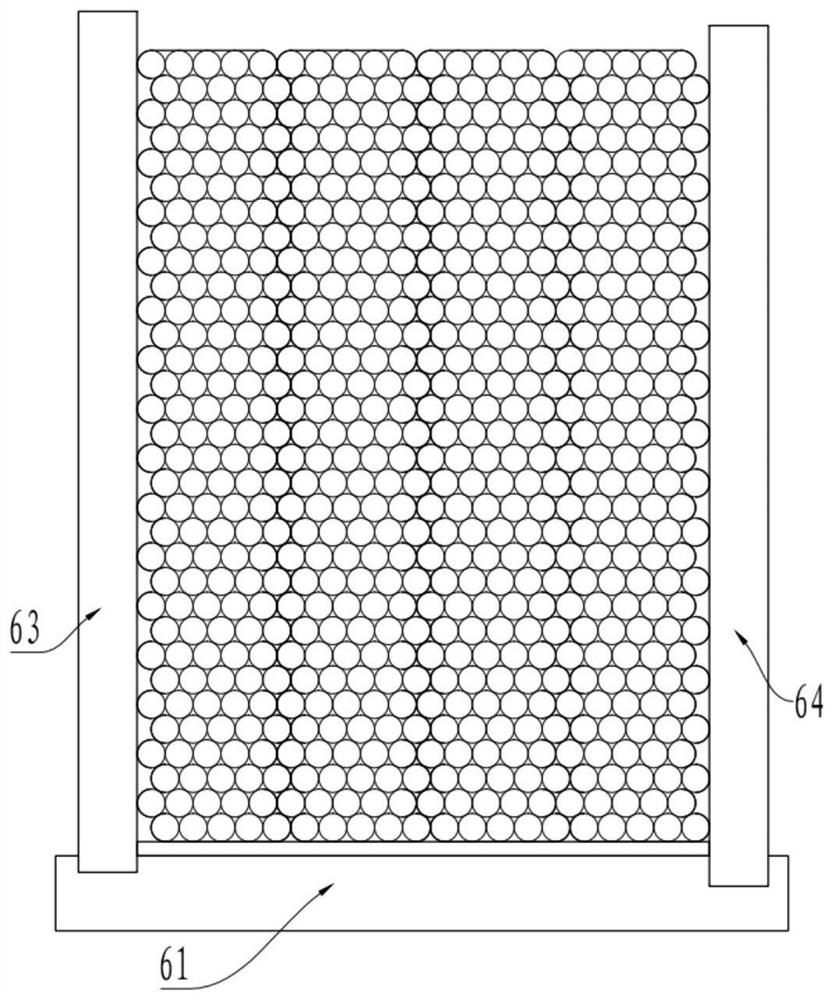

Air conditioner and cleaner extension nozzle

ActiveCN101765748ARealize compositionPrevent flowMechanical apparatusGas treatmentAir filterIndoor air

A structure for collecting dust removed from an air filter in an indoor unit is devised to save as much as possible the trouble of collection of the dust by a user. The indoor unit (13) has, in a casing (34), an indoor heat exchanger (37), an indoor fan (39) for sucking indoor air and ejecting it to the indoor heat exchanger (37), and the air filter (40) provided on the suction side of the indoor fan (39). The dust captured by the filter (40) is removed by dust removal means (50) and captured into a dust capture section (60). A nozzle connection section (78) is provided at a downstream exit of a dust collection path (77) that is a path used to convey the captured dust to the indoor side when it is collected, and the nozzle connection section (78) allows a nozzle (95a) of a cleaner (95) to be positioned at a specific position at which the cleaner (95) can suck dust.

Owner:DAIKIN IND LTD

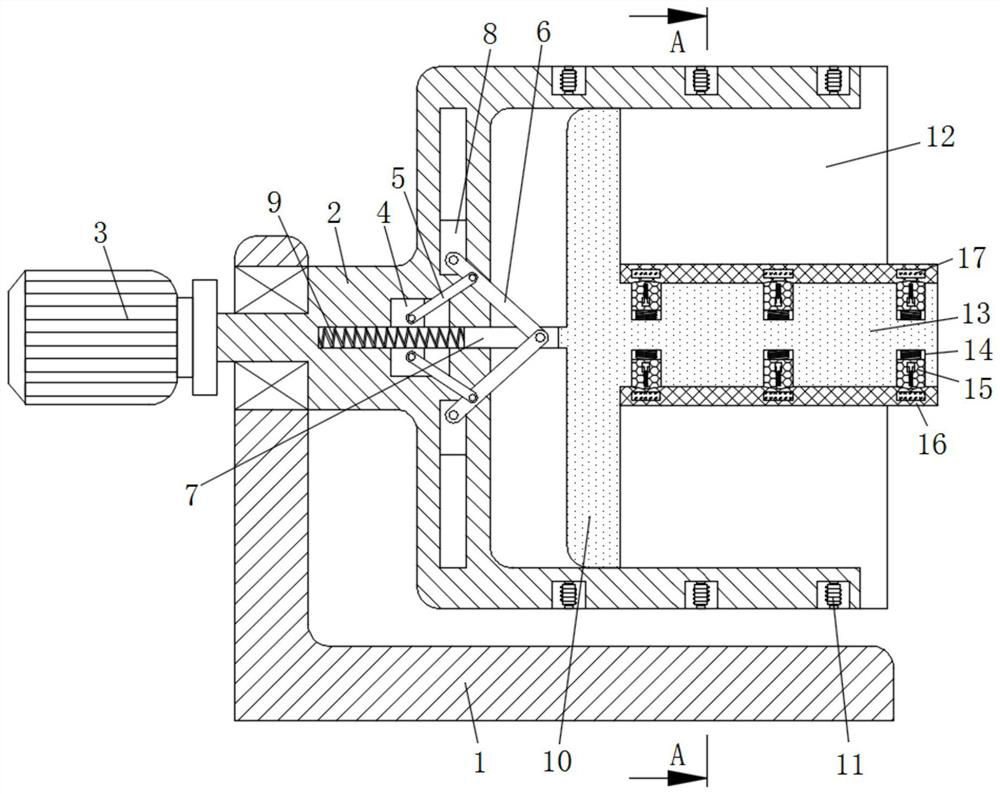

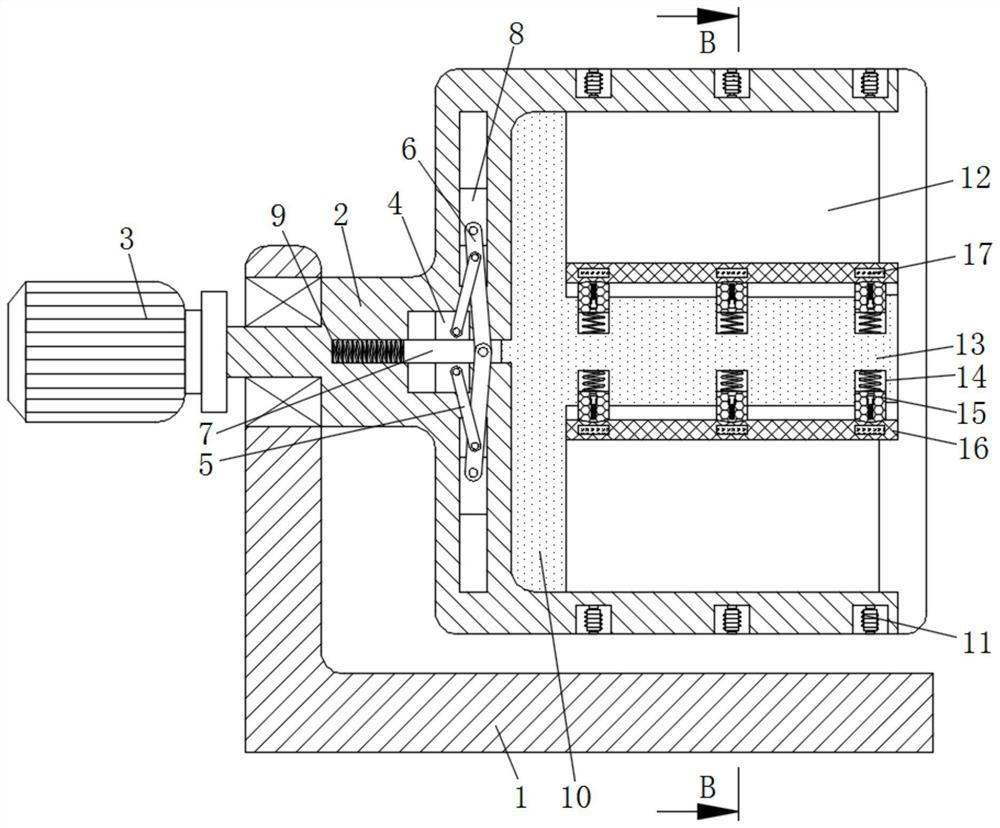

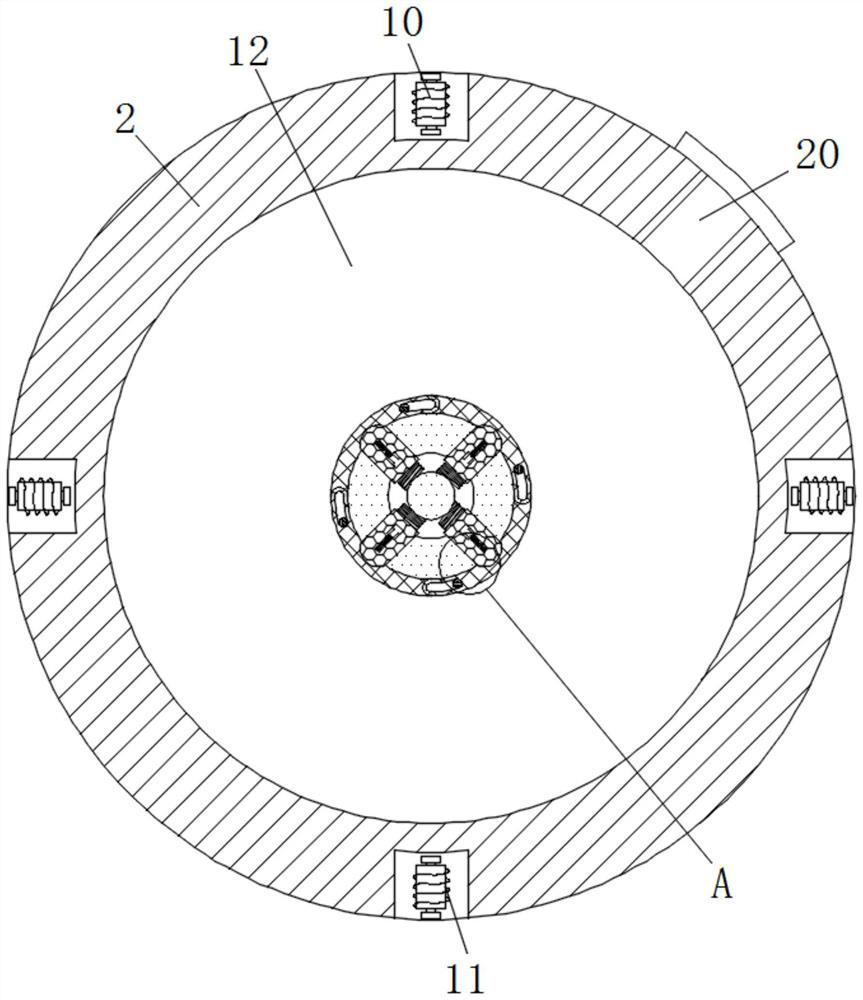

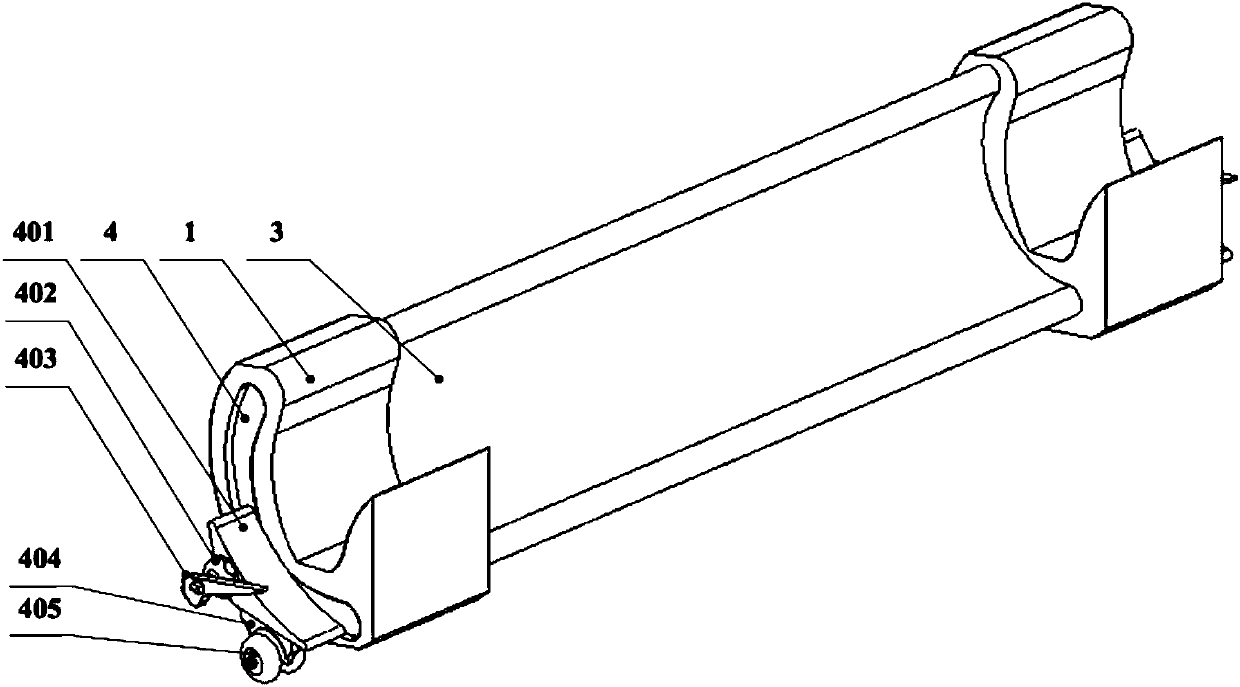

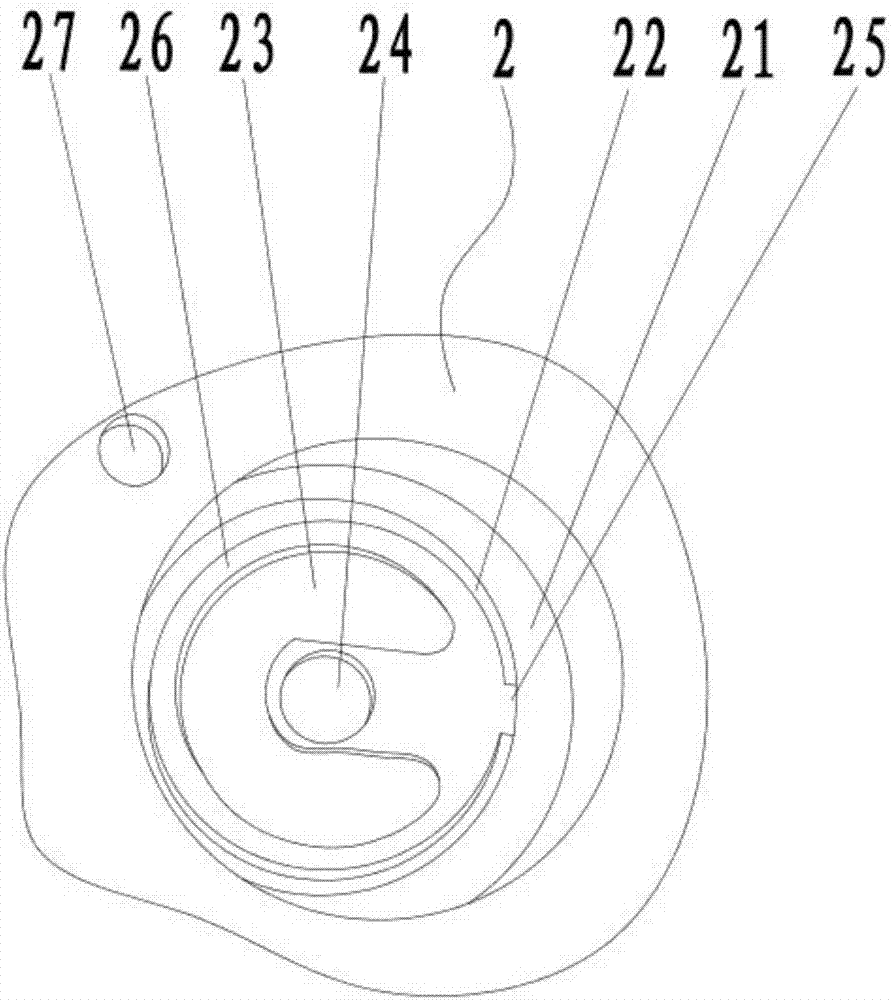

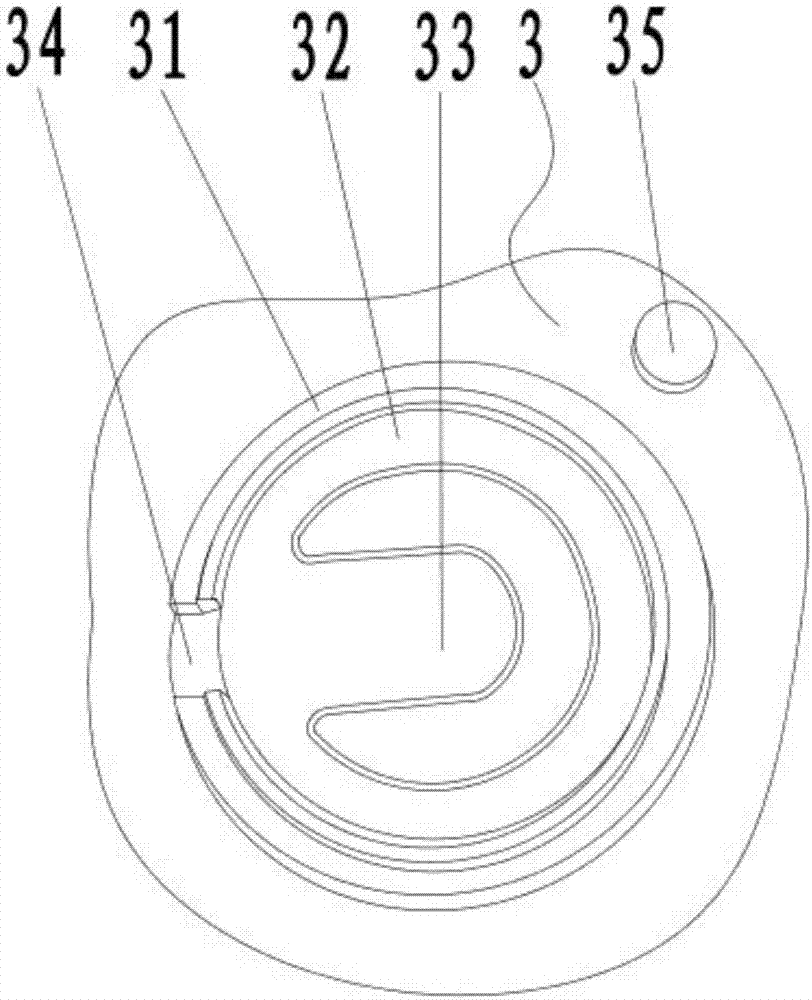

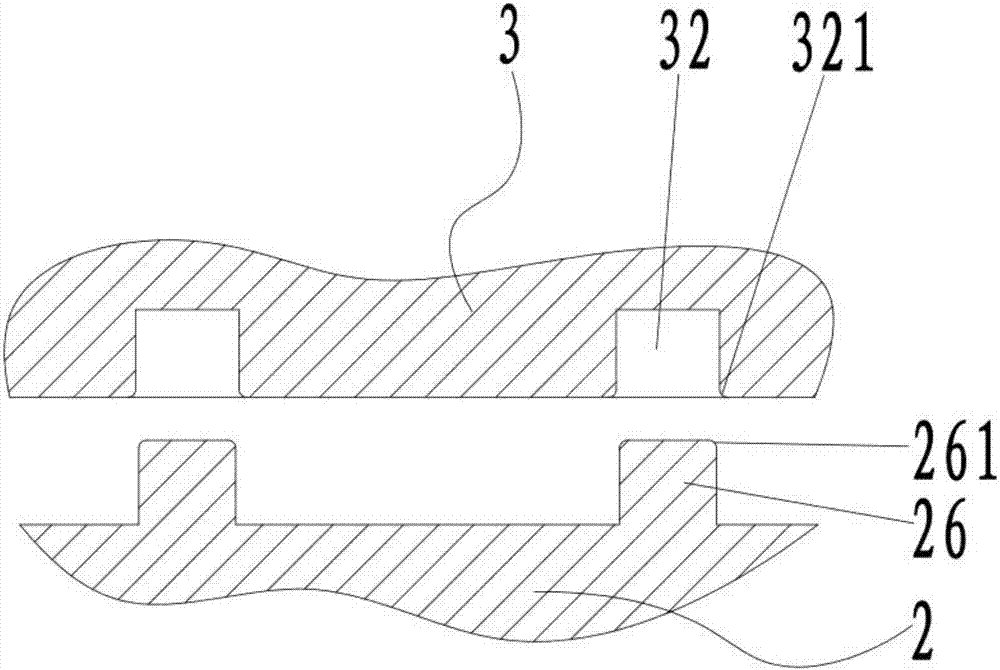

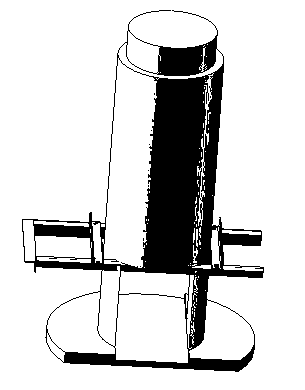

Casting equipment for automatically flattening inner wall of pipe based on centrifugal force

PendingCN113770322AReduce size fluctuationsAvoid appearance damageElectric machineryStructural engineering

The invention relates to the technical field of centrifugal casting, and discloses casting equipment for automatically flattening the inner wall of a pipe based on centrifugal force. The casting equipment for automatically flattening the inner wall of a pipe based on centrifugal force comprises a frame body, the top of the frame body is rotatably connected with a rotating frame, the left end of the rotating frame is in transmission connection with a first motor, the interior of the left side of the rotating frame is slidably connected with a hinge block, and a first connecting rod is hinged to the middle of the hinge block; a push block is hinged to the end, close to the center of the rotating frame, of the second connecting rod. According to the casting equipment for automatically flattening the inner wall of the pipe based on the centrifugal force, a second centrifugal block abuts against a contact point on the basis of the centrifugal force effect, an electromagnet attracts a first magnetic block to enable annular blocks to be unfolded mutually to extrude the inner hole face of a casting, the first centrifugal blocks are far away from each other under the centrifugal force effect, a push block moves leftwards to compress a first spring, and a first motor is closed after the casting is formed; a pushing block pushes the casting rightwards under the elastic action of the first spring, and appearance damage of the casting in the casting taking-out process is avoided.

Owner:宫峰

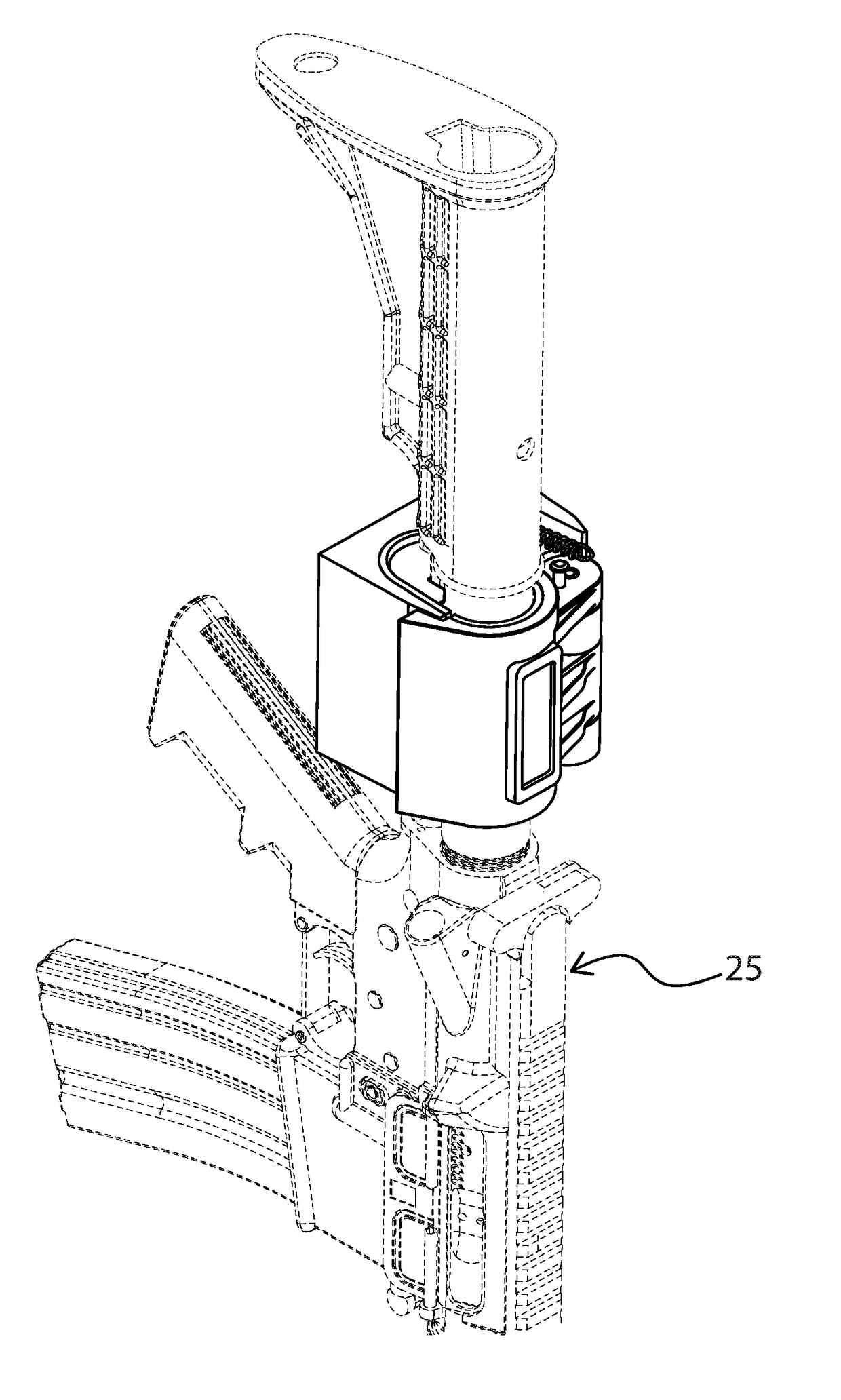

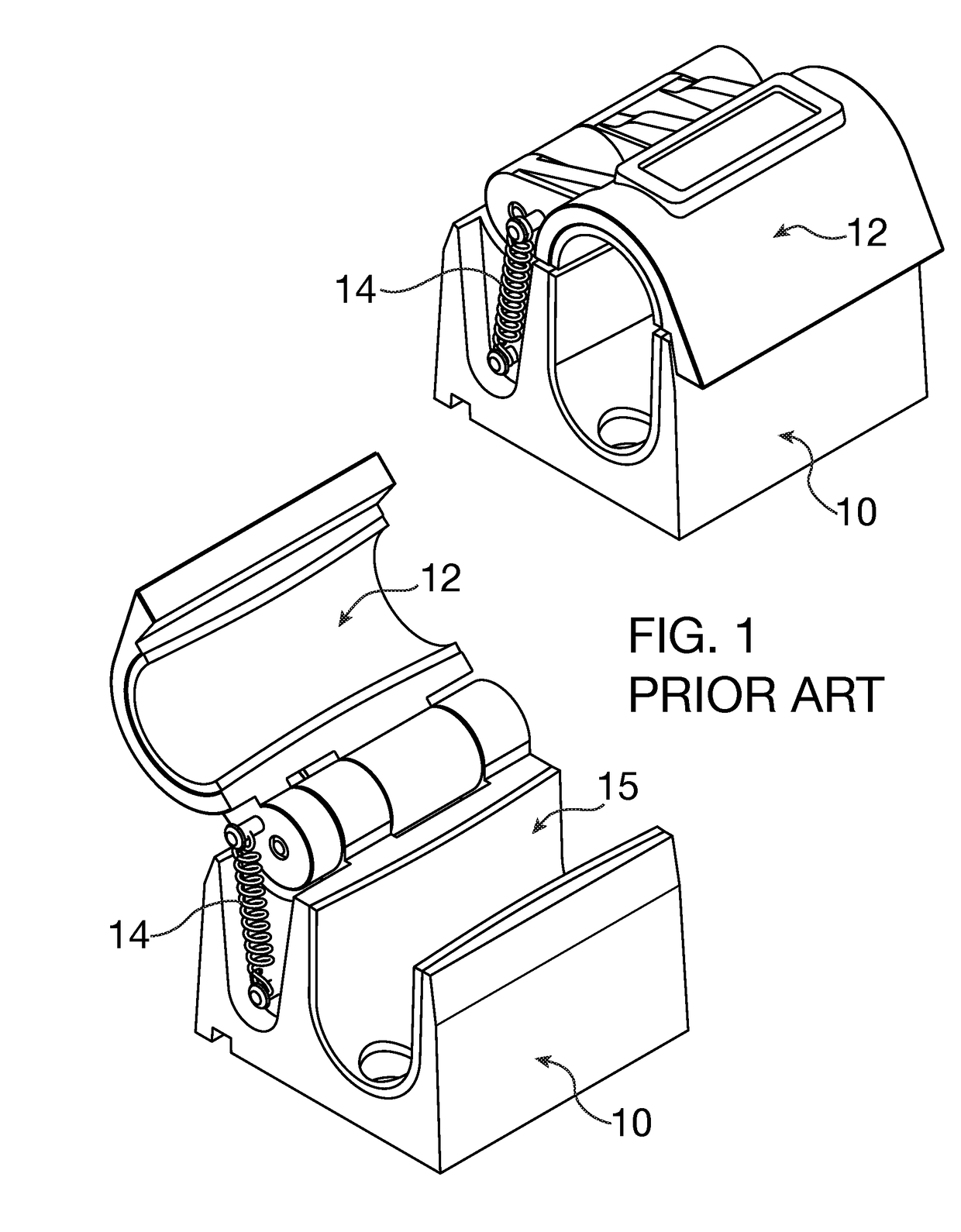

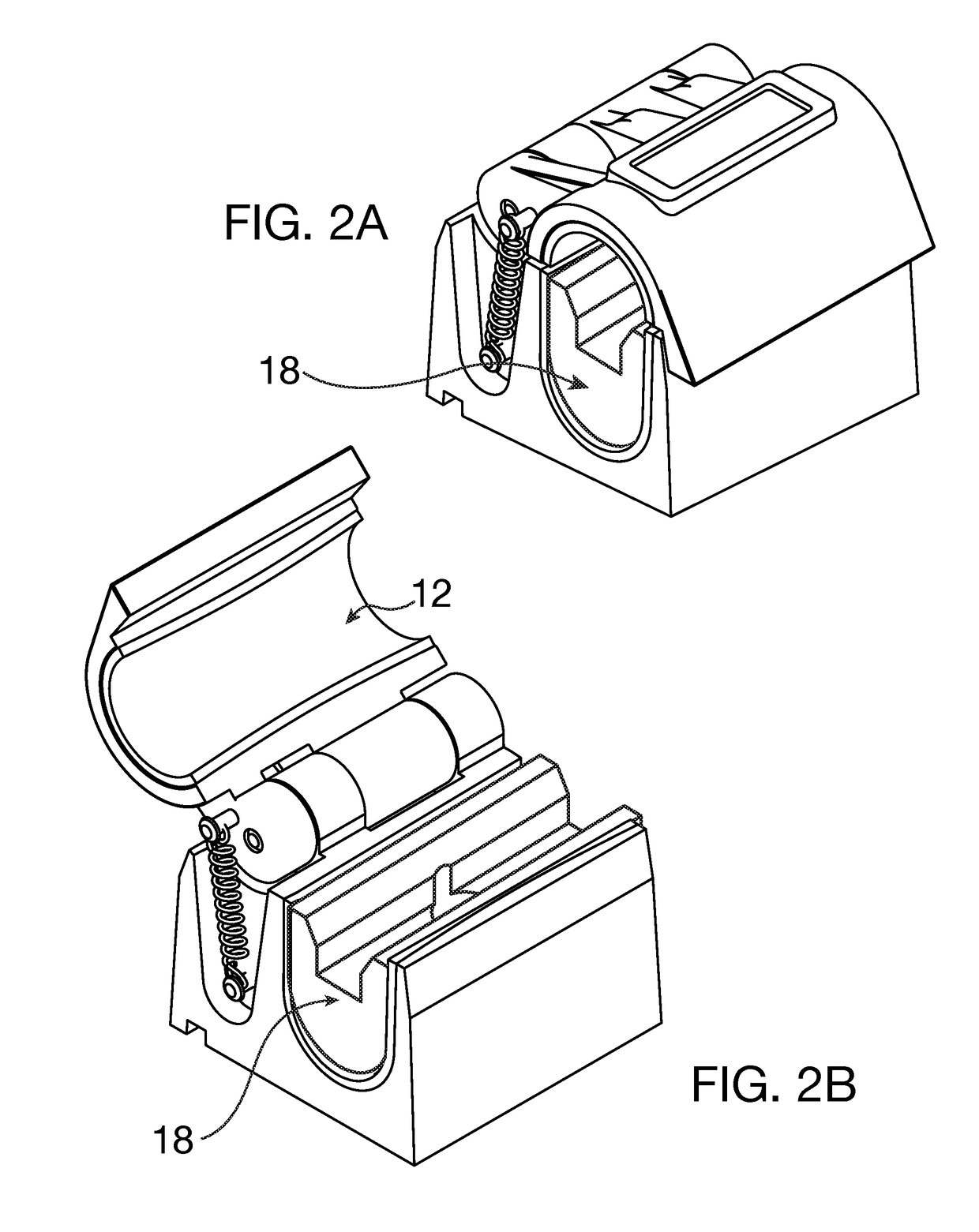

Clamshell gunlock with buffer insert

InactiveUS20170363379A1Easy to modifyPrevent rattlingSafety arrangementBuilding locksEngineeringShotgun pellet

An apparatus for adapting a clamshell-type of gunlock for a shotgun to lock a rifle. The clamshell gunlock can be easily modified using the apparatus without the need for basic changes to the gunlock. The apparatus has a single molded rubber part attached to the gunlock to hold the buffer tube of a rifle; providing a snug fitting constraint to hold the buffer tube of the rifle such that the rifle will not vibrate or move causing rattling sounds or damage to the rifle.

Owner:SANTA CRUZ GUNLOCKS

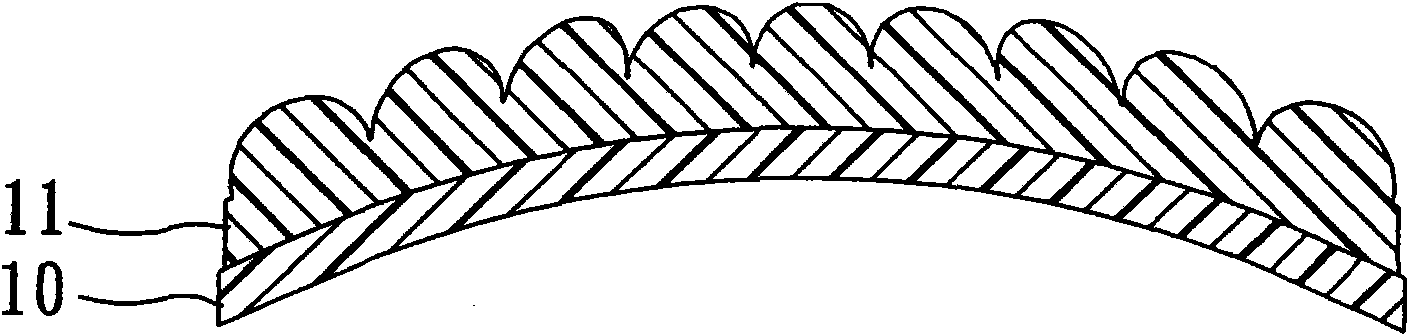

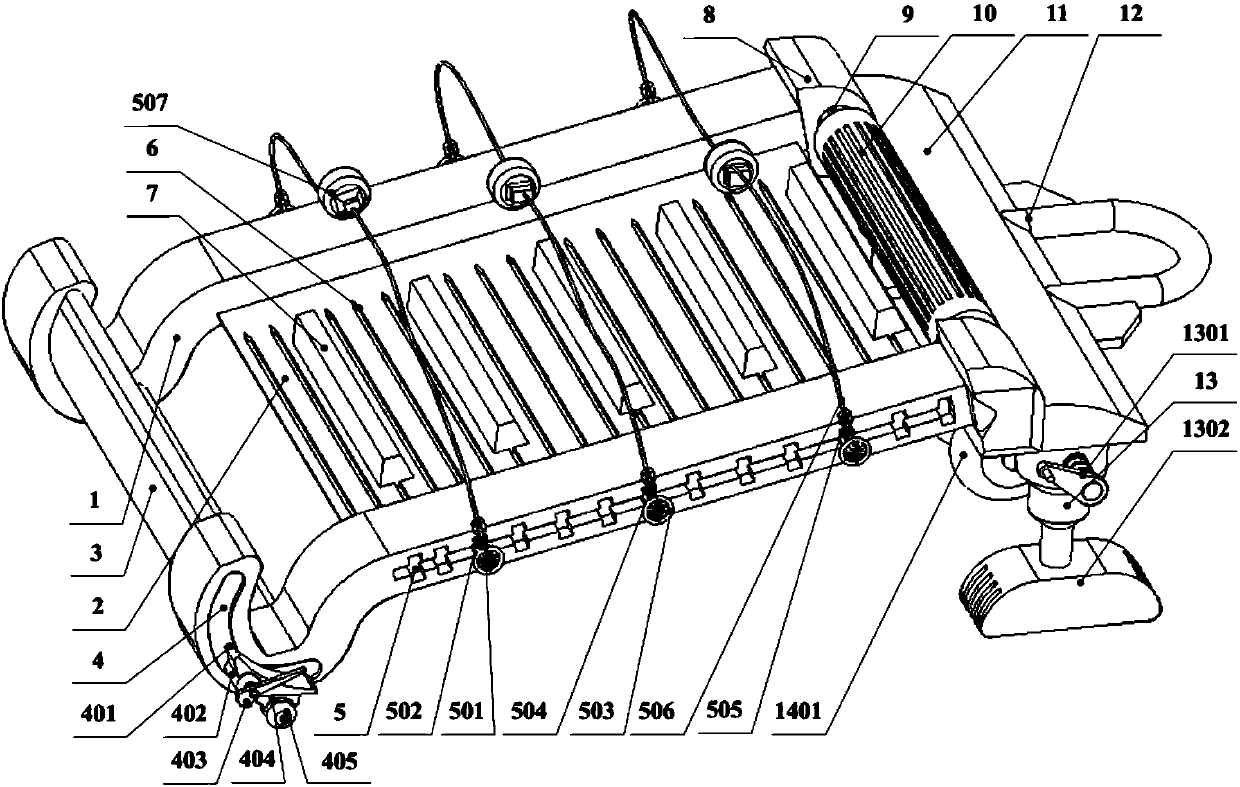

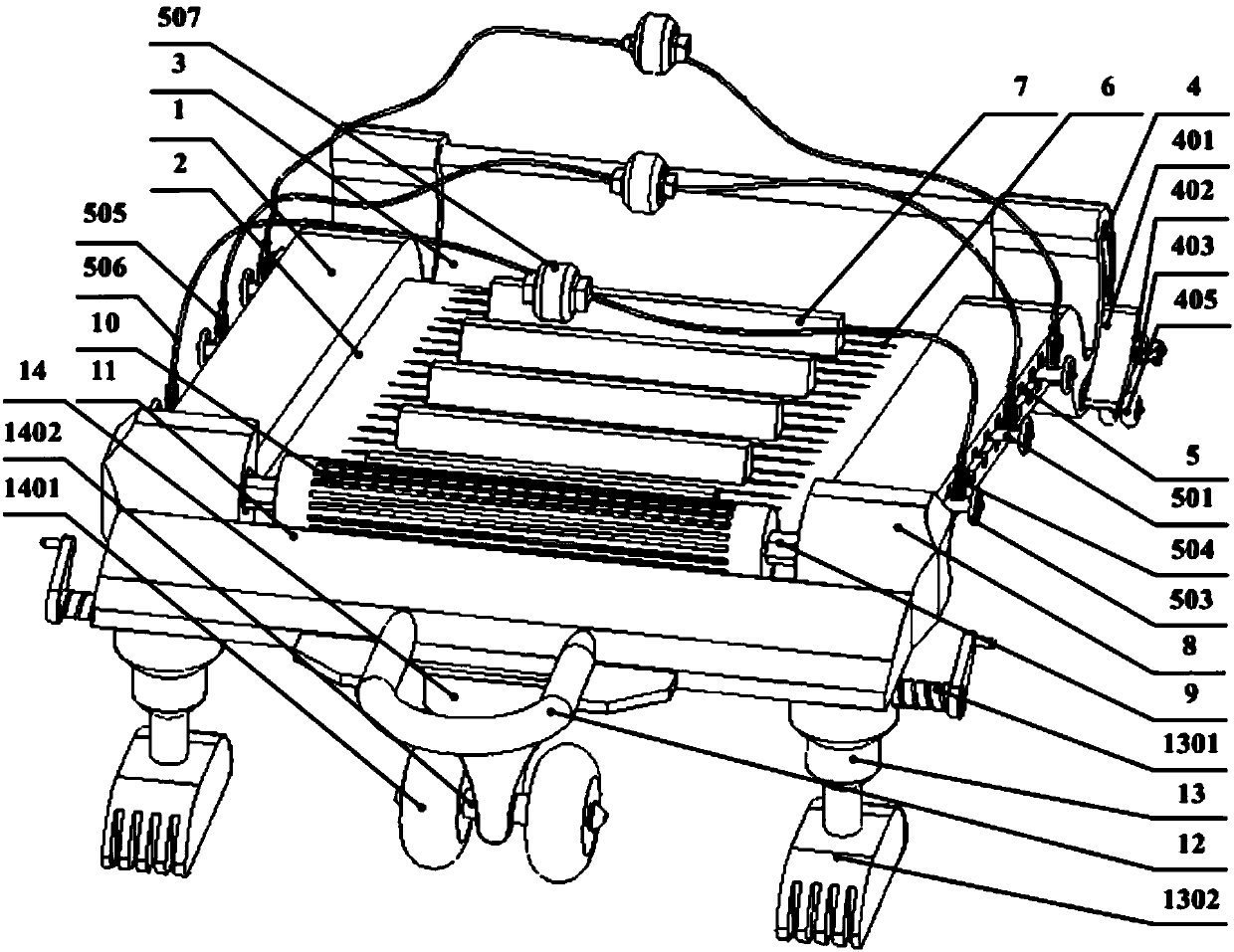

Sucking-upward and turning-downward cake demolding device

ActiveCN108991054AAvoid cosmetic damageArranged in an orderly mannerBaking ovenEngineeringMechanical engineering

Owner:广州浩胜食品机械有限公司

Dedicated towing device for contour plate

InactiveCN107792222AImprove handling efficiencyFit closelyVehicle with rollersVehicle fittings for liftingSubiculumRotary switch

The present invention relates to a drag tool, in particular to a drag tool for profiled plates, including a hook frame, a bottom plate, a baffle plate, a lower drag system, a locking system, a slot, a fixing table, a motor box, a rotating shaft, a transmission Shafts, connecting plates, hooks, lifting systems, and dragging systems; the lower support system includes track grooves, moon-shaped plates, guide rods, wrench switches, pulley blocks, and pulleys; the locking system includes positioning slots and positioning rods , engaging block, knob switch, fixed buckle, rope buckle, fixed rope, rope cover; the described lifting system includes a three-stage hydraulic shaft, a hand rocker, and a grab table; the described lifting system includes a fixed wheel group, a positioning Wheels and axles; the beneficial effects are: (1) It can meet the needs of vertical and horizontal handling operations at the same time, and can switch between the two, so that the handling efficiency is improved; (2) It can be adjusted for different sizes of profiled plate products The appearance of the device improves the fit between the product and the device; (3) It can reduce the difficulty and time-consuming of loading and unloading operations.

Owner:ANHUI SANBAO STEEL STRUCTURE

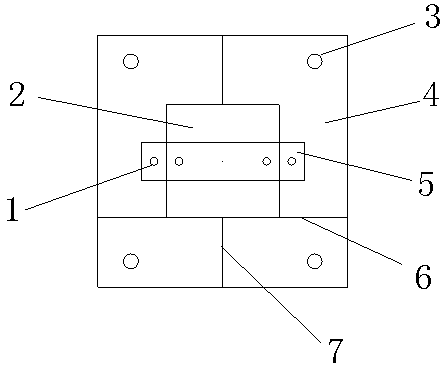

Easy-pulled bottle cap pull ring riveting edges gapless cutting and forming method

ActiveCN107952907AIncrease flatnessAvoid fit shockShaping toolsHollow articlesEngineeringScratch marks

The invention discloses an easy-pulled bottle cap pull ring riveting edges gapless cutting and molding method. A pull ring comprises an annular pull handle portion and a riveting portion connected with the inner side of the annular pull handle portion and used for riveting and being matched with a bottle cap. A specific molding method comprises the steps that a pull ring blank plate of which a contour is cut of the edges and molded is disposed between an upper die and a lower die of a stamping die, and the edges of the contour trimming edge of the pull ring blank plate are folded through declining and stamping of the lower die; the upper die cooperates with the lower die, a transition between a profiling inner depression of the annular pull handle portion, the lower end edge of the profiling inner depression of the riveting portion and an upper die main body is an arc-shaped chamfering transition, and the transition between a profiling protrusion of the annular pull handle portion, theupper end face edge of the profiling protrusion of the riveting portion and a lower die main body is an arc-shaped chamfering transition, so that when the upper die and the lower die cooperate with each other, the dies are not prone to be scraped and noticeable scratch marks are not prone to be left on the surface of the contour trimming edge of the pull ring blank plate.

Owner:YANTAI YILADE PACKAGING TECH CO LTD

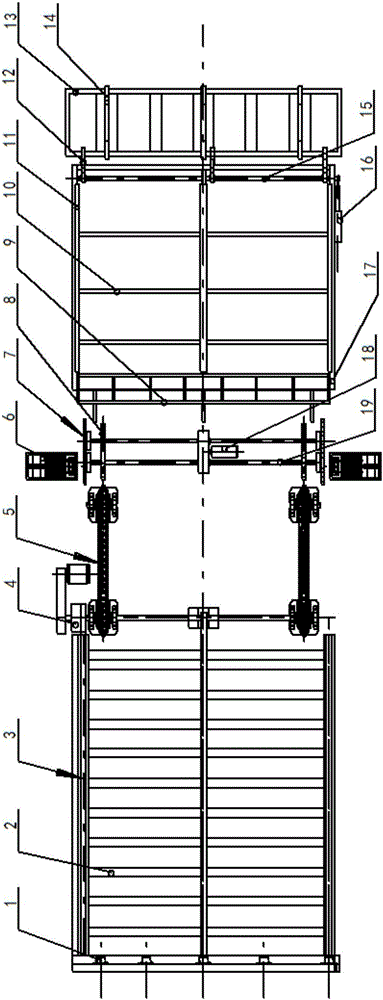

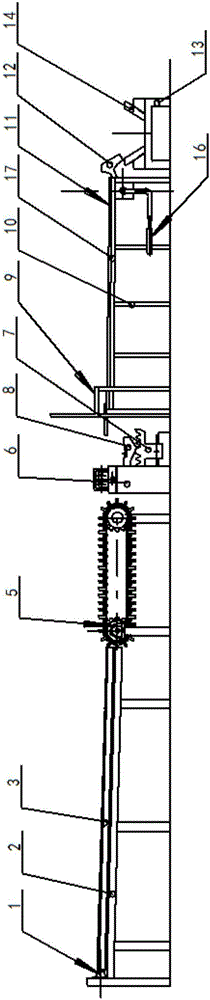

Galvanized steel pipe blue band identification packer

InactiveCN106697403AImprove the level of automated productionReasonable and smooth process structurePackagingEngineeringSteel tube

The invention relates to a galvanized steel pipe blue band identification packer. The galvanized steel pipe blue band identification packer comprises a connecting frame, chain transmission devices, a conveyor, blue application machines, a conveying frame and a packing frame. The connecting frame is of an inclined square frame structure; the two symmetrical chain transmission devices are connected to the tail end of the connecting frame and convey galvanized steel pipes onto the conveyor in a chain transmission mode; the blue application machines are arranged on the two sides of the conveyor in a mirror symmetry mode correspondingly; the galvanized steel pipes obtained after blue application are ferried onto the conveying frame through the conveyor, and the conveying frame is of an inclined square frame structure; and the packing frame is arranged at the tail end of the conveying frame, and the galvanized steel pipes are packed on the packing frame. The whole process is structurally reasonable and smooth, automatic operation is achieved, the production efficiency is high, and the automatic production level of the galvanized steel pipes is greatly improved.

Owner:天津市力拓钢制品有限公司

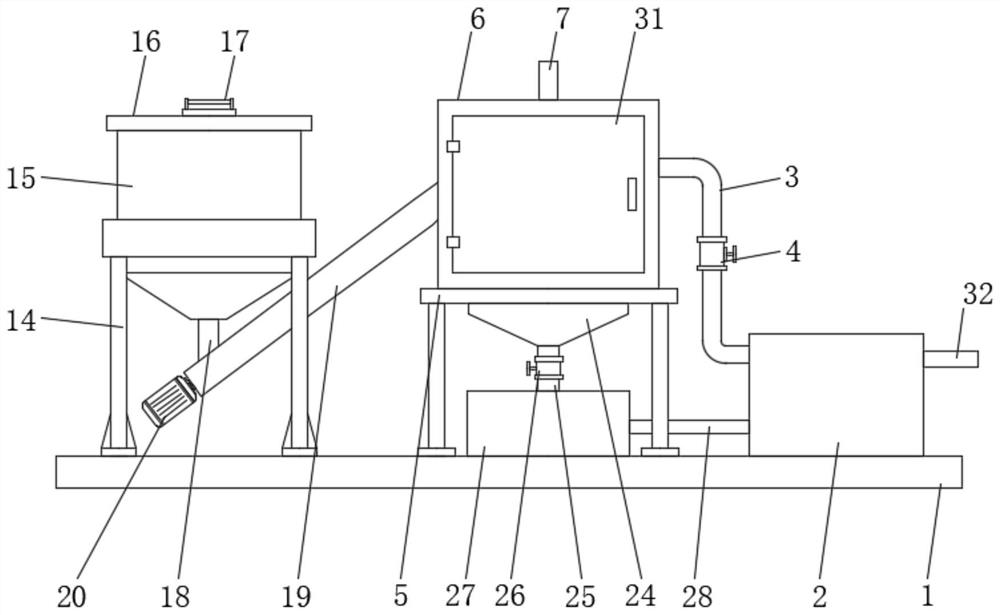

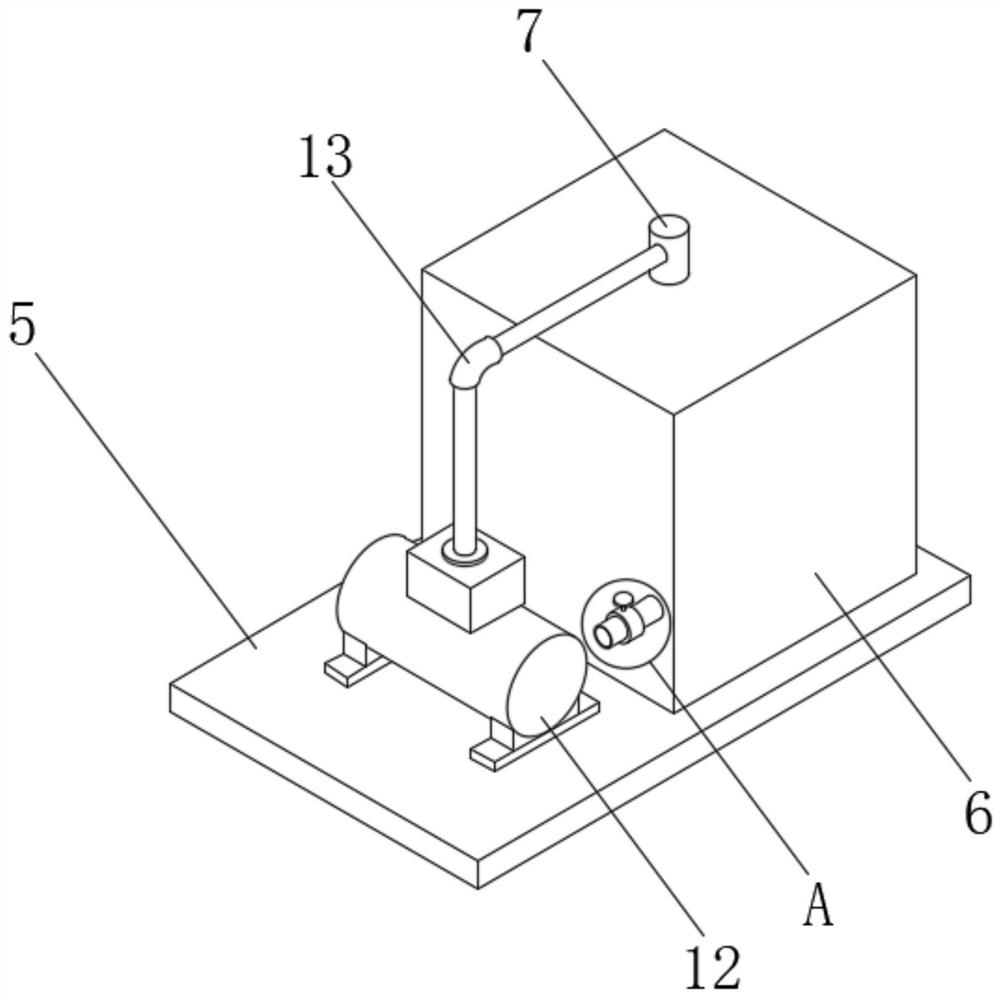

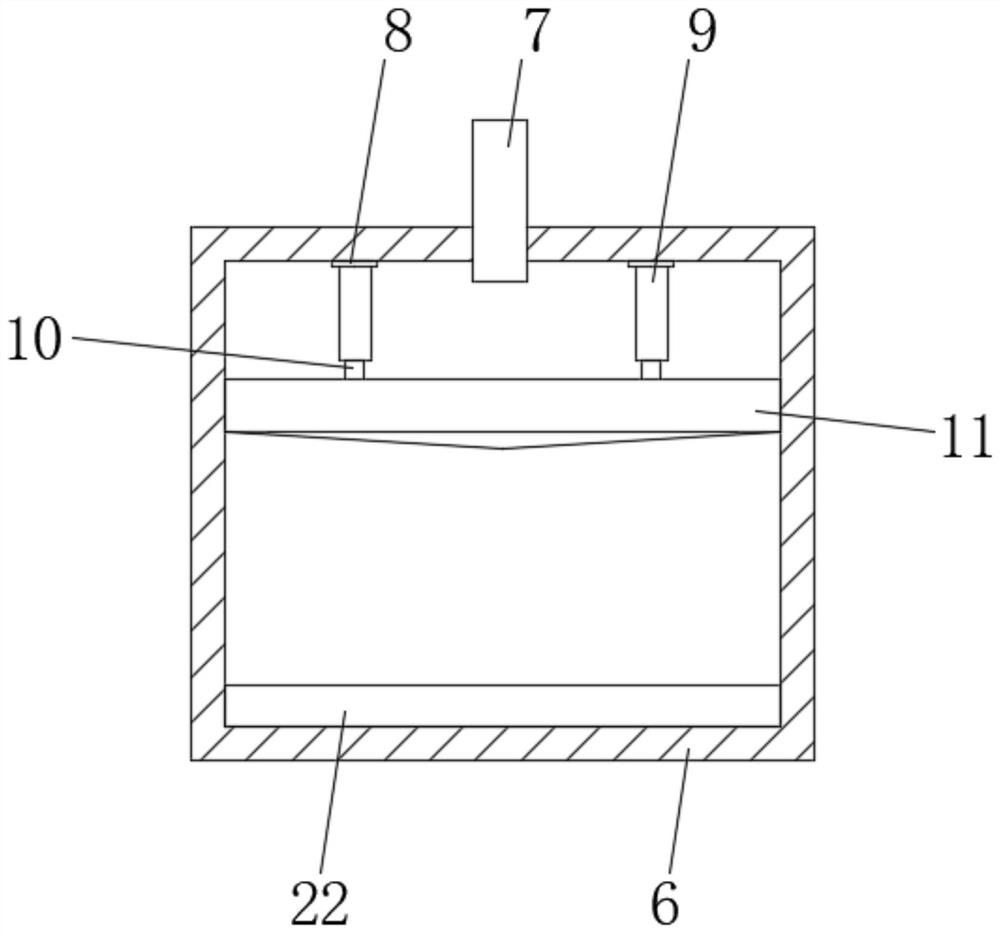

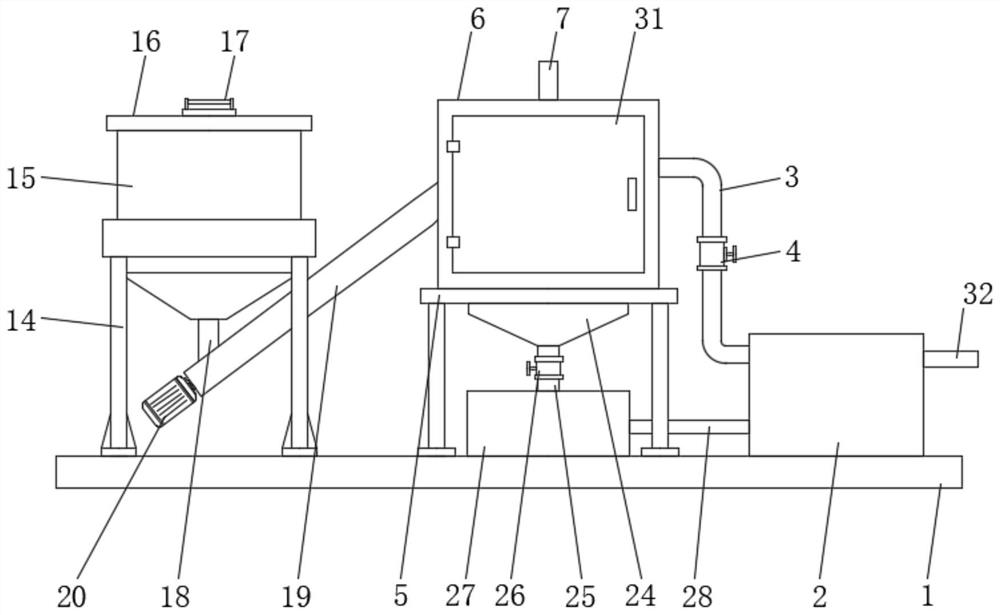

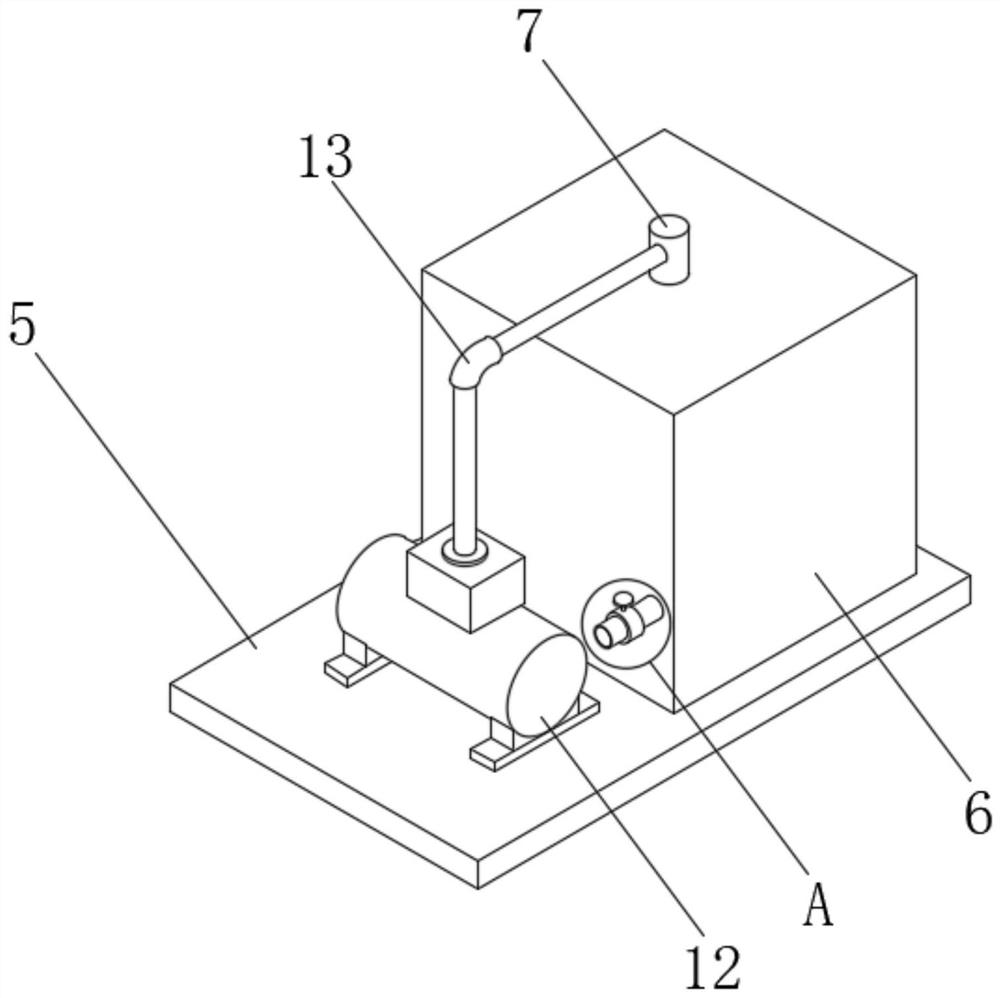

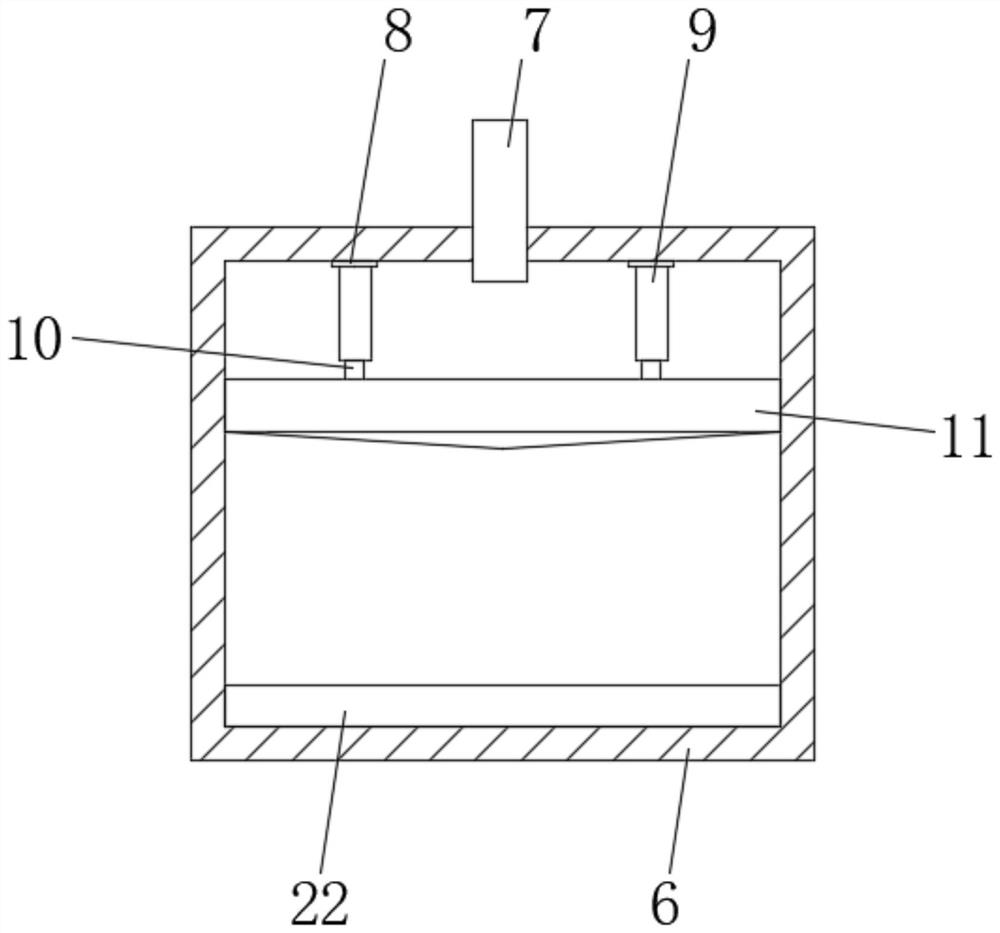

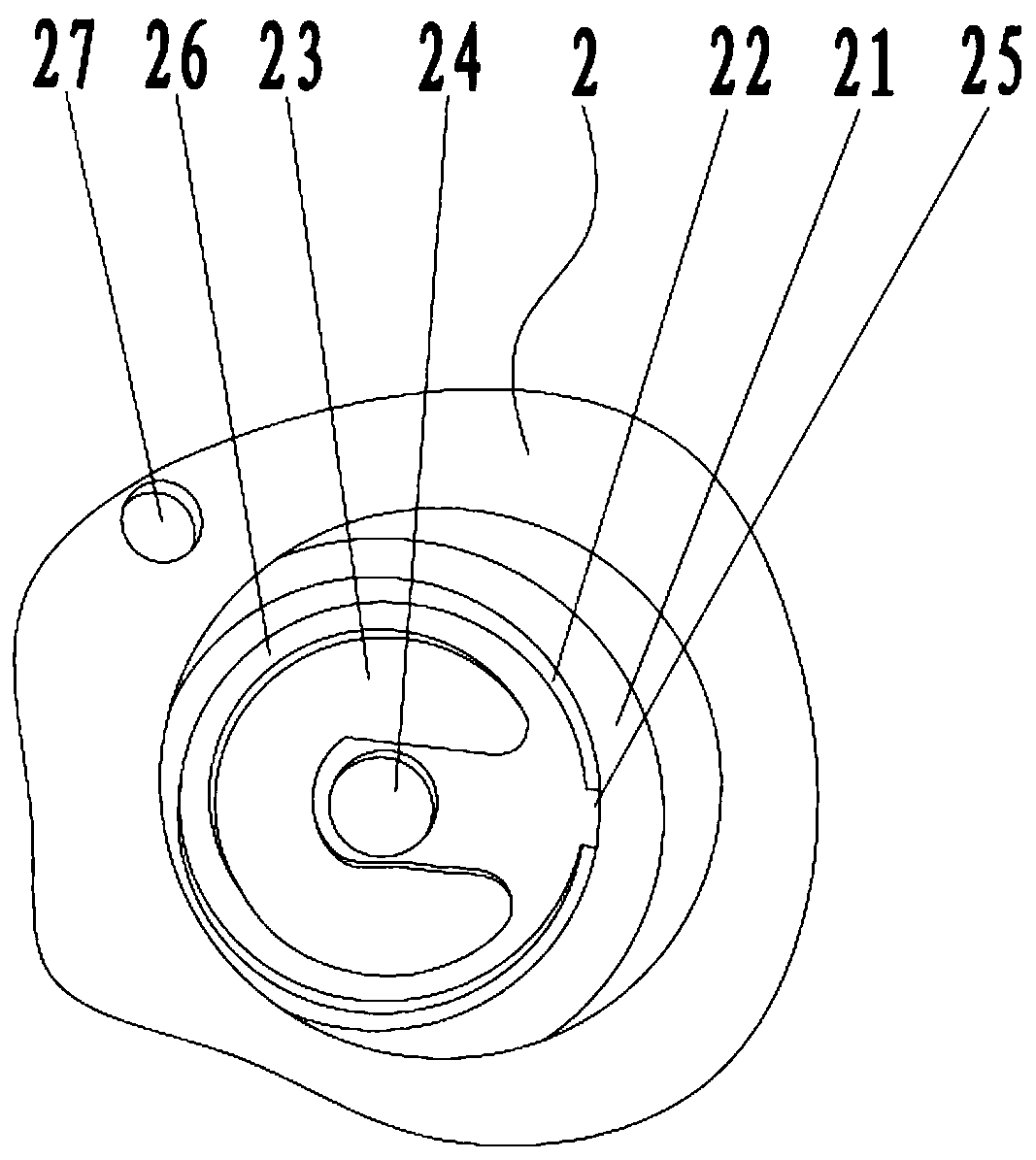

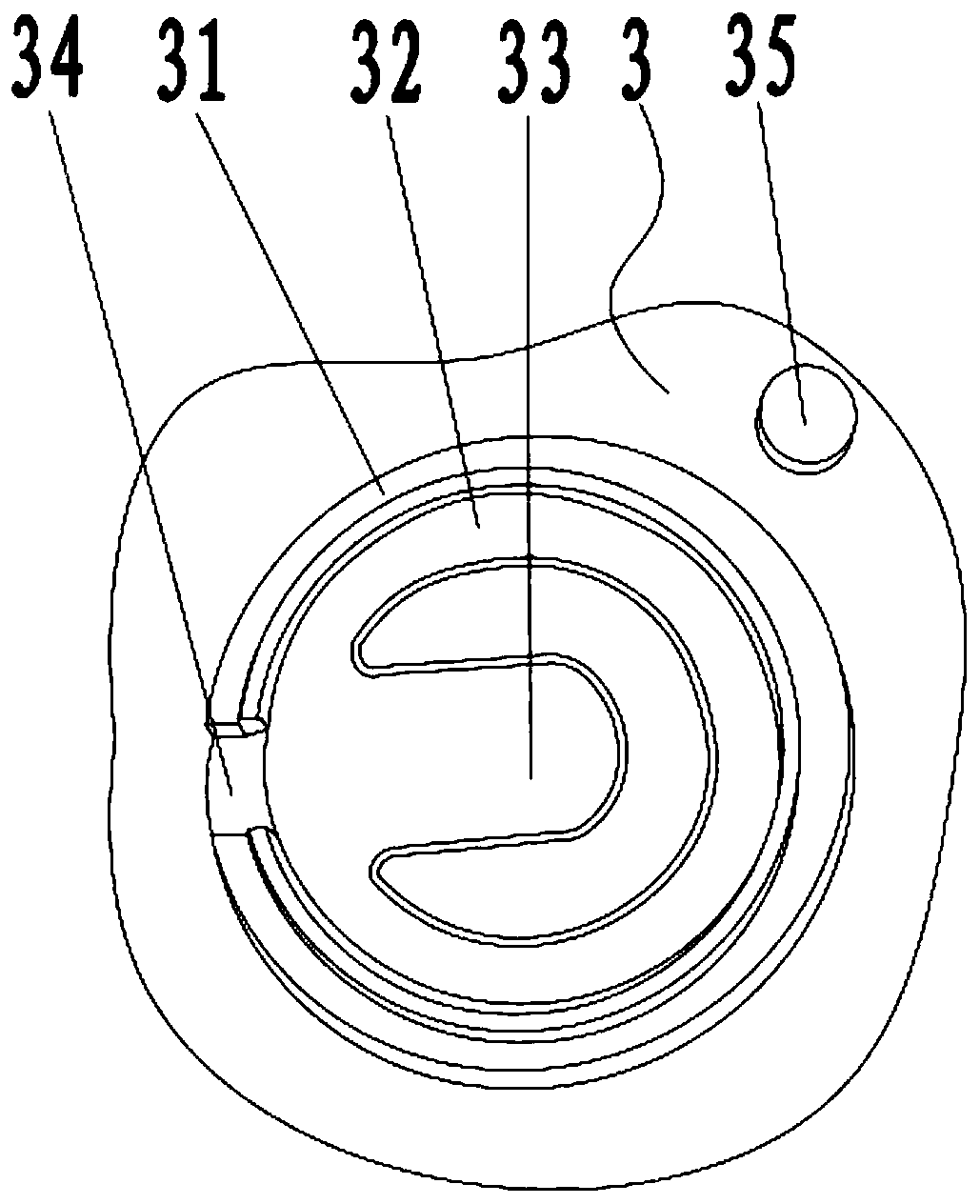

Granulated feed grease spraying machine

ActiveCN112450470AAvoid appearance damageIntegrity guaranteedFeeding-stuffLiquid spraying apparatusOil and greaseVegetable oil

The invention discloses a pellet feed grease spraying machine in the field of feed production. The device comprises a base, an atomizer is fixedly connected to the upper surface of the base, and a connecting pipe is fixedly connected to one side of the atomizer. A one-way valve is arranged on the outer surface of the connecting pipe, a supporting frame is fixedly connected to the top of the base,and a spraying box is fixedly connected to the top of the supporting frame. The top of the spraying box is fixedly connected with an air inlet pipe, and the inner top wall of the spraying box is fixedly connected with a mounting base. A sleeve is fixedly connected to the bottom of the mounting base, and a moving rod is inserted into the inner wall of the sleeve. A piston is fixedly connected to the bottom of the moving rod, an air pump is fixedly connected to the top of the supporting frame, and a connecting air pipe is fixedly connected to the output end of the air pump. According to the invention, through the arrangement of the atomizer, the connecting pipe, the one-way valve, the spraying box, the air inlet pipe, the sleeve, the moving rod, the piston, the air pump and the connecting air pipe, animal and vegetable oil is injected into the granulated feed, meanwhile, the complete appearance of the feed is ensured, and the appearance damage in the grease spraying process is avoided.

Owner:重庆市蜀达饲料有限公司

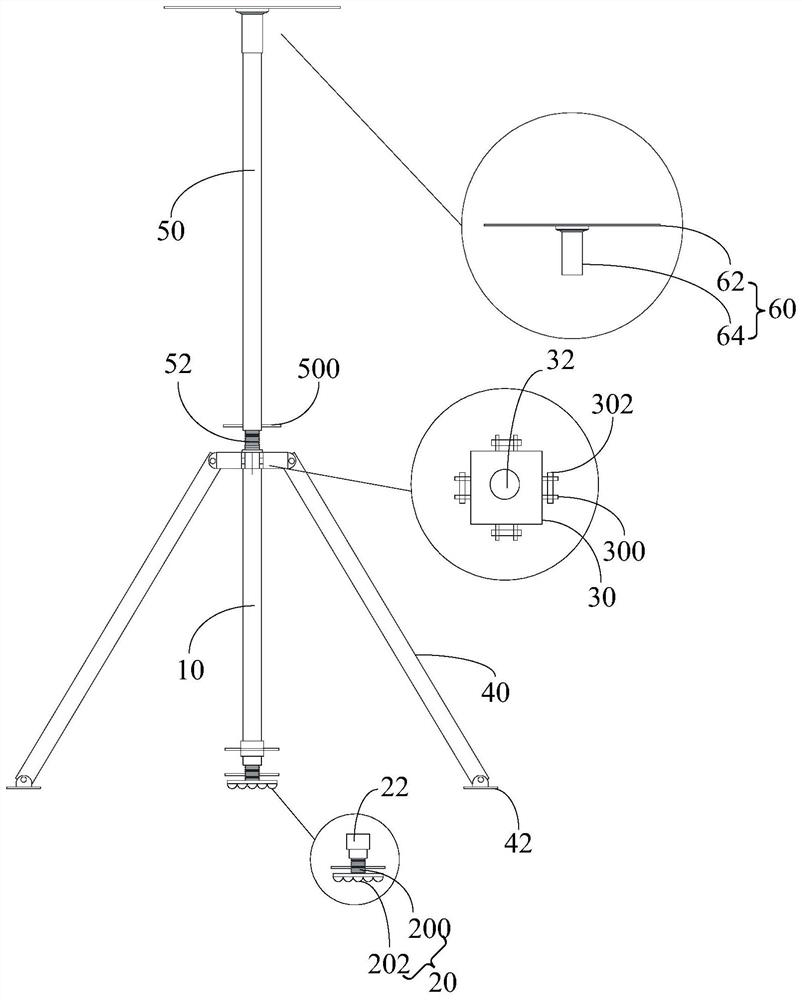

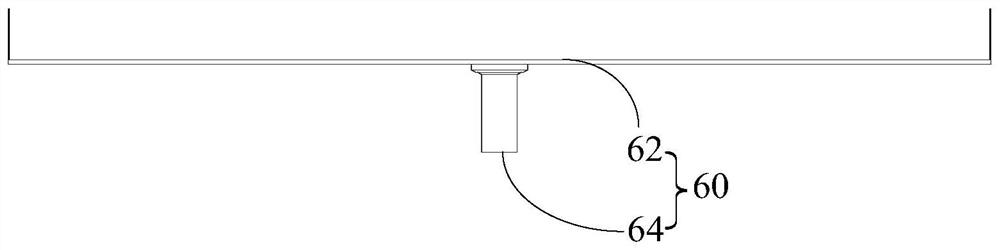

Supporting device for hoisting precast slabs and application and construction method thereof

PendingCN112320589ASimple structureSimple application of construction method stepsLoad-engaging elementsArchitectural engineeringStructural engineering

The invention relates to a supporting device for hoisting precast slabs and an application and construction method thereof. The supporting device for hoisting the prefabricated slabs comprises a firstsupporting rod, a rolling part, a connecting plate, a plurality of inclined supporting rods and a second supporting rod. The first supporting rod comprises a first end and a second end which are oppositely arranged, and the rolling part is connected with the first end through a first lifting part. The connecting plate is arranged at the second end and is connected with the second end. The multiple inclined supporting rods are arranged along the perimeter of the connecting plate and rotationally connected with the connecting plate. One end of the second supporting rod is connected with the first supporting rod through a second lifting part, and the other end is provided with a supporting part. According to the supporting device for hoisting the prefabricated slabs, the SP slabs can horizontally slide to the preset positions, violent impact or friction between the SP slabs and in-place SP slabs is avoided, appearance damage of the SP slabs is avoided, and the fitting degree of hoistingconstruction of all the SP slabs is guaranteed. In addition, the application and construction method of the supporting device for hoisting the prefabricated slabs is simple in step, easy to operate and suitable for application and popularization.

Owner:SHANGHAI CONSTR NO 5 GRP CO LTD

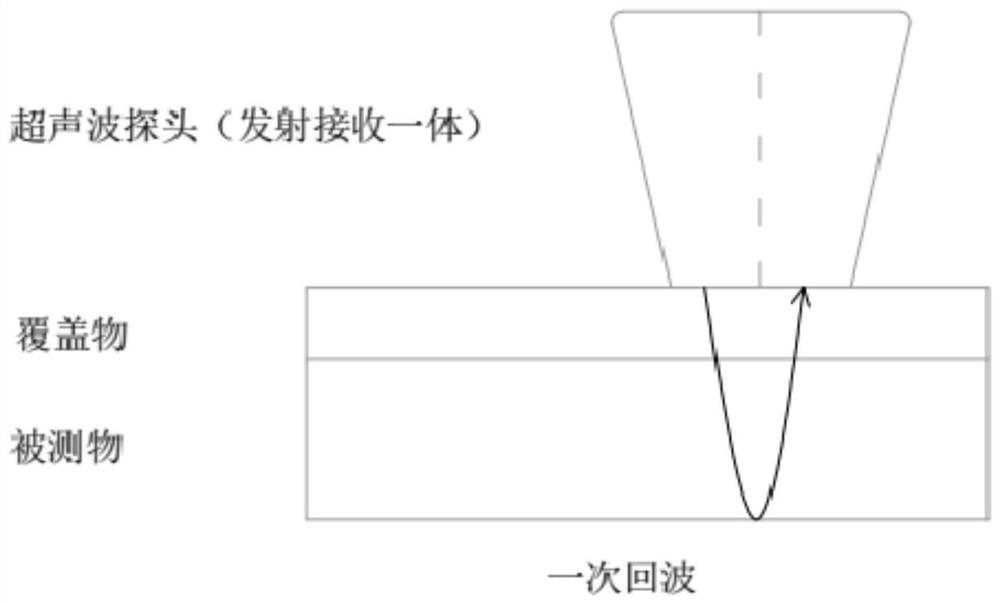

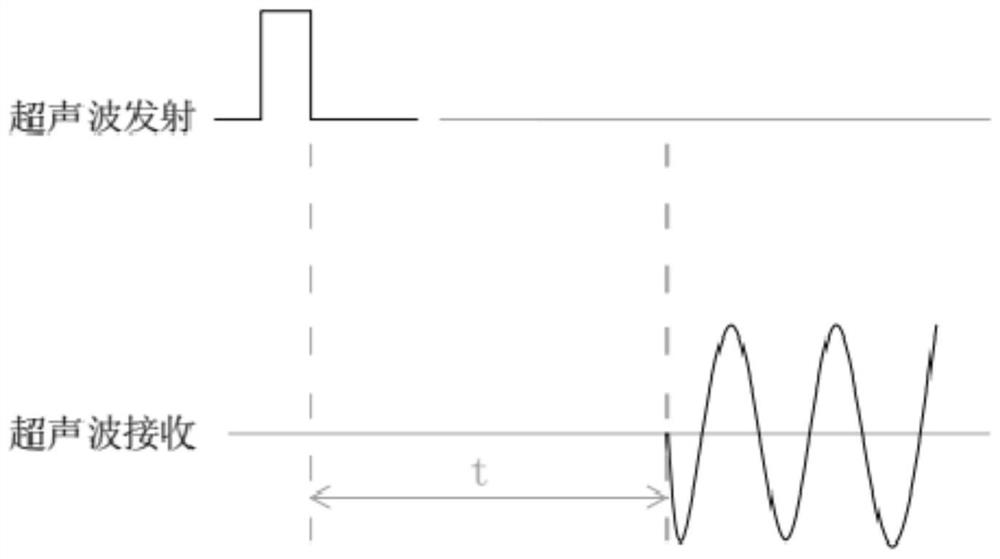

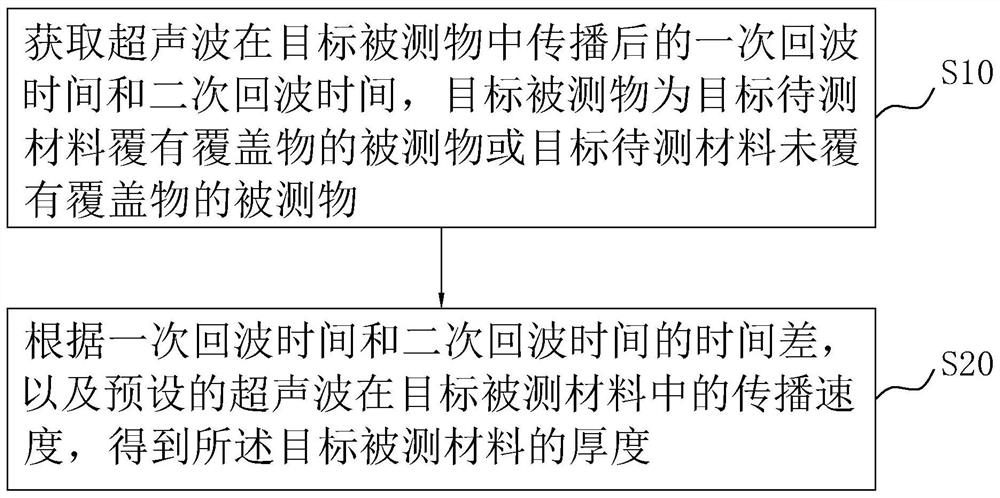

Object thickness measuring method, device and system based on ultrasonic waves, equipment and medium

PendingCN112433217AAvoid cosmetic damageEliminates the tedious process of removing mulchAcoustic wave reradiationEngineeringAcoustics

The invention relates to an object thickness measuring method, device and system based on ultrasonic waves, equipment and a medium. The method comprises the following steps: obtaining the primary echotime and secondary echo time of the ultrasonic waves after the ultrasonic waves are transmitted in a target measured object, wherein the target measured object is a measured object of which the target measured material is covered with a covering object or a measured object of which the target measured material is not covered with a covering object; and determining the thickness of the target measured material according to the time difference between the primary echo time and the secondary echo time and the preset propagation speed of the ultrasonic wave in the target measured material. The coating influence can be eliminated, the thickness of an object can be accurately measured, and nondestructive testing is truly achieved.

Owner:广州市东儒电子科技有限公司

A granular feed oil spraying machine

ActiveCN112450470BAvoid cosmetic damageIntegrity guaranteedFeeding-stuffLiquid spraying apparatusOil and greaseVegetable oil

Owner:重庆市蜀达饲料有限公司

No-gap cutting molding method for riveting edge of easy-pull bottle cap

ActiveCN107952907BExtend your lifeImprove appearance qualityShaping toolsHollow articlesEngineeringBottle cap

The invention discloses an easy-pulled bottle cap pull ring riveting edges gapless cutting and molding method. A pull ring comprises an annular pull handle portion and a riveting portion connected with the inner side of the annular pull handle portion and used for riveting and being matched with a bottle cap. A specific molding method comprises the steps that a pull ring blank plate of which a contour is cut of the edges and molded is disposed between an upper die and a lower die of a stamping die, and the edges of the contour trimming edge of the pull ring blank plate are folded through declining and stamping of the lower die; the upper die cooperates with the lower die, a transition between a profiling inner depression of the annular pull handle portion, the lower end edge of the profiling inner depression of the riveting portion and an upper die main body is an arc-shaped chamfering transition, and the transition between a profiling protrusion of the annular pull handle portion, theupper end face edge of the profiling protrusion of the riveting portion and a lower die main body is an arc-shaped chamfering transition, so that when the upper die and the lower die cooperate with each other, the dies are not prone to be scraped and noticeable scratch marks are not prone to be left on the surface of the contour trimming edge of the pull ring blank plate.

Owner:YANTAI YILADE PACKAGING TECH CO LTD

Air conditioner and cleaner extension nozzle using same

Owner:DAIKIN IND LTD

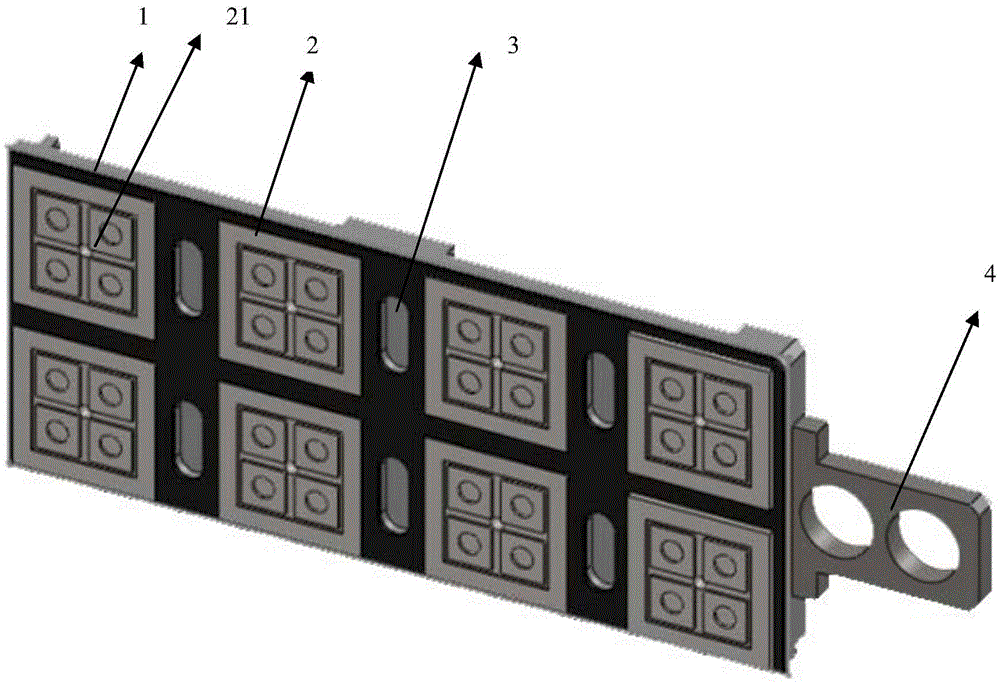

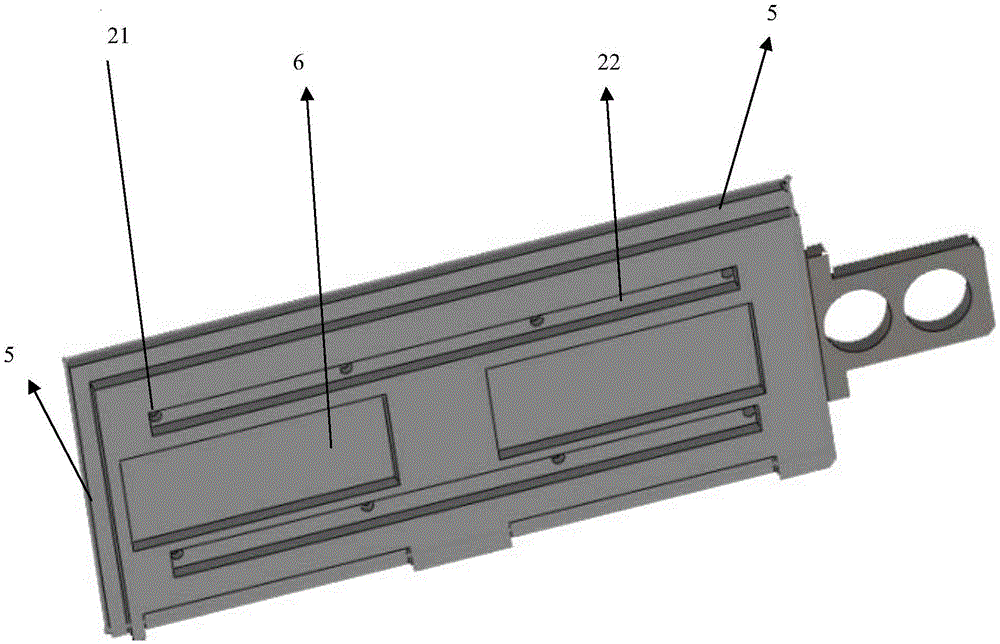

A visual vacuum carrier

ActiveCN104308862BAvoid cosmetic damageAvoid material lossManipulatorSuction cupsElectrical and Electronics engineering

A visual vacuum carrier is characterized a carrier plate serves as a body, a plurality of metal weights arranged at equal intervals are fixed to the front of the carrier plate, the center of each metal weight is provided with a vacuum hole penetrating the carrier plate, the metal weights are used for attracting a part to be carried, the surfaces of the metal weights match with the bottom of the part to be carried, the four edges of the back of the carrier plate are cut edges, the carrier plate is provided with a plurality of elongated vacuum slots in the horizontal direction, each elongated vacuum slot accommodates one vacuum hole arranged horizontally, a bottom tray is tightly connected with the back of the carrier plate through the cut edges, and the face, in contact with the elongated vacuum slots, of the bottom tray is provided with vacuum entries. The visual vacuum carrier is good in fixing effect, high in precision and effective in preventing the part to be carried, from appearance loss and material loss.

Owner:豪威半导体(太仓)有限公司

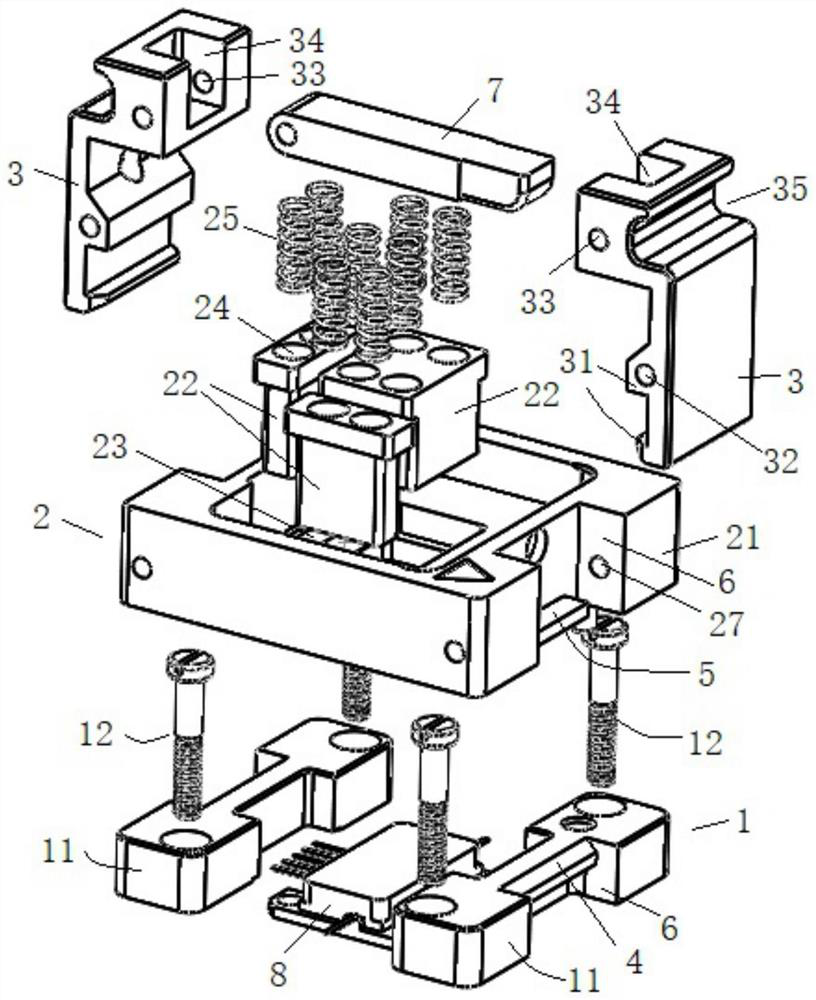

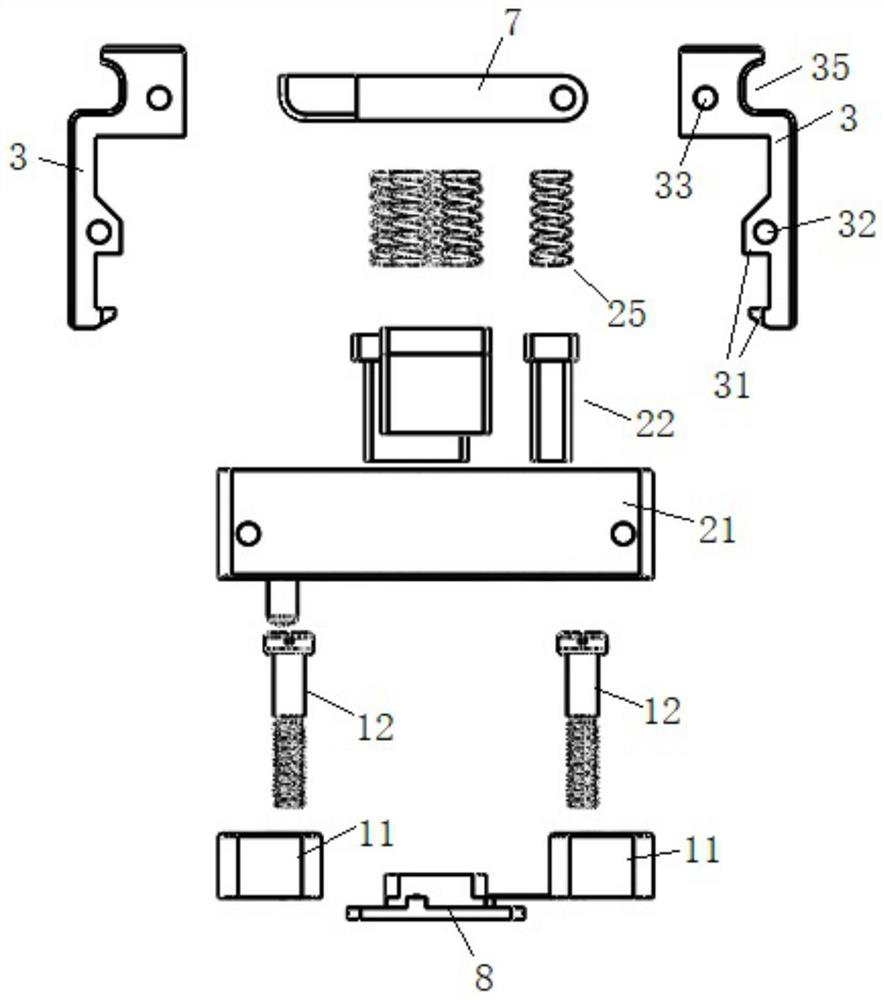

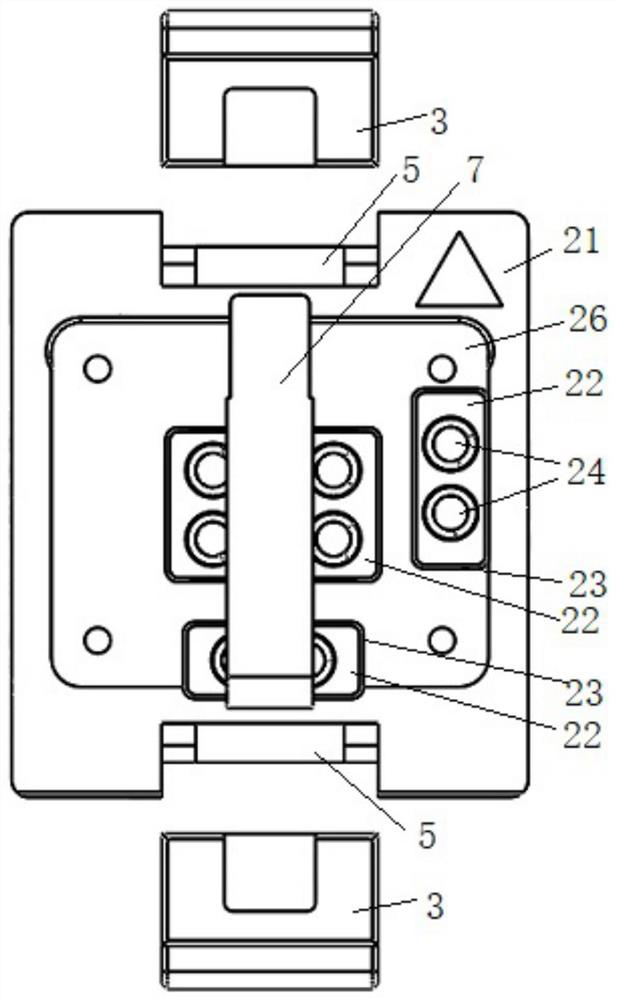

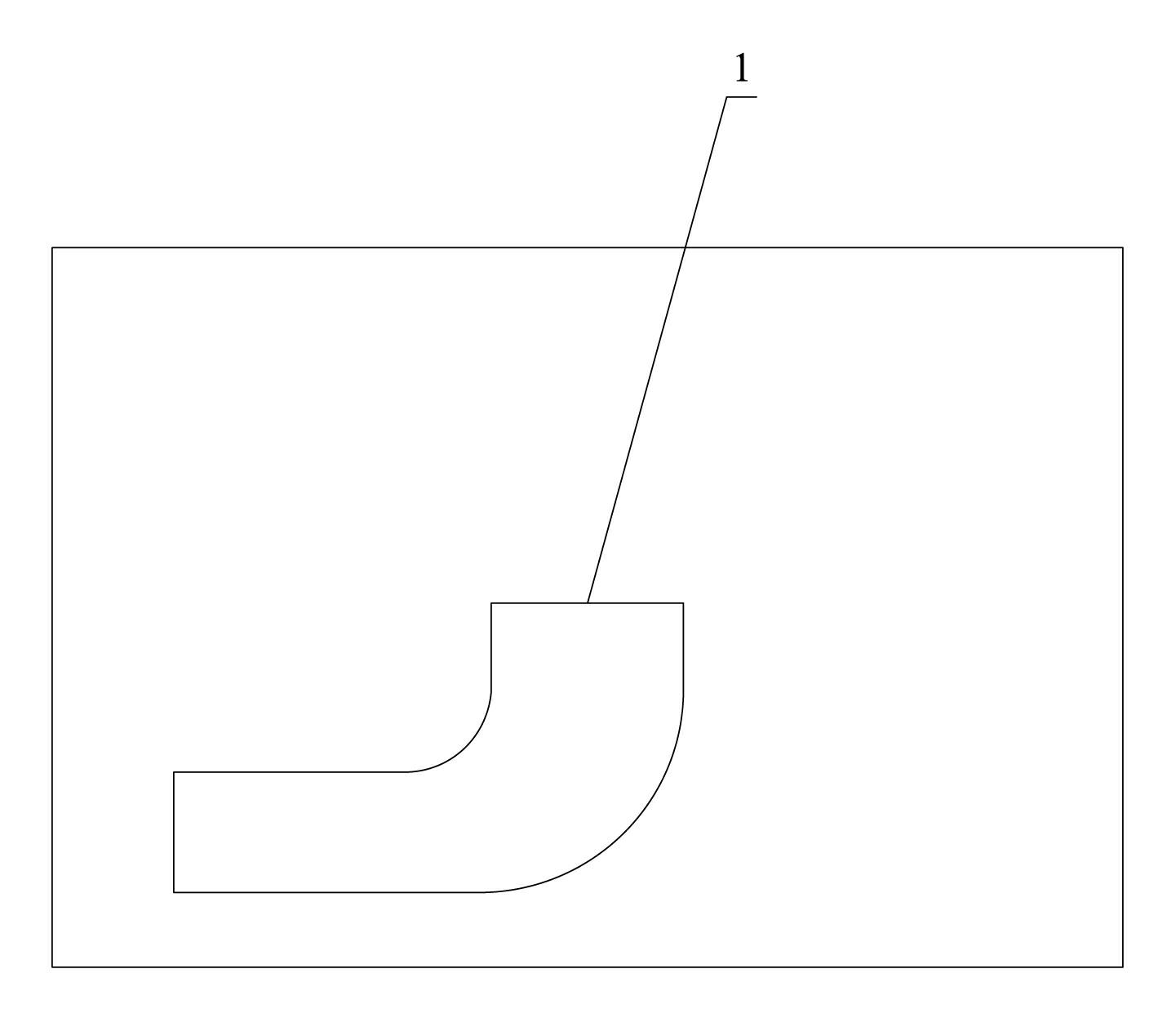

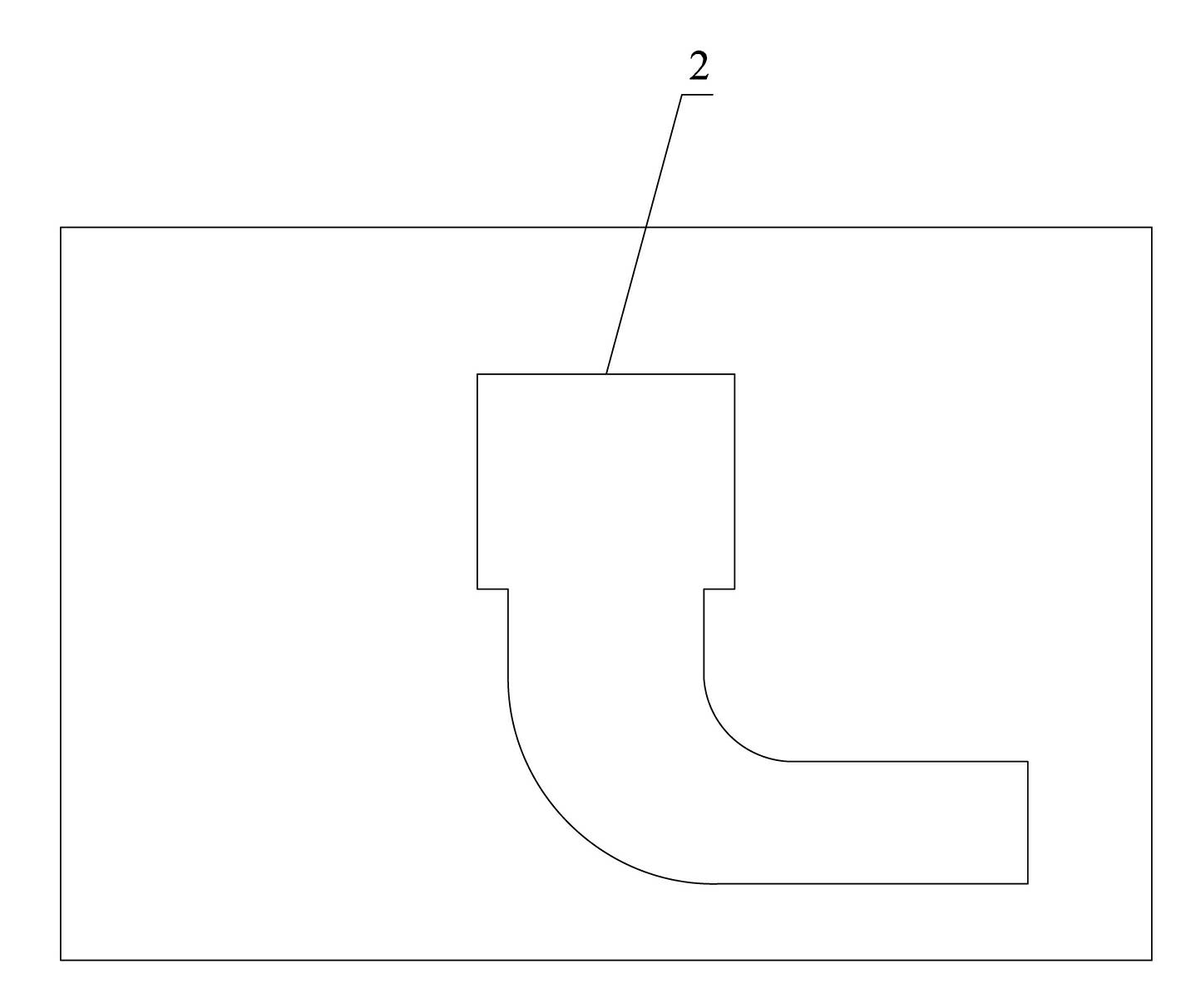

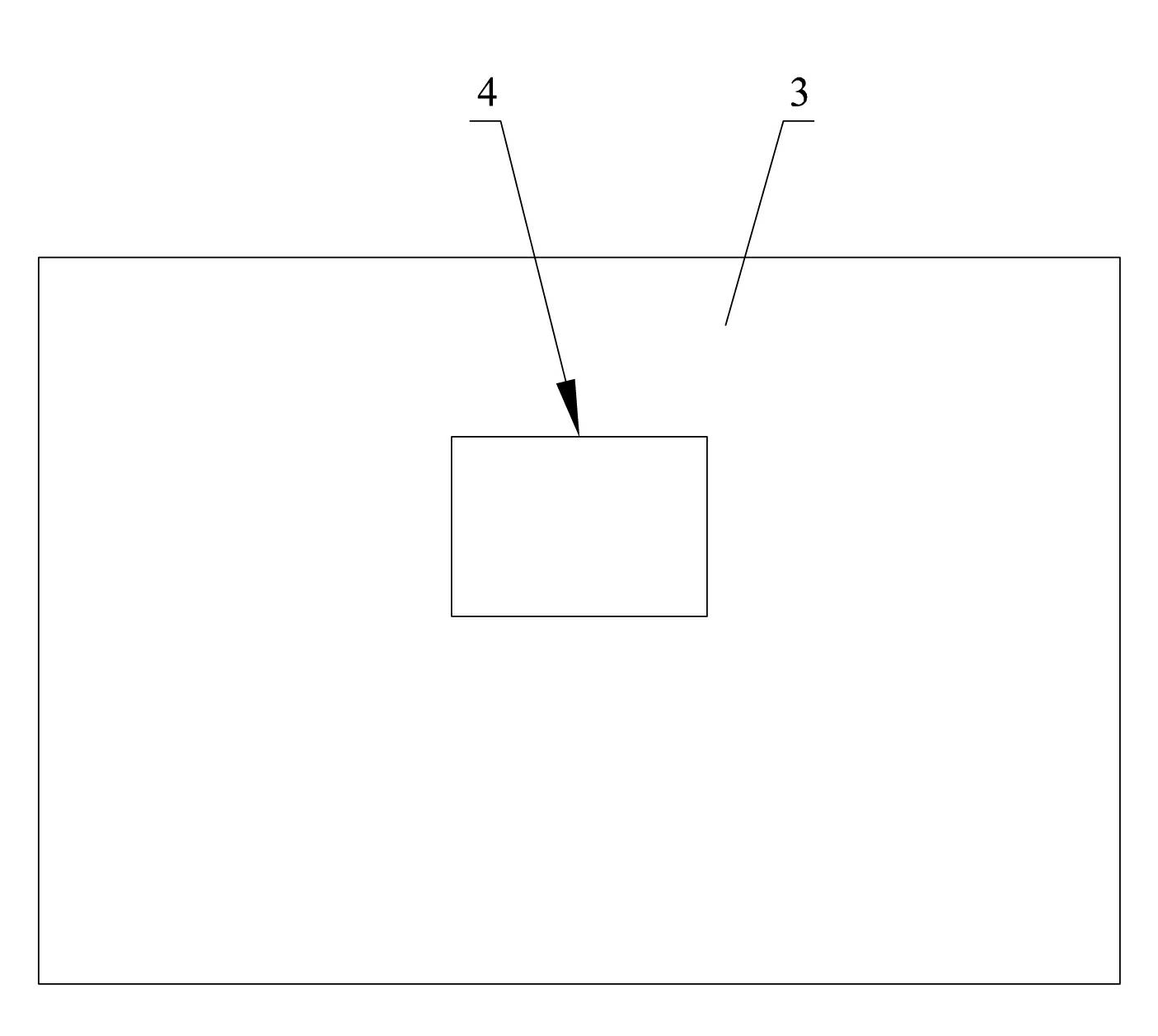

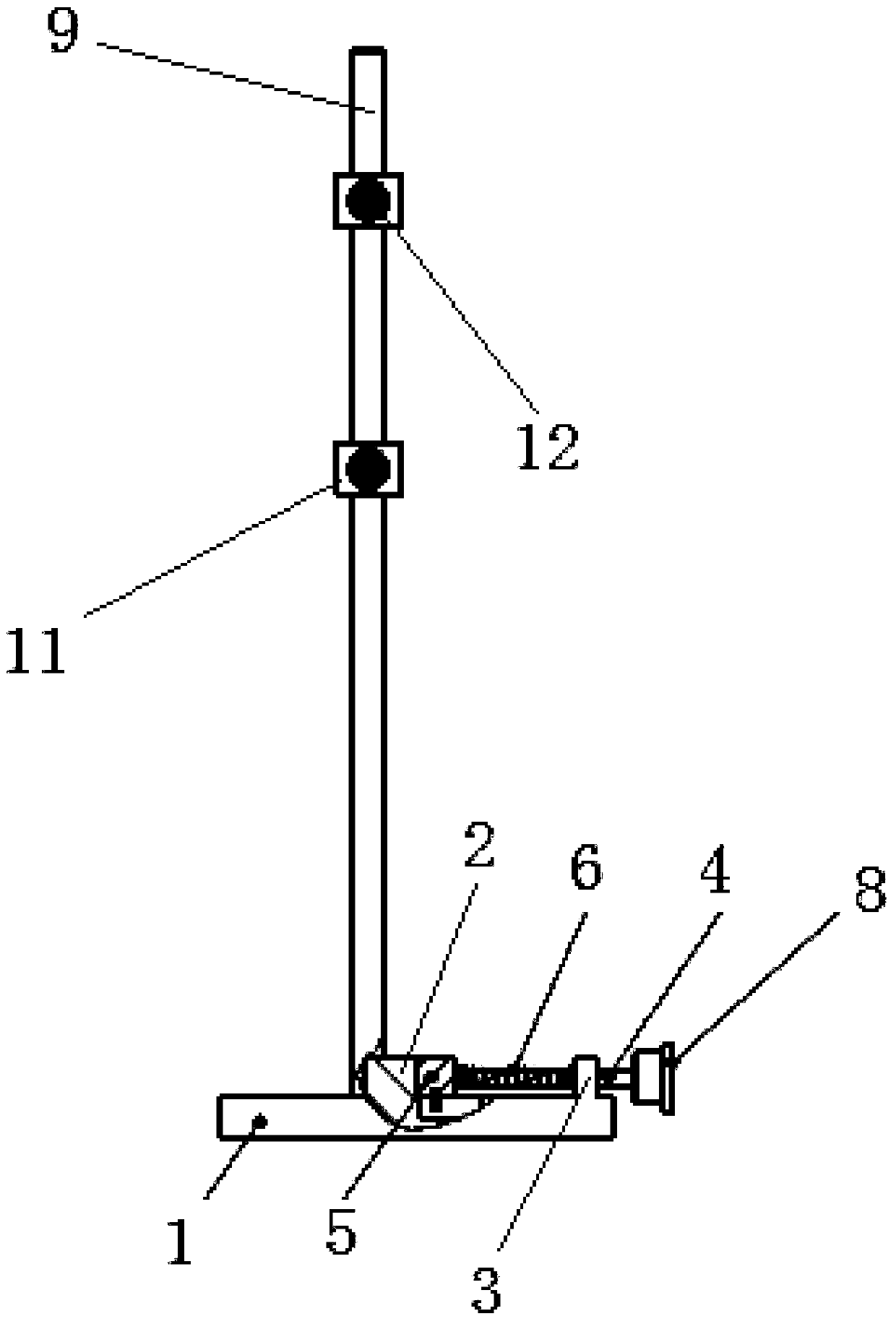

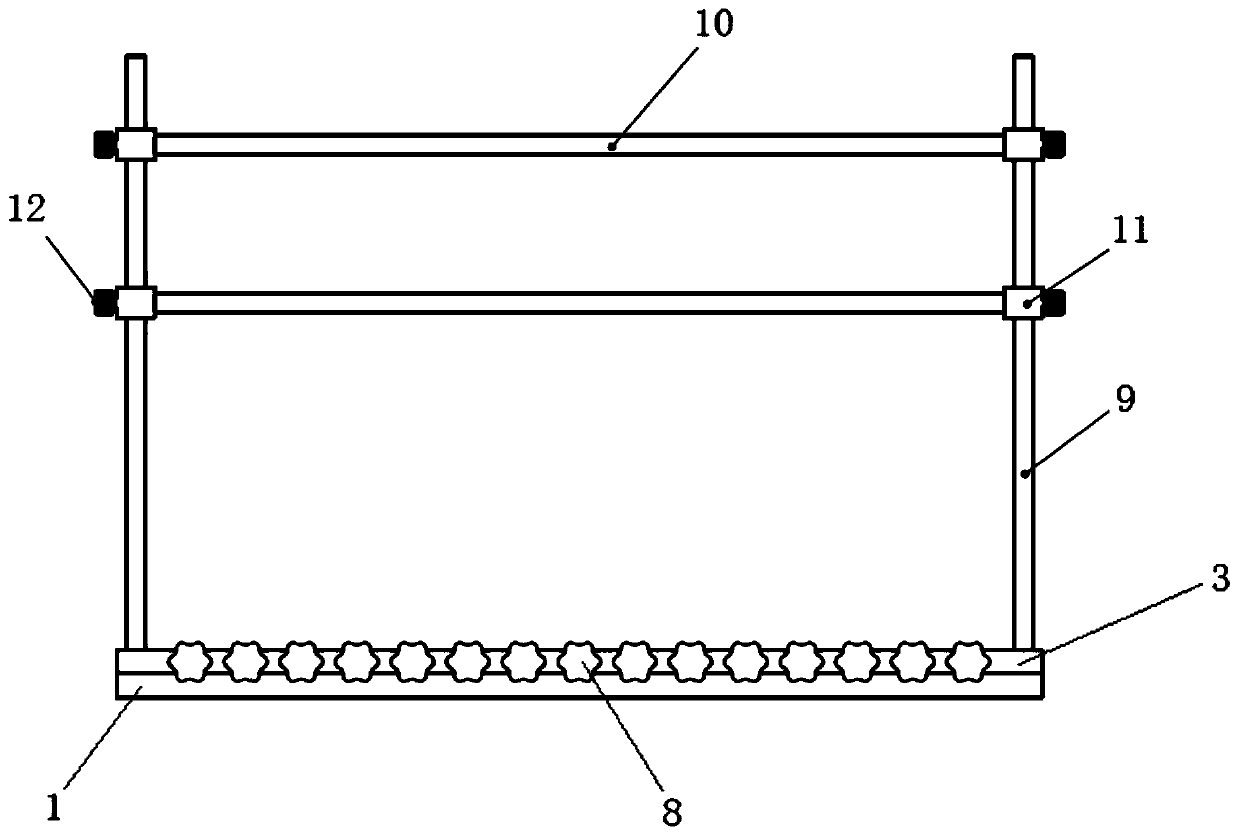

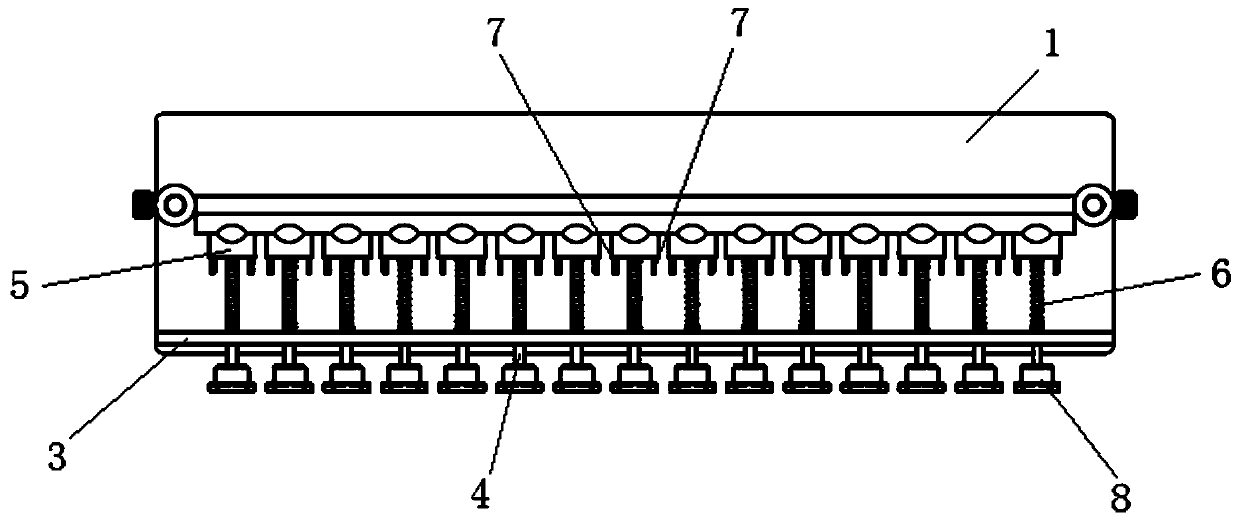

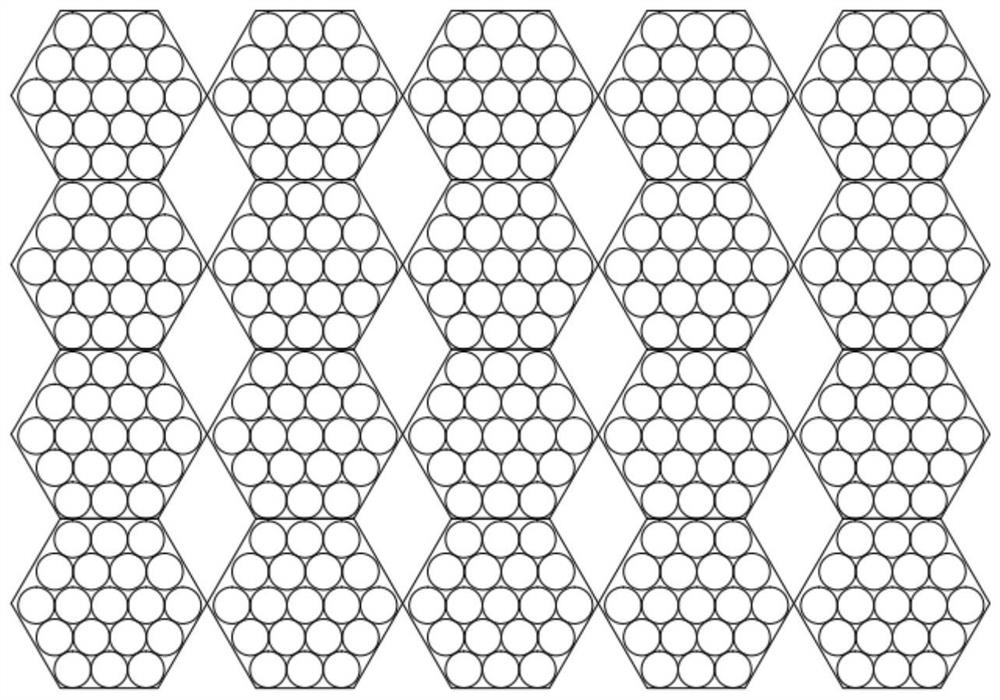

Nail-free clamp for electrical aging test

PendingCN114310711AEasy to connectSolve technical problems that have a large workload and require a lot of laborWork holdersDevice materialElectrical aging

The invention provides a nail-free clamp for an electrical aging test, and belongs to the technical field of aging tests of discrete semiconductor devices, the nail-free clamp comprises a fixing part, a pressing block assembly and two groups of buckles, the pressing block assembly is clamped and fixed at the upper end of the fixing part by using the two groups of buckles, and meanwhile, a to-be-tested product is fixed at the upper end of an aging plate. The connection mode of the two groups of buckles, the fixing part and the pressing block assembly is simple, the to-be-tested product is fixed without using screws and pressing strips, and the fixing operation efficiency of the product is high. The nail-free clamp for the electrical aging test solves the technical problems that in the aging test in the prior art, the mode of fastening a product to be tested is large in workload and large in occupied labor force, and has the technical effects that the universality is high, appearance damage is avoided, the workload and labor force are reduced, and the operation efficiency is improved by about 3.5 times.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

Manufacturing process of soft-type printed circuit board with different appearances at upper and lower layers

ActiveCN102186315ALow costReduced assembly spaceMultilayer circuit manufactureEngineeringPrinted circuit board

The invention relates to a manufacturing process of a soft printed circuit board with different appearances at upper and lower layers, which is used for manufacturing a first stack and a second stack of the soft printed circuit board with different appearances at upper and lower layers. The manufacturing process comprises the following steps of: (1) adding an auxiliary layer between the first stack and the second stack, wherein the auxiliary layer is provided with hollow dodging areas in identical-appearance areas of the first stack and the second stack; (2) after the first stack and the second stack having duplicate layers are manufactured based on a general flow, unfolding edge area cavities of the identical-appearance areas of the first stack and the second stack; (3) die cutting the first stack and the second stack according to the appearances of the first stack and the second stack respectively; and (4) drawing out the auxiliary layer to obtain the soft printed circuit board withdifferent appearances at upper and lower layers. Since the auxiliary layer is added between the stacks with different appearances in the invention, appearance damage caused by mutual interference of the appearances is avoided, and soft circuit boards with different appearances are integrated together to reduce the cost and assembly space of adapting parts.

Owner:CHUNHUA TECHNOLOGICAL KUSN

Connector encapsulation tool

PendingCN110649447AEasy potting operationPotting operation safetyContact member assembly/disassemblyEngineeringStructural engineering

The invention discloses a connector encapsulation tool, which comprises a base, a positioning mechanism arranged on the base, and a cable fixing support arranged on the base. The positioning mechanismcomprises a fixing block arranged on the base, a fixing fence arranged on the base and spaced apart from the fixing block, and an elastic assembly arranged on the fixing fence. Compared with the prior art, the connector encapsulation tool has the following beneficial effects: (1) convenience, safety and reliability in encapsulation operation of a connector can be ensured; and (2) the applicability is relatively wide.

Owner:EAST CHINA INST OF COMPUTING TECH

Shaft part packaging line and packaging method thereof

PendingCN114771942APrevent stackingAvoid appearance damageWrapper twisting/gatheringBundling machine detailsMechanical engineeringSingle row

The invention relates to the technical field of intelligent equipment, and particularly discloses a shaft part packing line which comprises a feeding device, a feeding device and a packing device, the feeding device is used for pushing parts fed by the feeding device to the packing device for packing, the feeding device comprises an inclined frame, a limiting piece and a pushing-out mechanism, and the limiting piece protrudes out of the inclined frame; the push-out mechanism comprises a push plate capable of ascending and descending, the push plate is provided with a guide face with the inclined direction the same as that of the inclined frame, the device further comprises a quantity limiting piece, the quantity limiting piece is located above the inclined frame before the push plate is ejected out, and only a single row of parts can pass through the distance between the quantity limiting piece and the inclined frame. According to the scheme, the problem that in the prior art, the feeding quantity is unstable during part feeding in the procedure before part packaging is solved.

Owner:CHONGQING LONGYU PRECISION COPPER TUBE CO LTD

Post production process of thin panels

The invention discloses a post production process of thin panels. The post production process includes subjecting a PANEL to preforming before a gold immersion procedure, subjecting the preformed PANEL to gold immersion, integral panel testing and final check and verification, and integral panel surface treatment procedure sequentially, subjecting the PANEL subjected to the integral panel surface treatment to second SET panel forming and screwing, subjecting SET panels to secondary check and verification, package and delivery. The preforming treatment step includes screwing shape of each SET panel on the PANEL before gold immersion, connection parts are reserved among the SET panels, and blue adhesive layers are attached on two plate surfaces of the integral PANEL after the PANEL is subjected to preforming. By producing the thin plates by the post production process, quality of PCBs (printed circuit boards) of the thin panels can be effectively improved, and rejection rate is decreased.

Owner:南通胜宏科技有限公司

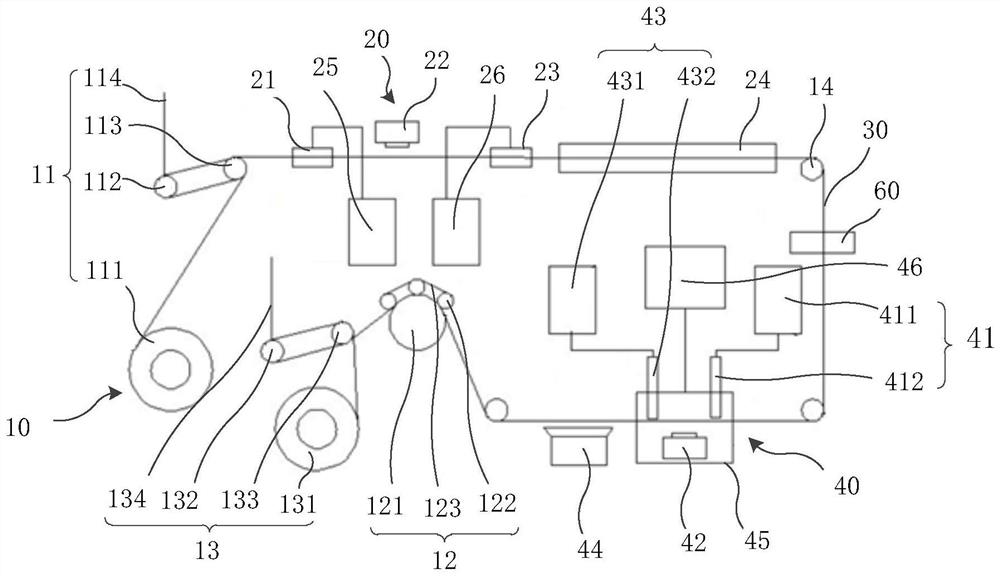

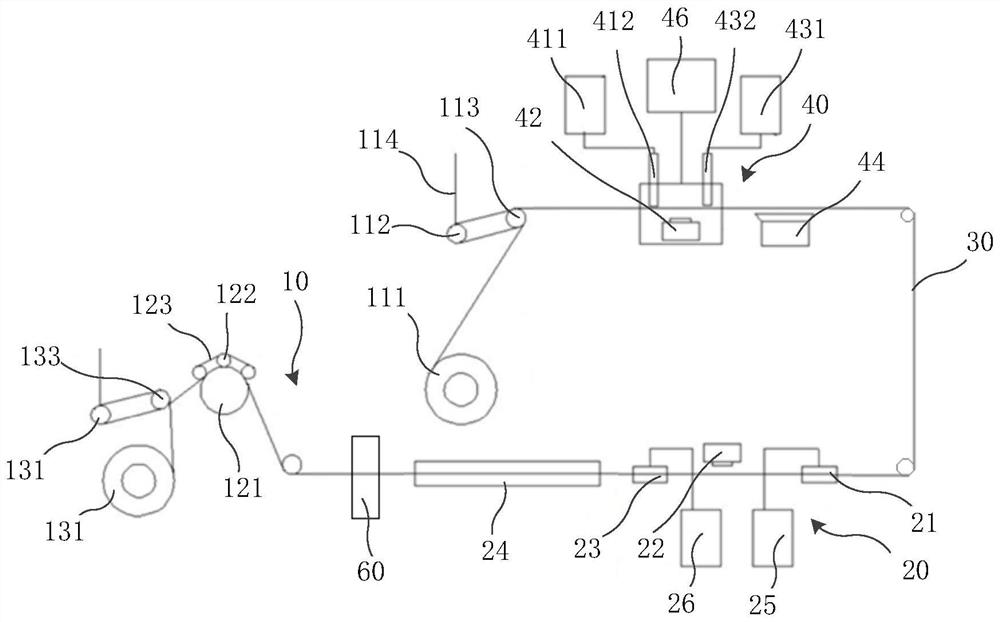

Optical fiber color ring tinting machine

PendingCN114226111AAvoid cosmetic damageIncrease productivityPretreated surfacesTypewritersEngineeringMaterials science

The invention provides an optical fiber color ring tinting machine which comprises a conveying device, a tinting system, a color ring printing system and a controller, the conveying device is used for conveying optical fibers, so that the optical fibers sequentially pass through the tinting system and the color ring printing system; the controller is used for controlling the working states of the coloring system and the color ring printing system; the color ring printing system comprises a first spraying device, a color ring detection device, a second spraying device and a color ring curing device which are sequentially arranged at intervals in the conveying direction of the optical fiber, the first spraying device is used for coating a preset part of the optical fiber with a color ring, and the color ring curing device is used for fixing the color ring coated on the optical fiber; and the controller is also used for controlling the second spraying device to coat the color ring when the color ring detection device detects that the color ring coated on the preset part of the optical fiber is abnormal. The problem of color ring printing missing can be solved, and the quality of optical fiber color ring printing is improved.

Owner:JIANGDONG TECH CO LTD +2

Manufacture method of light-cured composite film

ActiveCN101941353BLower fixed costsImprove overall performanceSynthetic resin layered productsSpecial ornamental structuresPolymer sciencePrinting ink

The invention discloses a manufacture method of a light-cured composite resin film, comprising the following steps of: (1) providing a plastic substrate, light-cured composite resin, a printing ink layer and plastic, wherein the plastic substrate is provided with an upper surface and a lower surface; (2) coating the upper surface of the plastic substrate with the light-cured composite resin; (3) impressing and solidifying the light-cured composite resin to form a plurality of patterns; (4) forming the plastic substrate and the plurality of patterns; (5) coating the printing ink layer on the lower surface of the plastic substrate; and (6) ejecting and attaching the plastic on the printing ink layer.

Owner:ENTIRE TECH CO LTD

Single crystal furnace mounting bracket

InactiveCN103103605AAvoid damageAvoid cosmetic damageBy pulling from meltSingle crystalMechanical engineering

The invention relates to a single crystal furnace mounting bracket, which is welded by angle iron, the surface of the angle iron is covered with a rubber protector. The single crystal furnace mounting bracket has the advantages of simple structure, low cost, manpower saving, and safety and reliability, and is used for installing, dismounting and transporting of a single crystal furnace.

Owner:FUJIAN CASTECH CRYSTALS

Manufacturing process of soft-type printed circuit board with different appearances at upper and lower layers

ActiveCN102186315BLow costAvoid cosmetic damageMultilayer circuit manufactureEngineeringPrinted circuit board

The invention relates to a manufacturing process of a soft printed circuit board with different appearances at upper and lower layers, which is used for manufacturing a first stack and a second stack of the soft printed circuit board with different appearances at upper and lower layers. The manufacturing process comprises the following steps of: (1) adding an auxiliary layer between the first stack and the second stack, wherein the auxiliary layer is provided with hollow dodging areas in identical-appearance areas of the first stack and the second stack; (2) after the first stack and the second stack having duplicate layers are manufactured based on a general flow, unfolding edge area cavities of the identical-appearance areas of the first stack and the second stack; (3) die cutting the first stack and the second stack according to the appearances of the first stack and the second stack respectively; and (4) drawing out the auxiliary layer to obtain the soft printed circuit board withdifferent appearances at upper and lower layers. Since the auxiliary layer is added between the stacks with different appearances in the invention, appearance damage caused by mutual interference of the appearances is avoided, and soft circuit boards with different appearances are integrated together to reduce the cost and assembly space of adapting parts.

Owner:CHUNHUA TECHNOLOGICAL KUSN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com