Manufacturing process of soft-type printed circuit board with different appearances at upper and lower layers

A printed circuit board and manufacturing process technology, applied in the direction of multi-layer circuit manufacturing, etc., can solve problems such as inability to manufacture, and achieve the effect of reducing assembly space, avoiding appearance damage, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

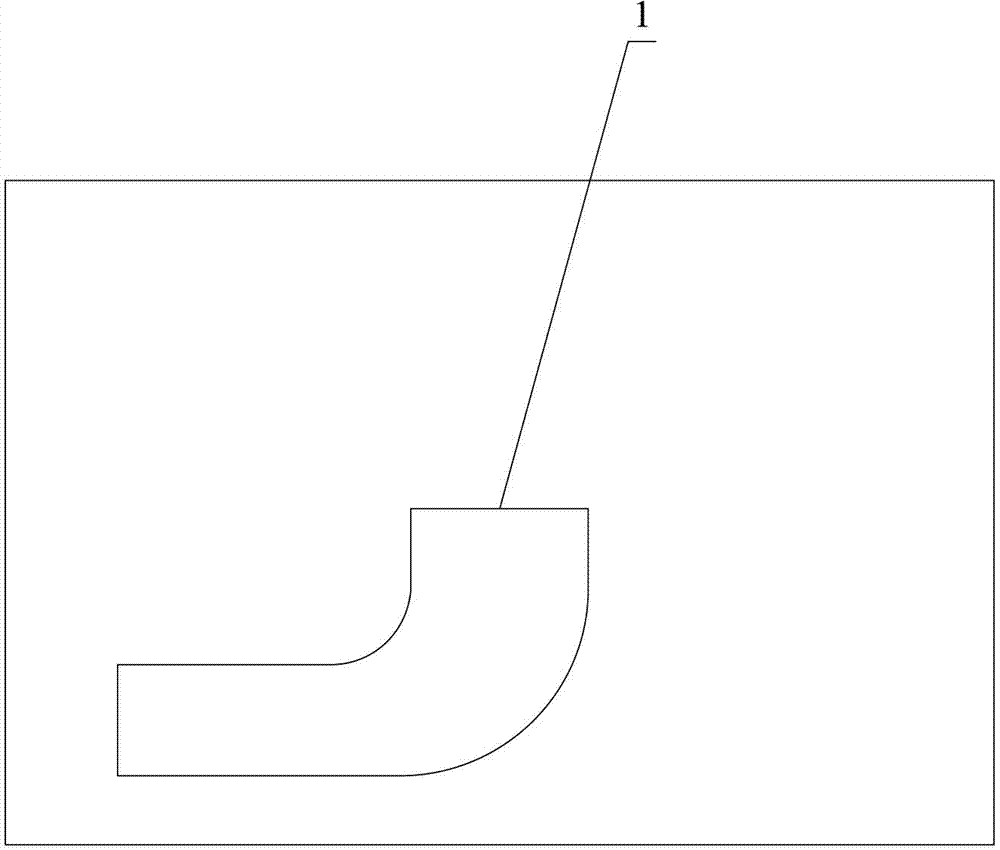

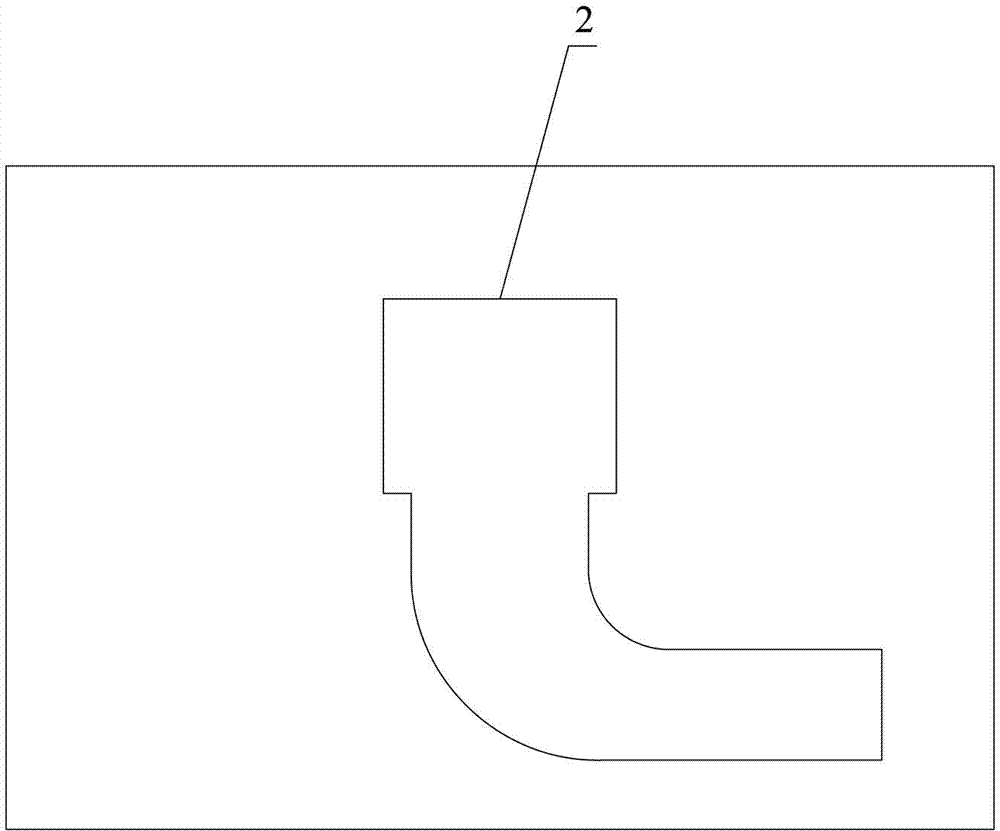

[0023] Embodiment one: see attached figure 1 to attach Figure 5 shown.

[0024] A manufacturing process of flexible printed circuit boards with different shapes on the upper and lower layers, which is used to make the first stack 1 and the second stack 2 of the flexible printed circuit boards with different shapes on the upper and lower layers, which includes the following steps:

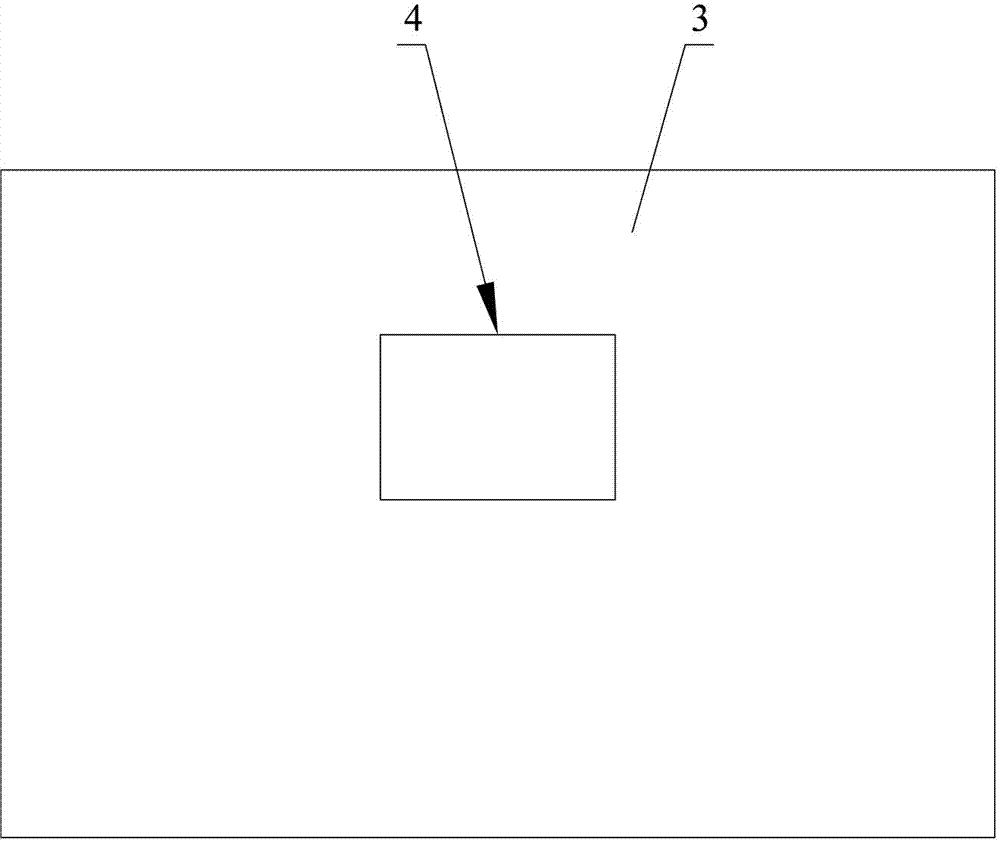

[0025] (1) An auxiliary layer 3 made of polyimide is added between the first stack 1 and the second stack 2; in the same shape area of the first stack 1 and the second stack 2, the auxiliary layer has Hollow avoidance area 4;

[0026] (2) After the above-mentioned first stack 1 and second stack 2 with the auxiliary layer 3 are produced according to the general process, pull out the 5 holes in the edge area of the same shape area of the first stack 1 and the second stack 2 ;

[0027] (3) Die-cut the first stack 1 and the second stack 2 according to their shapes by half-cutting or laser met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com