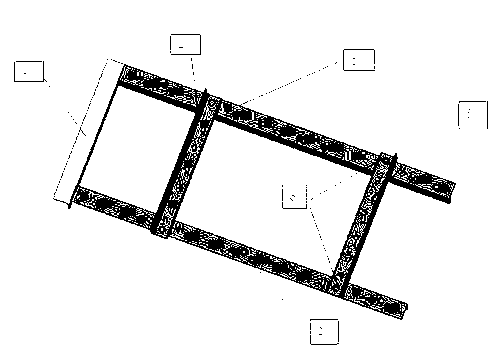

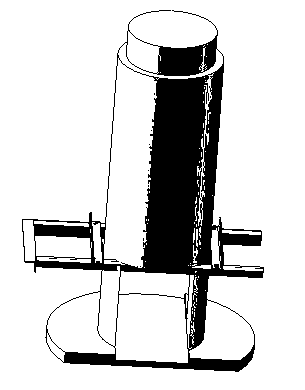

Single crystal furnace mounting bracket

A technology for mounting brackets and single crystal furnaces, which is used in the field of disassembly and handling, mounting brackets for single crystal furnaces, and the installation of DJL series pulling method single crystal furnace heads. It can solve scratches, scratches on precision parts, poor safety, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0008] Embodiment one: To install and disassemble the DJL-400 burner head, remove the movable baffle (5) first, put the bracket on the parallel groove of the burner head, and fix the movable baffle (5) tightly with the fixing bolts (6) to prevent the furnace The head slides down during the transportation process, and then the whole burner head is forked up from the bottom of the bracket with a forklift to install and disassemble the burner head.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com