Rapid cylinder bar ranking device

A rapid sorting, cylindrical rod technology, applied in transportation and packaging, conveyor objects, etc., can solve problems such as low efficiency, poor accuracy, lack of sorting devices, etc., to reduce friction, improve integrity, and reduce friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

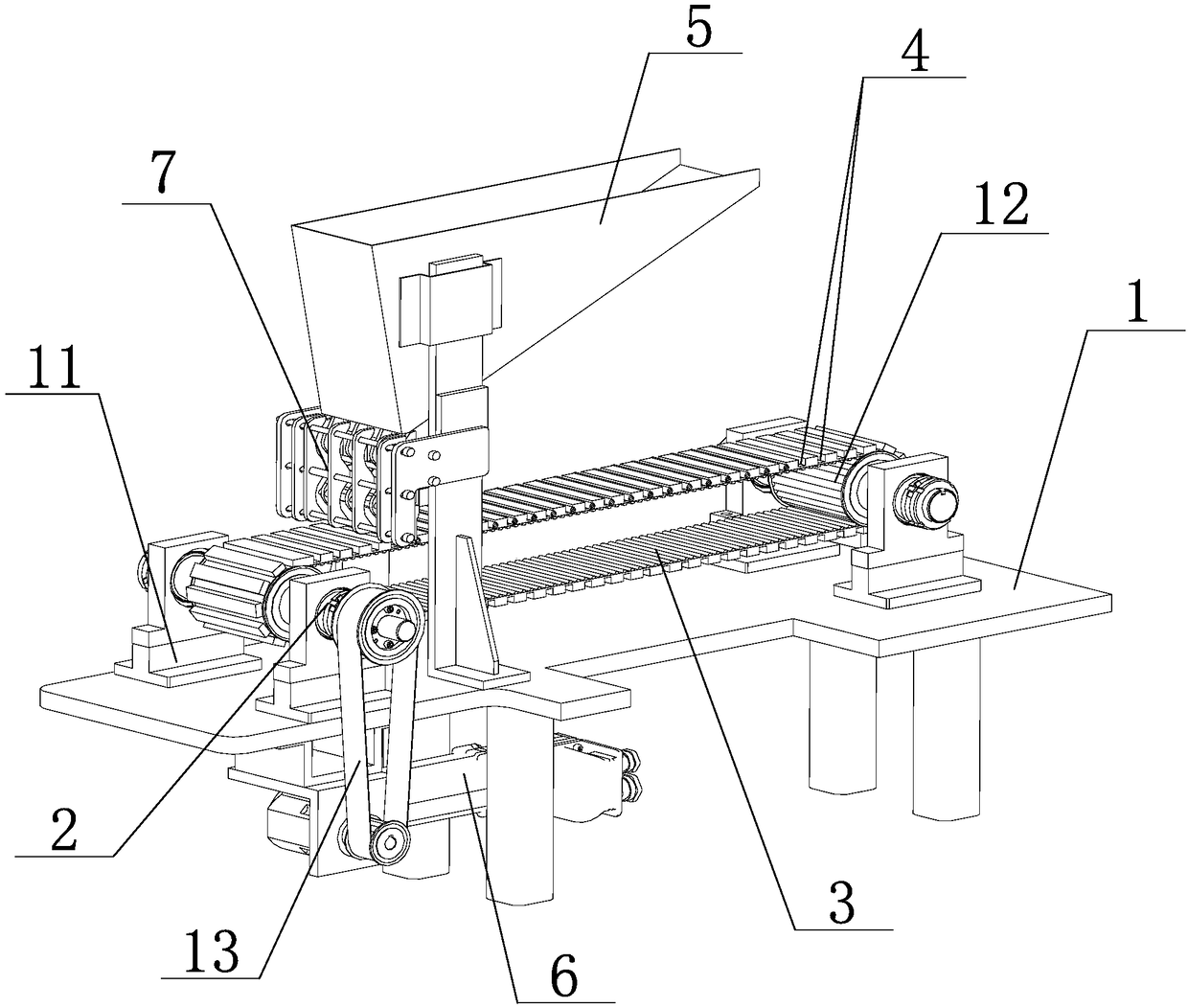

[0026] Such as figure 1 As shown, a quick sorting device for cylindrical bars in the present invention includes a workbench 1, two sets of transmission devices 2 are arranged on the workbench 1, a timing belt 3 is set between the two sets of transmission devices 2, and two sets of transmission devices 2 Driven by the power unit 6, the synchronous belt 3 can be driven to move, and the upper surface of the synchronous belt 3 is evenly spaced with discharge grooves 4 along the movement direction of the synchronous belt 3, and the movement of the discharge groove 4 and the synchronous belt 3 The directions are perpendicular to each other. A hopper 5 is arranged above the synchronous belt 3. The bottom of the hopper 5 has a long groove whose width only allows a slender cylindrical bar to pass through at the same time. The long groove and the discharge groove 4 are parallel to each other.

[0027] The sorting device of the present invention realizes the rapid sorting of cylindrical ...

Embodiment 2

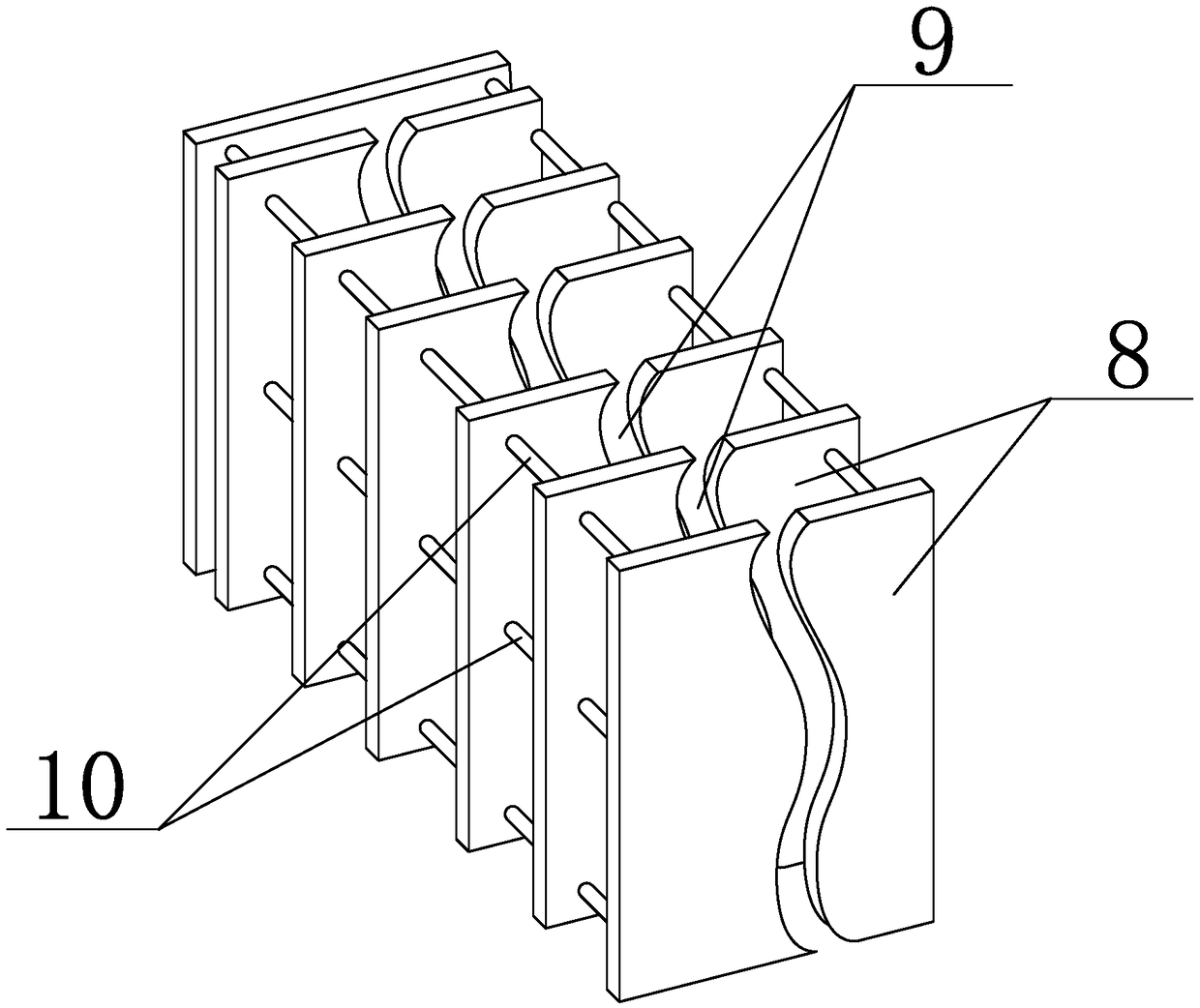

[0029] Such as figure 1 and 2 As shown in the present invention, a quick sorting device for cylindrical bar materials, the long groove below the hopper 5 is connected with a blanking device 7, and the blanking device 7 includes a plurality of parallel and vertically arranged blanking plates 8, the blanking plate 8 is provided with a serpentine trough 9 that runs through the top and bottom of the blanking plate 8, the top of the serpentine chute 9 is aligned with the long groove, and multiple parallel serpentine troughs between all the blanking plates 8 9 communicate with each other to form a serpentine blanking channel, and the two sides of the serpentine blanking chute 9 between two adjacent blanking plates 8 are respectively connected by fixing rods 10 .

[0030]Since it is impossible to ensure that the cylindrical bar is completely in a horizontal state during the movement of the cylindrical bar, when the cylindrical bar falls out of the long groove of the hopper, there ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com