A visual vacuum carrier

A vehicle and vacuum technology, applied in the field of vehicles, can solve problems such as shaking and low precision, and achieve the effects of improved efficiency, high precision, and light material quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

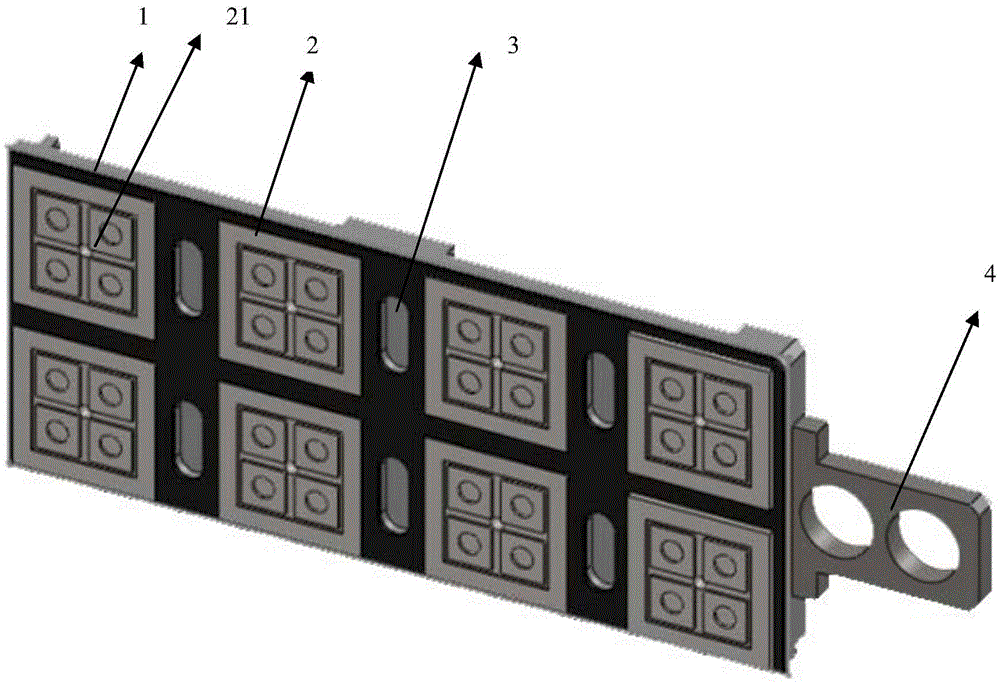

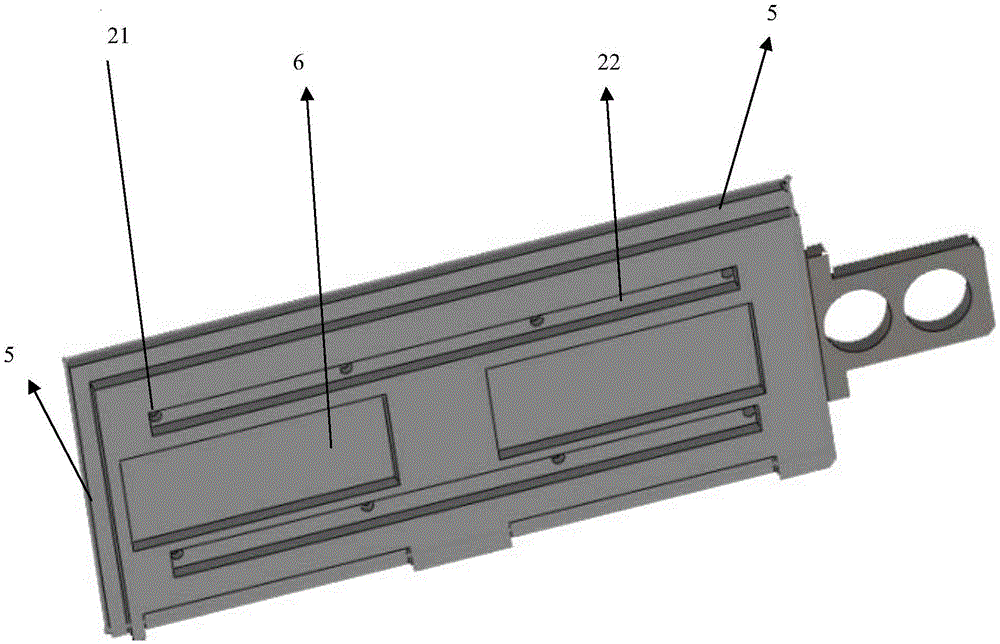

[0024] refer to Figure 1-2 , the present invention provides a visual vacuum carrier, which can be installed on a mechanical arm or a mechanical device, and can also be hand-held. Its main body is a carrier board 1, on the front of the carrier board 1, a number of metal blocks 2 at equal intervals are fixed. The metal blocks are used to absorb the components to be loaded. The material of the metal blocks can be aluminum. figure 1 The connection method between the middle metal block and the carrier plate 1 is bolted, but other feasible fixing methods can also be used, which are not limited here. The material of the metal block can be hardened aluminum or other metal materials, which is not limited here. In the middle of each metal block 2, there is a vacuum hole 21 that runs through the carrier plate 1. When the adsorption is started, a vacuum pressure is formed between the surface of the metal block and the bottom of the component to be loaded through the vacuum hole 21, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com