Optical fiber color ring tinting machine

A technology of color ring and optical fiber, which is applied to typewriters, coatings, pre-treated surfaces, etc., can solve problems such as missing color ring printing, and achieve the effects of avoiding appearance damage, improving production efficiency, and reducing quality hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

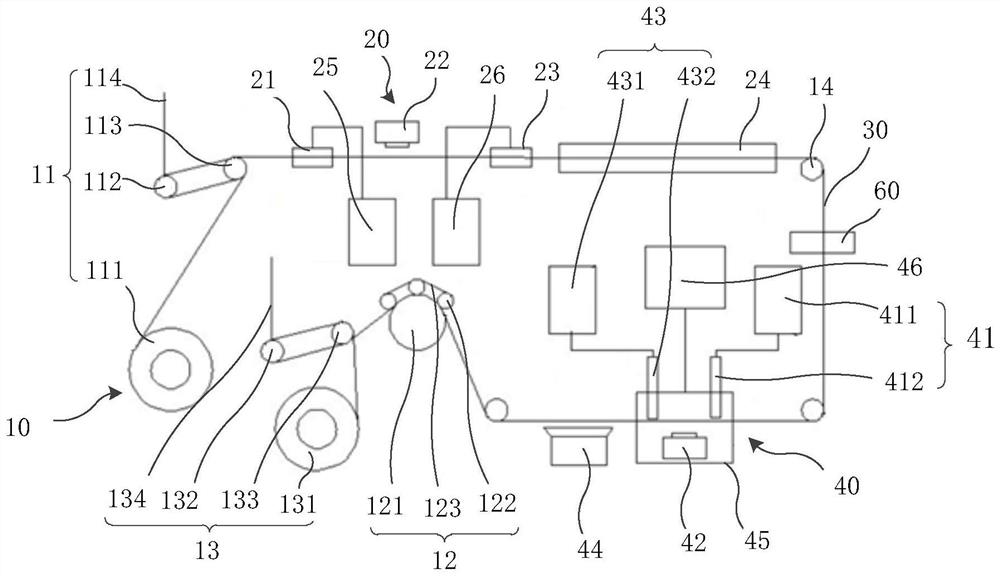

[0080] refer to figure 1 As shown, the present invention provides an optical fiber color ring coloring machine, comprising: a conveying device 10, a coloring system 20, a color ring printing system 40 and a controller 50, the conveying device 10 is used to transport the optical fiber 30, so that the optical fiber 30 passes through the coloring system in turn 20 and the color circle printing system 40, the controller 50 is electrically connected with the coloring system 20 and the color circle printing system 40, and the controller 50 is used to control the working status of the coloring system 20 and the color circle printing system 40.

[0081] The color ring printing system 40 includes a first spraying device 41, a color ring detection device 42, a second spraying device 43 and a color ring curing device 44 arranged at intervals along the conveying direction of the optical fiber 30. The first spraying device 41 is used to print on the optical fiber 30. The predetermined posi...

Embodiment 2

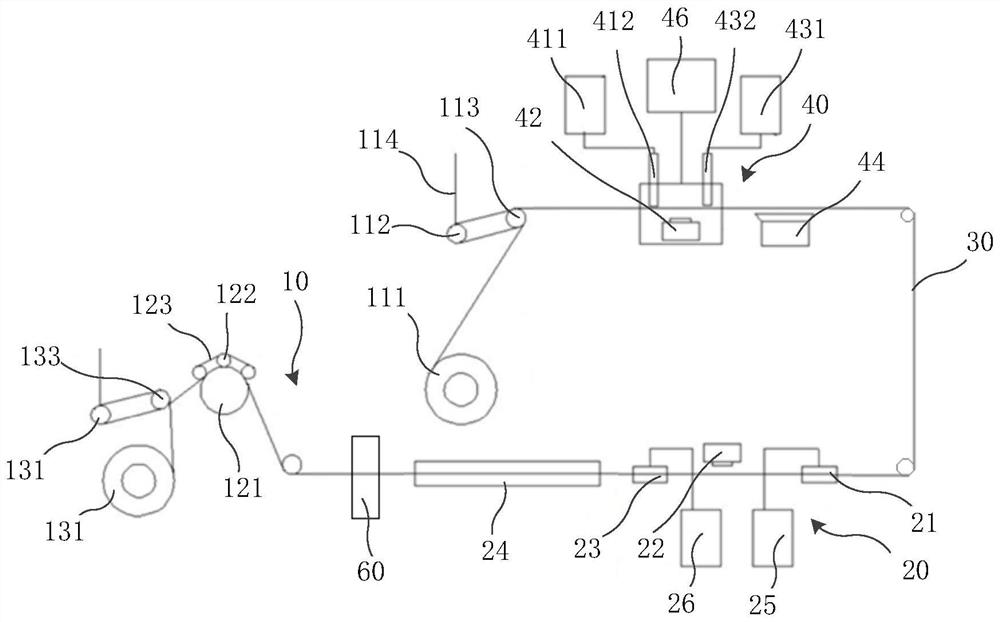

[0122] refer to figure 2 As shown, the difference between the second embodiment and the first embodiment is that the conveying device 10 is used to convey the optical fiber 30, so that the optical fiber 30 passes through the color ring printing system 40 and the coloring system 20 in sequence, and along the conveying direction of the optical fiber 30, the color ring printing system 40, the coloring system 20 and the measuring device 60 are arranged in sequence.

[0123] A kind of optical fiber color ring coloring machine provided in this embodiment can produce colored optical fiber, color ring optical fiber, and optical fiber 30 with both coloring and color ring. The difference is that the optical fiber color ring coloring machine provided in this embodiment, When producing the optical fiber 30 in which the coloring and the color ring exist simultaneously, the color ring is produced first, and then the coloring is carried out. After the coloring operation is completed, the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com