Patents

Literature

43results about How to "No discontinuity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

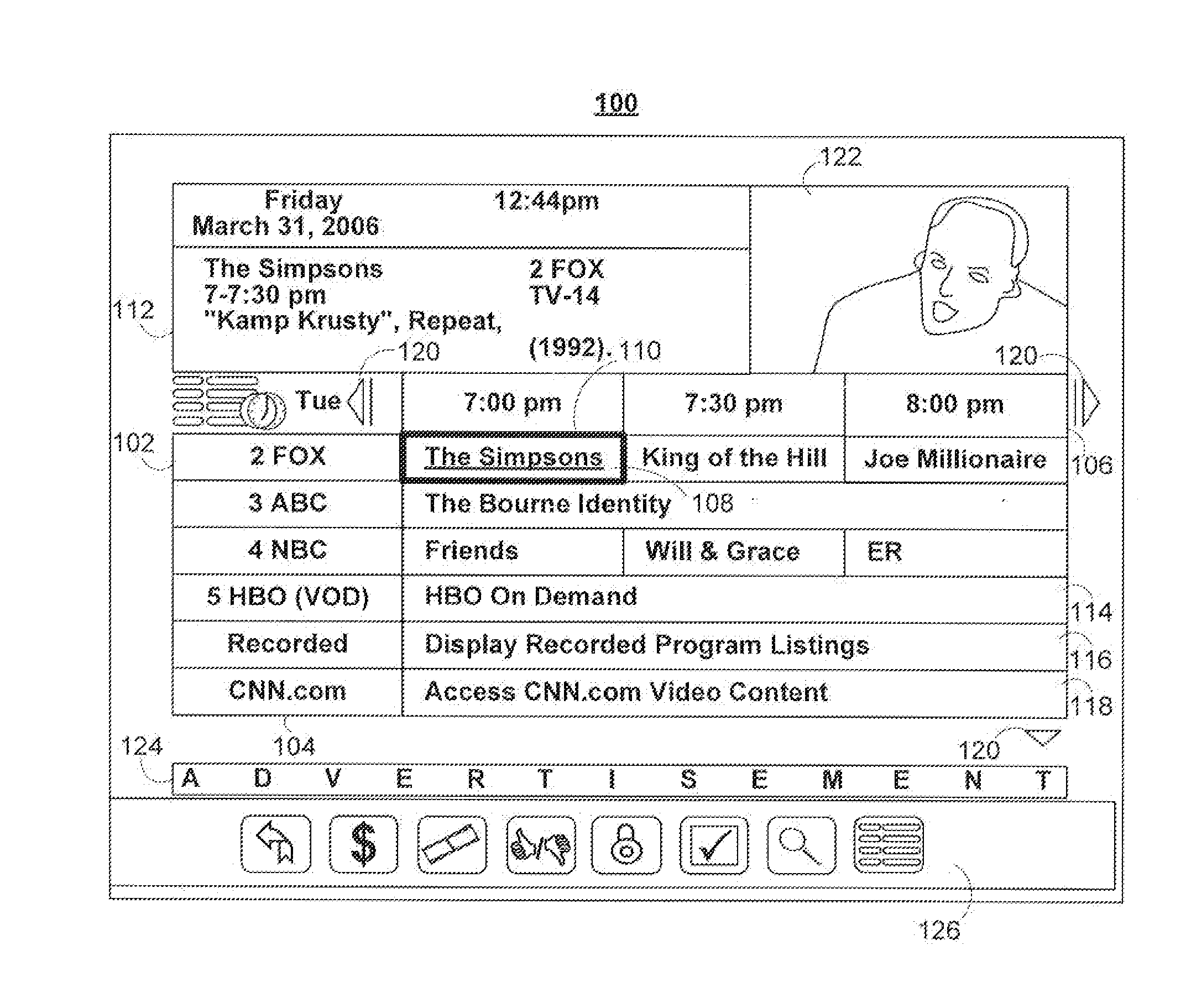

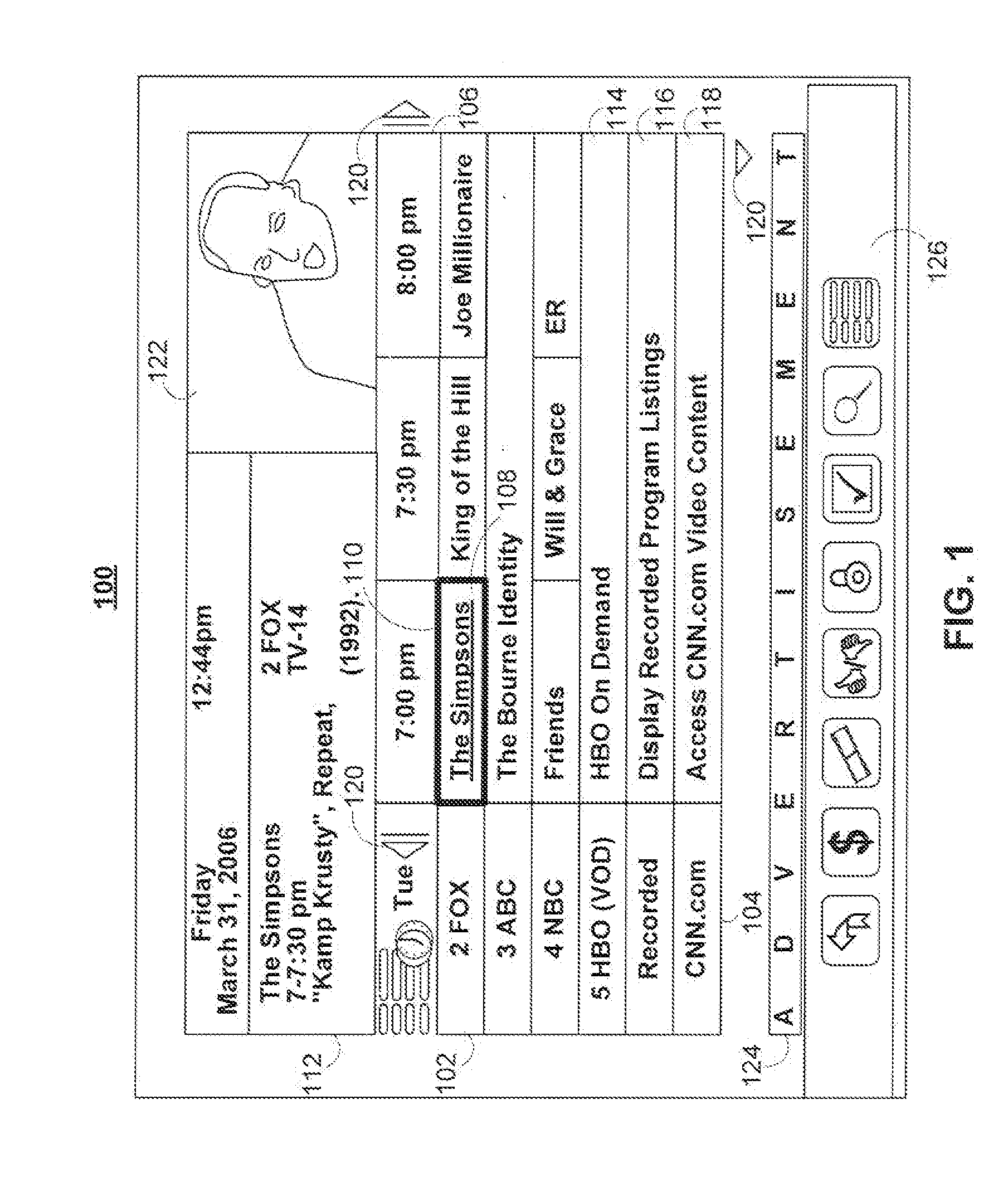

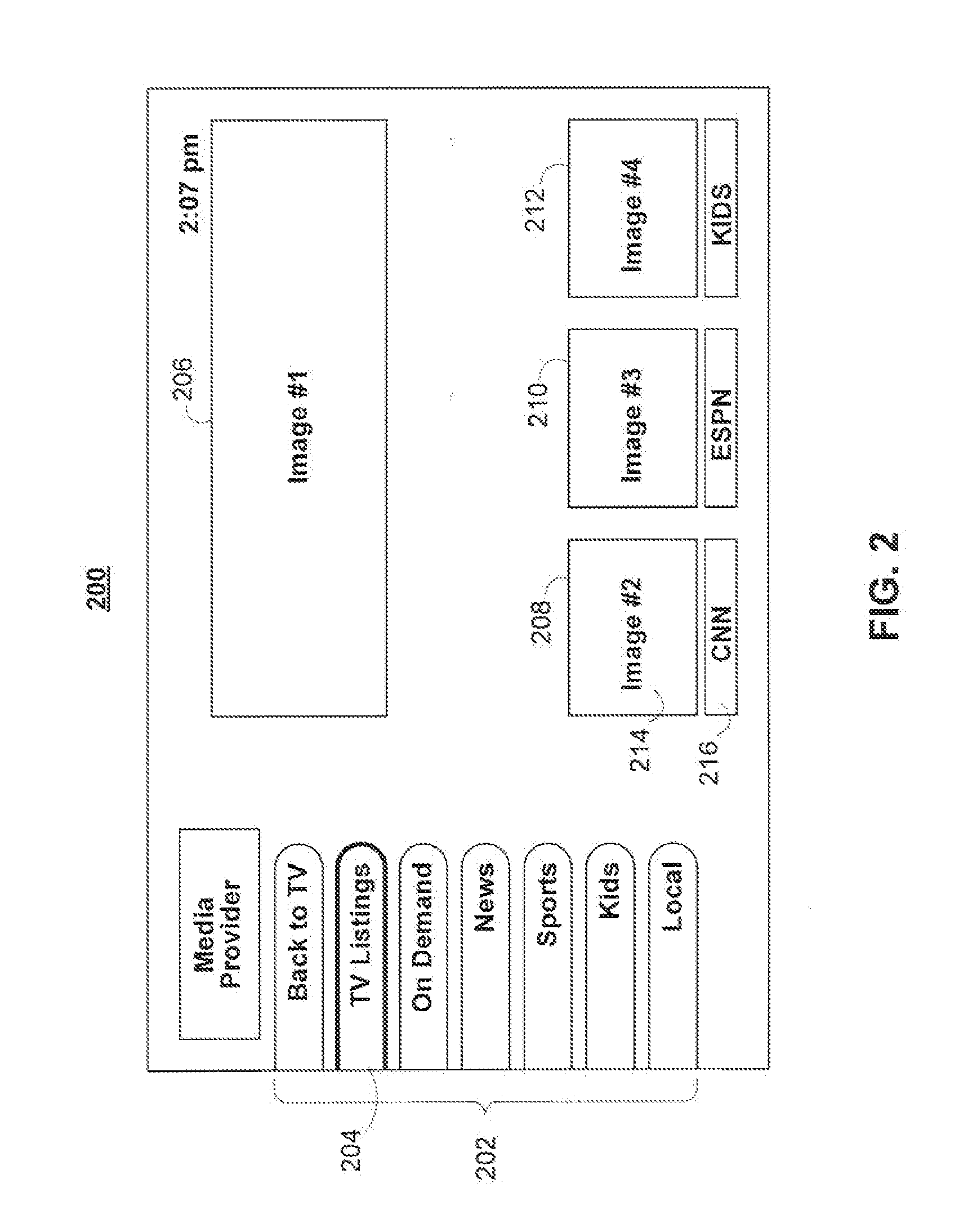

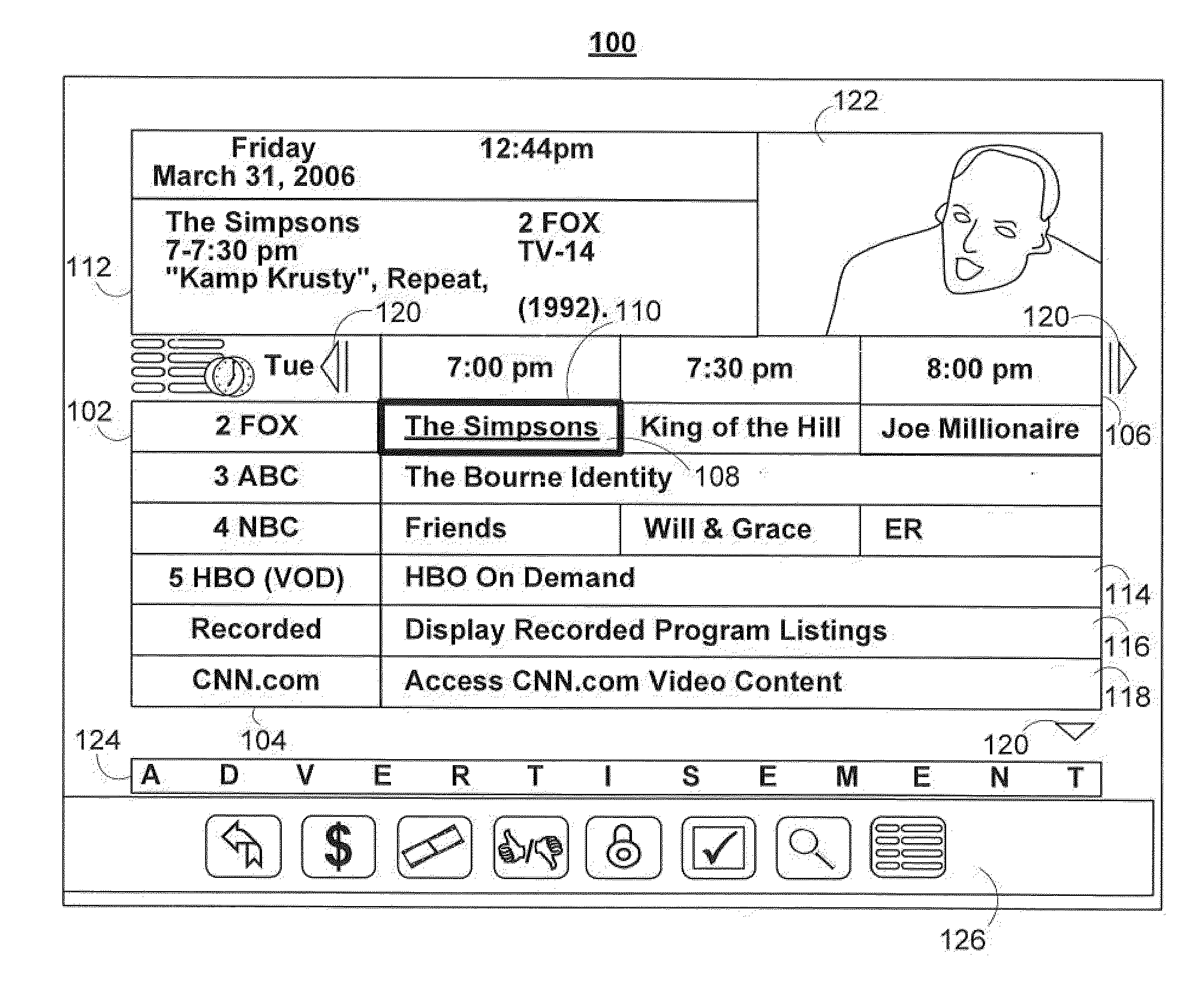

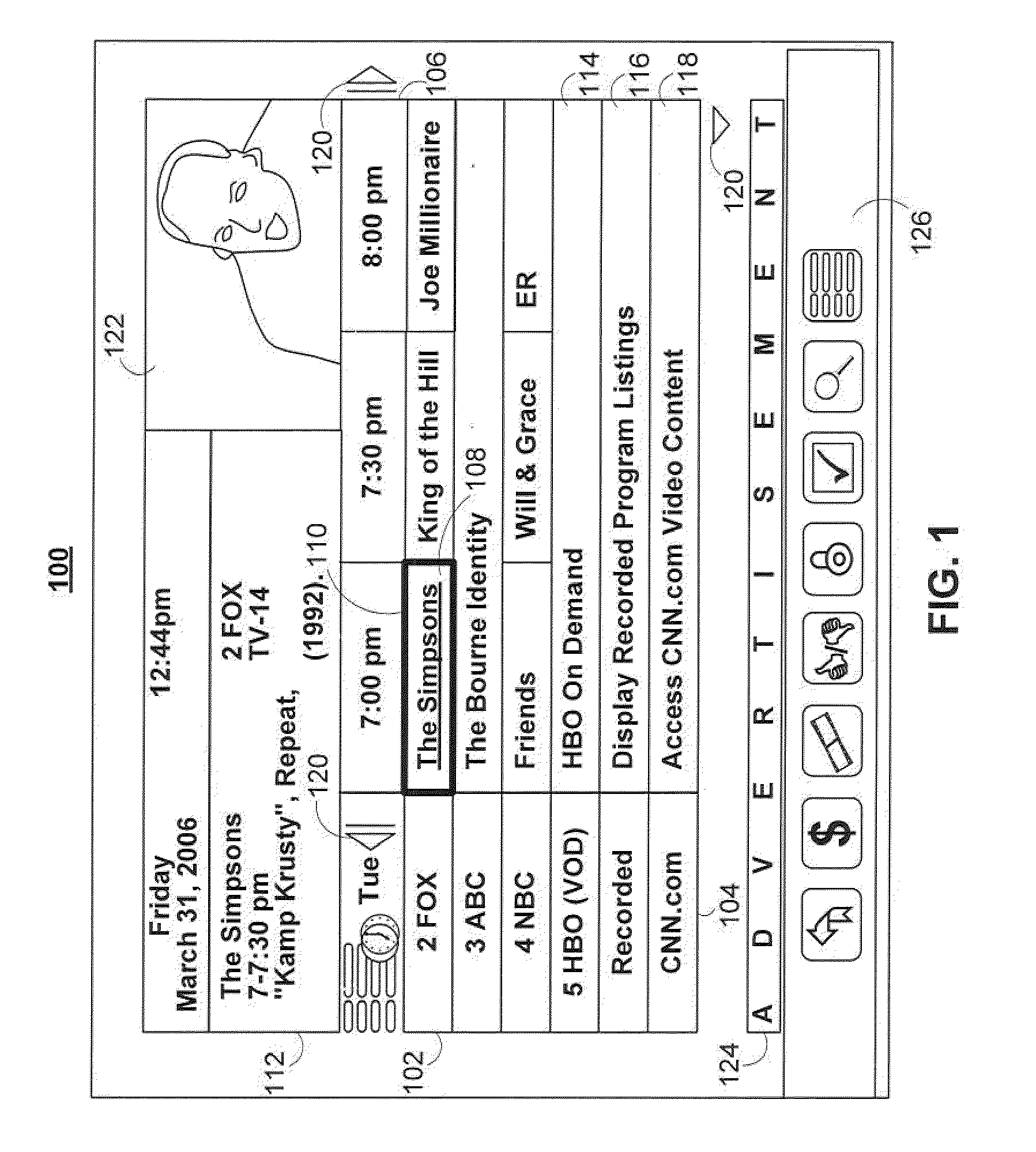

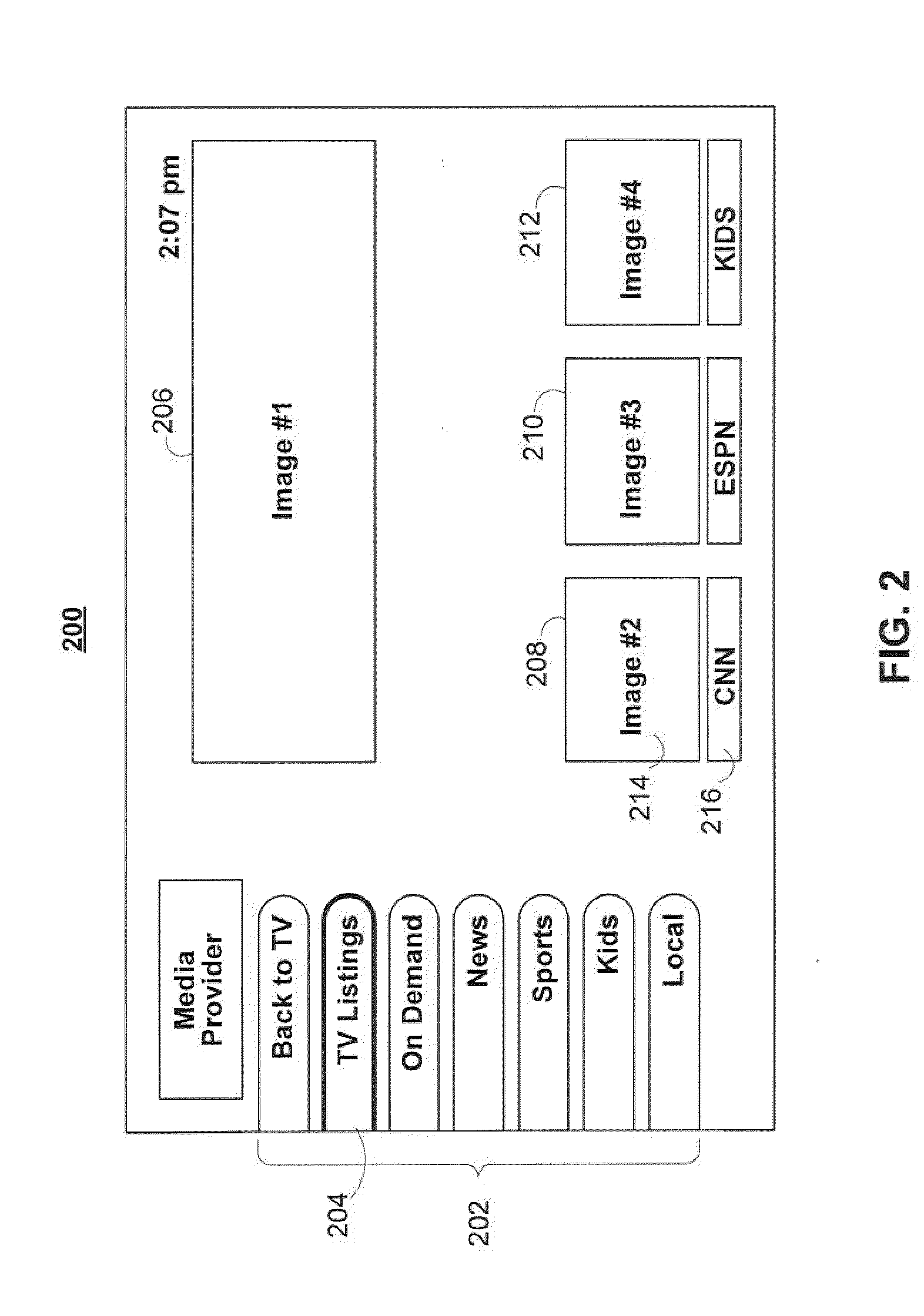

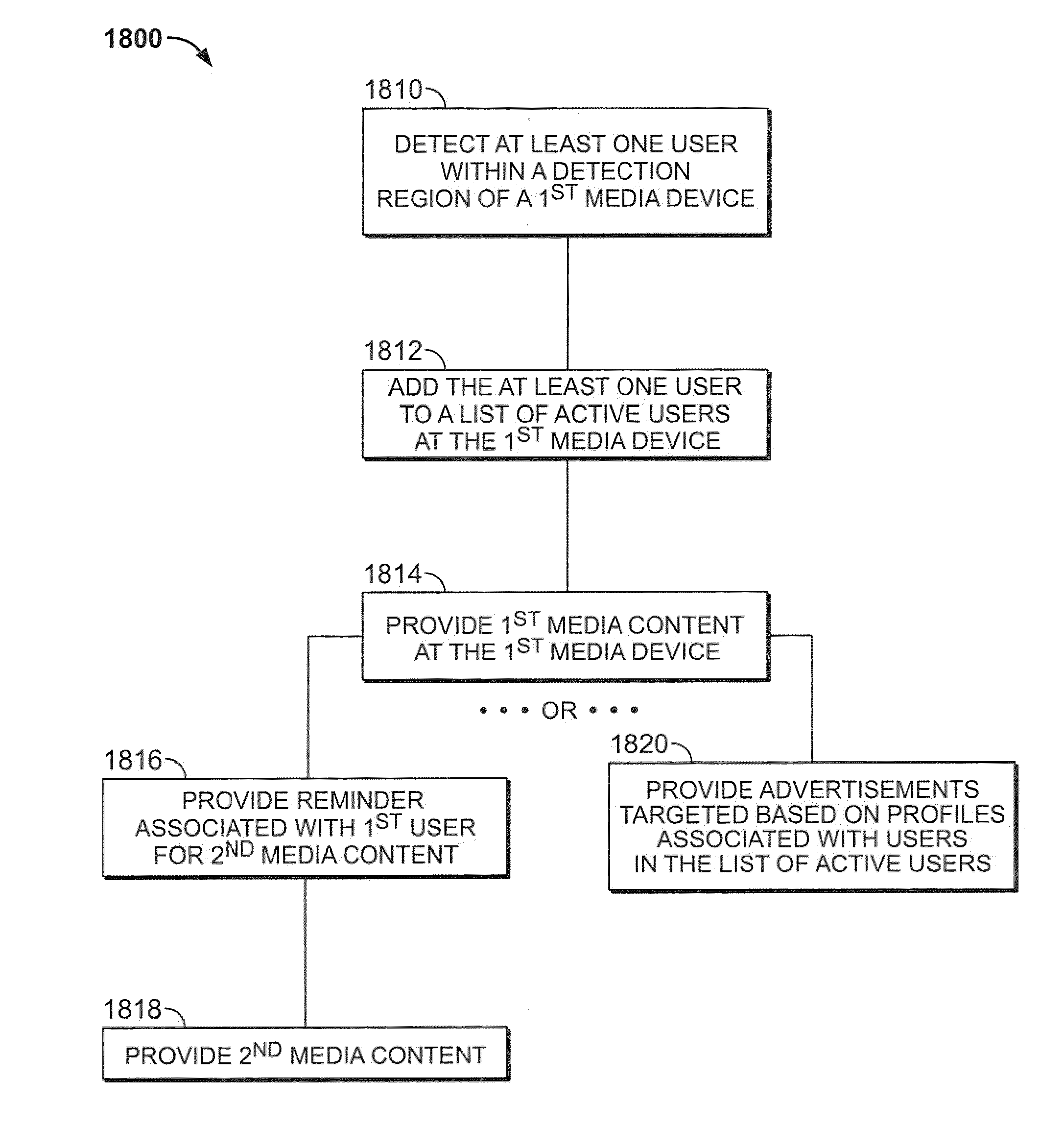

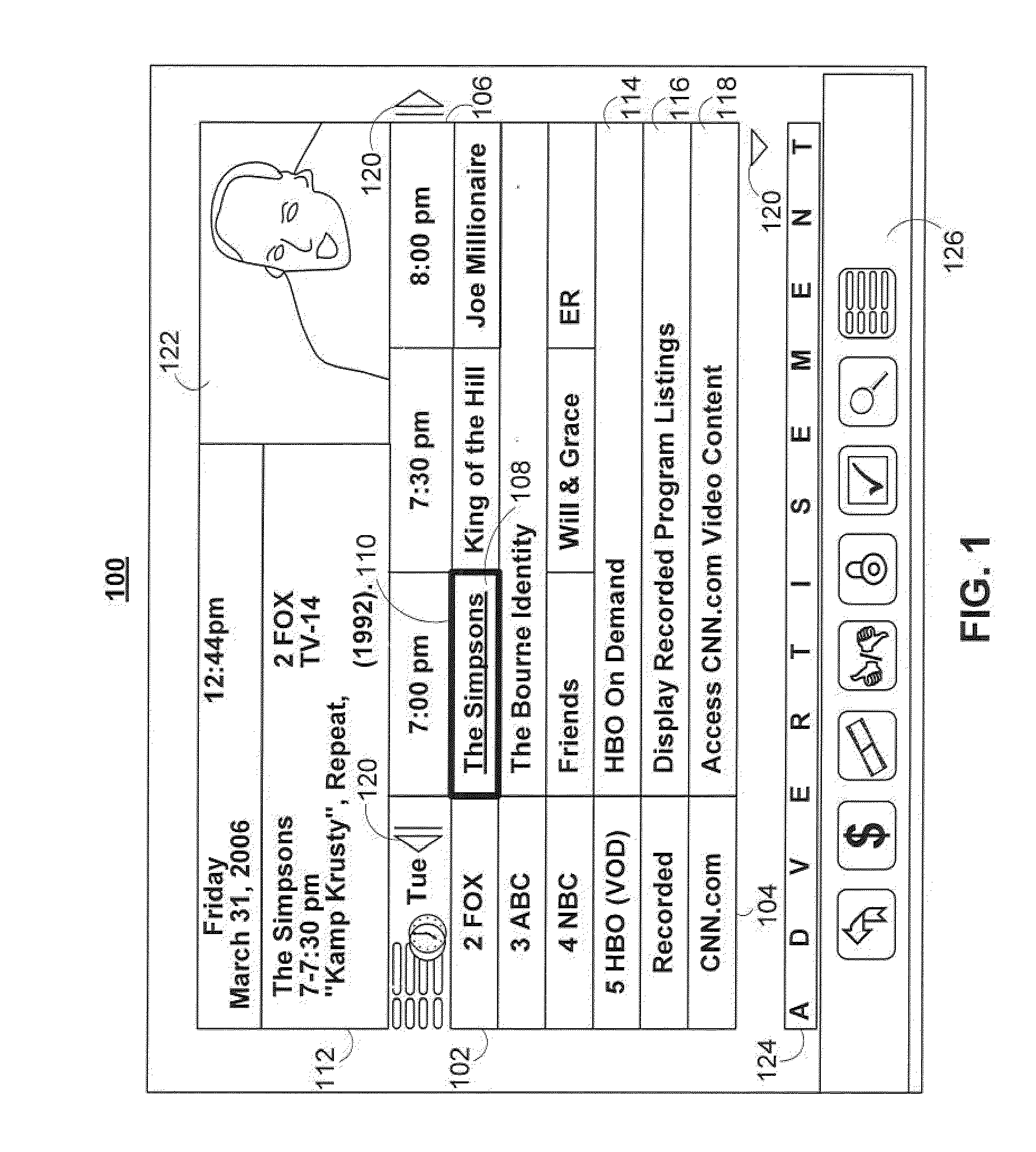

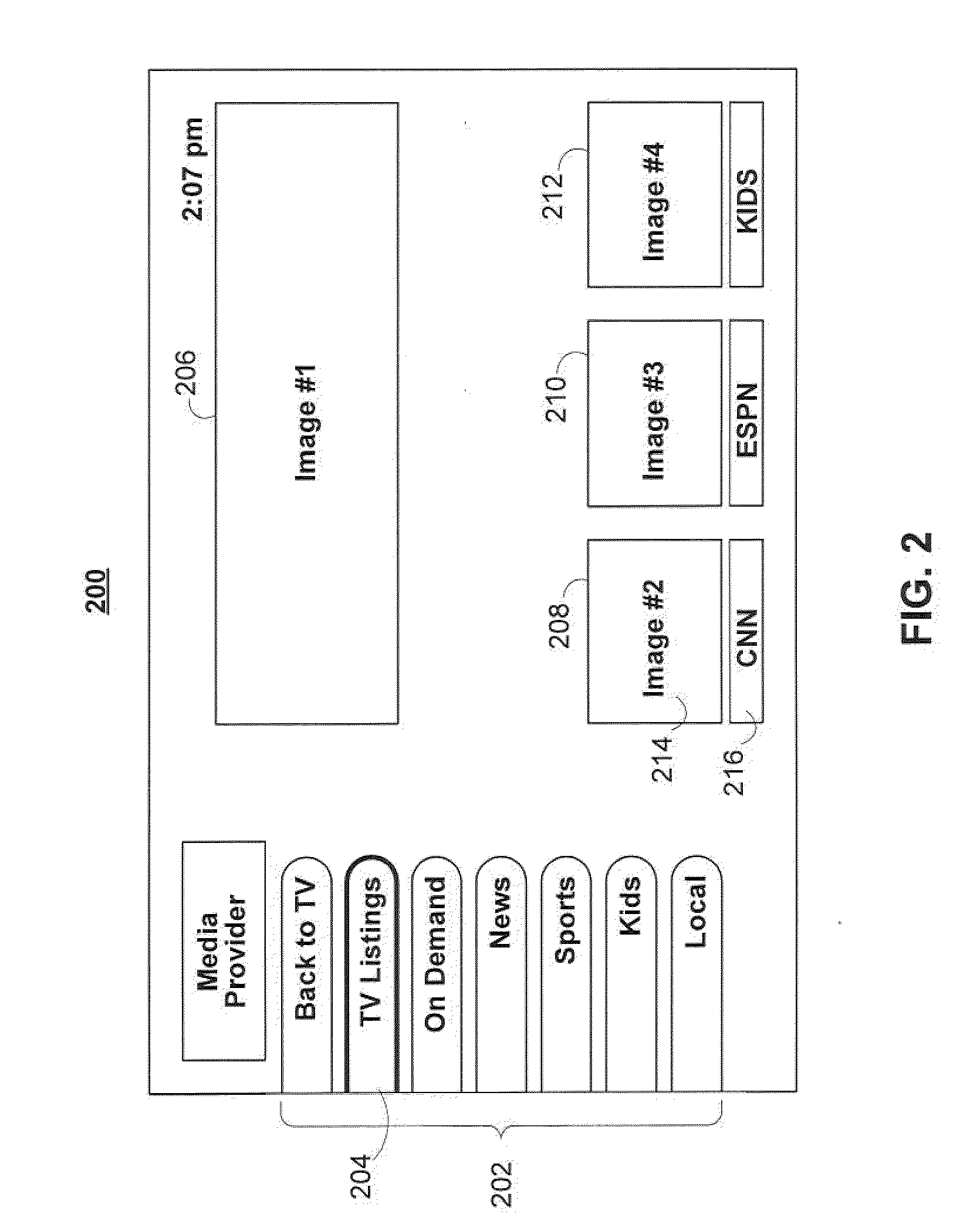

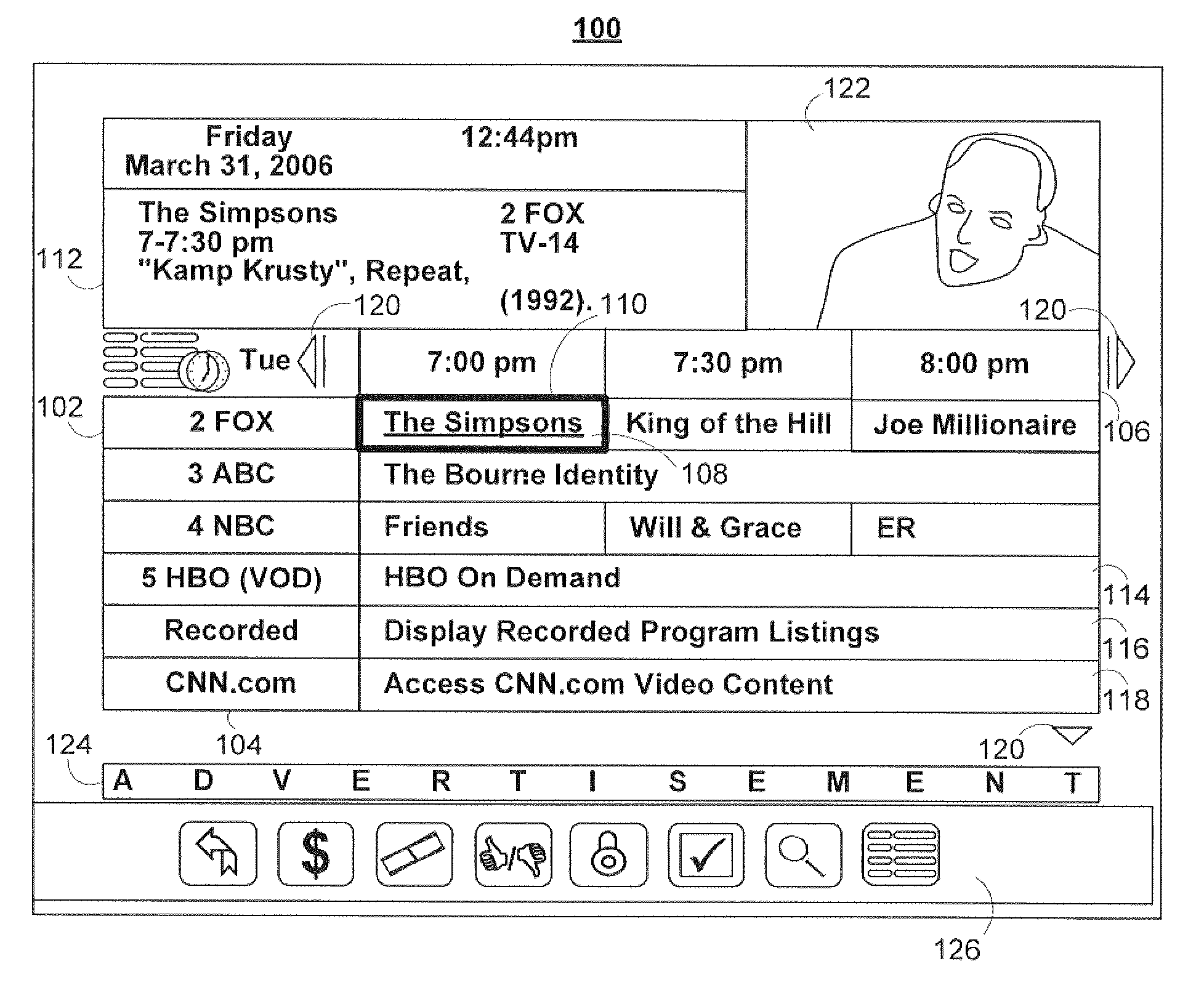

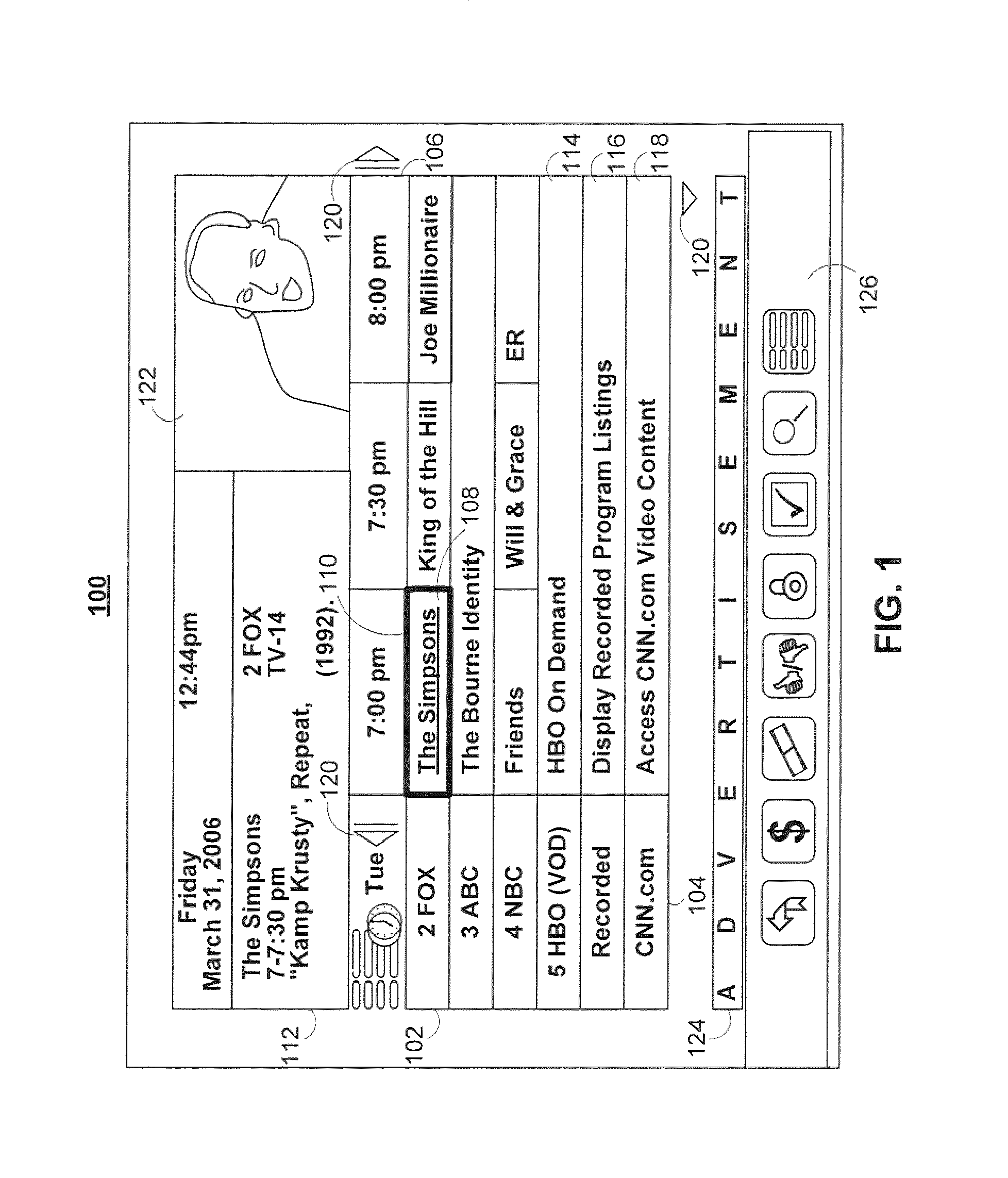

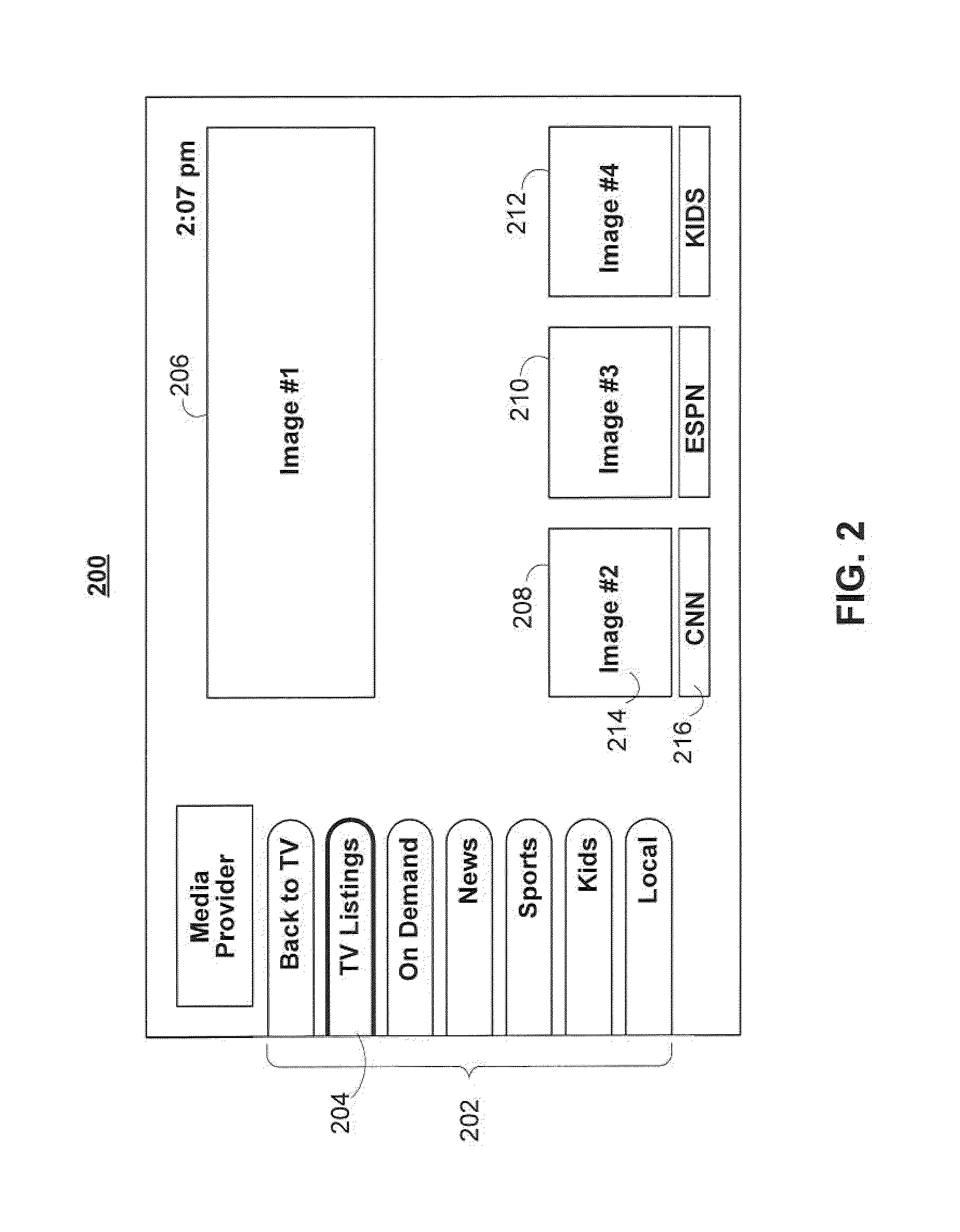

Systems and methods for automatically detecting users within detection regions of media devices

ActiveUS20110069940A1Efficiently tailoredNo discontinuityTelevision system detailsRecording carrier detailsMedia content

Systems and methods are presented for detecting users within a range of a media device. A detection region may be defined that is within the range of the media device and smaller than the range. The detection region may be stored. It may be determined whether a user is within the detection region. The media device may be activated and settings associated with the user may be applied when a user is within the detection region. In some embodiments, settings associated with a user may be compared to provided media content when the user is within the detection region. The content may change when the settings conflict with the media content. Reminders may be provided to or directed to a plurality of users within the range of the media device.

Owner:ROVI GUIDES INC

Systems and methods for providing automatic parental control activation when a restricted user is detected within range of a device

InactiveUS20110072452A1Efficiently tailoredNo discontinuityAnalogue secracy/subscription systemsSelective content distributionBiological activationHuman–computer interaction

Systems and methods are presented for detecting users within a range of a media device. A detection region may be defined that is within the range of the media device and smaller than the range. The detection region may be stored. It may be determined whether a user is within the detection region. The media device may be activated and settings associated with the user may be applied when a user is within the detection region. In some embodiments, settings associated with a user may be compared to provided media content when the user is within the detection region. The content may change when the settings conflict with the media content. Reminders may be provided to or directed to a plurality of users within the range of the media device.

Owner:UNITED VIDEO PROPERTIES

Systems and methods for providing reminders associated with detected users

InactiveUS20110070819A1Efficiently tailoredNo discontinuityDigital data information retrievalDigital data processing detailsMedia content

Systems and systems are presented for detecting users within a range of a media device. A detection region may be defined that is within the range of the media device and smaller than the range. The detection region may be stored. It may be determined whether a user is within the detection region. The media device may be activated and settings associated with the user may be applied when a user is within the detection region. In some embodiments, settings associated with a user may be compared to provided media content when the user is within the detection region. The content may change when the settings conflict with the media content. Reminders may be provided to or directed to a plurality of users within the range of the media device.

Owner:UNITED VIDEO PROPERTIES

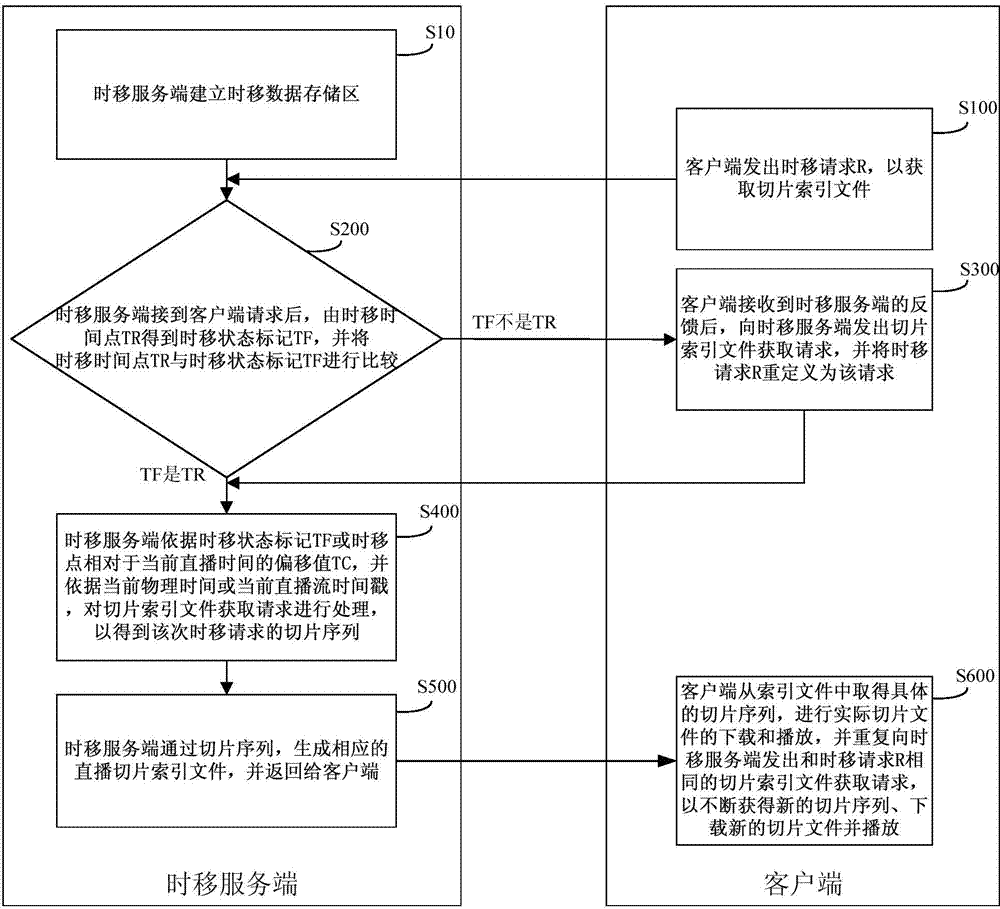

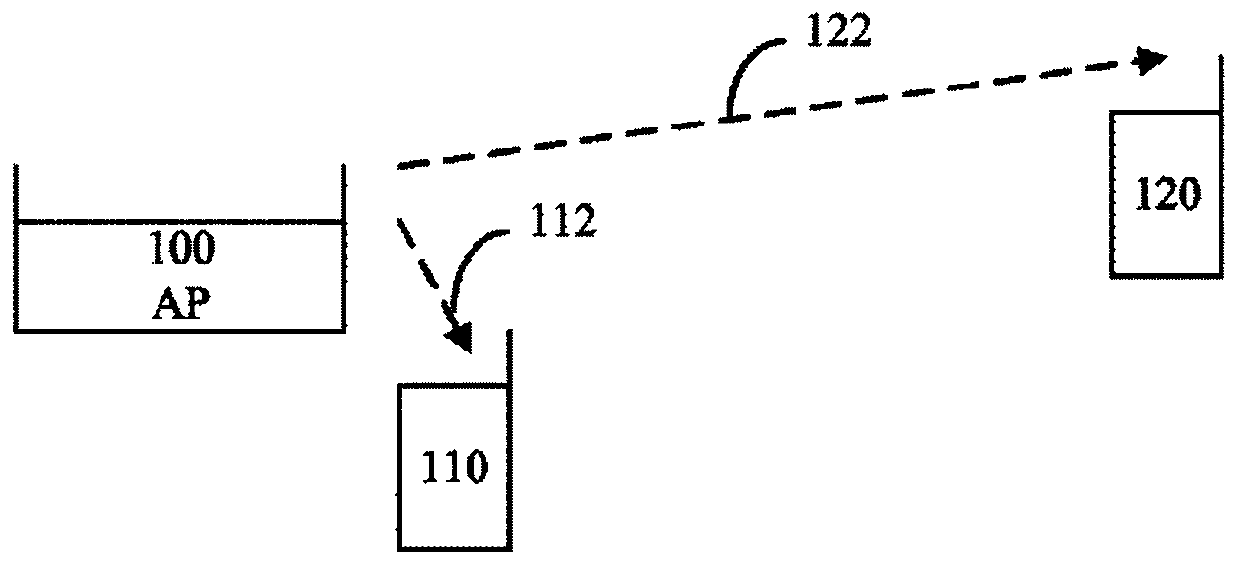

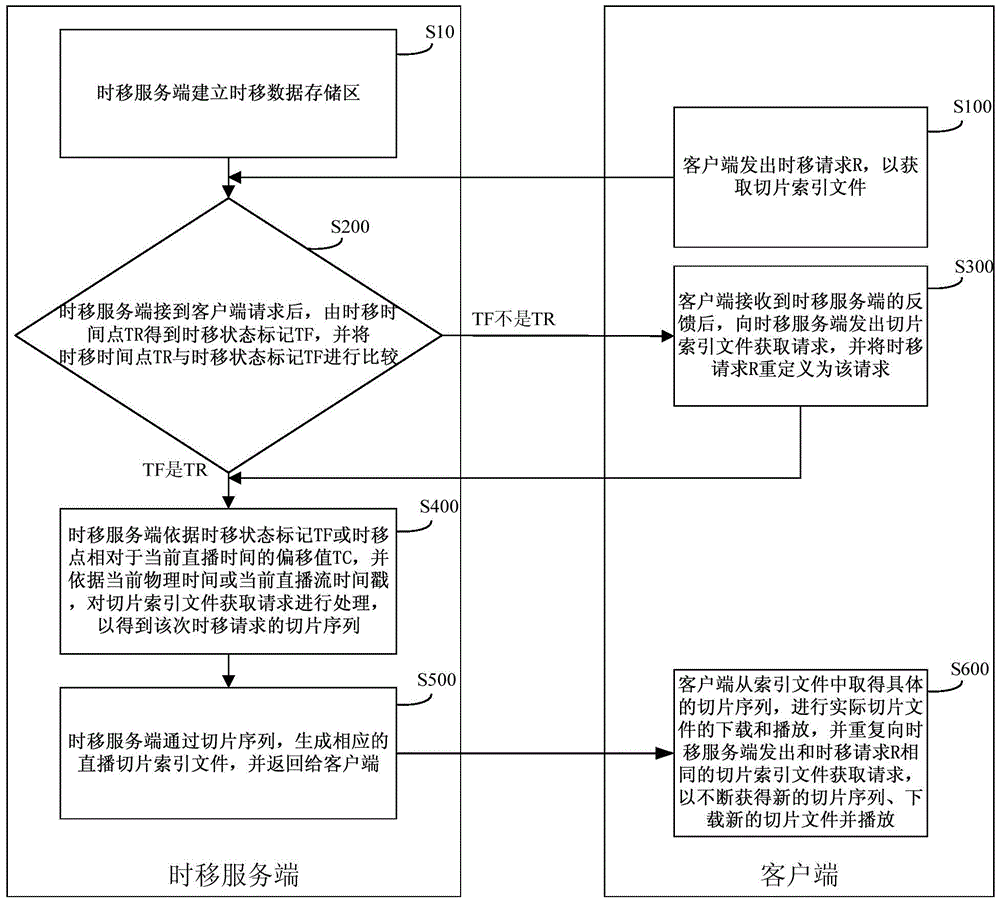

Internet-oriented large-scale live time shifting method and system based on fragment transmission

ActiveCN103581693AEasy to implementRealization of Live Time Shift ServiceSelective content distributionThe InternetClient-side

The invention provides an internet-oriented large-scale live time shifting method based on fragment transmission. The method comprises the steps that a client-side sends a time shifting request to obtain fragment index files; a time shifting server-side obtains time shifting status marks through time shifting time points; the client-side sends an acquisition request for the fragment index files to the time shifting server-side after receiving feedback from the time shifting server-side; the time shifting server-side processes the acquisition request for the fragment index files to obtain fragment sequences of the time shifting request this time; the time shifting server-side generates corresponding live fragment index files through the fragment sequences and returns the live fragment index files to the client-side; the client-side obtains the specific fragment sequences from the index files, downloads and plays the actual fragment files and repeatedly sends the same acquisition request for the fragment index files. A system where the method is implemented comprises the time shifting server-side and the client-side. The client side is simple and easy to implement, the time shifting index range required to be obtained does not need calculating, and time shifting indexes obtained each time do not need to be reserved or merged.

Owner:BEIJING QINGYUAN XINCHUANG TECH

Systems and methods for automatically detecting users within detection regions of media devices

ActiveUS9014546B2Efficiently tailoredNo discontinuityTelevision system detailsColor television signals processingMedia content

Owner:ROVI GUIDES INC

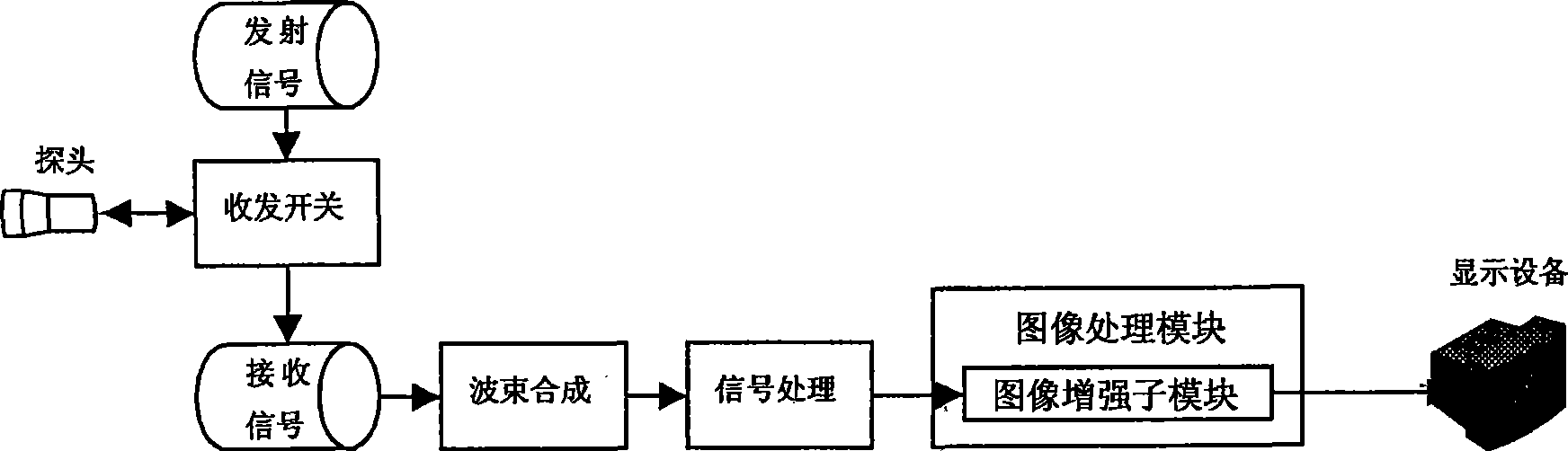

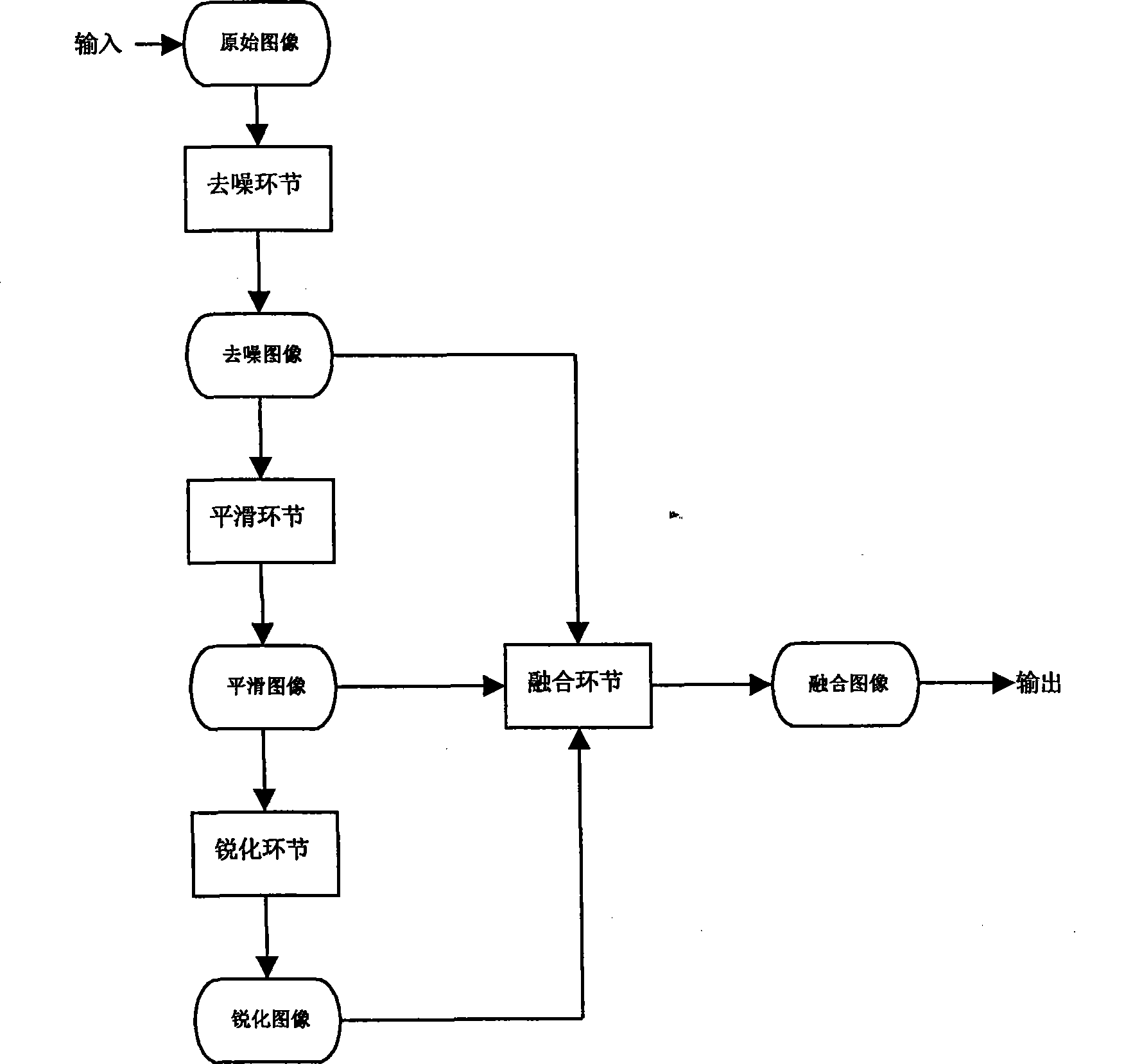

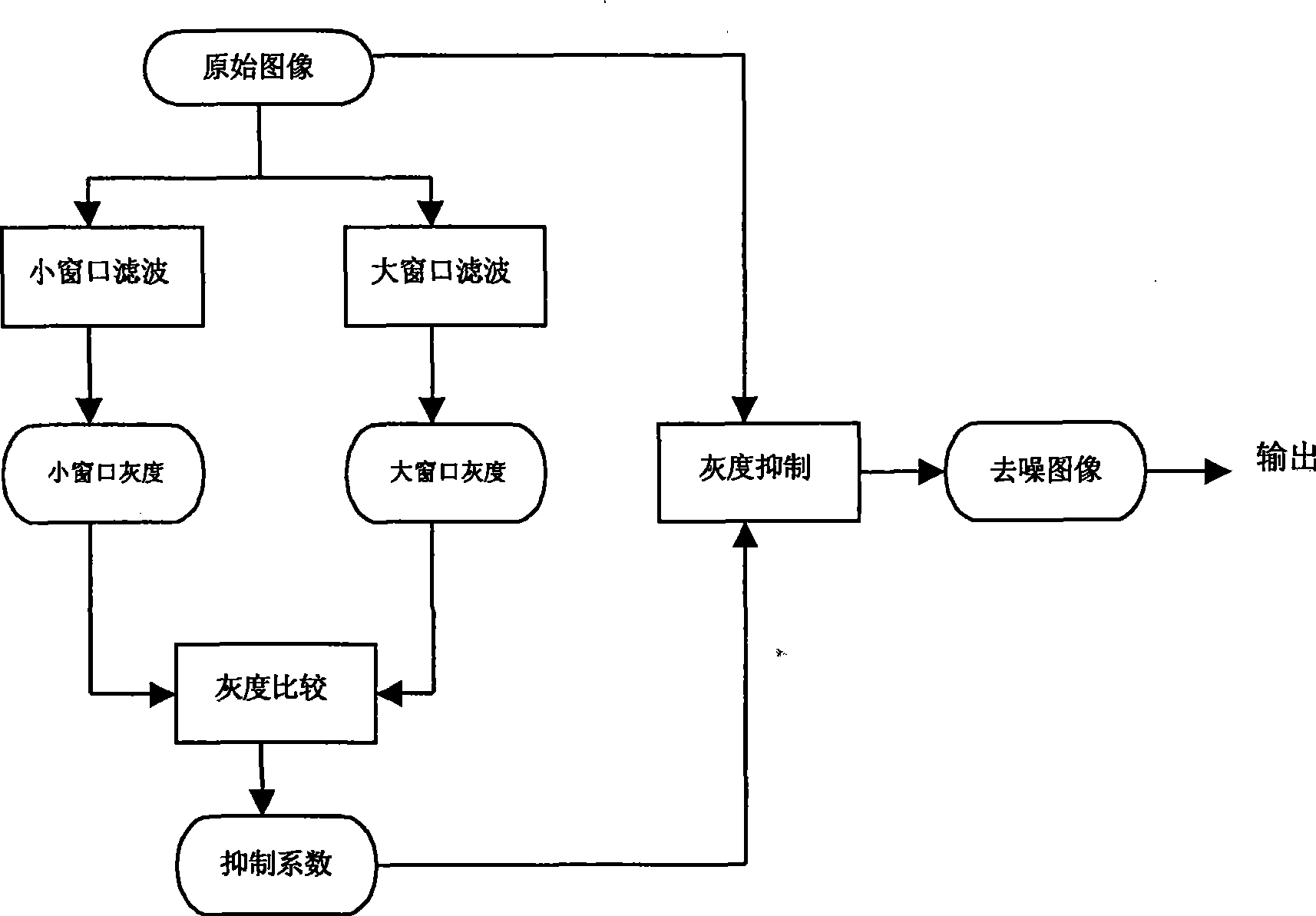

Method for ultrasonic image reinforcement and noise suppression

ActiveCN101459766AEnhanced inhibitory effectNo discontinuityTelevision system detailsColor television detailsSonificationImaging processing

The invention discloses a method and a system for improving the quality of images, the method and the system comprise a denoise segment, a smoothing segment, a sharpening segment and a syncretizing segment, wherein the denoise segment is used for eliminating lumen noises in original images, the smoothing segment is used for eliminating spot noises in the images output by the denoise segment, the sharpening segment is used for increasing details and characteristics in the images output by the smoothing segment, the syncretizing segment is used for syncretizing the images output by the denoise segment, the smoothing segment and the sharpening segment. The images output by the syncretizing segment can be sent to a display device for displaying after the processing of an image processing module and other sub-modules.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD

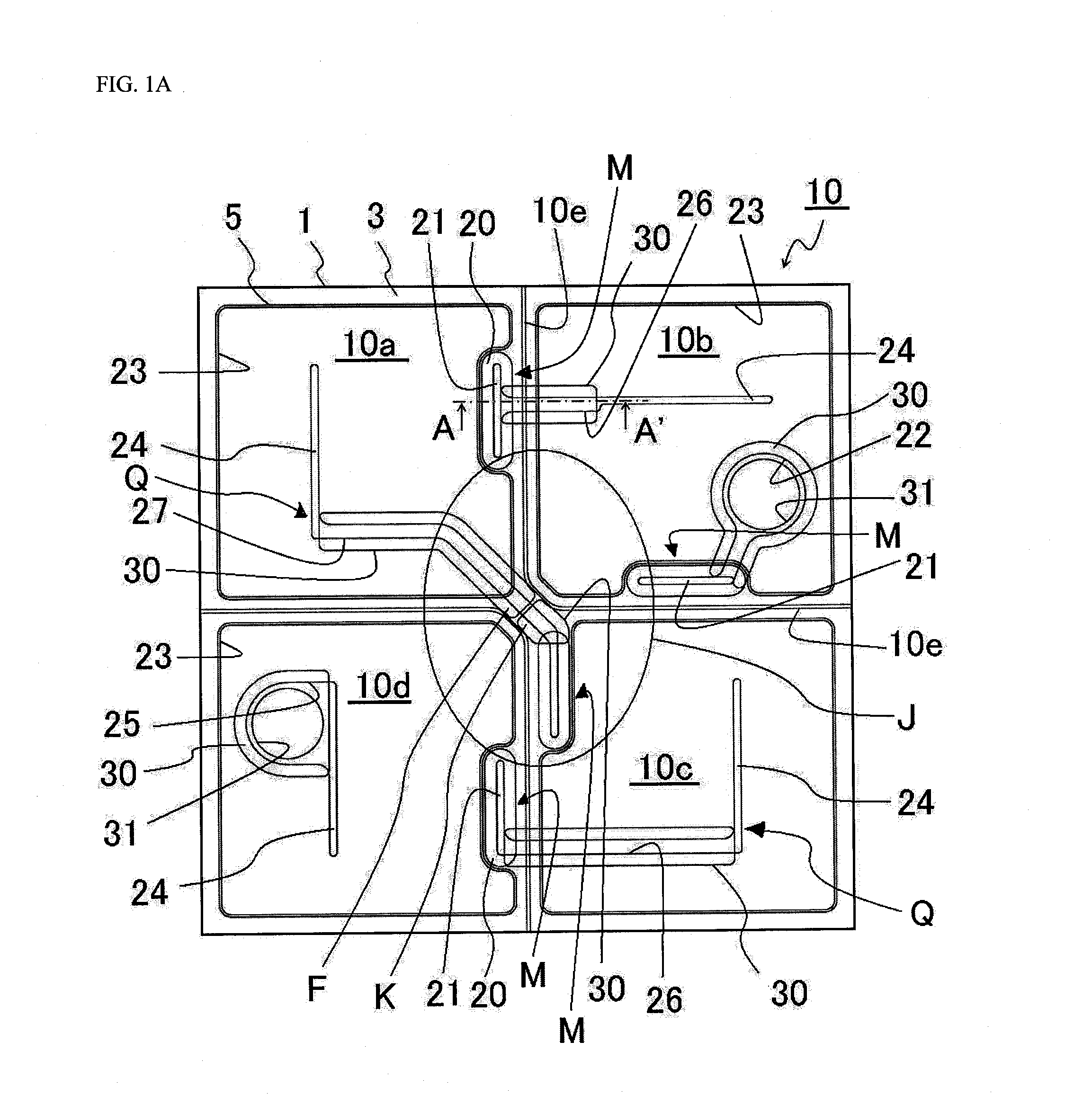

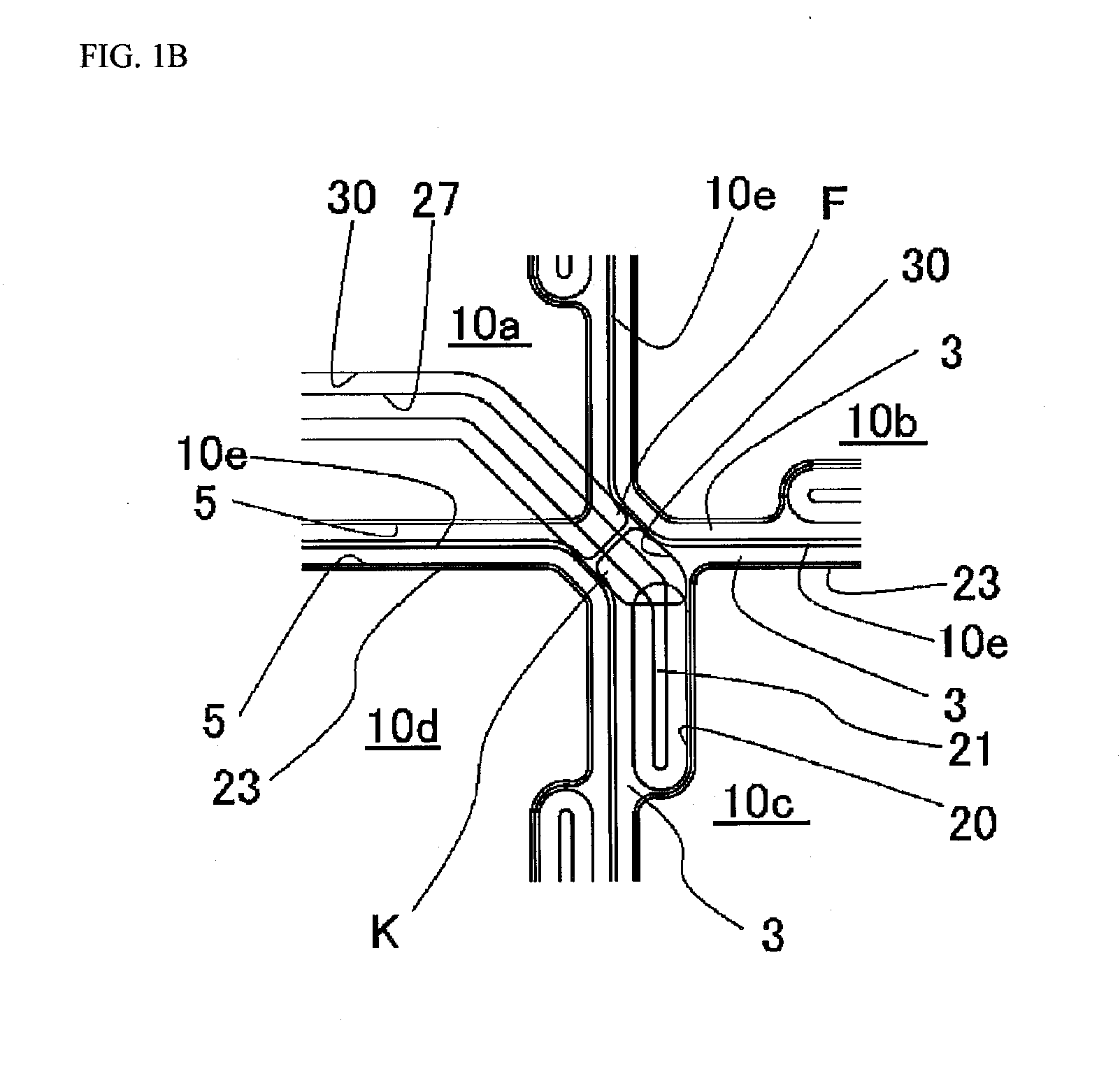

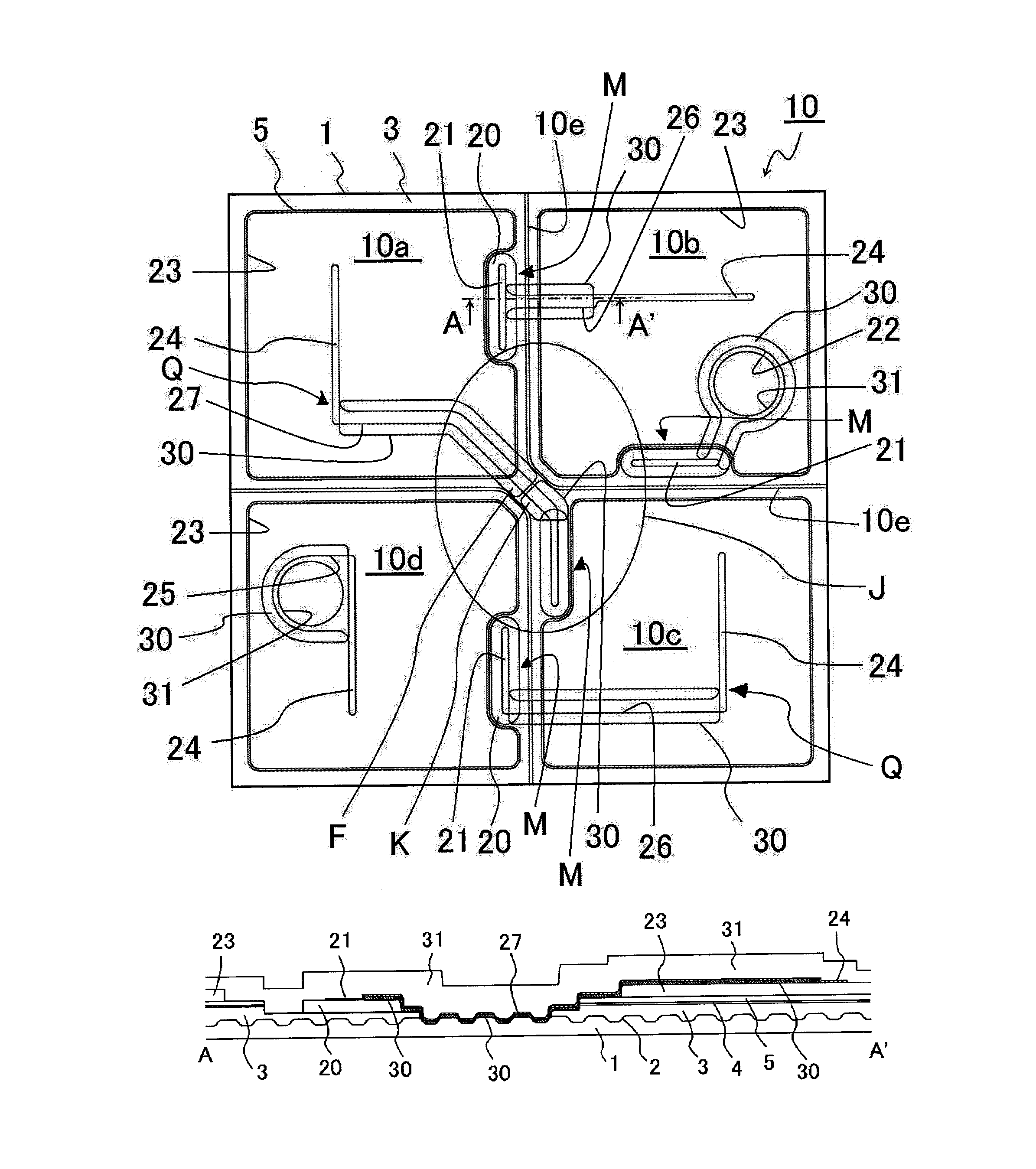

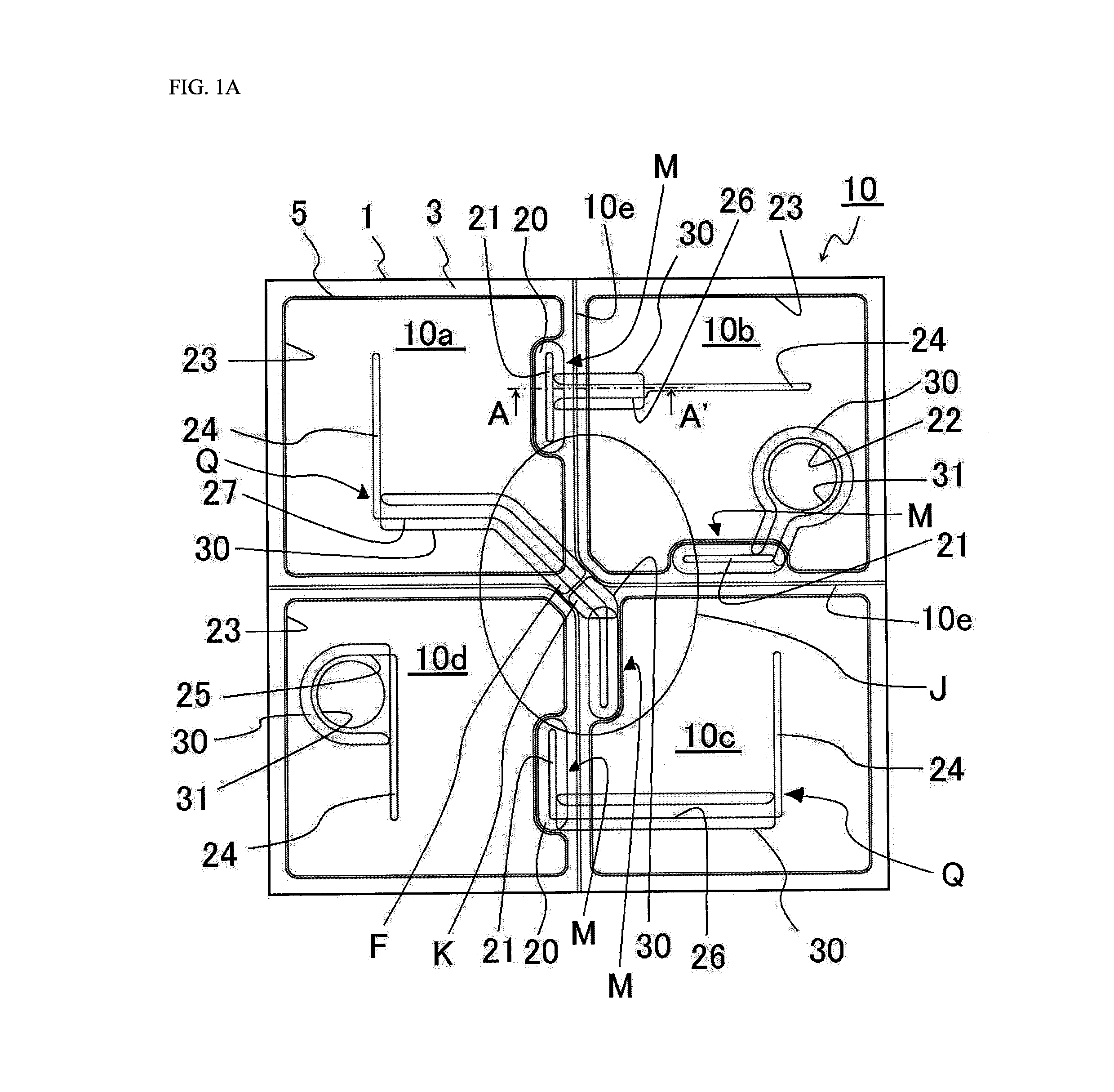

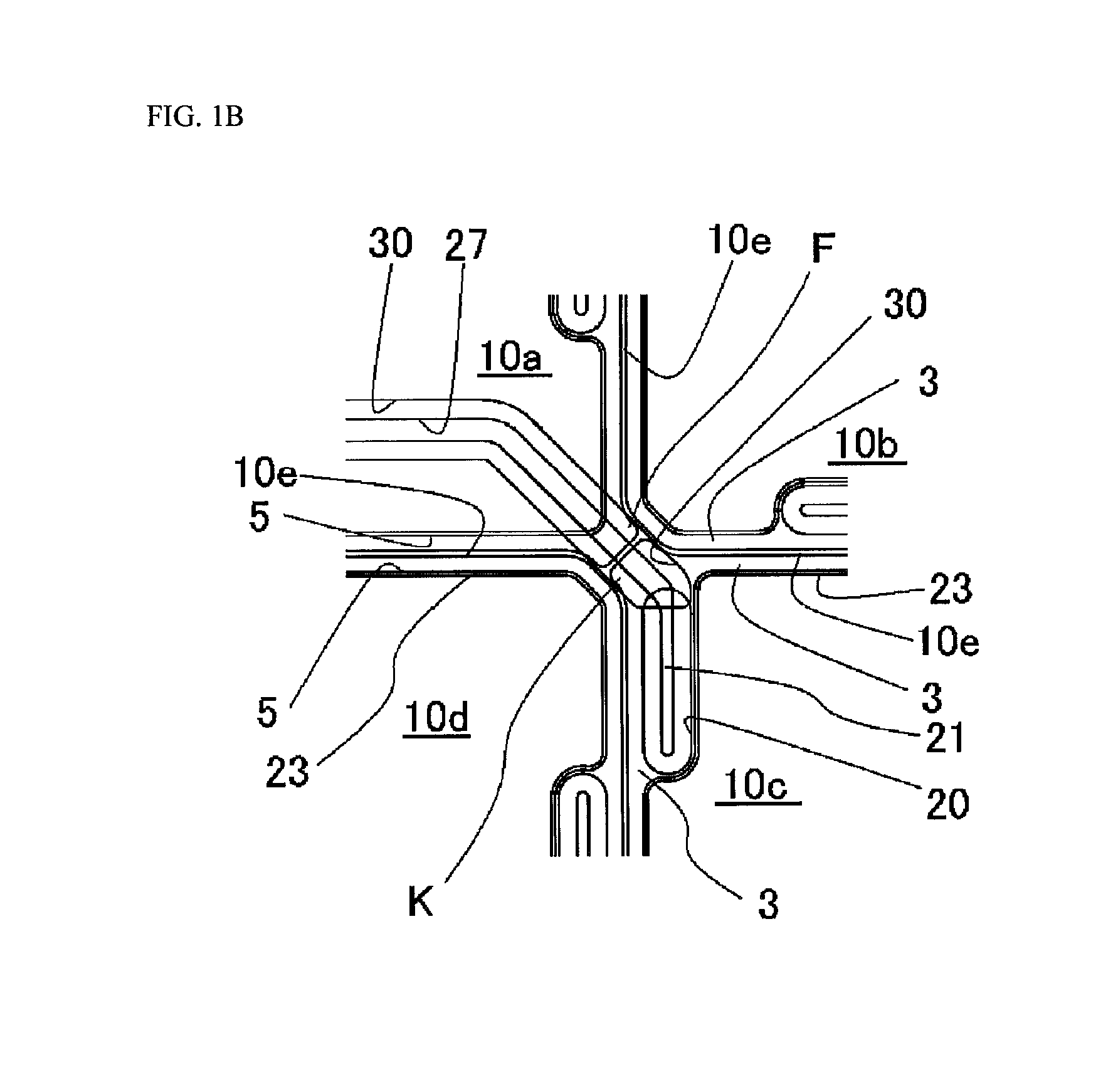

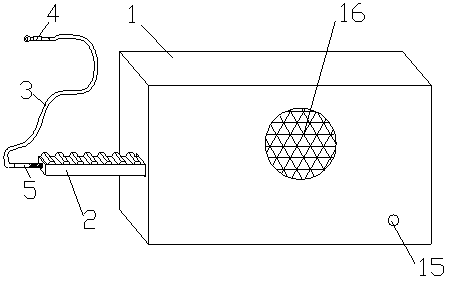

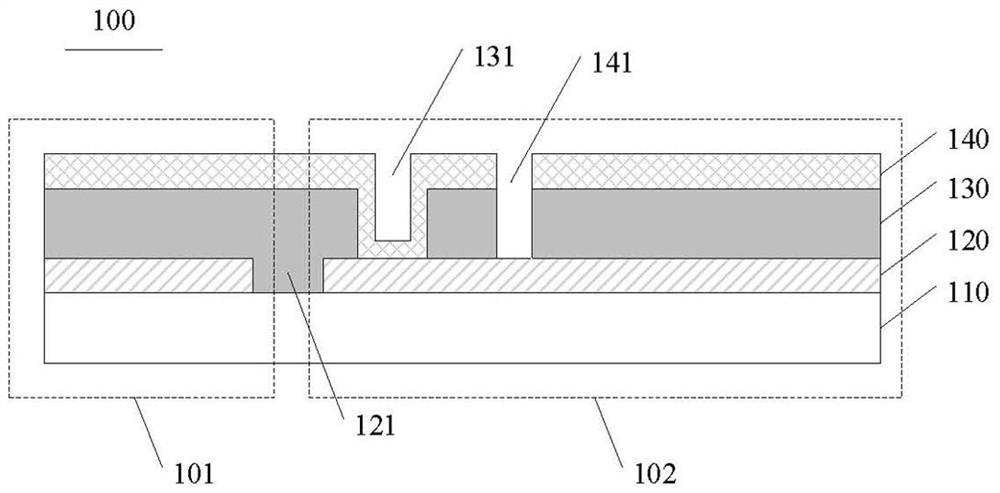

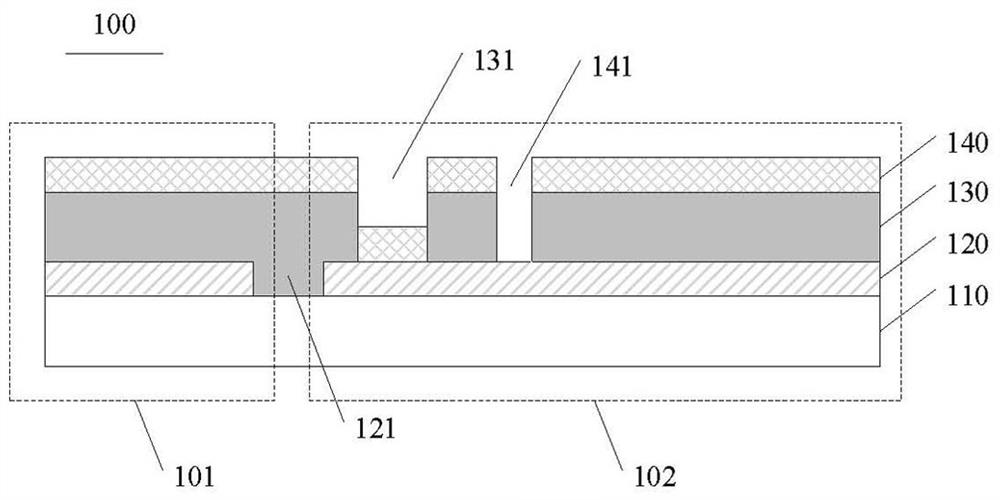

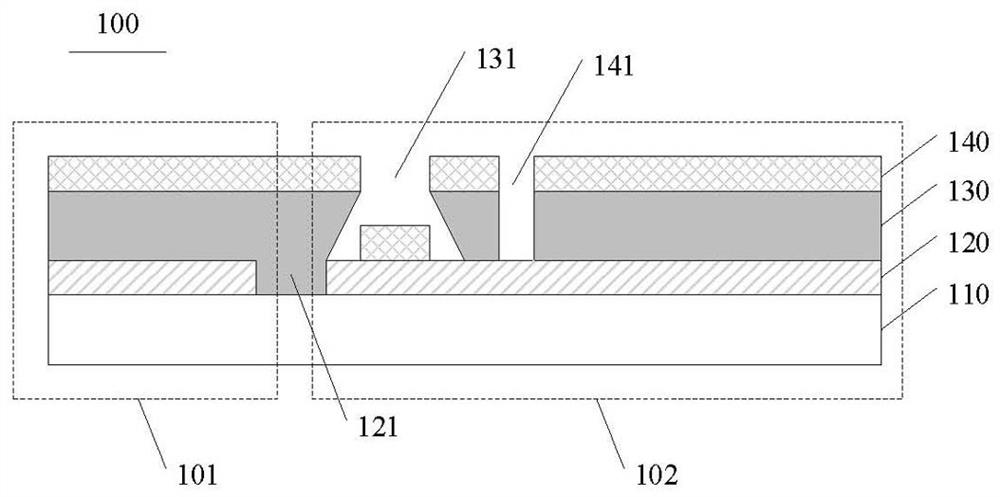

Semiconductor light emitting element

ActiveUS20140209938A1No discontinuityHigh emission intensitySolid-state devicesSemiconductor devicesSemiconductor

A semiconductor light emitting element includes: an insulating substrate having a plurality of convex portions on a surface thereof; a plurality of light emitting element components having semiconductor laminated bodies that are laminated on the insulating substrate and are separated from one another by a groove that exposes the convex portions; and a connector connecting between the light emitting element components. The light emitting element components include a first light emitting element component and a second light emitting element component. The first light emitting element component is separated from the second light emitting element component with the groove in between, and has a first protrusion that protrudes toward the second light emitting element component. The connector includes a first connector having a shape that straddles the groove and that follows the convex portions, and has a straight section.

Owner:NICHIA CORP

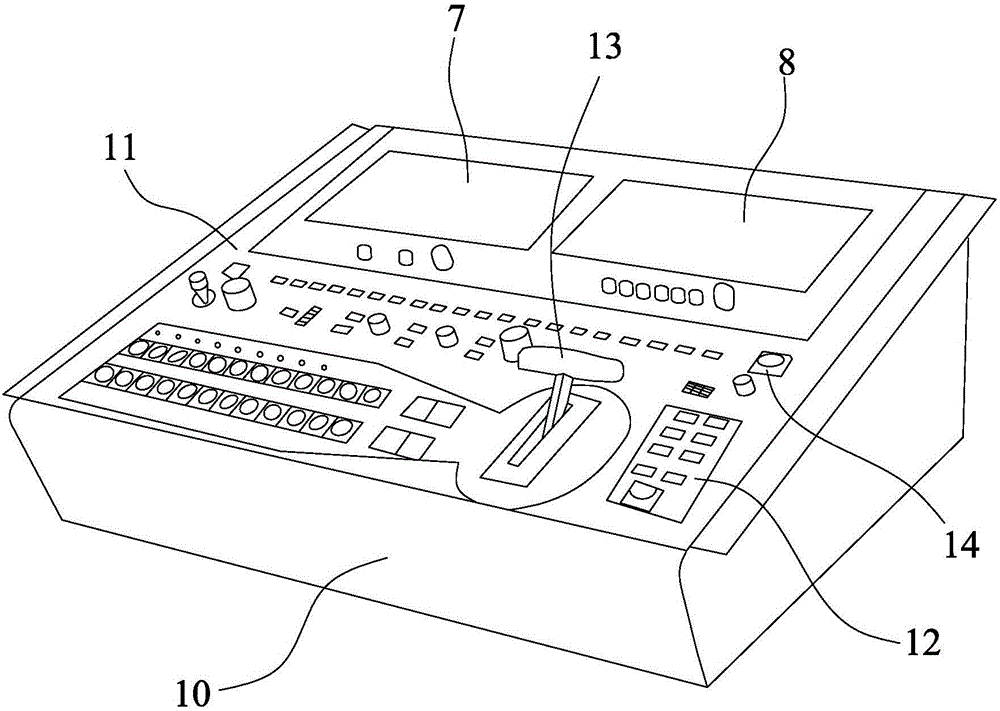

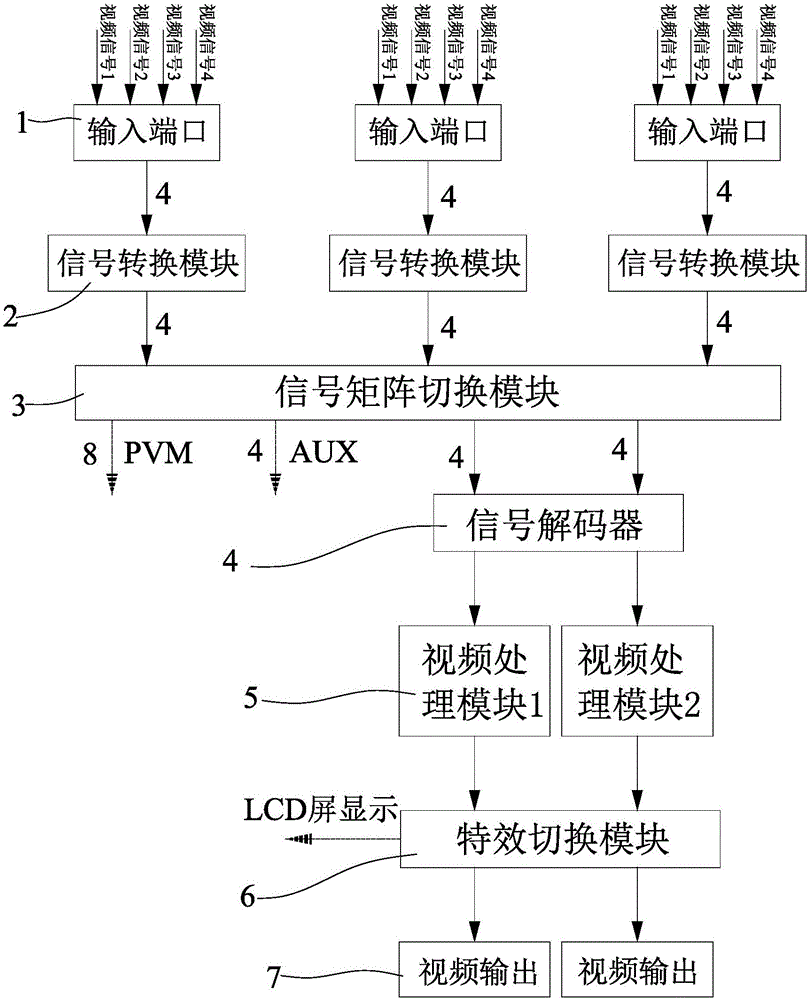

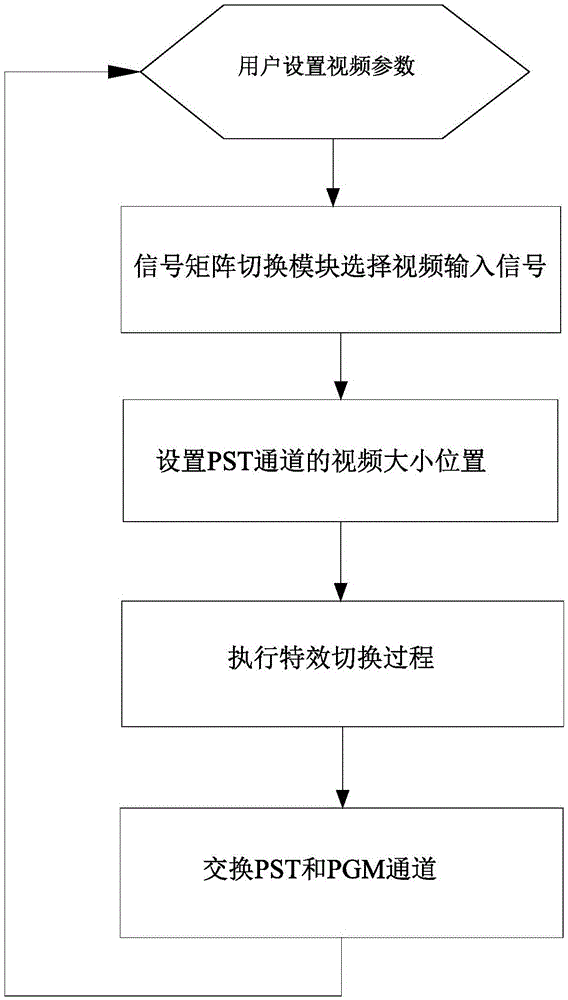

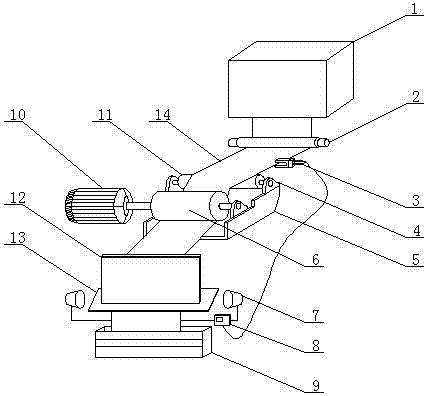

Special-effect switching device and special-effect switching method of desktop video processing control console

PendingCN106161995ASolve the problem that there will be a short black screenIncrease pleasureTelevision system detailsColor television detailsLED displayVideo processing

The invention discloses a special-effect switching device and a special-effect switching method of a desktop video processing control console. The special-effect switching device comprises an input port, a signal switching module, a signal matrix switching module, a signal decoder, a video processing module, a special-effect switching module, a pre-monitoring window and a main output display screen; the input port is connected with the signal switching module, the signal switching module is connected to the signal matrix switching module, the signal matrix switching module is connected with the signal decoder, the signal decoder is connected with the video processing module, and the video processing module is connected with special-effect switching module, the pre-monitoring window and the main output display screen; the special-effect switching device provided by the invention solves the problem of short-time blank screen of an LED display screen in a traditional video source switching process, thereby improving user happiness and enhancing user experience.

Owner:XIAMEN RGBLINK SCI & TECH

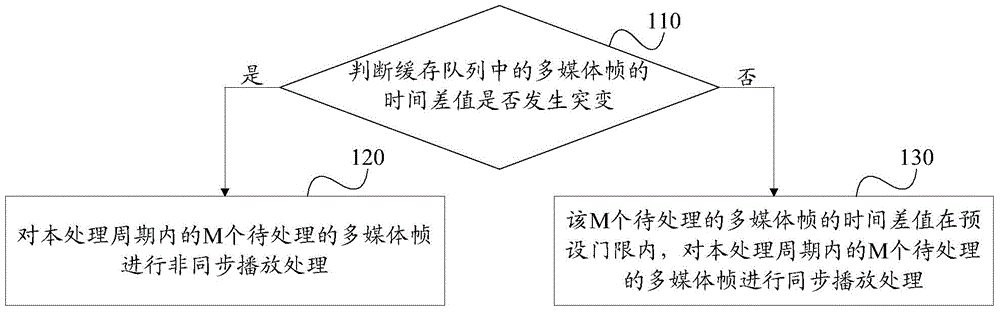

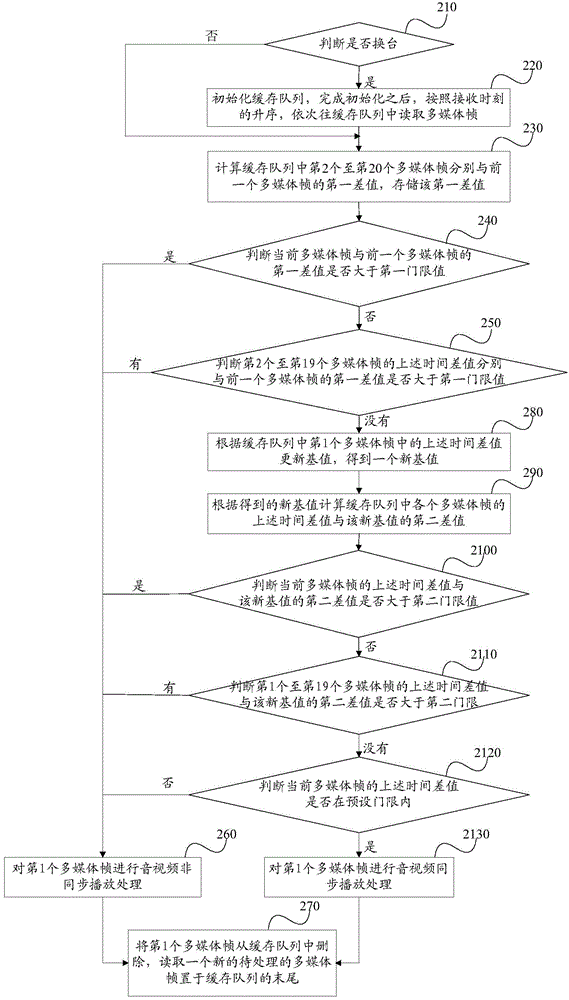

Multimedia-frame processing method and device

ActiveCN104394450ANo discontinuityAvoid problems such as discontinuitiesSelective content distributionTime differenceComputer science

The invention discloses a multimedia-frame processing method and device. The method comprises determining whether time difference values of multimedia frames in a buffer queue mutate, wherein the time difference values are the differences between display time label indication moments and receiving moments of the multimedia frames, the buffer queue comprises N to-be-processed multimedia frames which are sorted according to receiving moments, and N is an integer; performing non-synchronous playing on M to-be-processed multimedia frames in the processing period wherein the M to-be-processed multimedia frames are the front M multimedia frames which are arranged in an ascending mode according to the receiving moments in the buffer queue; performing synchronous playing on M to-be-processed multimedia frames in the processing period if non multimedia frames with the time difference values mutated in the buffer queue and the time difference values of the M to-be-processed multimedia frames are within the preset threshold. By means of the method and the device, good transient and steady state responses are achieved.

Owner:HISENSE BROADBAND MULTIMEDIA TECH

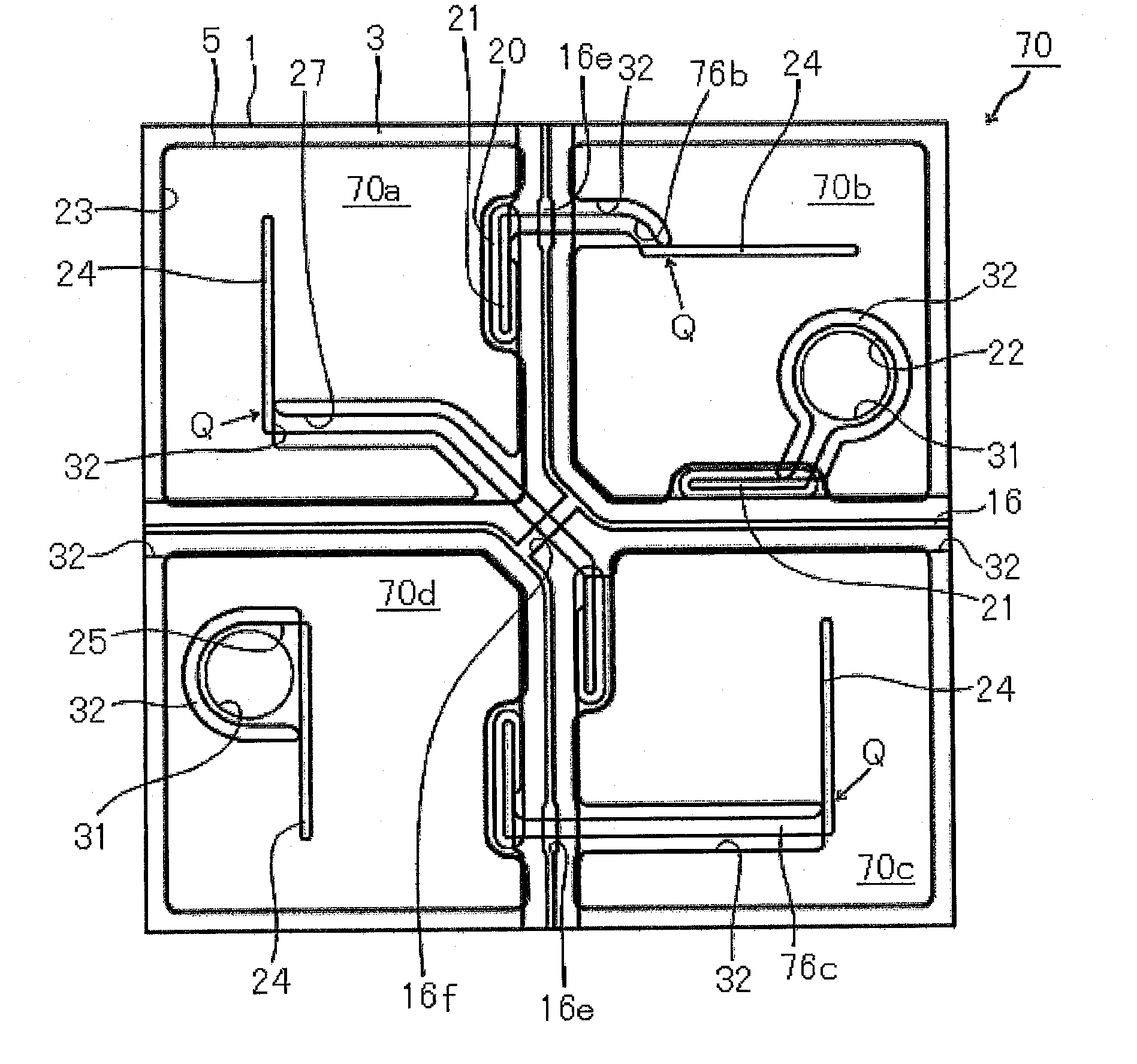

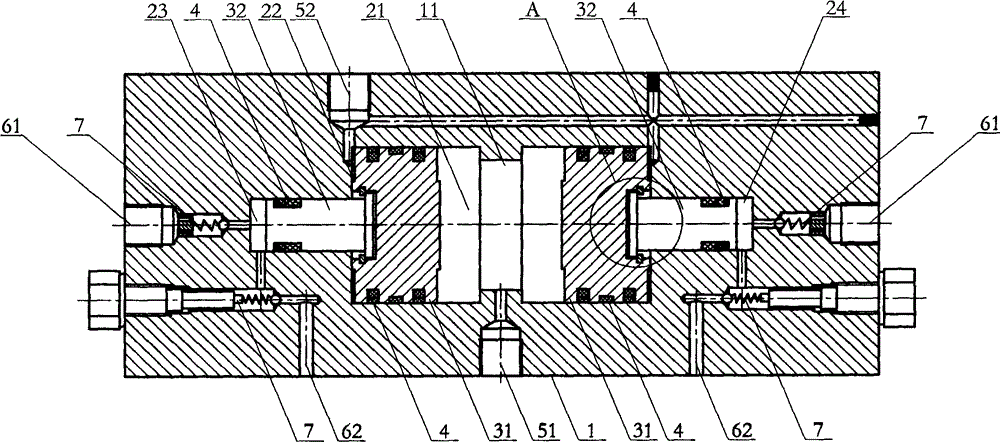

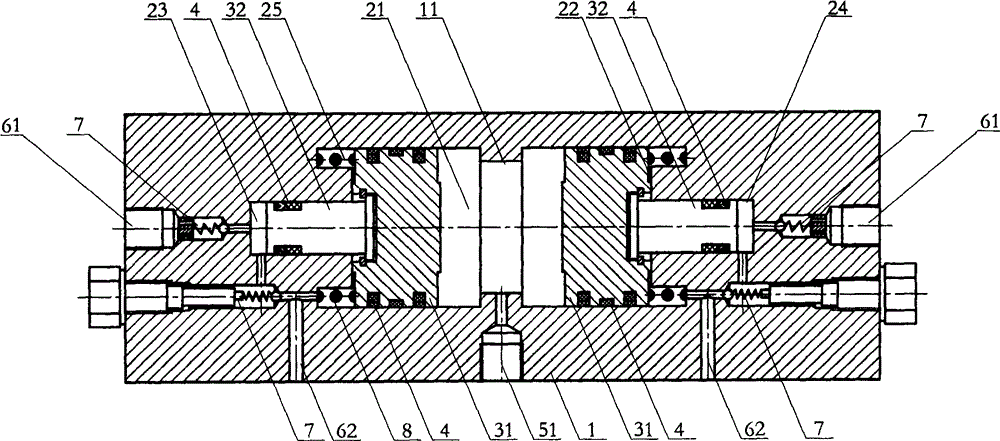

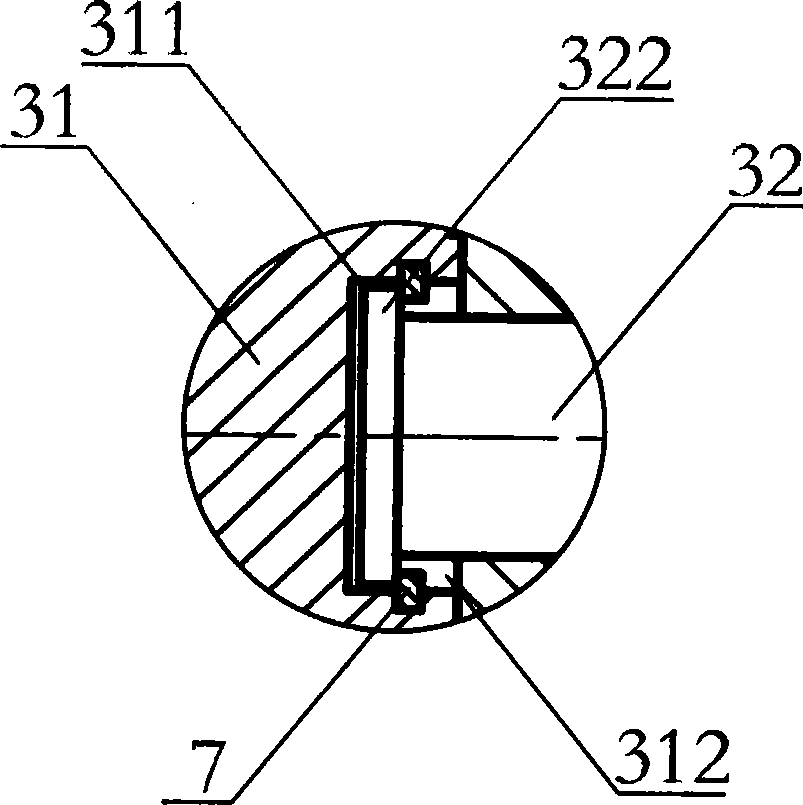

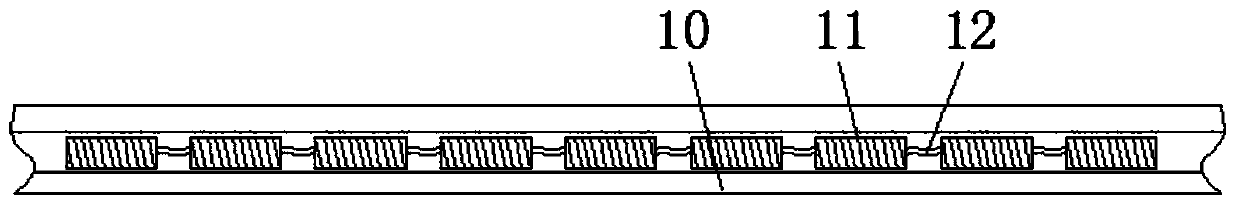

Booster pump and boosting method thereof

ActiveCN104948410ANo discontinuityMeet the needs of actual high-pressure operationsPositive displacement pump componentsPiston pumpsPlunger pumpHigh pressure

The invention relates to a booster pump and a boosting method thereof. A middle cavity, a left cavity and a right cavity are arranged in the middle of the inner side of a booster pump body. A locating column is arranged in the middle of the inner wall of the middle cavity. Piston rods are arranged on the two sides of the locating column. The piston rods comprise upper piston rods and lower piston rods. The section areas of the upper piston rods are at least two times of the section areas of the lower piston rods. The upper piston rods are arranged in the middle cavity. The lower piston rods are arranged in the left cavity and the right cavity. Through a plunger pump in the prior art, oil liquid with certain pressure intensity is provided for a driving cavity of the booster pump by a device, by controlling the ratio of the section areas of the upper piston rods and the section areas of the lower piston rods, oil liquid with certain pressure intensity is generated in the left cavity and the right cavity at the same time, namely the higher the ratio of the section areas of the upper piston rods and the section areas of the lower piston rods is, the higher the pressure intensity of the generated oil liquid is, the device generates high pressure intensity, meanwhile, large-flow oil liquid can be generated, discontinuity does not exist, and practical high-pressure working requirement is met.

Owner:季金锋

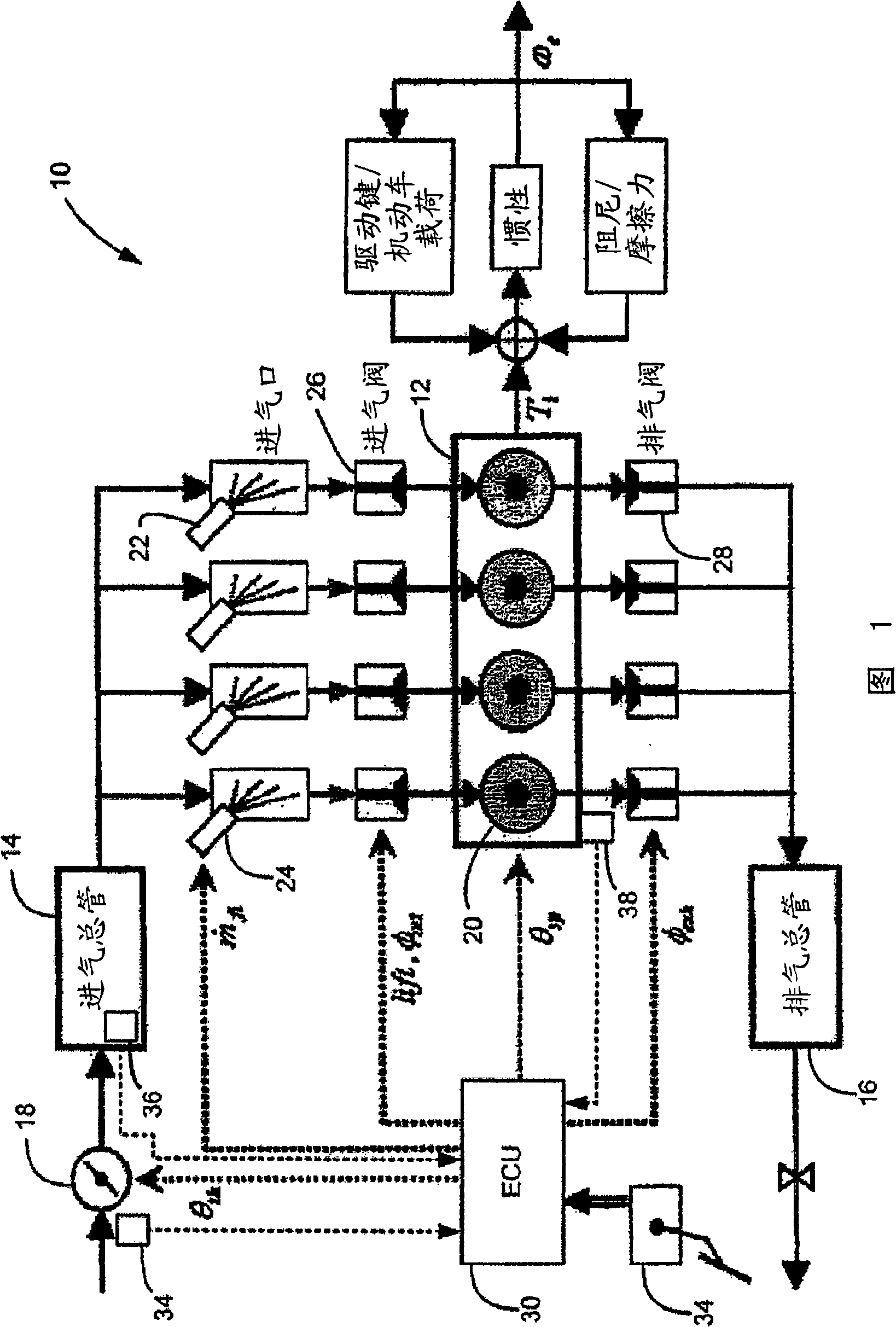

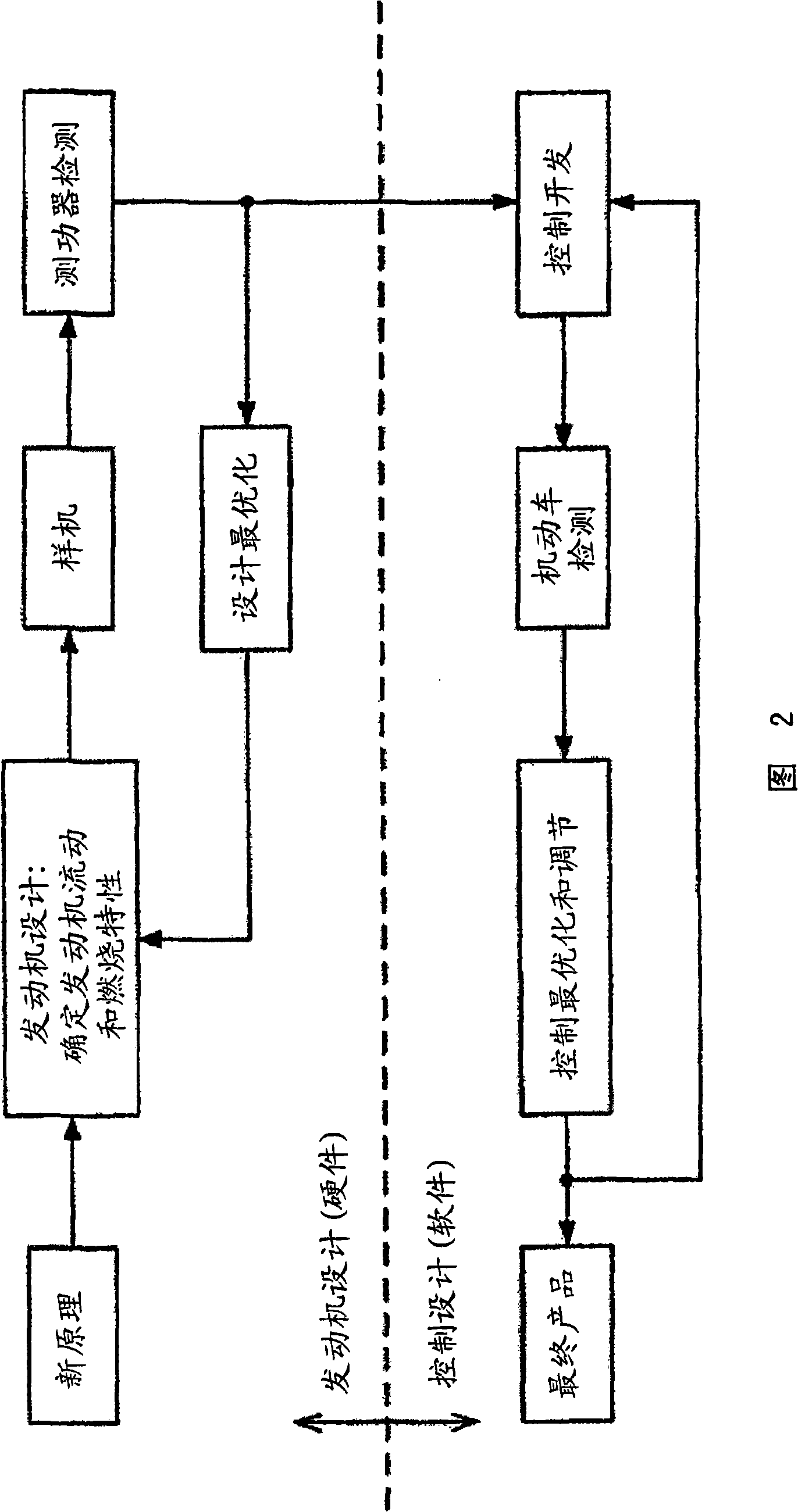

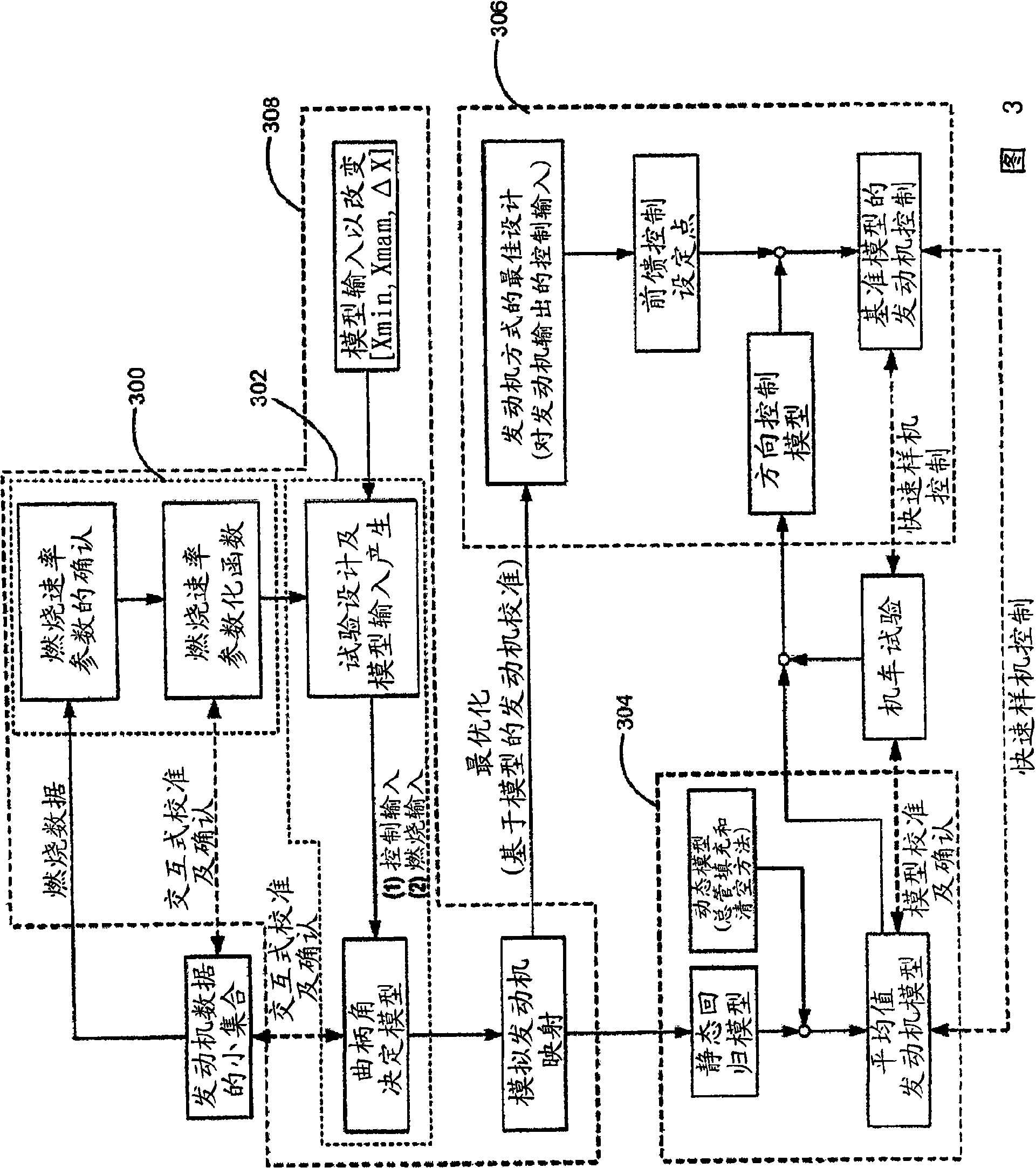

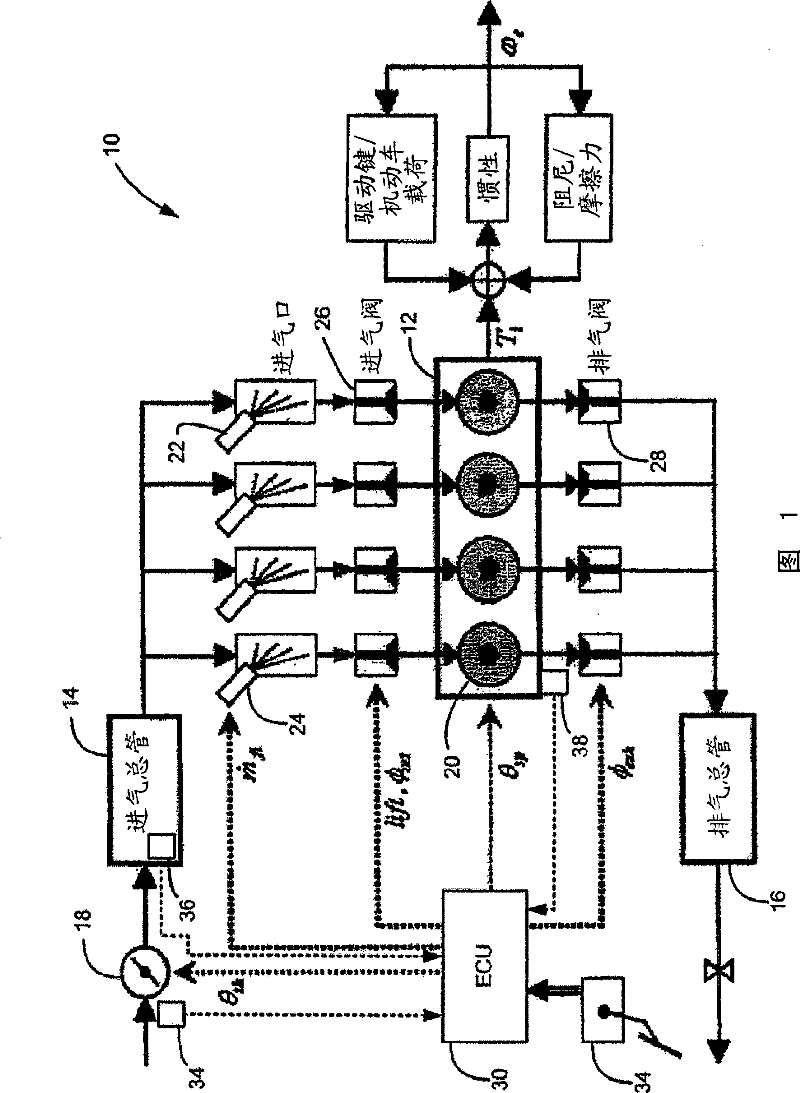

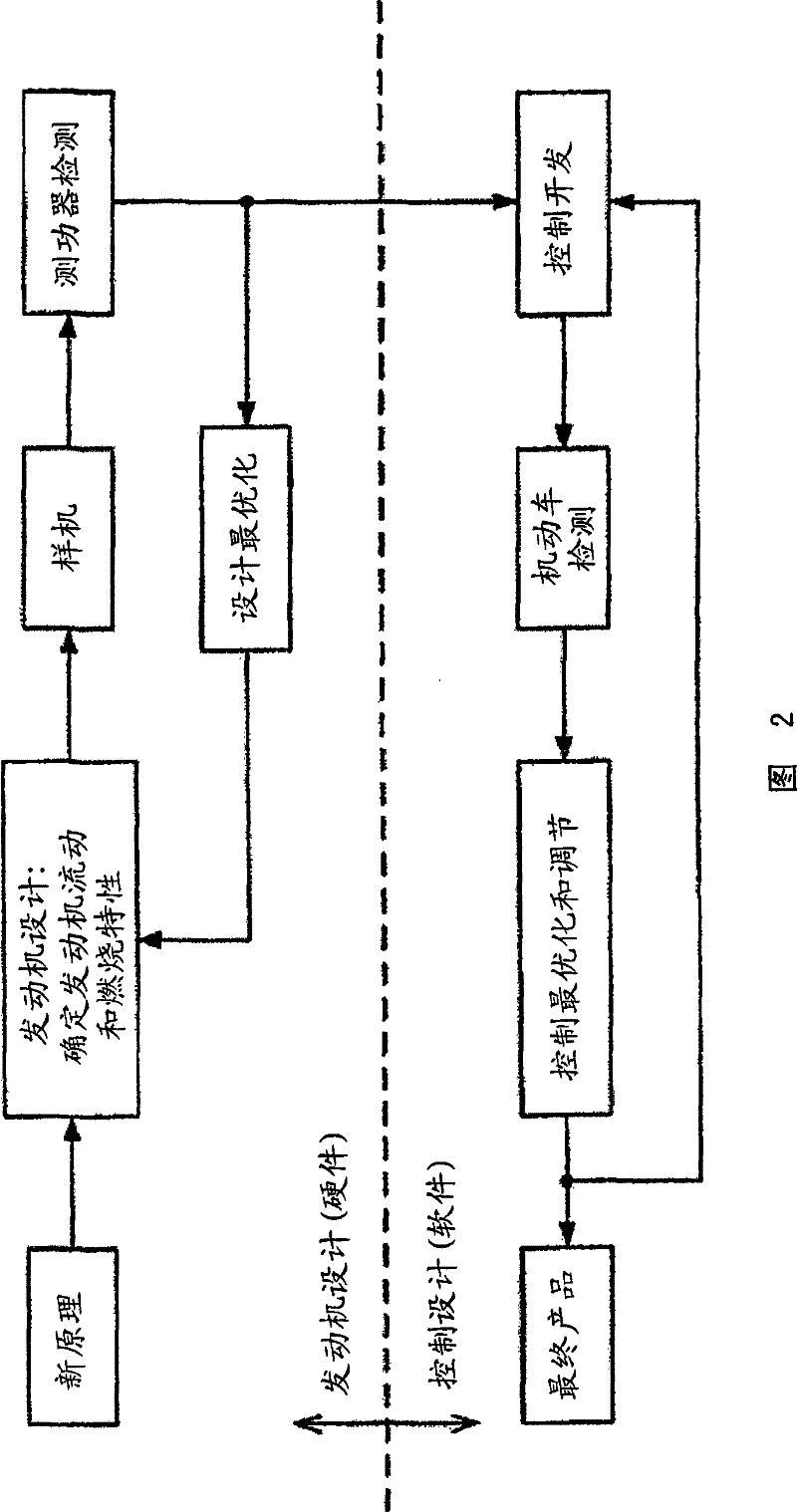

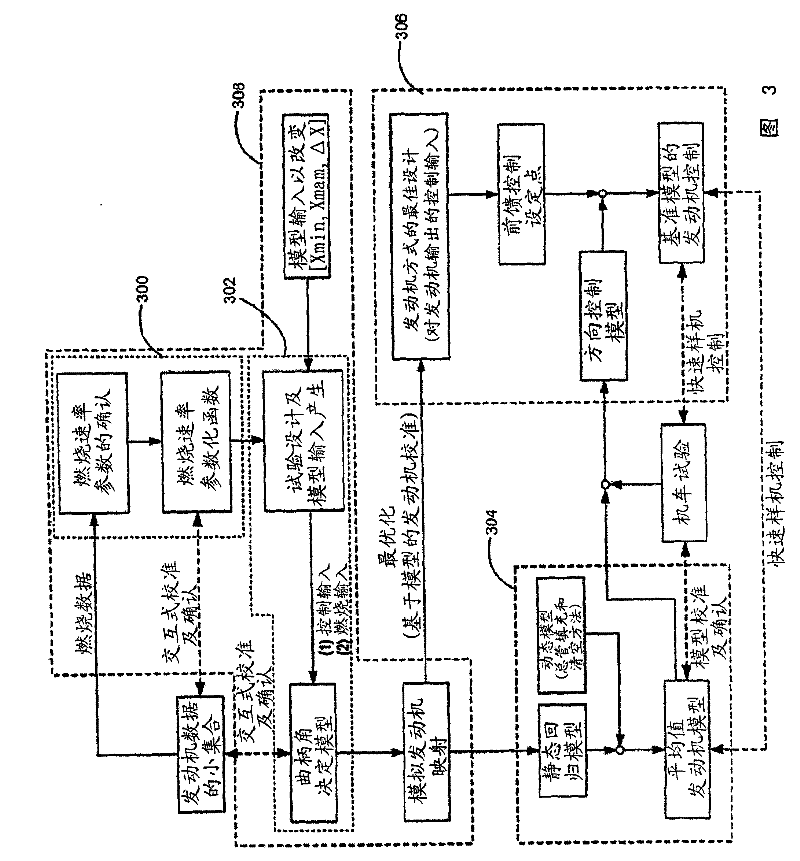

Rapid bench examination and modeling method for engine

The invention discloses a bench testing method during the development process of an engine as well as a method for building an engine model, including testing the engine under the operation conditions of a plurality of actual engines and searching the actual engine data which accords with the operation conditions of the actual engine; confirming a plurality of parameter functions based on the actual engine data and each parameter function is corresponding to one operation parameter of the engine; generating a plurality of combustion functions used for the operation conditions of a plurality of engines which include a plurality of the operation conditions of the actual engines and a plurality of the operation conditions of virtual engines; calibrating the virtual model of the engine based on a plurality of combustion parameters and applying the virtual model to carry out bench testing on a plurality of engines.

Owner:GM GLOBAL TECH OPERATIONS LLC

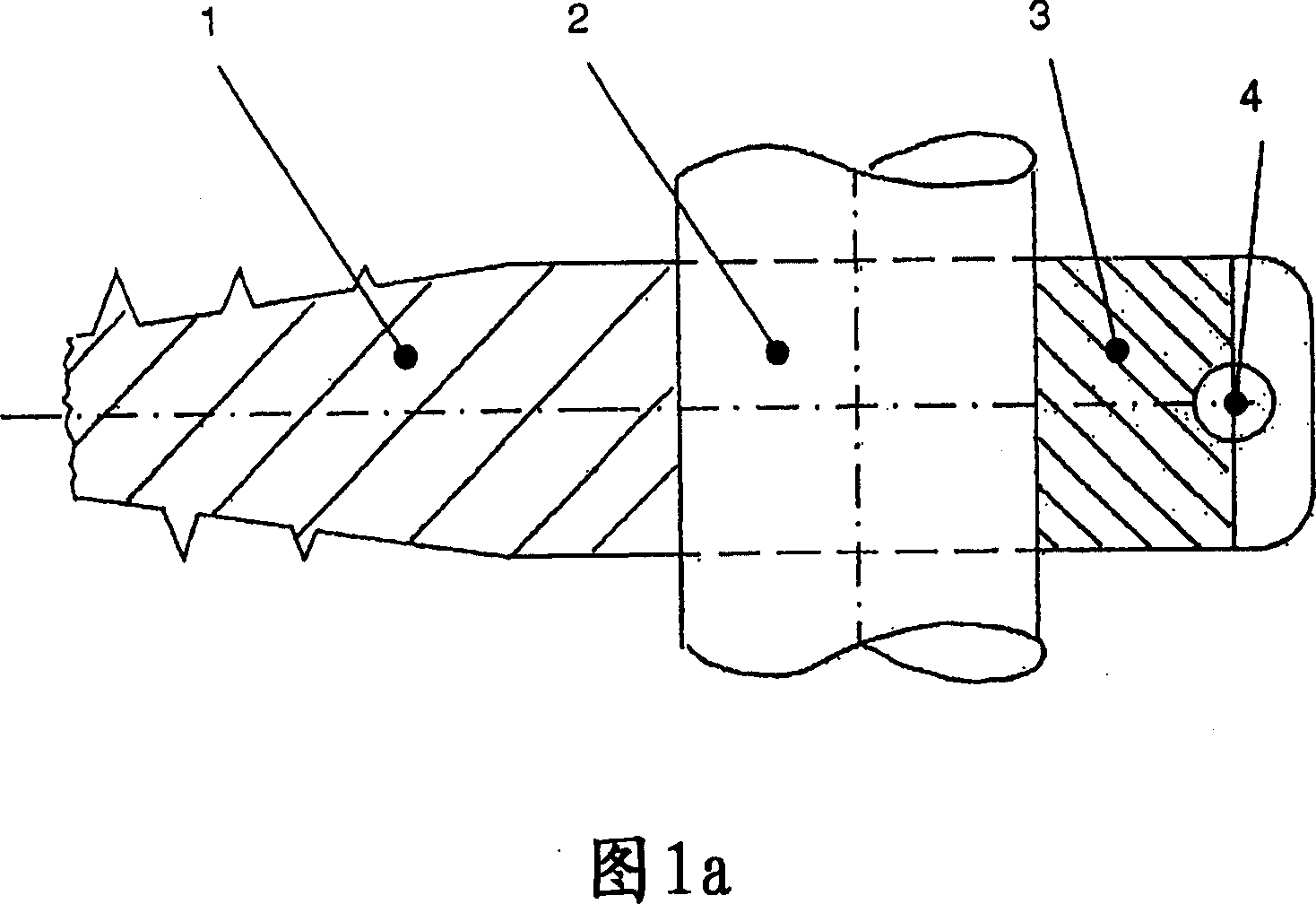

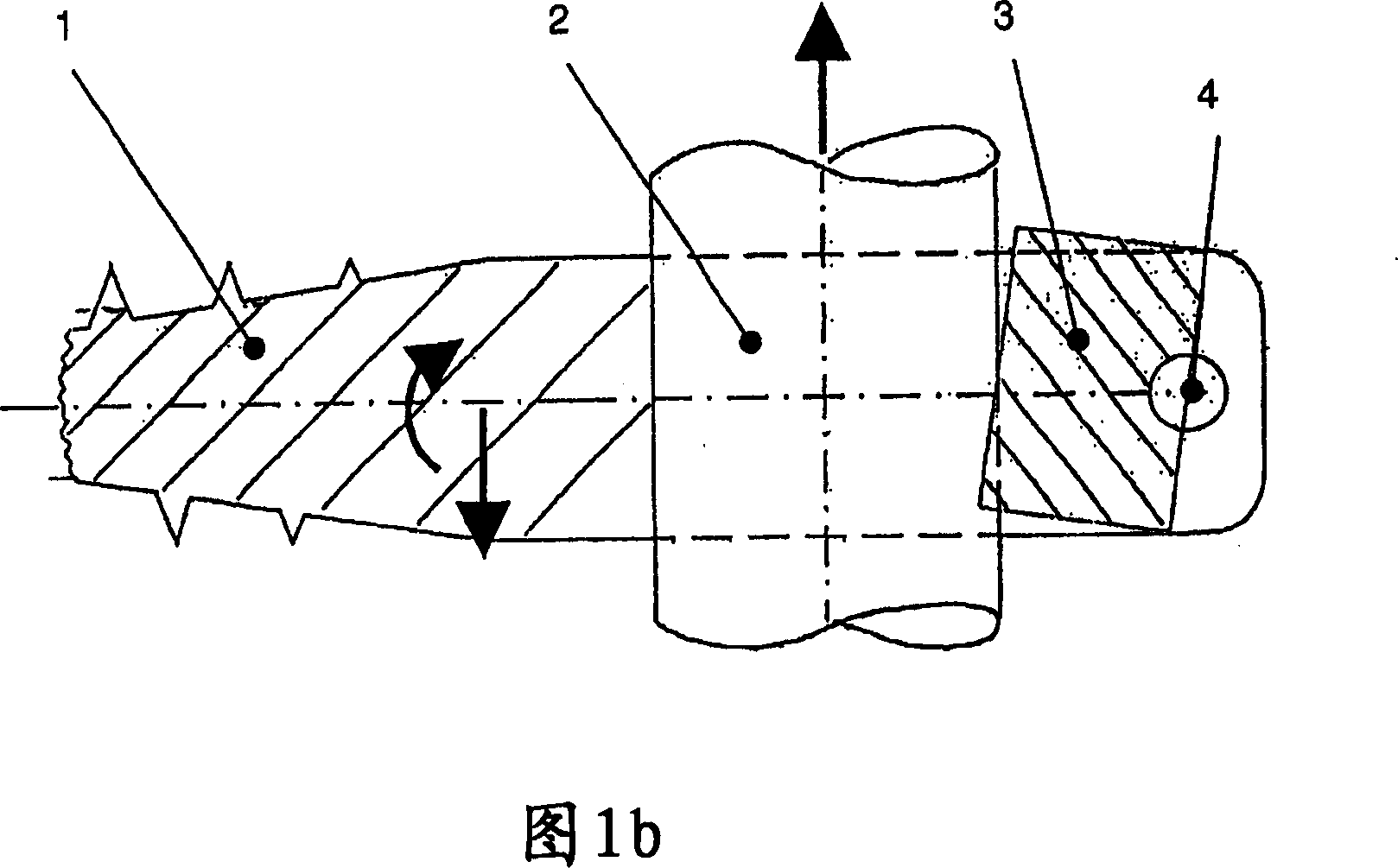

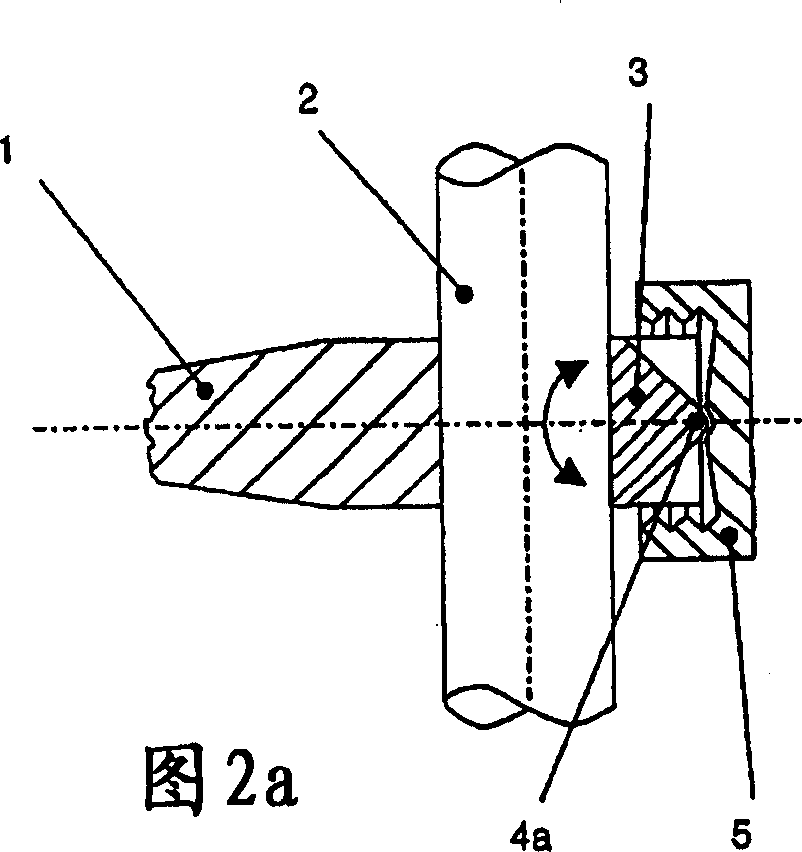

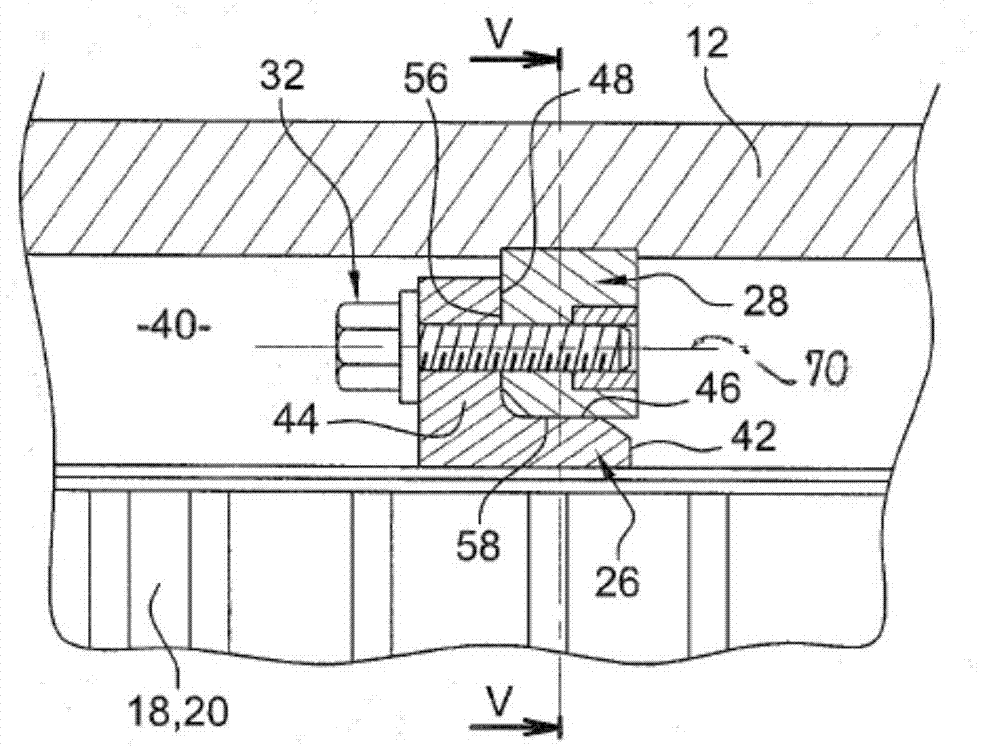

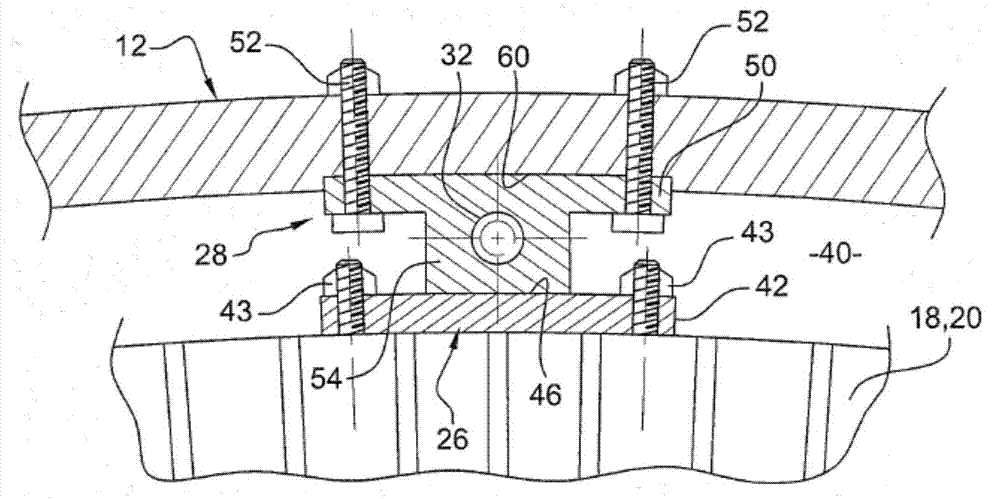

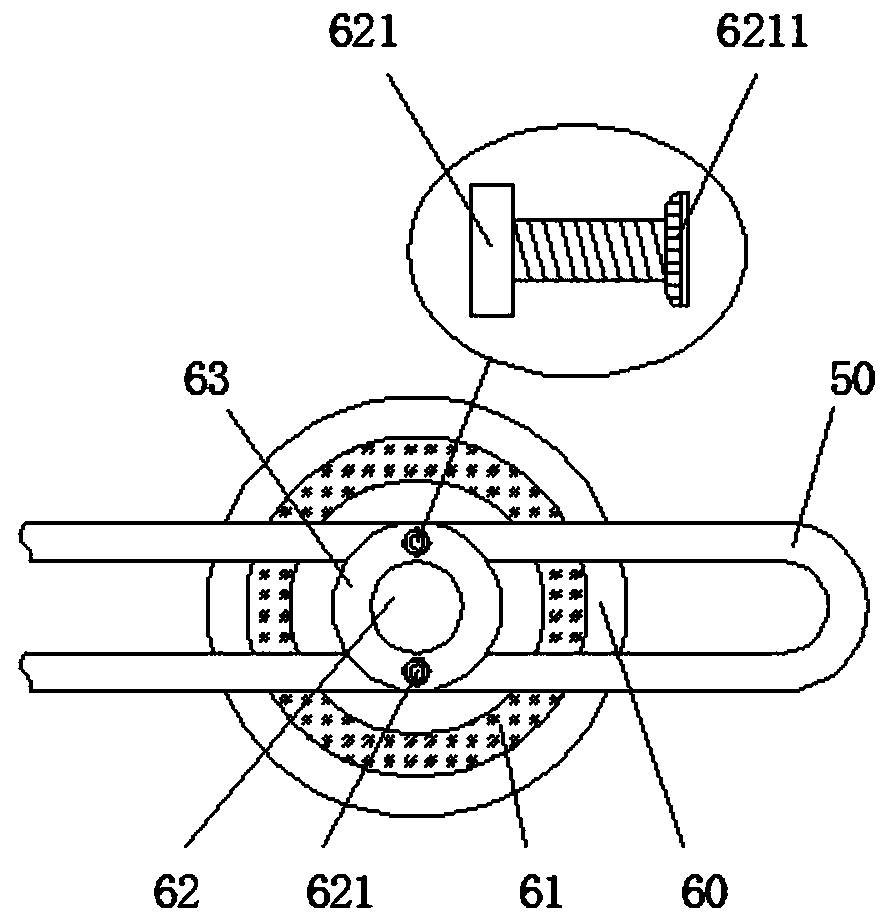

Dynamic clamping device for spinal implant

InactiveCN1931105ADurable and reliable deliveryPrecise positioningInternal osteosythesisSpinal implantsSpinal columnSpinal implant

To provide a spinal implant for stabilizing the vertebra bone by elasticity. An elastic rod is fixed to a receiving part of a stalk-like screw in a mode of non-forced engagement by a movable filling piece and a fixing element, and this non-forced engagement is additionally supported by contribution of dynamic engagement when load is applied.

Owner:伯德比德尔曼股份公司

Semiconductor light emitting element

ActiveUS9041039B2No discontinuityHigh emission intensitySolid-state devicesSemiconductor devicesSemiconductorOptoelectronics

A semiconductor light emitting element includes: an insulating substrate having a plurality of convex portions on a surface thereof; a plurality of light emitting element components having semiconductor laminated bodies that are laminated on the insulating substrate and are separated from one another by a groove that exposes the convex portions; and a connector connecting between the light emitting element components. The light emitting element components include a first light emitting element component and a second light emitting element component. The first light emitting element component is separated from the second light emitting element component with the groove in between, and has a first protrusion that protrudes toward the second light emitting element component. The connector includes a first connector having a shape that straddles the groove and that follows the convex portions, and has a straight section.

Owner:NICHIA CORP

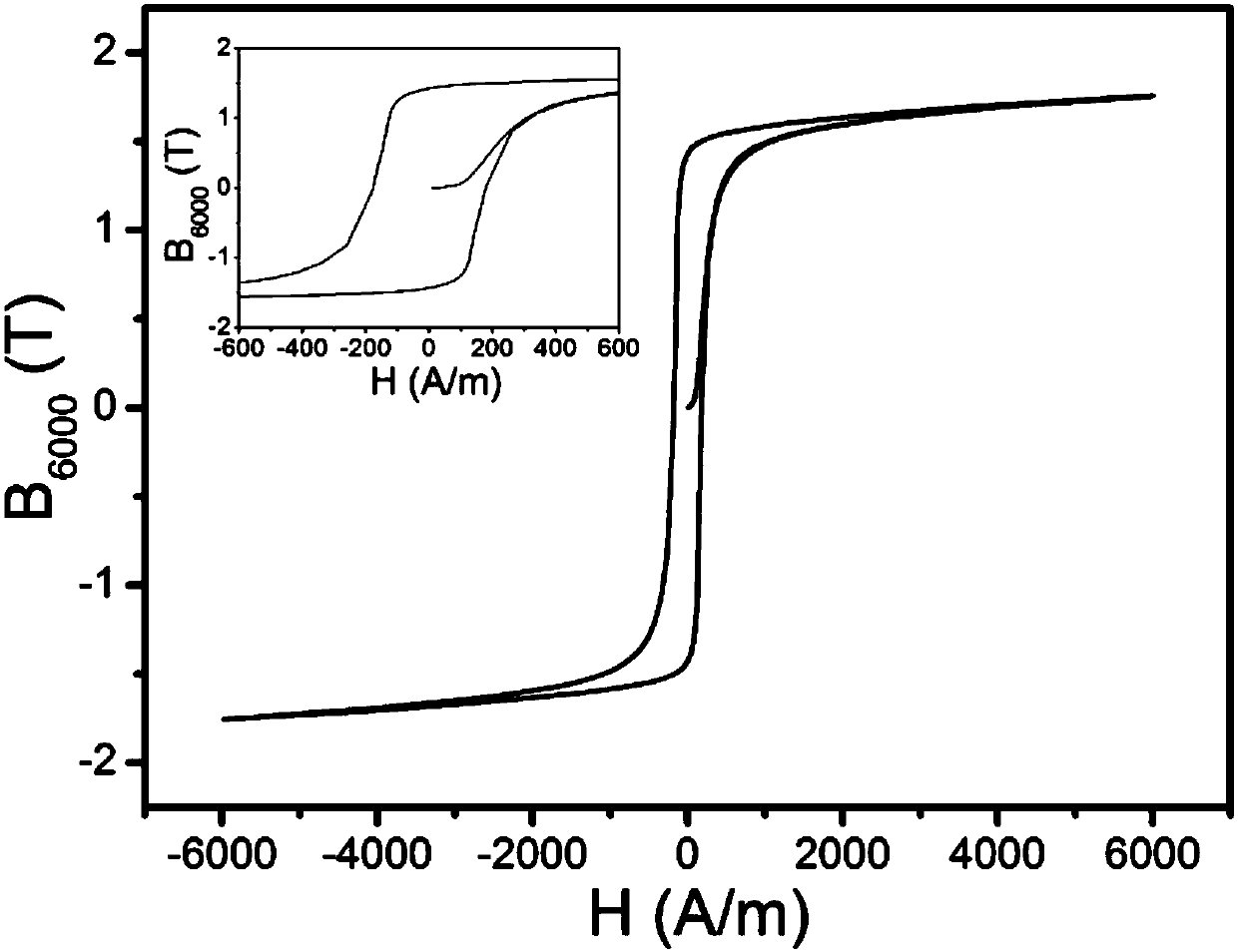

Preparation method of engine fuel nozzle electromagnetic valve magnetic element

InactiveCN107815592ASave resourcesSave energyTransportation and packagingMetal-working apparatusIron powderVolumetric Mass Density

The invention discloses a preparation method of an engine fuel nozzle electromagnetic valve magnetic element, and belongs to the technical field of engine electromagnetic valve preparation. Firstly, carbonyl iron powder is uniformly mixed with various alloy powder; then, the mixed powder is uniformly mixed with a proper binding agent for mixing at a certain temperature to prepare an injection feedwith uniform mixing and excellent fluidity; and a blank of an electromagnetic valve magnetic element is prepared by adopting an injection molding technology. After the solvent degreasing and the removal of part of the binding agent are performed on an injection blank firstly, the remained binding agent in the blank is totally removed by adopting a heating decomposition method, and the blank is sintered by 1-8 hours at 1200-1400 DEG C to obtain an electromagnetic valve magnetic element product. In the prepared electromagnetic valve magnetic element material, the density is higher than 98%, thesaturated magnetic induction strength B6000 is 1.5-1.7 T, the maximum magnetic conductivity is 5-25 mH / m, the coercivity is less than 160 A / m, the resistivity is 50-100 u omega.cm, and the product size precision is less than +-0.3%.

Owner:UNIV OF SCI & TECH BEIJING

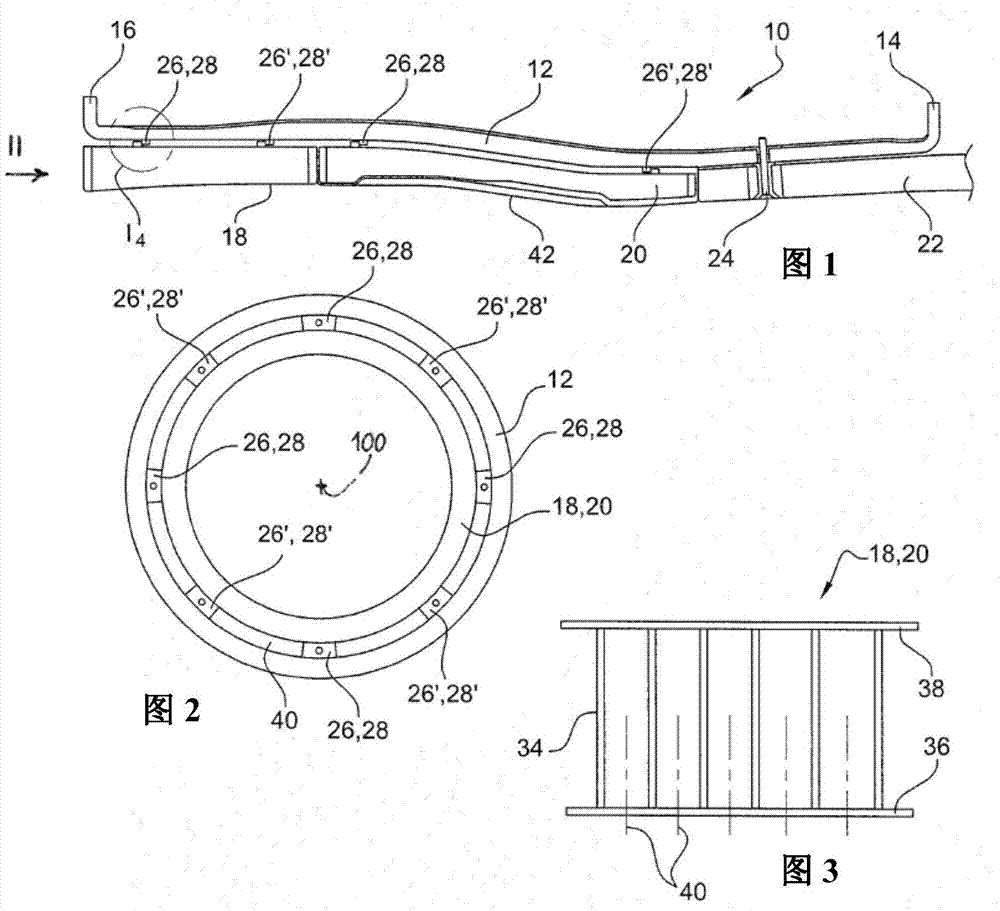

Turbomachine casing

ActiveCN104769233AHelp with installationWeight increaseEngine manufactureEngine fuctionsAerospace engineeringSurface plate

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

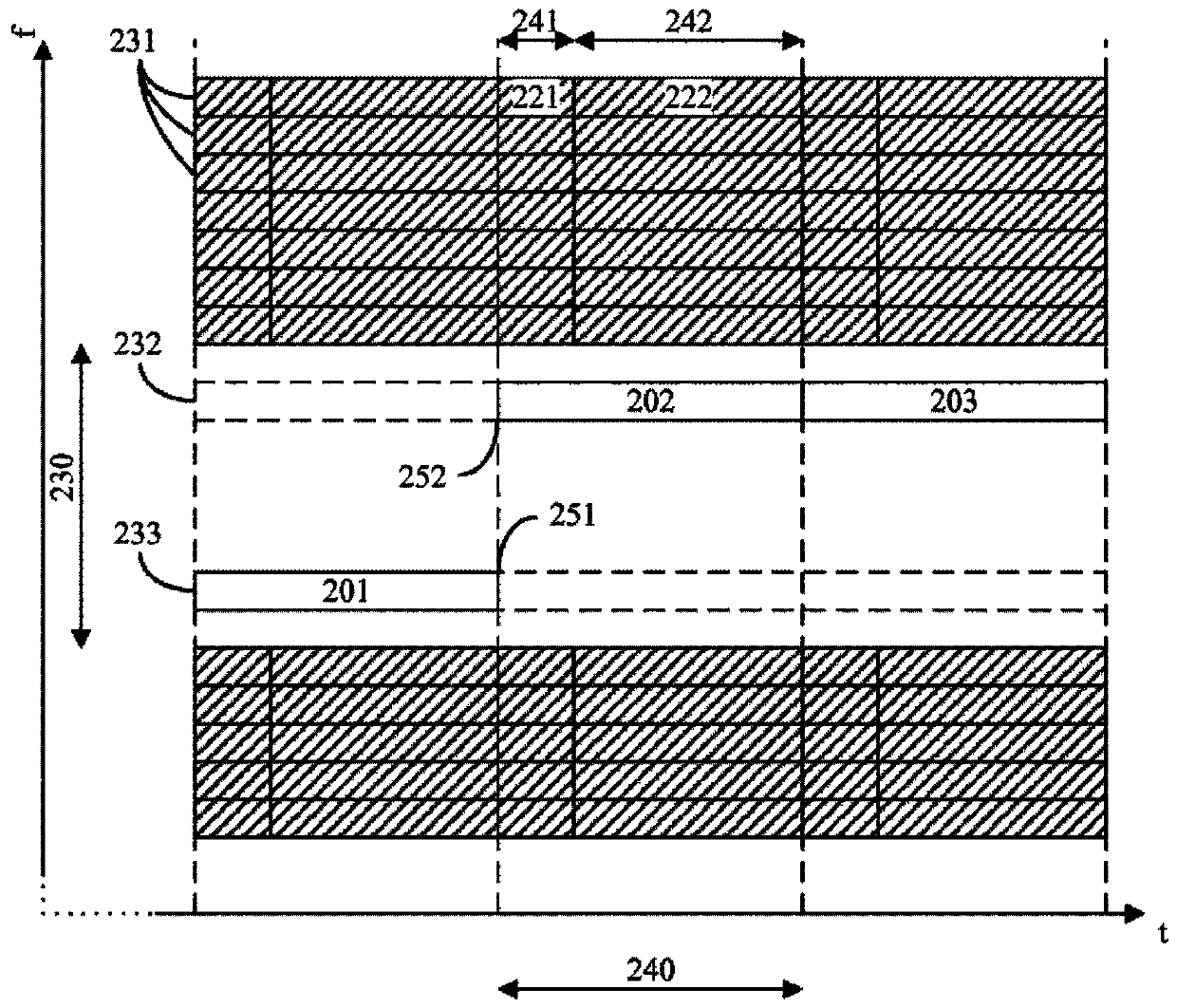

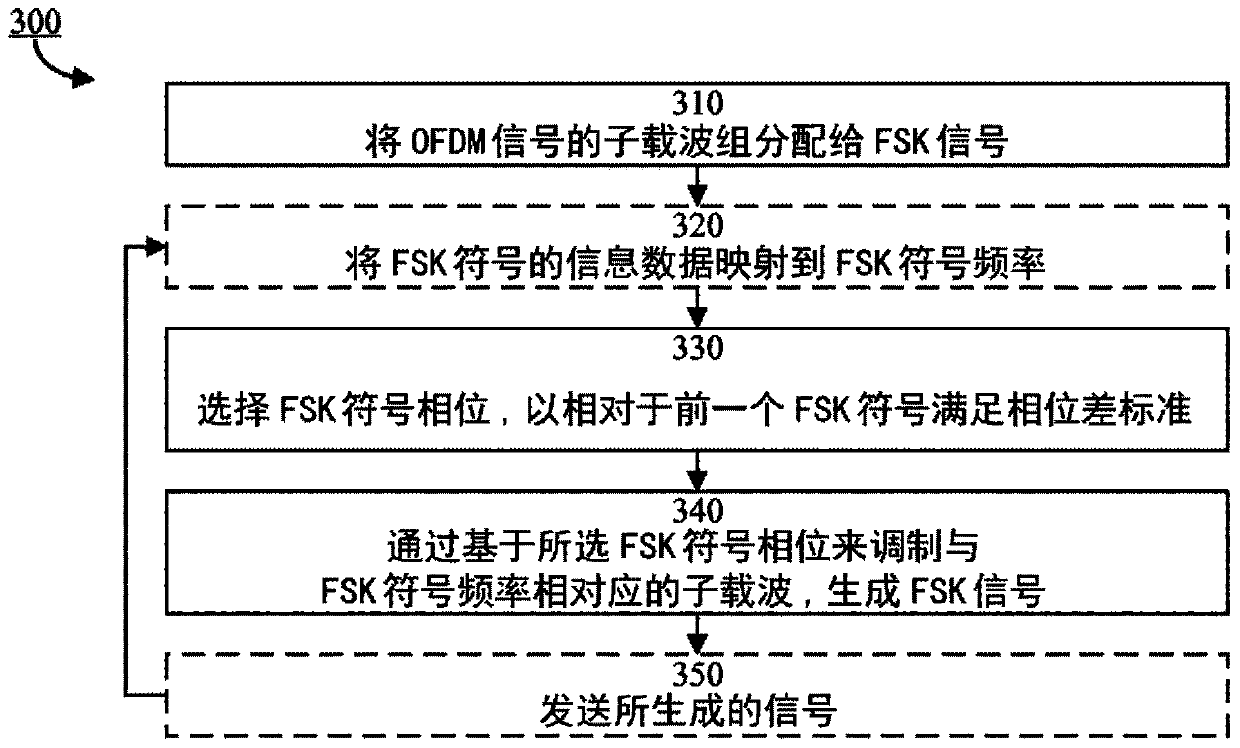

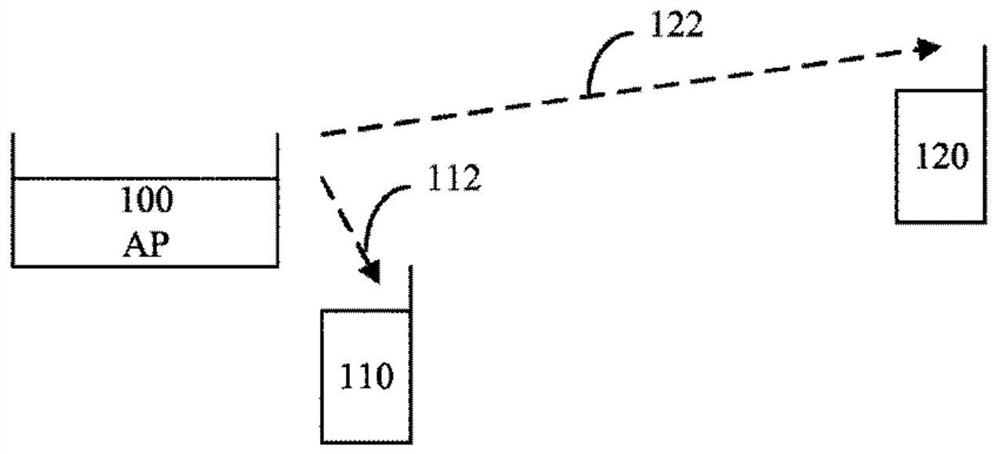

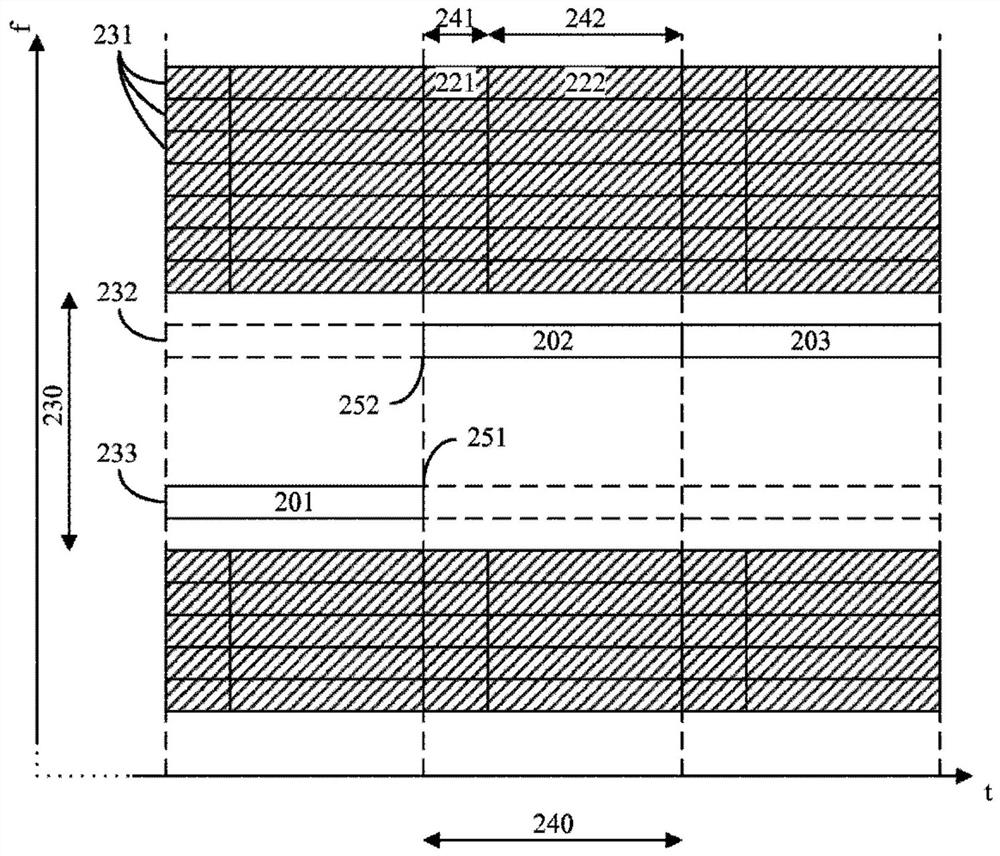

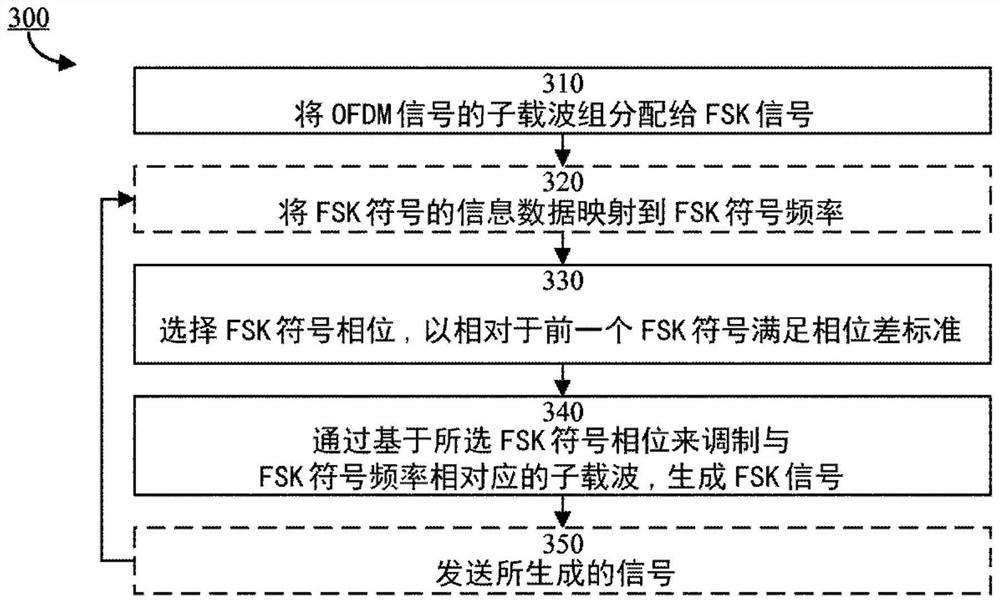

Generating an fsk signal comprised in an OFDM signal

ActiveCN110546930AMinimize distortionDistortion mitigationFrequency-modulated carrier systemsMulti-frequency code systemsCarrier signalFrequency shift

A method is disclosed of generating a frequency shift keying (FSK) signal comprised in an orthogonal frequency division multiplexing (OFDM) signal comprising a plurality of sub-carriers. The FSK signal comprises FSK symbols wherein each FSK symbol has a corresponding FSK symbol frequency. The method comprises assigning (310) a set of adjacent sub-carriers to transmission of the FSK signal (whereinthe set is a sub-set of the plurality of sub-carriers), and associating each FSK symbol frequency with a corresponding sub-carrier in the set of adjacent sub-carriers. The method also comprises selecting (330), for each FSK symbol (201, 202, 203) to be transmitted, an FSK symbol phase such that an FSK signal phase at a start (252) of the FSK symbol (202) to be transmitted meets a phase differencecriterion in relation to the FSK signal phase at an end (251) of an immediately previous FSK symbol (201). The method further comprises generating (340) the FSK signal comprising the FSK symbol to betransmitted by modulating the sub-carrier corresponding to the FSK symbol frequency based on the selected FSK symbol phase and muting the remaining sub-carriers of the set. Corresponding arrangement,access point and computer program product are also disclosed.

Owner:TELEFON AB LM ERICSSON (PUBL)

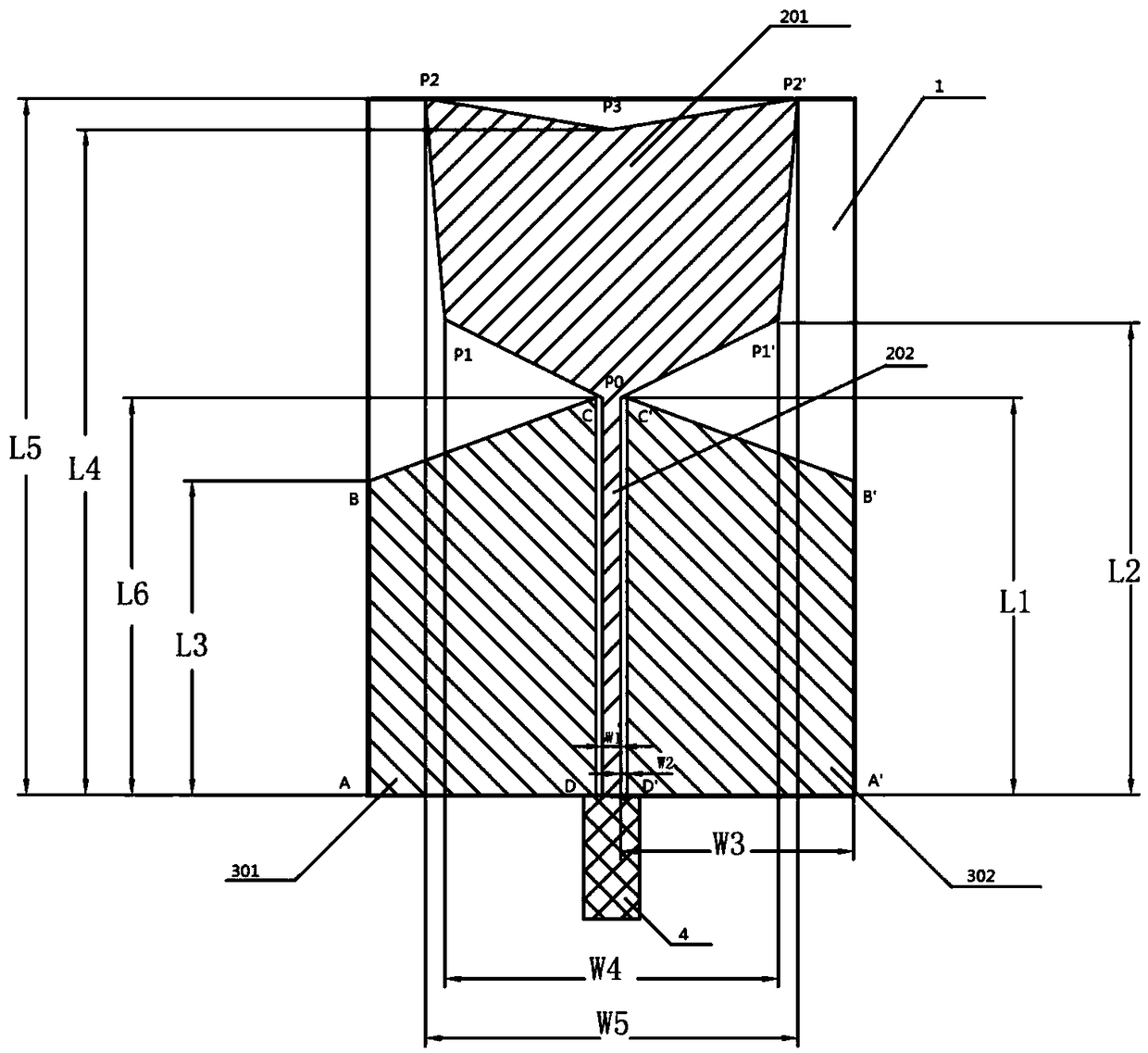

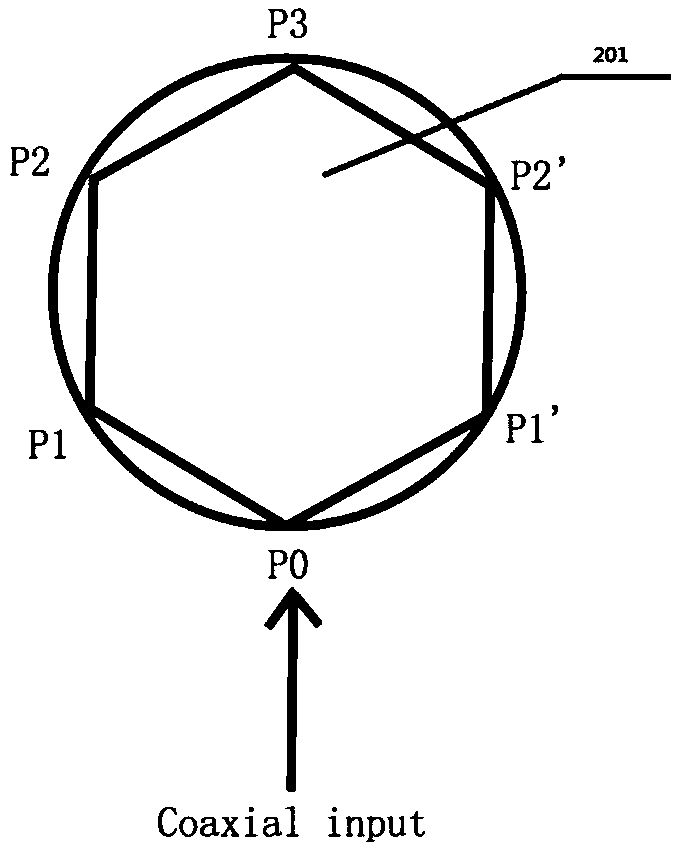

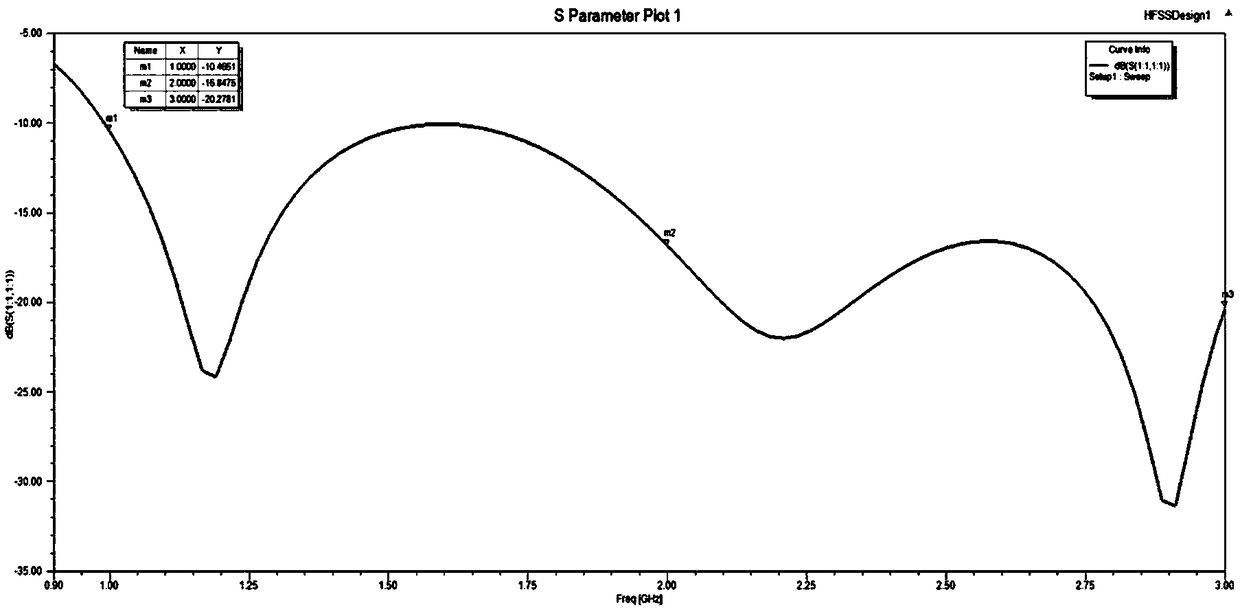

An antenna

ActiveCN108987922AAchieve modularityEasy to disassembleAntenna supports/mountingsRadiating elements structural formsElectrical conductorHand held

The invention discloses an antenna, which is used for the handheld mobile equipment of the whole vehicle electromagnetic compatibility test. The antenna comprises a base plate, a center conductor anda ground plane, wherein, the center conductor and the ground plane are fixed on the same bonding surface of the base plate and are in the same plane, and the radiating unit of the center conductor ishexagonal. The antenna is small in size, mounted on handheld mobile devices for vehicle EMC testing, which can be conveniently placed beside the device under test in the vehicle, As that antenna coverthe whole test frequency band, the t time is greatly reduced, the working efficiency is improved, the test cost is reduce, and the problem that the antenna is not suitable for the whole vehicle testdue to the large size or requires at least three antennas to cover the whole test frequency band is solved.

Owner:FAW VOLKSWAGEN AUTOMOTIVE CO LTD

Rapid bench examination and modeling method for engine

The invention discloses a bench testing method during the development process of an engine as well as a method for building an engine model, including testing the engine under the operation conditions of a plurality of actual engines and searching the actual engine data which accords with the operation conditions of the actual engine; confirming a plurality of parameter functions based on the actual engine data and each parameter function is corresponding to one operation parameter of the engine; generating a plurality of combustion functions used for the operation conditions of a plurality of engines which include a plurality of the operation conditions of the actual engines and a plurality of the operation conditions of virtual engines; calibrating the virtual model of the engine based on a plurality of combustion parameters and applying the virtual model to carry out bench testing on a plurality of engines.

Owner:GM GLOBAL TECH OPERATIONS LLC

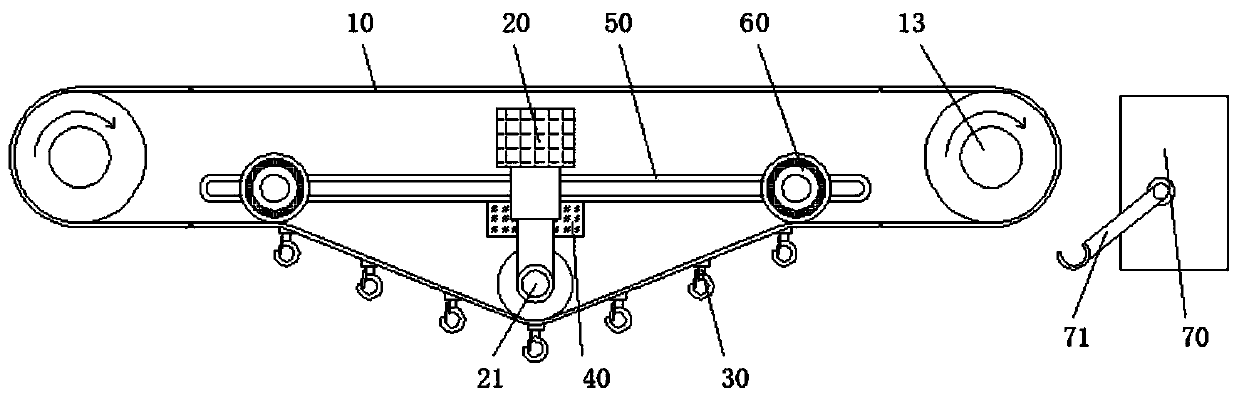

New energy motor vehicle energy recovery power generating system

PendingCN111396275ANo discontinuitySmooth and comfortable drivingAuxillary drivesMachines/enginesNew energyGear wheel

The invention provides a new energy motor vehicle energy recovery power generating system. The system is composed of a machine shell, a drive rack, a transmission line and an energy conversion power generating mechanism. The energy conversion power generating mechanism comprises two front and back one-way bearings, a big gear wheel, a small gear wheel and a power generator. One end of the transmission line is connected to the lower end of a damping spring of a chassis, the outer wall of the transmission line is fixed to the portion, at the upper end of the damping spring, of the vehicle chassis, the other end of the transmission line is connected with the drive rack, and the drive rack drives the one-way bearings to rotate. By means of gear transmission, the change of the distance gap between the lower portion of a tire vibration damper and the chassis in the driving process of the vehicle chassis is converted into dynamic energy to drive the power generator to work to generate power,the drive rack cooperates with the two front and back one-way bearings to convert stretching and shrinking of the gap between the vehicle chassis and the tire damper into continuous dynamic energy transmission, in one direction, of a power generator system, the power generator rotates without interruption, and meanwhile, as jolts from the ground are stably absorbed by the power generating system,a damping system can operate more smoothly.

Owner:李子信

Continuous feeding system for automobile trim electroplating and feeding device thereof

The invention provides a continuous feeding device for automobile trim electroplating. The continuous feeding device for automobile trim electroplating comprises a driving belt, a hydraulic rod, a suspension mechanism, a sliding suspension frame, pull-in limiting wheels and an electric motor. Turning wheels are arranged in the middle positions of the two sides of the driving belt. The turning wheel on one side is provided with a motor used for controlling the turning wheel to rotate. The hydraulic rod is arranged in the middle position of the driving belt. The bottom of an output shaft of thehydraulic rod is rotatably connected with a limiting wheel. The limiting wheel abuts against the upper edge of the driving belt. The continuous feeding device has the advantages that the position of the driving belt can be adjusted through the hydraulic rod; the position of the suspension mechanism on the driving belt can be adjusted according to different depths of an electroplating bath, so thatautomobile trims suspended on the suspension mechanism are located in more suitable positions in the electroplating bath, and the electroplating effect is better. Besides, the continuous feeding device can be suitable for electroplating baths at different depths, and is free of intermittent feeding in the electroplating process and wider in application range.

Owner:宣城托新精密科技有限公司

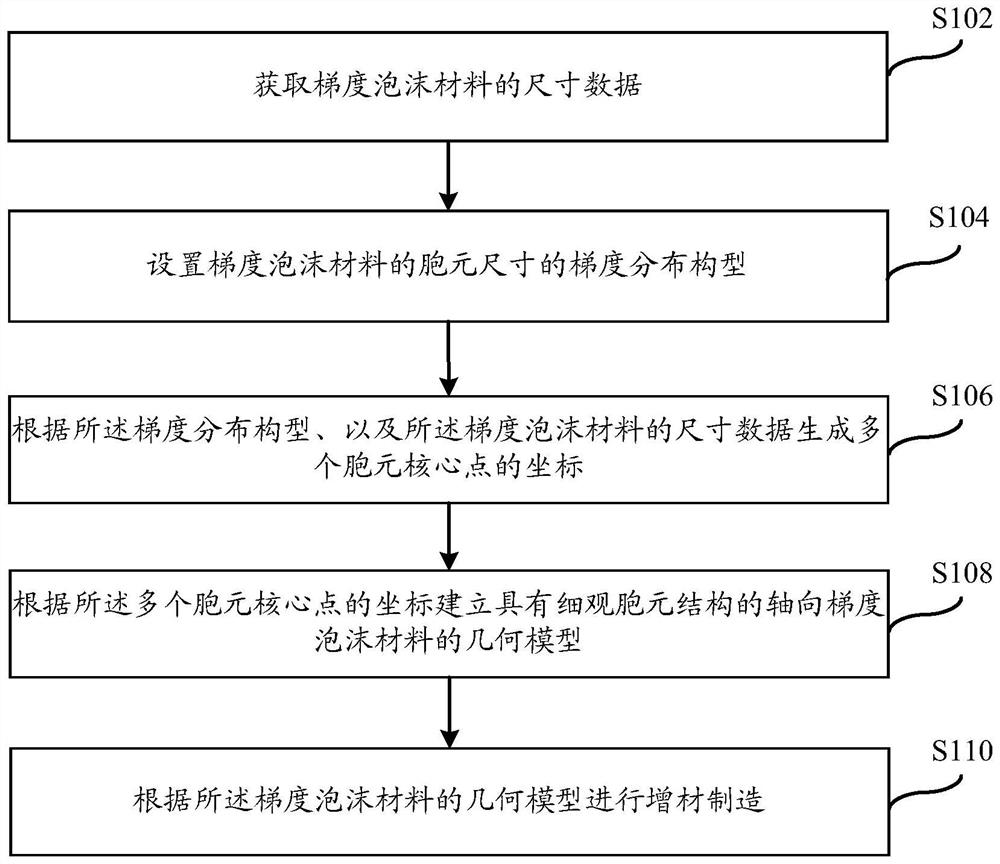

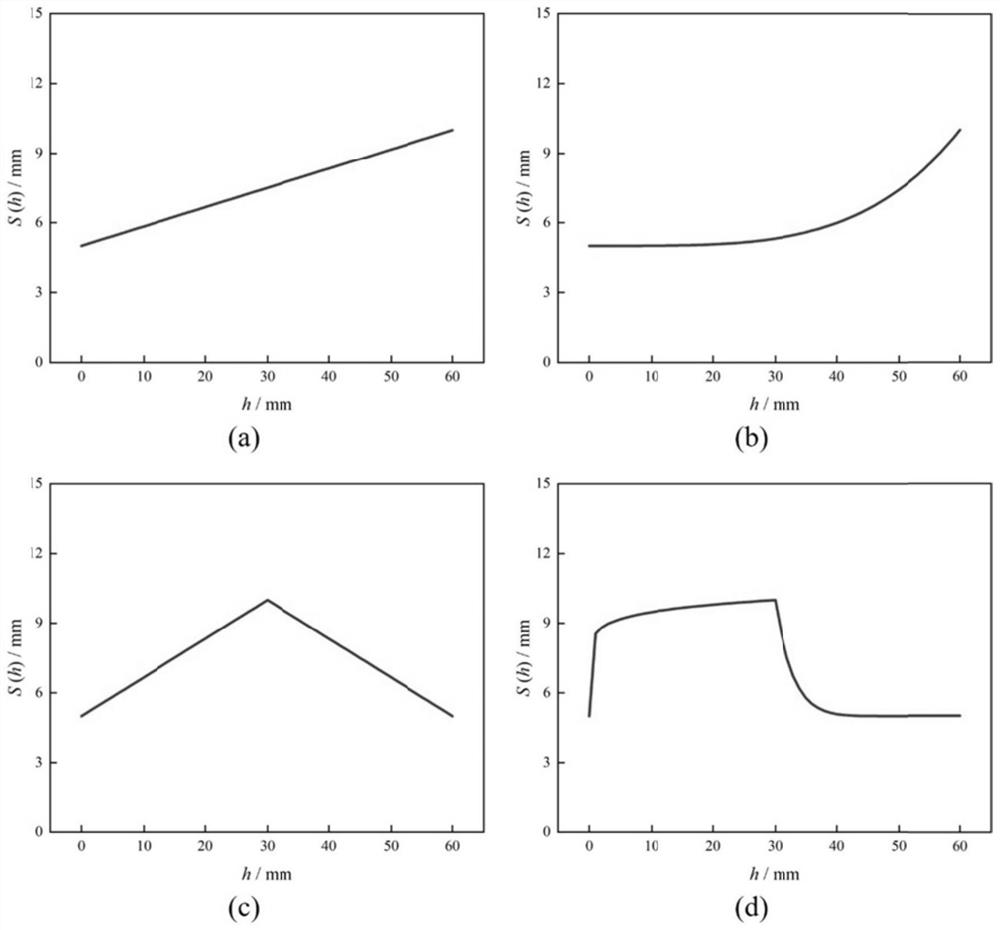

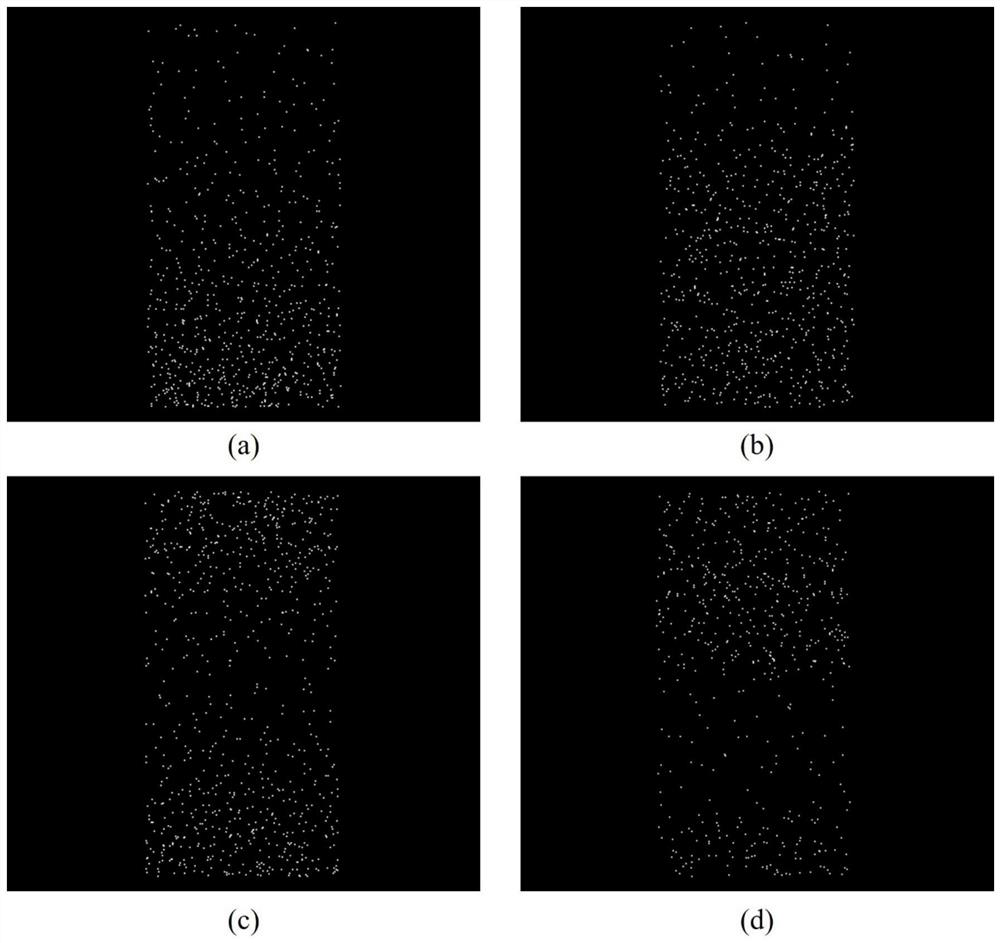

Additive manufacturing method and system for foam material with continuously controllable gradient change

PendingCN114407367AAchieve continuous changeNo discontinuityAdditive manufacturing apparatusManufacturing data aquisition/processingGeometric modelingAdditive layer manufacturing

The invention discloses an additive manufacturing method and system for a gradient change continuous and controllable foam material. The additive manufacturing method comprises the steps that size data of a gradient foam material are obtained; setting a gradient distribution configuration of the cell size of the gradient foam material; generating coordinates of a plurality of cell element core points according to the gradient distribution configuration and the size data of the gradient foam material, wherein the position of the newly generated cell element core point is related to the position of the existing cell element core point; establishing a geometric model of the axial gradient foam material with a mesoscopic cell element structure according to the coordinates of the plurality of cell element core points, wherein each cell element has a tetrakaidecahedron structure; and additive manufacturing is conducted according to the geometric model of the axial gradient foam material. According to the invention, the foam material with continuous and controllable gradient change can be prepared.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

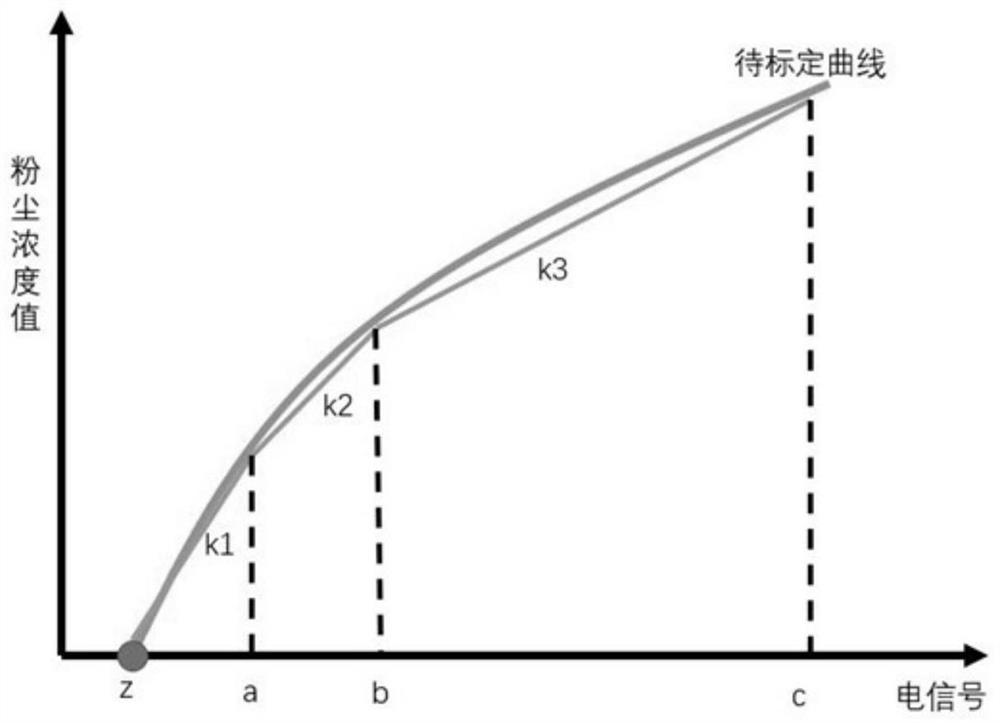

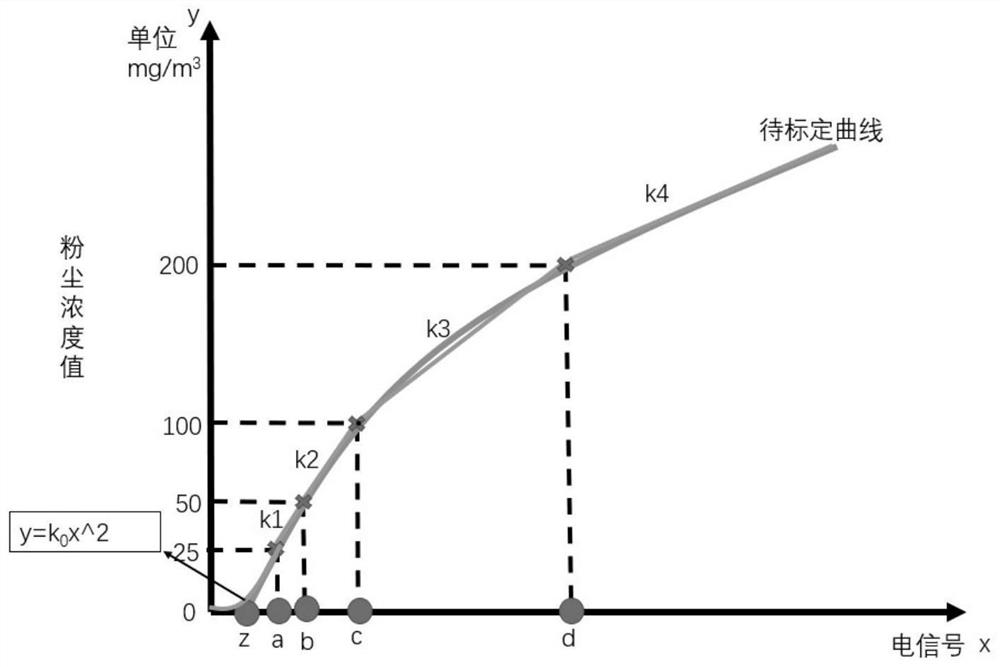

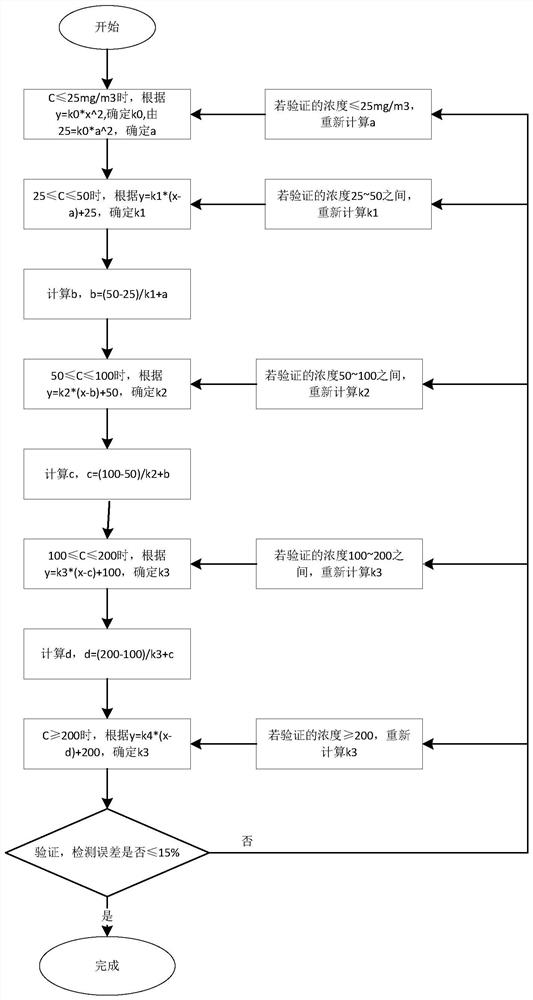

Dust concentration sensor calibration method

ActiveCN113405958AQuick CalibrationReduce the impactParticle suspension analysisMaterial weighingCalibration curveBiology

The invention relates to a dust concentration sensor calibration method, which belongs to the technical field of dust concentration detection. The method comprises the following steps of S1, collecting an electric signal generated by dust by using a detector, S2, acquiring the actual dust concentration through weighing and sampling, S3, comparing the value of the electric signal with the value of the actual dust concentration to determine a curve relation between the value of the electric signal and the value of the dust concentration, S4, according to the curve determined in the step S3, respectively acquiring electric signal values a-e corresponding to dust concentration values of 25, 50, 100, 200 and 1000 mg / m<3>, and S5, respectively calibrating the curves of five segments of 0 to 25 mg / m<3>, 25 to 50 mg / m<3>, 50 to 100 mg / m<3>, 100 to 200 mg / m<3> and 200 to 1000mg / m<3>. Rapid calibration can be realized, a calibration curve is continuous, and the influence of a background value on a low-concentration detection result is reduced; the interference of a zero point is eliminated, and the low-concentration detection precision is improved.

Owner:CHINA COAL TECH ENG GRP CHONGQING RES INST

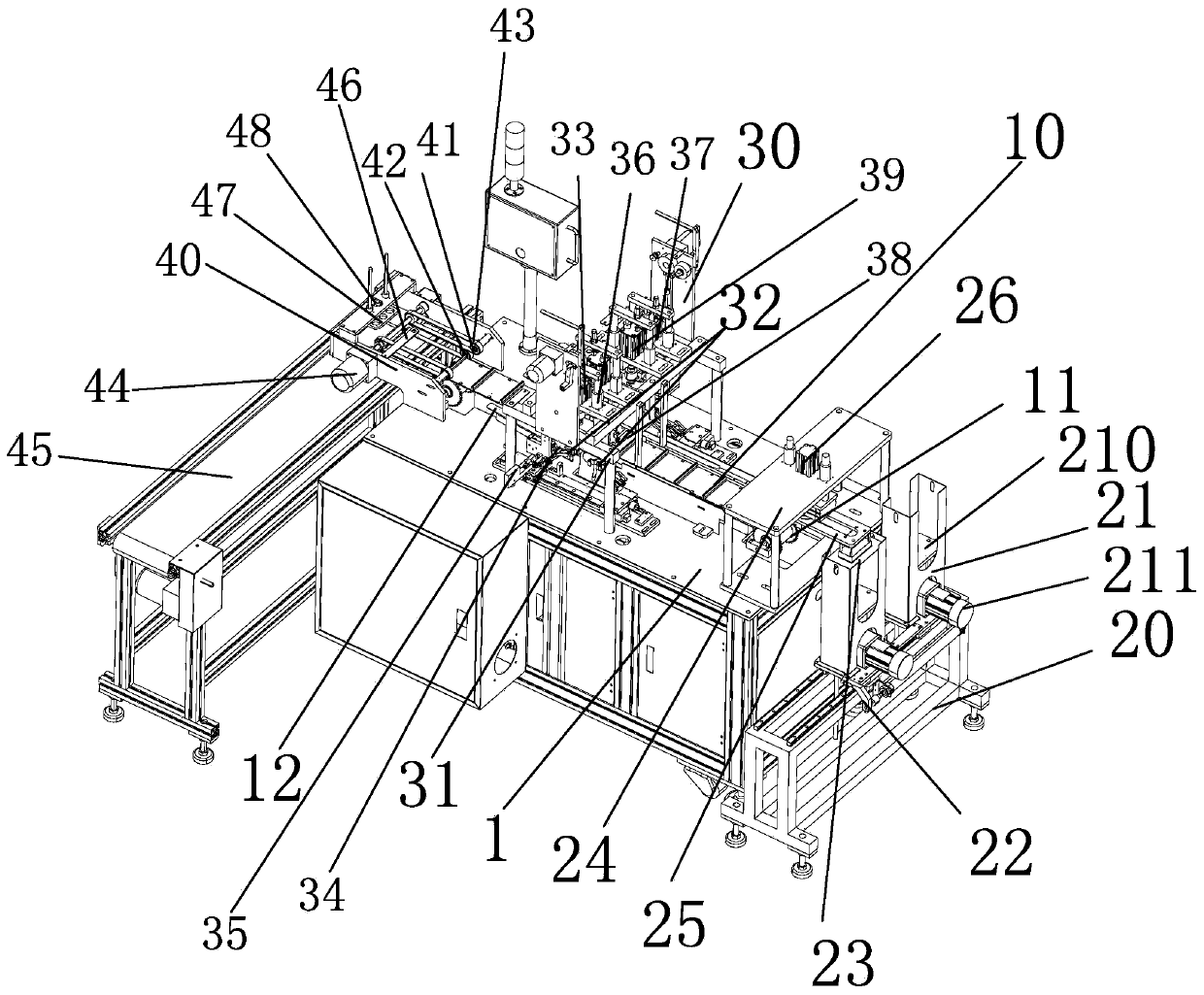

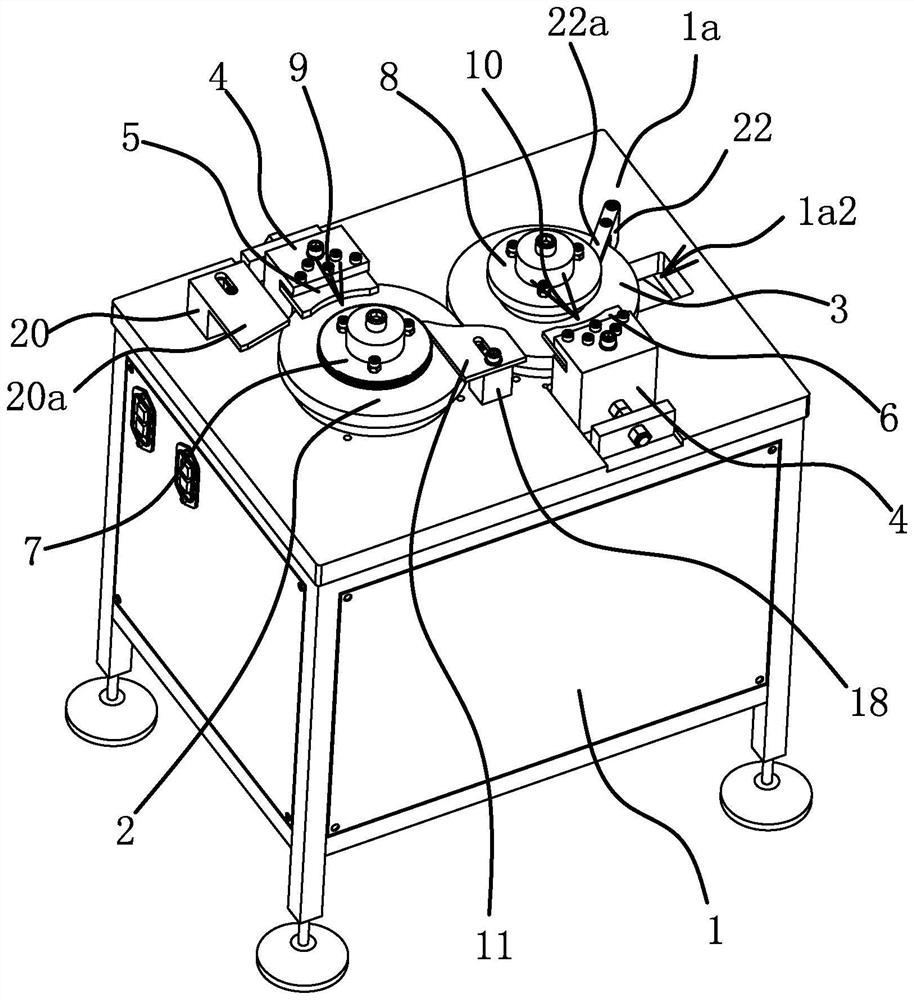

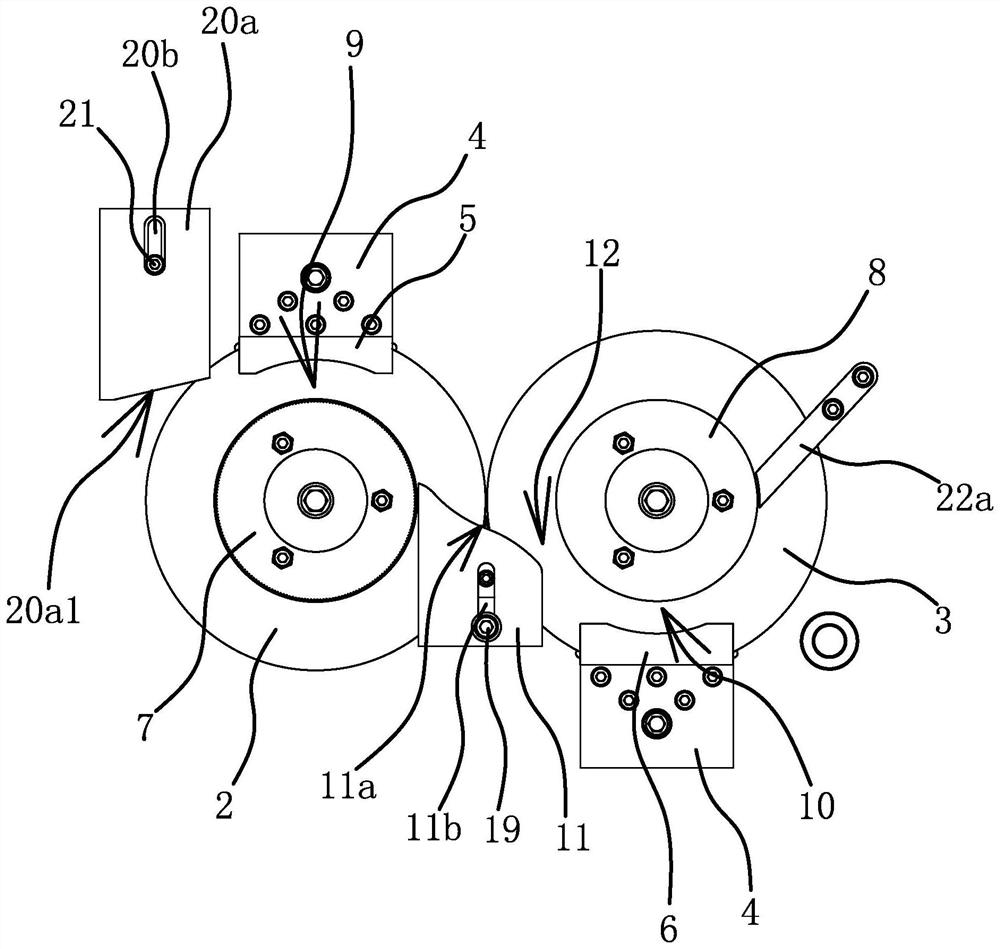

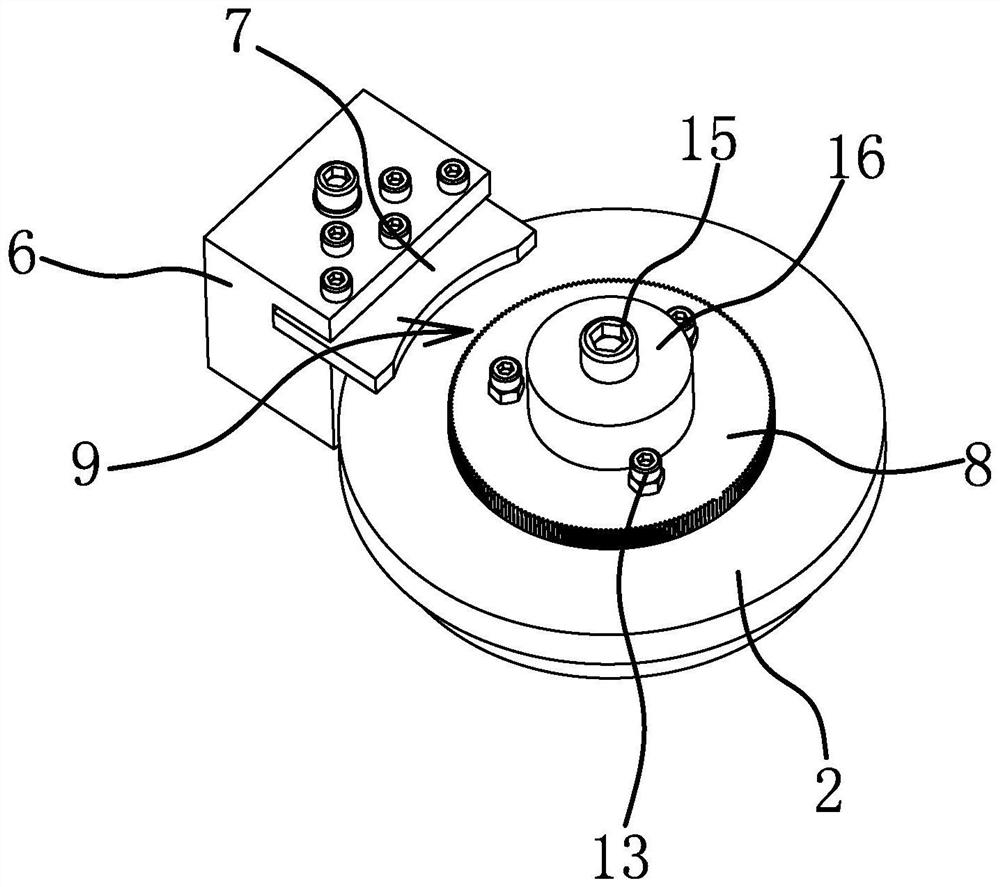

Automatic mask ear hanging rope spot welding machine

InactiveCN111449322AIncrease productivityShorten control timeProtective garmentClothes making applicancesEngineeringSpot welding

The invention discloses an automatic mask ear hanging rope spot welding machine, and aims to provide the automatic mask ear hanging rope spot welding machine characterized by high automation degree, strong practicality and simple structure. The key points of the technical scheme are as follows: a feeding device, an ear hanging rope spot welding device and a discharging device are arranged on a rack, according to the mask production equipment, the three devices are communicated through a conveying device, the production efficiency of masks is greatly improved, continuous feeding is conducted incooperation with the feeding device, the management and control time of personnel is shortened, and the good practical effect is improved. The automatic mask ear hanging rope spot welding machine issuitable for the technical field of medical protection tool production equipment.

Owner:伟柏智能装备(浙江)有限公司

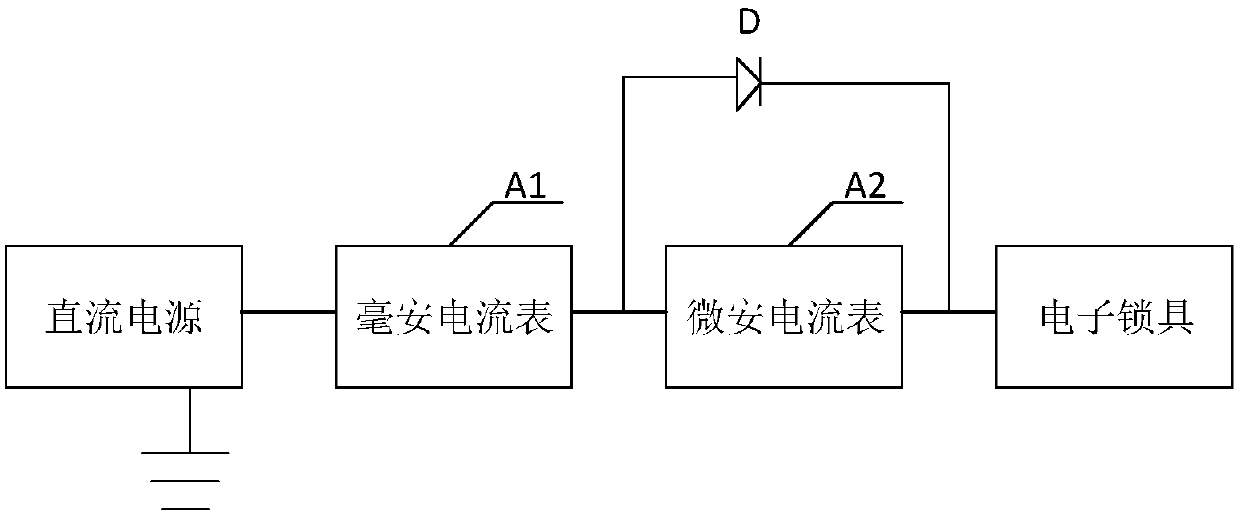

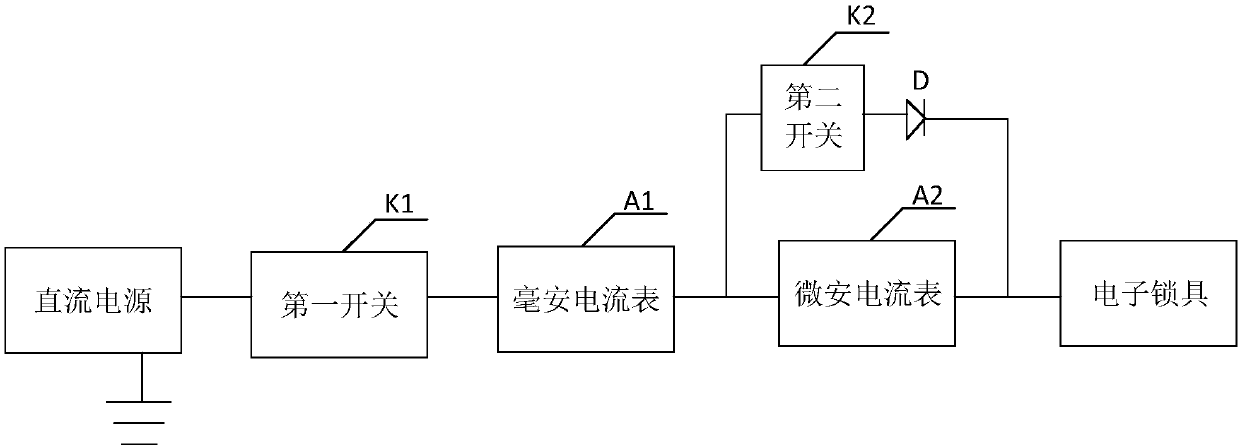

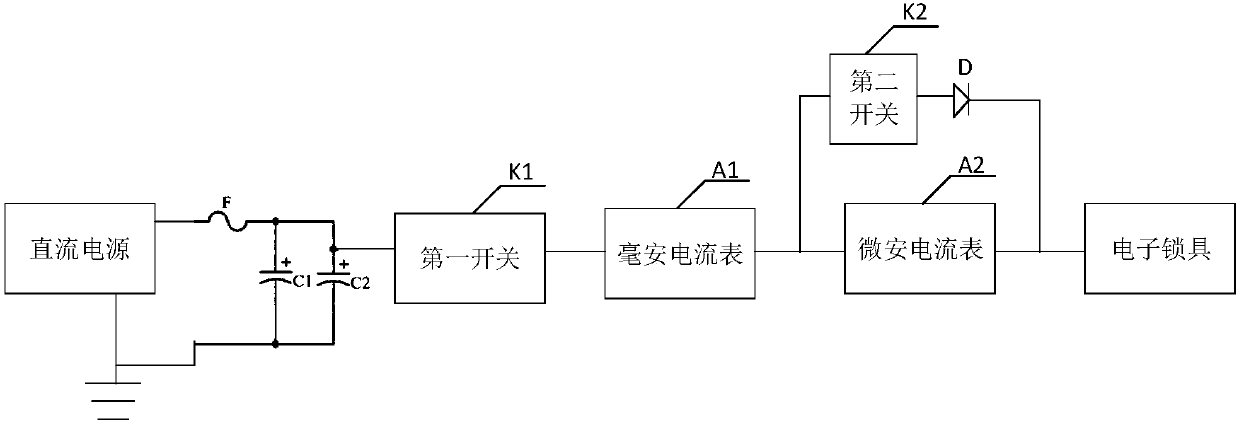

Device for testing current of electronic lock

InactiveCN110068721AThe testing process is simpleImprove test efficiencyAltering measuring range circuitsCurrent measurements onlyAnodeTest efficiency

The invention discloses a device for testing a current of an electronic lock. The device comprises a milliampere ampere meter, a microampere ampere meter and a diode used for being disconnected duringinflow of a microampere current and being connected during inflow of a milliampere current, wherein the positive output end of a direct-current power source is connected with the input end of the milliampere ampere meter, the negative output end of the direct-current power source is grounded, the output end of the milliampere ampere meter is connected with the input end of the microampere amperemeter and an anode of the diode, and a cathode of the diode is connected with the output end of the microampere ampere meter and the electronic lock. It can be seen that the two ampere meters can be automatically switched according to the state of the electronic lock, thus the testing process is simplified, and the testing efficiency is improved; and in the switching process of the two ampere meters, the incontinuity of the power supply current of the electronic lock is avoided, misoperation of the electronic lock is not liable to be caused, testing difficulty is lowered, and testing accuracyis improved.

Owner:KUNSHAN BRANCH INST OF MICROELECTRONICS OF CHINESE ACADEMY OF SCI

Internet-oriented large-scale live broadcast time-shifting method and system based on fragmented transmission

ActiveCN103581693BEasy to implementRealization of Live Time Shift ServiceSelective content distributionThe InternetBroadcast transmission

The invention provides an internet-oriented large-scale live time shifting method based on fragment transmission. The method comprises the steps that a client-side sends a time shifting request to obtain fragment index files; a time shifting server-side obtains time shifting status marks through time shifting time points; the client-side sends an acquisition request for the fragment index files to the time shifting server-side after receiving feedback from the time shifting server-side; the time shifting server-side processes the acquisition request for the fragment index files to obtain fragment sequences of the time shifting request this time; the time shifting server-side generates corresponding live fragment index files through the fragment sequences and returns the live fragment index files to the client-side; the client-side obtains the specific fragment sequences from the index files, downloads and plays the actual fragment files and repeatedly sends the same acquisition request for the fragment index files. A system where the method is implemented comprises the time shifting server-side and the client-side. The client side is simple and easy to implement, the time shifting index range required to be obtained does not need calculating, and time shifting indexes obtained each time do not need to be reserved or merged.

Owner:BEIJING QINGYUAN XINCHUANG TECH

Integrated production device for efficiently producing high-quality sesame-line special-shaped bags

PendingCN106863913AIntegrity guaranteedNo discontinuityBag making operationsPaper-makingProcess engineeringIndustrial engineering

The invention discloses an integrated production device for efficiently producing high-quality sesame-line special-shaped bags. The device comprises a printing device, a transmission rod, a photoelectric sensor, a rod base, a supporting base, a driving rod, acoustic generators, a data processor, a bag collection device, a motor, a stretching acting rod, a folding edger and a cutter. The integrated production device has the beneficial effects that the driving rod, the transmission rod, the stretching acting rod and the folding edger are arranged in the manufacturing process of the special-shaped bags, raw materials are kept continuous and uninterrupted all the time in the whole processing process, it is effectively ensured that no interruption phenomenon occurs in the manufacturing process, production efficiency is greatly improved, and meanwhile it is ensured that the manufactured finished product is extremely high in quality. The acoustic generators are arranged on the two sides of the cutter, and integrity of the produced bags is ensured through an acoustic wave production method. In addition, the device has the extremely-high environmental protection property, an acoustic controller is connected with the photoelectric sensor, and control is convenient. Compared with the traditional technology of manufacturing sesame-line special-shaped bags manually, the device has the advantages that the manufacturing process is simple, and the manufacturing cost is low.

Owner:明达塑胶科技(苏州)有限公司

Laser scribing method and solar cell

InactiveCN113894432ANo discontinuityRealize concatenationFinal product manufacturePhotovoltaic energy generationPhotoelectric conversionLaser scribing

The invention provides a laser scribing method and a solar cell. A first electrode layer and a photoelectric conversion layer located on the first electrode layer are arranged on a substrate, the first electrode layer is provided with a first laser scribing groove, then laser scribing is performed on the photoelectric conversion layer to obtain a second laser scribing groove, and the second laser scribing groove is used for later forming electrode contact between the sub-electrodes, and series connection between the multiple sub-electrodes is achieved. An obtuse angle is formed between the first side wall, close to the first laser scribing groove, of the second laser scribing groove and the bottom of the second laser scribing groove, so that when a second electrode layer is formed on the photoelectric conversion layer, the obtuse angle is formed between the first side wall of the second laser scribing groove and the bottom of the second laser scribing groove, therefore, the second electrode layer can uniformly cover the first side wall and the bottom of the second laser scribing groove, the situation that the second electrode layer is discontinuous on the first side wall and the bottom of the second laser scribing groove is avoided, and the problem of open circuit among a plurality of sub-cells is avoided.

Owner:HUANENG CLEAN ENERGY RES INST +1

generate fsk signal included in ofdm signal

ActiveCN110546930BMinimize distortionDistortion mitigationFrequency-modulated carrier systemsMulti-frequency code systemsTelecommunicationsCarrier signal

A method of generating a Frequency Shift Keying (FSK) signal included in an Orthogonal Frequency Division Multiplexing (OFDM) signal comprising a plurality of subcarriers is disclosed. The FSK signal includes FSK symbols, where each FSK symbol has a corresponding FSK symbol frequency. The method includes: allocating a group of adjacent subcarriers to transmit FSK signals, the group being a subset of a plurality of subcarriers; associating each FSK symbol frequency with a corresponding subcarrier in a group of adjacent subcarriers; For each FSK symbol to be transmitted, select the FSK symbol phase such that the phase of the FSK signal at the beginning of the FSK symbol to be transmitted meets the phase difference criterion with respect to the phase of the FSK signal at the end of the previous FSK symbol; based on the selected FSK symbol Phase modulating the subcarrier corresponding to the FSK symbol frequency and muting the remaining subcarriers of the group, generating an FSK signal comprising the FSK symbol to be transmitted.

Owner:TELEFON AB LM ERICSSON (PUBL)

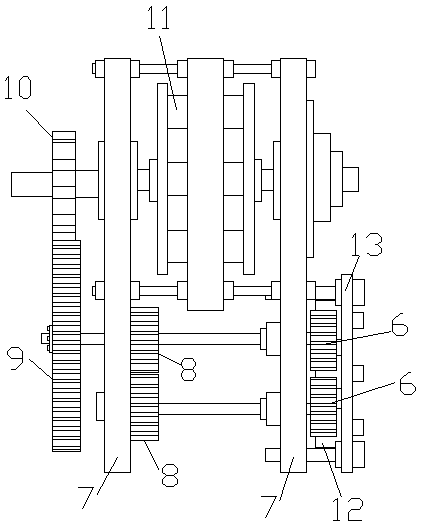

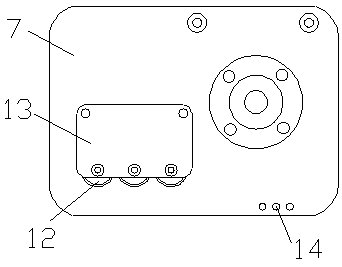

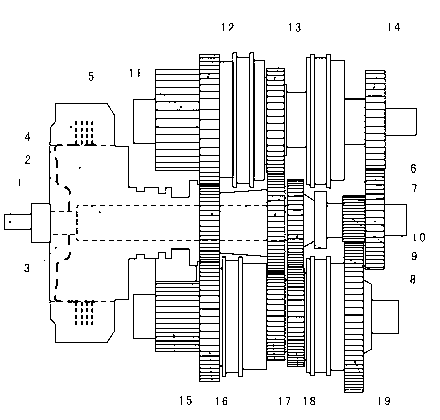

Dual-clutch uninterrupted transmission capable of continuously outputting power

InactiveCN103322136AGuaranteed uptimeNo discontinuityToothed gearingsGearing controlEngineeringClutch

The invention discloses a dual-clutch uninterrupted transmission capable of continuously outputting power. The dual-clutch uninterrupted transmission capable of continuously outputting power comprises a first clutch, a second clutch, a first input shaft , a second input shaft, a plurality of power end gears and a plurality of gear-level gears, wherein the power input ends of the first clutch and the second clutch are respectively connected to a rotating shaft of a motor, the power output end of the clutch is connected to the first input shaft, the power output end of the second clutch is connected to the second input shaft; shafts of the power end gears are respectively connected to the first input shaft and the second input shaft, and the power end gears and the gear-level gears are in meshed connection with one another. The dual clutches in the dual-clutch uninterrupted transmission are electronic-controlled and hydraulic-driven, in the gear shifting process, at least one group of gears for outputting power can be ensured, and interruption situations due to lack of the power are avoided, so that the run of an automobile is more stable.

Owner:SICHUAN JUYOU ECOLOGY ARRICULTURAL TECH

Machining equipment for outer surface of workpiece

PendingCN113752735ANo discontinuityRealize automatic unloadingOther artistic work equipmentsEmbossing decorationsPhysicsEngineering

The invention provides machining equipment for the outer surface of a workpiece, and belongs to the technical field of machining. The machining equipment solves the problem that the production efficiency is low. The machining equipment comprises a top plate, a first rotating disc, a second rotating disc, a first matching plate and a second matching plate, wherein the first rotating disc, the second rotating disc, the first matching plate and the second matching plate are arranged on the top plate. A first disc is arranged on the first rotating disc, and a first forming channel which can conduct gear hobbing or character hobbing on the workpiece when the first rotating disc rotates is formed between the end of the first matching plate and the peripheral face of the first disc. A second disc is arranged on the second rotating disc, and a second forming channel which can conduct gear hobbing or character hobbing on the workpiece when the second rotating disc rotates is formed between the end of the second matching plate and the peripheral face of the second disc. The first rotating disc and the second rotating disc are arranged side by side and are opposite in rotating direction, and the first forming channel and the second forming channel are different in height. A material guiding plate is further arranged on the top plate in parallel. An inclined material guiding face is arranged at the end of the material guiding plate, one end of the material guiding face is located on the first rotating disc and is close to the projection of the first disc on the first rotating disc, and the other end of the material guiding face is located on the second rotating disc. The machining equipment has the advantages of being high in production efficiency, high in automation degree and the like.

Owner:浙江博民机电股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com