New energy motor vehicle energy recovery power generating system

An energy recovery and power generation system technology, applied in machines/engines, mechanisms that generate mechanical power, mechanical equipment, etc., can solve problems affecting human life quality and health, uneven distribution of fossil energy, limited reserves, etc., to achieve a compact structure , The effect of large power generation energy and noiseless installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

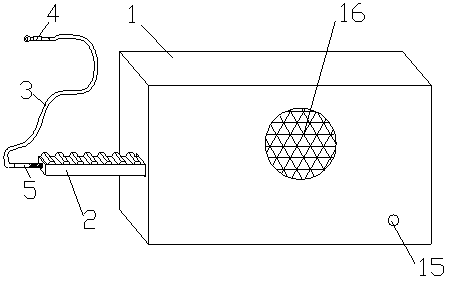

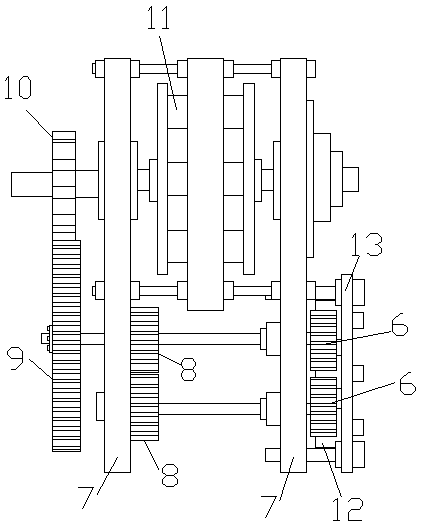

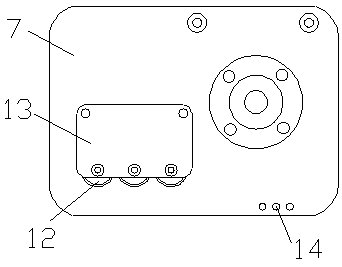

[0017] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, a new energy vehicle energy recovery power generation system is composed of a casing 1, a drive rack 2, a transmission line 3, and an energy conversion power generation mechanism. A heat dissipation window 16 is provided on the side of the casing, and the energy conversion power generation mechanism is built in the casing In 1, the energy conversion power generation mechanism includes two front and rear unidirectional bearings 6, a large gear plate 9, a pinion disk 10, and a generator 11. The front and rear unidirectional bearings 6 are respectively fixed on the bracket, and the rear unidirectional bearing passes through one The transmission gear plate 8 is connected with the large gear plate 9. The transmission gear plate at the end of the one-way bearing at the front meshes and connects with the transmission gear plate at the end of the one-way bearing at the back. A number of load-bearing wheels 12 are in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com