Machining equipment for outer surface of workpiece

A technology for processing equipment and outer surfaces, which is applied in the field of processing equipment for the outer surface of workpieces, can solve problems such as low production efficiency, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

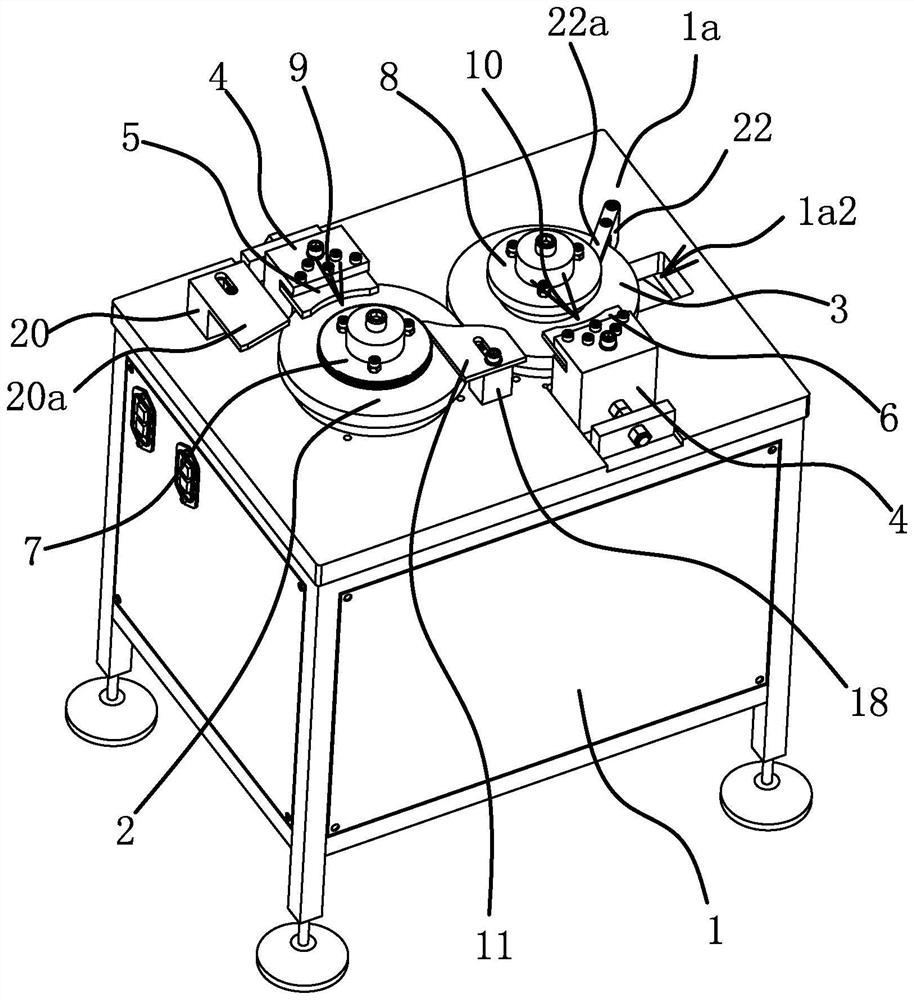

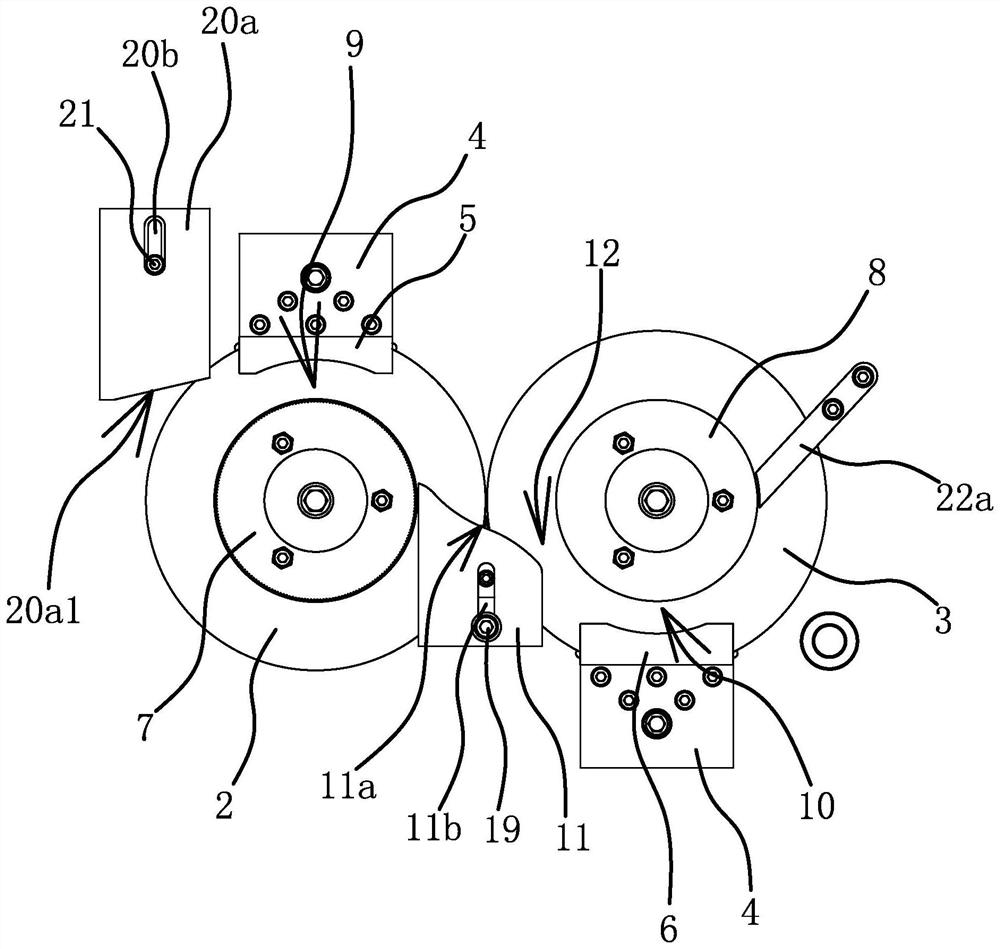

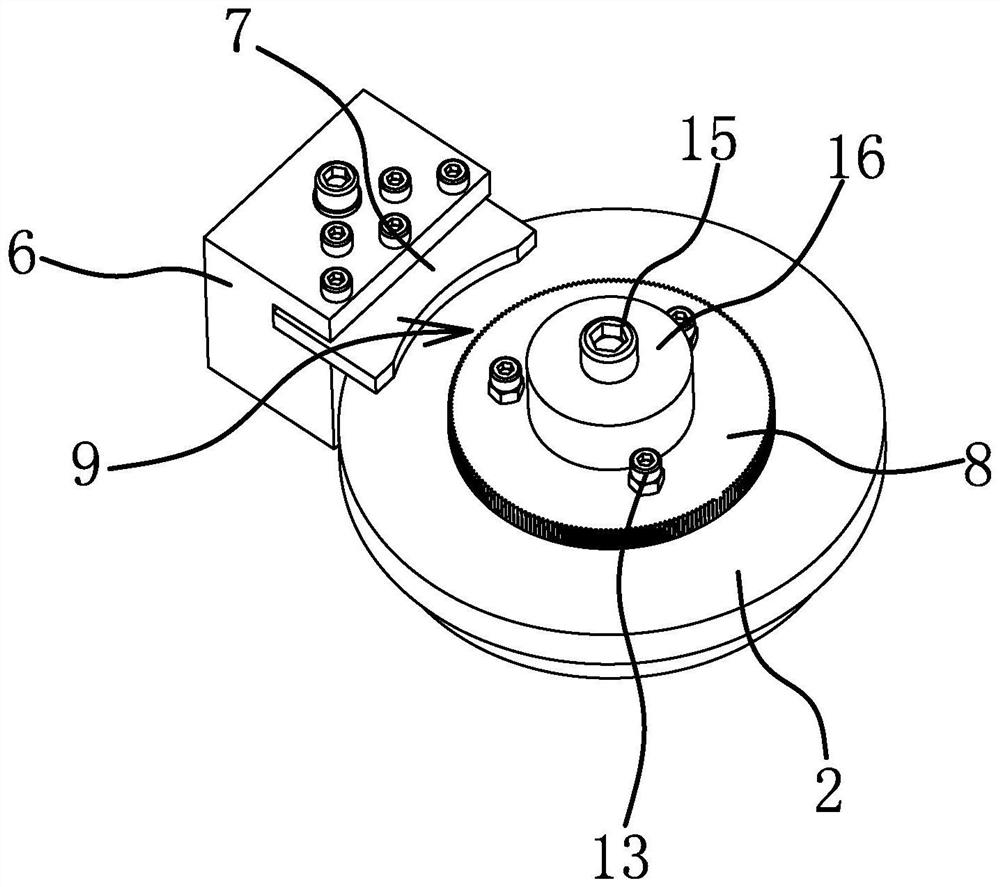

[0037] Such as figure 1 , figure 2 with Figure 4 As shown, the processing equipment for the outer surface of the workpiece includes a frame 1 with a top plate 1a and a turntable one 2 and a turntable two 3 both arranged on the top plate 1a, and the turntable one 2 and the turntable two 3 are arranged side by side. Wherein, a transmission shaft 1 23 and a transmission shaft 2 24 are rotated on the top plate 1a, the turntable 1 2 is connected to the transmission shaft 1 23, the turntable 2 3 is connected to the transmission shaft 2 24, and two motors 25 are connected below the top plate 1a. The output shaft of one of the motors 25 is connected with the lower end of the transmission shaft one 23 through a coupling 26 , and the output shaft of the other motor 25 is connected with the lower end of the transmission shaft two 24 through a coupling 26 . On the top plate 1a, mounting seats 4 are respectively fixed on the sides of the turntable 1 2 and the turntable 2 3, and the mou...

Embodiment 2

[0045] The structure and principle of the present embodiment are basically the same as those of the first embodiment, the difference is that in the present embodiment, the arc surface one and the arc surface two are smooth surfaces, and the outer peripheral surface of the disc one 7 and the disc two 8 The outer peripheral surface is provided with continuously distributed teeth, that is, the hobbing of the lower outer surface of the workpiece is completed in the first forming channel 9 and the gear hobbing of the upper outer surface of the workpiece is completed in the second forming channel 10 .

Embodiment 3

[0047]The structure and principle of this embodiment are basically the same as that of Embodiment 1. The difference is that in this embodiment, the outer peripheral surface of disk 17 is a smooth surface, and the arc surface 1 is protrudingly provided with fonts, and the arc surface 2 It is a smooth surface, and the outer peripheral surface of the disc two 8 is provided with continuously distributed teeth, that is, the workpiece completes the hobbing process on the lower outer surface in the forming channel one 9 and completes the hobbing process on the upper end outer surface in the forming channel two 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com