Turbomachine casing

A turbine casing and casing technology, which is applied to gas turbine units, air inlets of turbine/propulsion units, mechanical equipment, etc., can solve problems such as time-consuming and achieve the effect of optimizing jet aircraft tolerances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

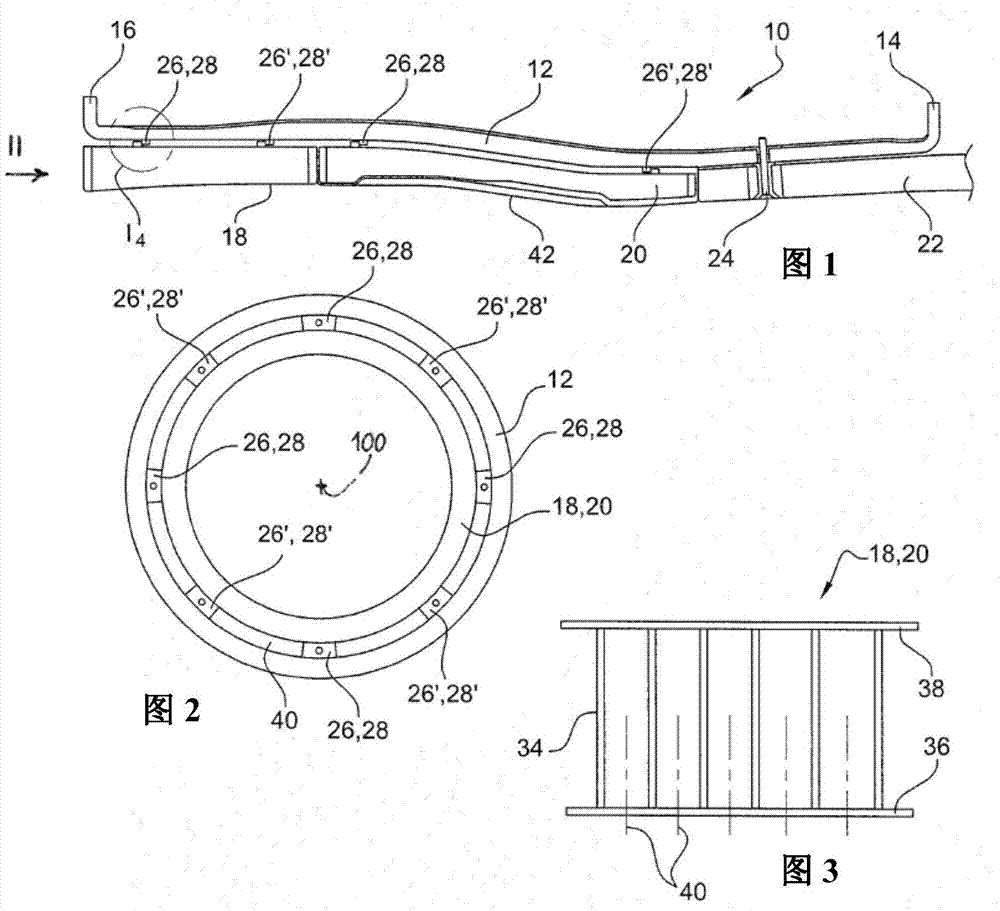

[0029] First refer to figure 1 , figure 1 Shown is a fan casing 10 of a turbomachine such as a turbojet or a propeller turbine, which belongs to the nacelle which encloses the engine of the turbomachine and inside which the fan rotates, which creates an auxiliary air flow, so Said auxiliary air flow flows between the nacelle and the engine, forming part of the thrust generated by the turbine.

[0030] The housing 10 comprises a generally cylindrical wall 12 comprising, at its longitudinal ends, fixed annular flanges 14, 16. The downstream flange 14 is fixed to the flange of the intermediate case (not shown) by screw-nut type means and the upstream flange 16 is fixed by screw-nut type means to the flange of the air intake in the nacelle (not shown). out).

[0031] The housing comprises sound-insulating annular panels 18, 20, 22 covering the cylindrical inner surface of the wall 12 and fixed to the same wall.

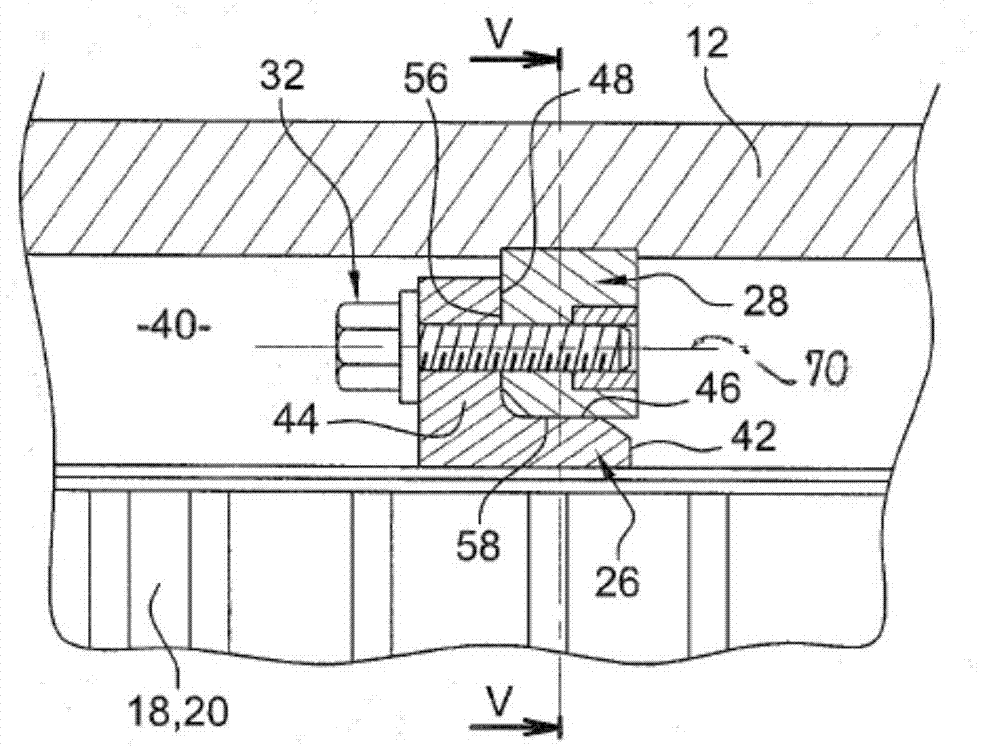

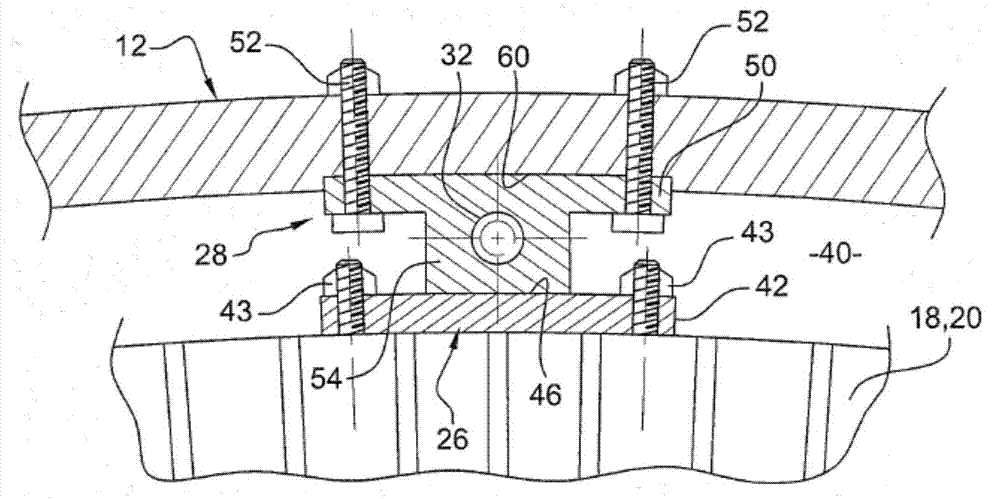

[0032] In the example shown, the wall 12 carries three annular p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com