Preparation method of engine fuel nozzle electromagnetic valve magnetic element

A technology of fuel nozzles and solenoid valves, applied in circuits, magnetic materials, electrical components, etc., can solve the problems of materials that are difficult to achieve saturation magnetic induction, low magnetic properties of materials, and low density of materials, and achieve high magnetic permeability, Easy sintering and densification, high material strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

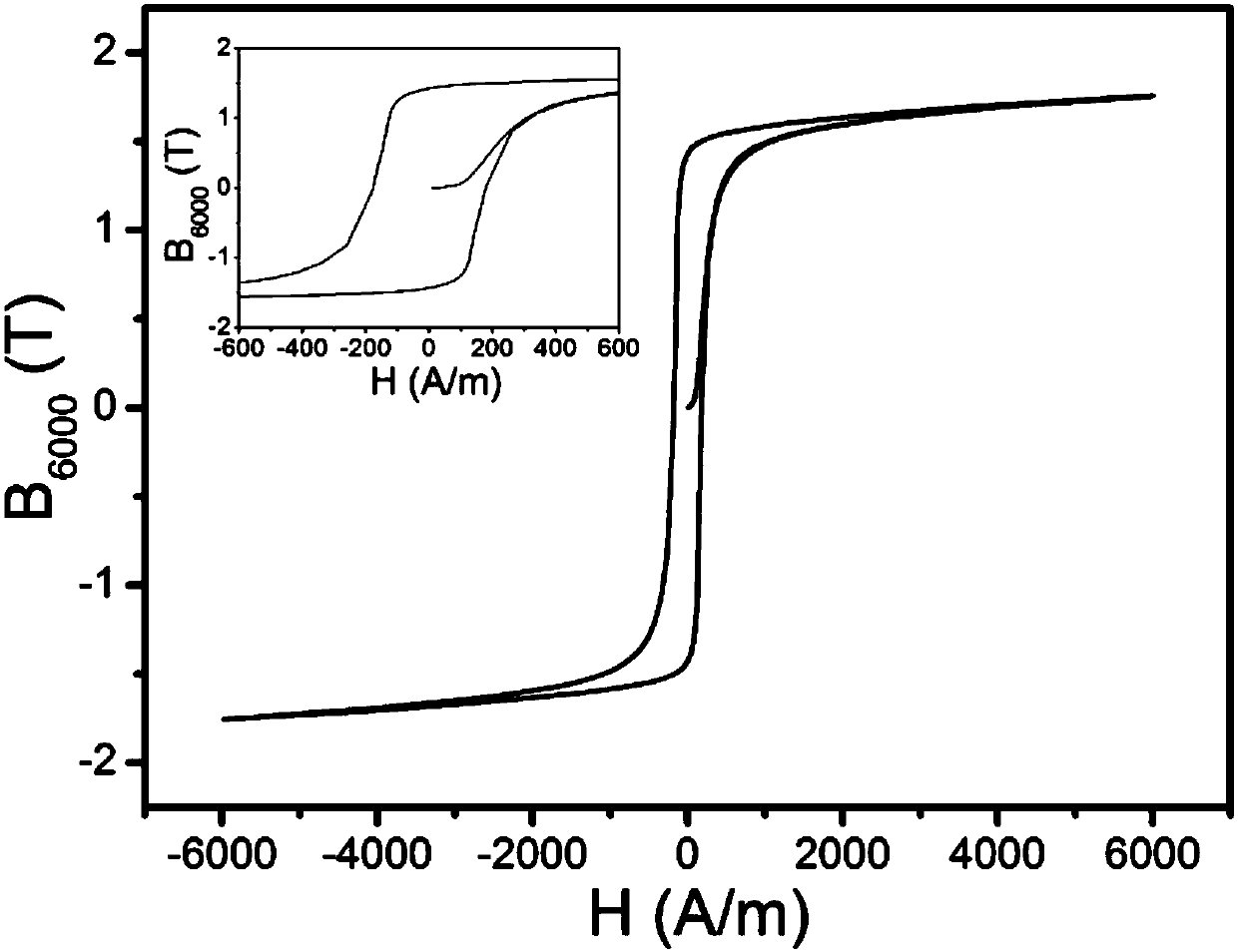

Embodiment 1

[0024] All kinds of raw materials are distributed according to the ingredients of 94% iron, 0.8% phosphorus, 5% silicon, and 0.2% carbon, and the powders of various raw materials are ball milled for 2 hours, and the mixed powder and ingredients are 60% paraffin, 20% high-density polymer A binder composed of ethylene, 15% polypropylene and 5% stearic acid was kneaded for 2 hours at a temperature of 165°C at a volume ratio of 60% of the powder to prepare a uniformly mixed injection feed of the binder and powder , The injection feed is formed on an injection molding machine, the forming parameters are: injection temperature 160°C, injection pressure 90MPa, injection speed 80%, pressure holding time 4s, and the molded blank of the magnetic core of the solenoid valve is obtained. First, soak the molded billet in trichlorethylene or n-heptane at a constant temperature of 25°C for 12 hours, and then dry the solvent degreasing billet, then heat the melted billet slowly from room temper...

Embodiment 2

[0026] All kinds of raw materials are batched according to the ingredients of 96% iron, 0.6% phosphorus, 3% silicon and 0.4% chromium, and the powders of various raw materials are ball milled for 2 hours, and the mixed powder and ingredients are 60% paraffin, 20% high-density polymer A binder composed of ethylene, 15% polypropylene and 5% stearic acid was kneaded for 2 hours at a temperature of 165°C at a volume ratio of 60% of the powder to prepare a uniformly mixed injection feed of the binder and powder , The injection feed is formed on an injection molding machine, the forming parameters are: injection temperature 160°C, injection pressure 90MPa, injection speed 80%, pressure holding time 4s, and the molded blank of the magnetic core of the solenoid valve is obtained. First, soak the molded billet in trichlorethylene or n-heptane at a constant temperature of 25°C for 12 hours, and then dry the solvent degreasing billet, then heat the melted billet slowly from room temperatu...

Embodiment 3

[0028]All kinds of raw materials are batched according to the ingredients of 97% iron, 1% phosphorus, 1% silicon, 0.4% chromium and 0.6% manganese, and the powders of various raw materials are ball milled for 2 hours, and the mixed powder and ingredients are 60% paraffin, 20 A binder composed of % high-density polyethylene, 15% polypropylene and 5% stearic acid is mixed at a temperature of 165°C for 2 hours according to the volume ratio of the powder at 60%, and the binder and the powder are mixed uniformly The injection feed is molded on an injection molding machine, and the molding parameters are: injection temperature 160°C, injection pressure 90MPa, injection speed 80%, pressure holding time 4s, and the molded blank of the solenoid valve core is obtained. First, soak the molded billet in trichlorethylene or n-heptane at a constant temperature of 25°C for 12 hours, and then dry the solvent degreasing billet, then heat the melted billet slowly from room temperature to 800°C i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| saturation magnetic induction | aaaaa | aaaaa |

| magnetic permeability | aaaaa | aaaaa |

| coercivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com