Shaft part packaging line and packaging method thereof

A technology for shaft parts and parts, which is applied in the packaging line of shaft parts and its packaging field, which can solve the problem of unstable feeding quantity and achieve the effect of avoiding damage to the appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The following is further described in detail by specific embodiments:

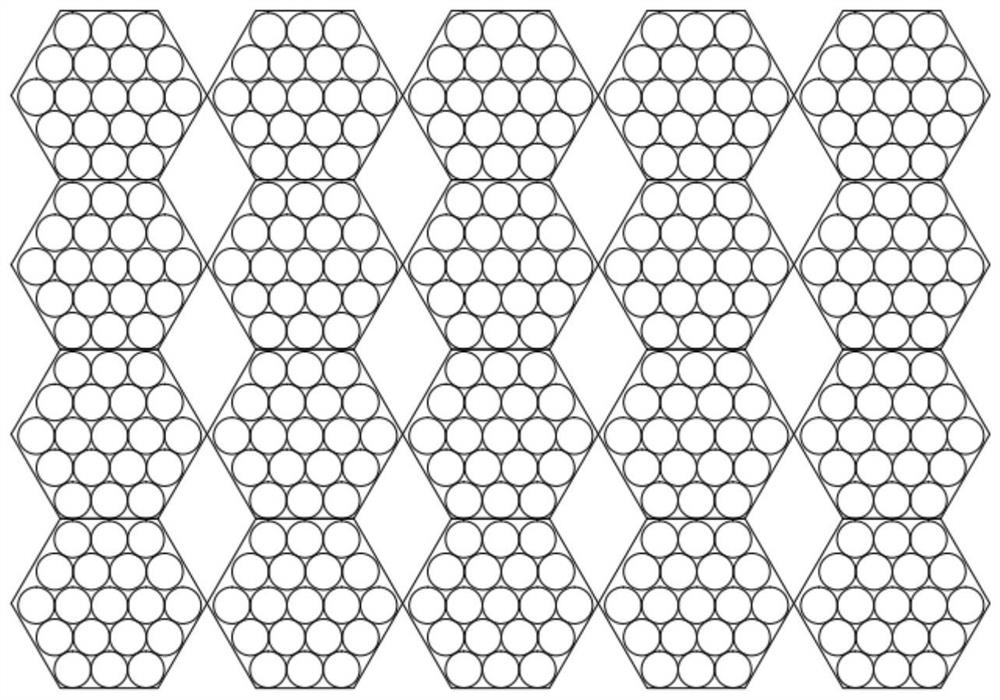

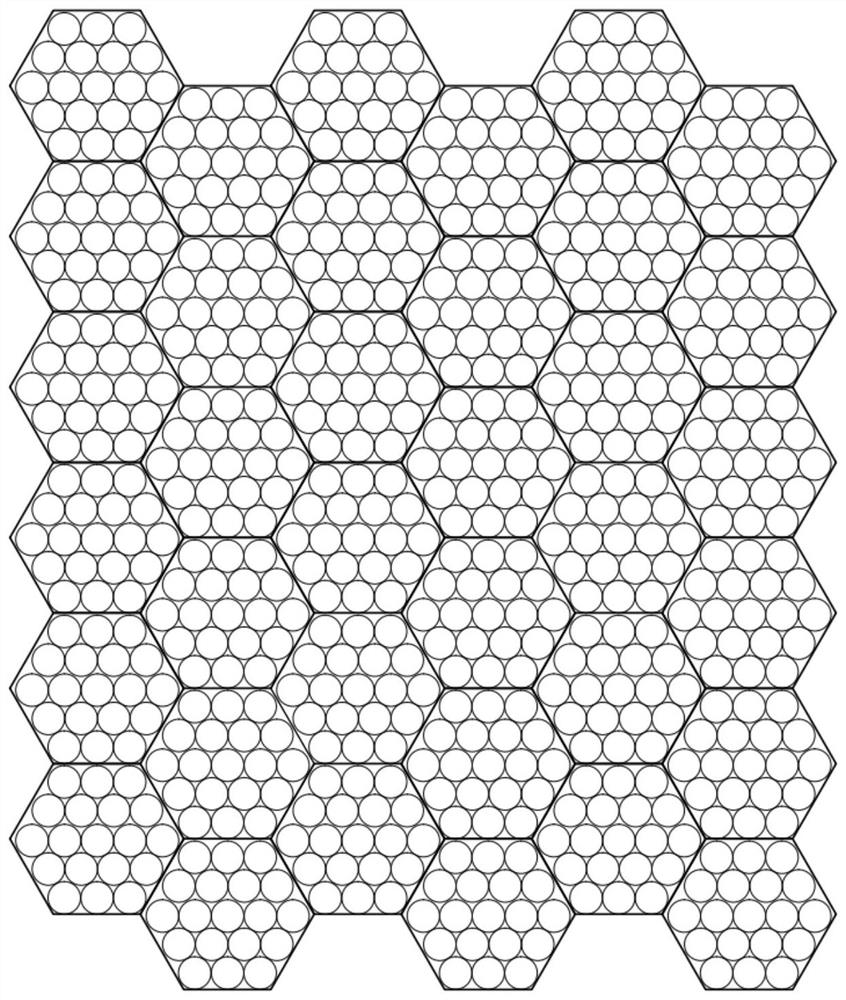

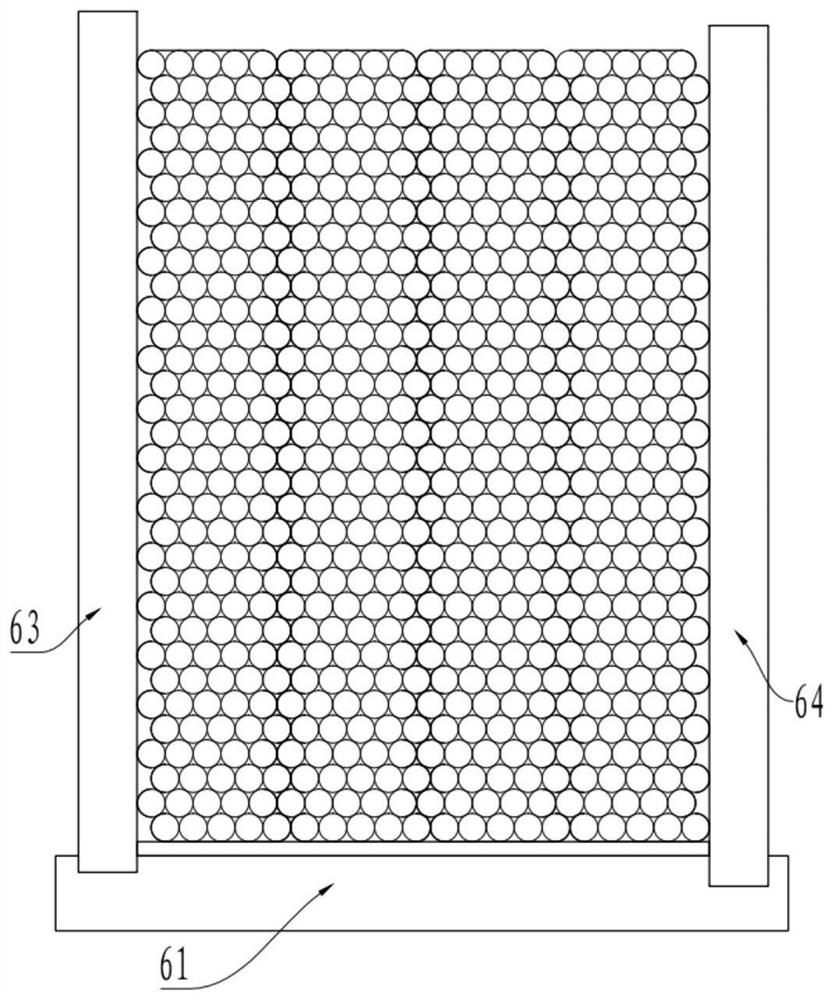

[0052] Reference numerals in the drawings include: feeding device 900, tilting frame 91, auxiliary tilting plate 99, height adjusting mechanism 92, lifting adjuster 921, lifting adjusting frame 922, limiter 93, connecting plate 94, turntable 951, Rotating shaft 952, positioning rod 953, positioning hole 954, limit plate 955, limit piece 95, push-out mechanism 96, push plate 961, separation protrusion 962, flip plate 97, drive member 971, collection groove 1, push plate 2, Synchronous plate 3, packing device 1000, unwinding mechanism 100, film pulling mechanism 200, film pulling seat 21, film pulling frame 22, first rack 23, starter motor 24, support mechanism 300, support plate 31, lifting mechanism 400, Fixed frame 4, gripper 40, first linear module 41, mounting frame 42, drive motor 43, moving frame 44, second rack 45, lifting module 46, connecting frame 401, support plate 402, mounting plate 403...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com