Galvanized steel pipe blue band identification packer

A technology of galvanized steel pipe and blue ribbon, which is applied in the field of metallurgy, can solve problems such as inability to realize continuous industrial production, affect the appearance of galvanized steel pipe, and affect the appearance quality of galvanized steel pipe, so as to facilitate blue positioning and improve automatic production Level, to avoid the effect of appearance damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

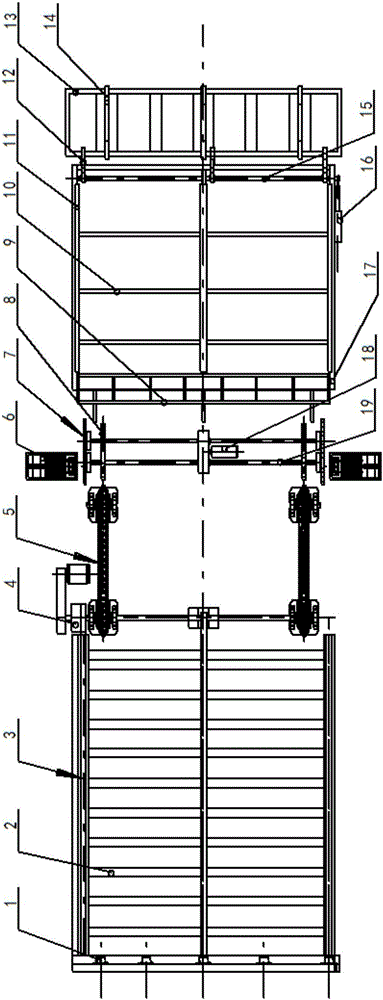

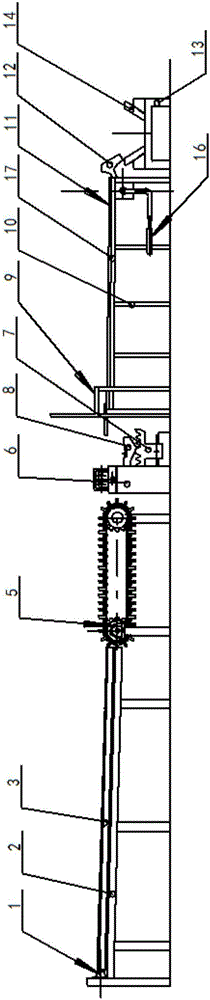

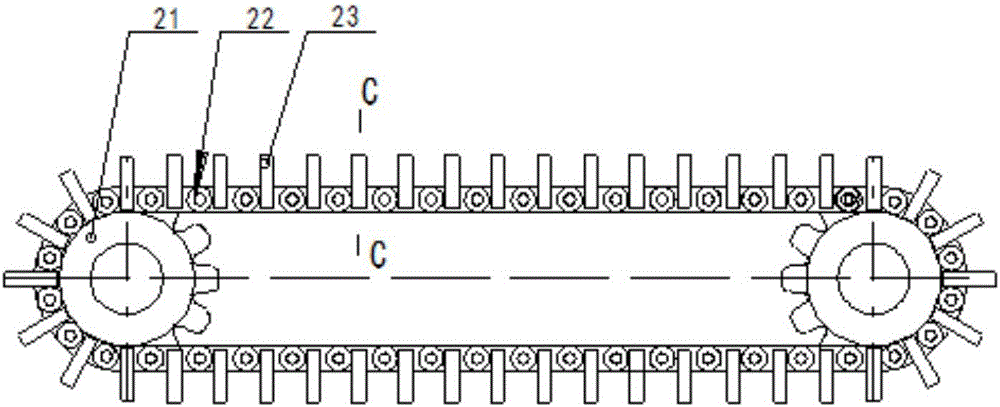

[0035] A galvanized steel pipe blue tape marking packing machine, including a connecting frame 2, a chain drive 5, a conveyor, a bluing machine 6, a conveying frame 10 and a packing frame 13, the connecting frame is an inclined square frame structure, after receiving passivation The galvanized steel pipe is connected to the chain drive at the end of the connecting frame. The chain drive is two symmetrical. The chain drive transmits the galvanized steel pipe to the conveyor through the chain transmission mode. A bluing machine is set up for the bluing operation of the galvanized steel pipes. After bluing, the galvanized steel pipes are ferried to the transmission frame through the conveyor. The transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com