Fully-automatic supply method

A fully automatic, feeding technology, which is applied in thin material processing, winding strips, sending objects, etc., can solve the problems of insufficient intelligence level, time-consuming and labor-intensive, etc., to improve automation level, high efficiency, reduce coil loading The effect of false and counterfeit problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

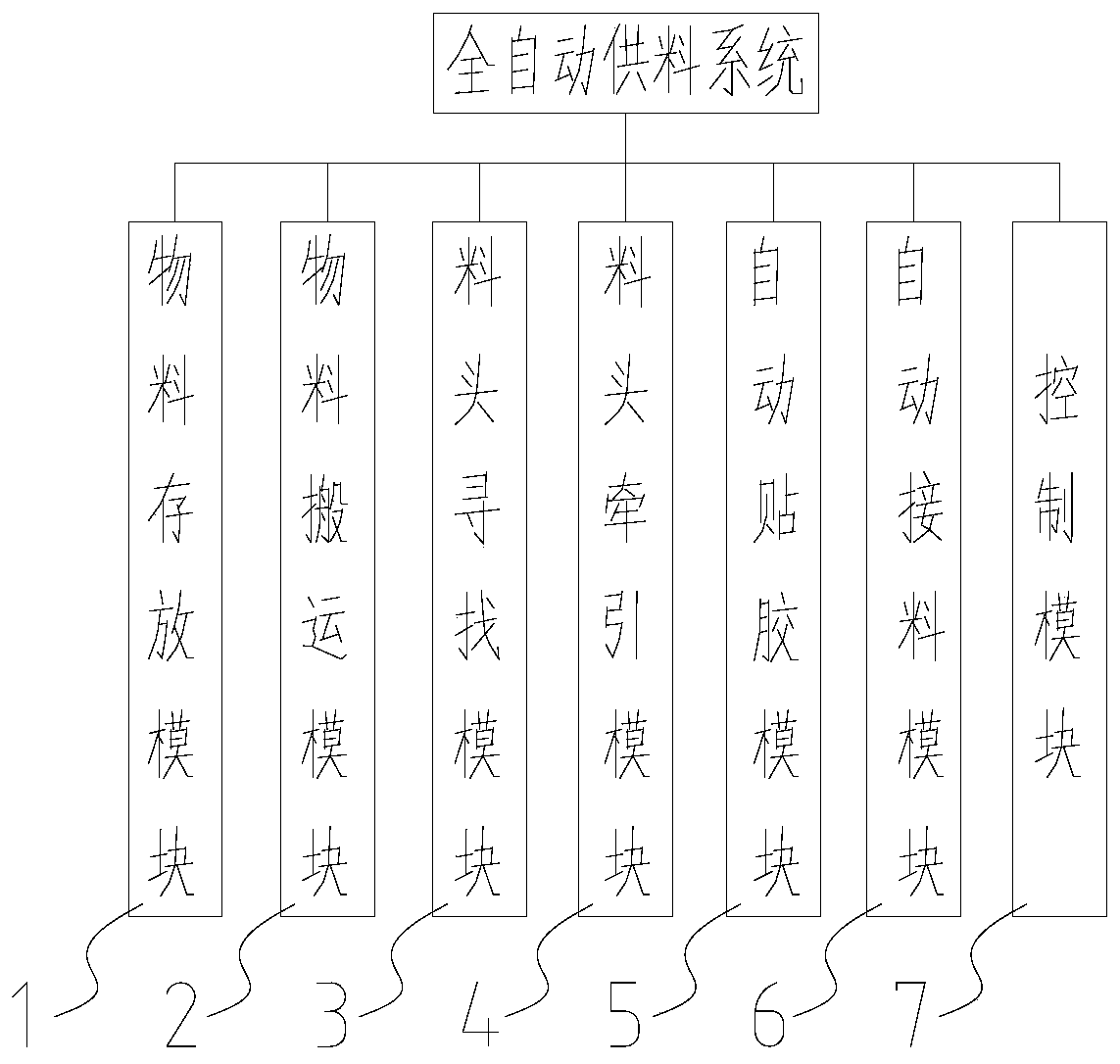

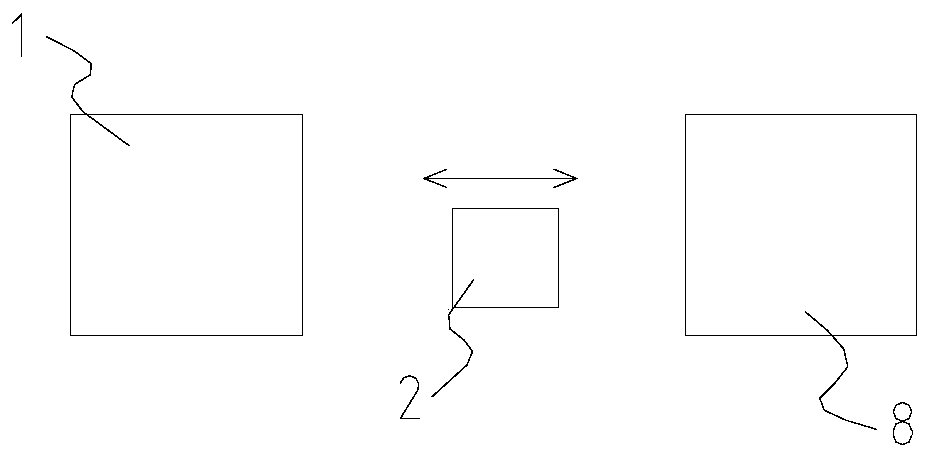

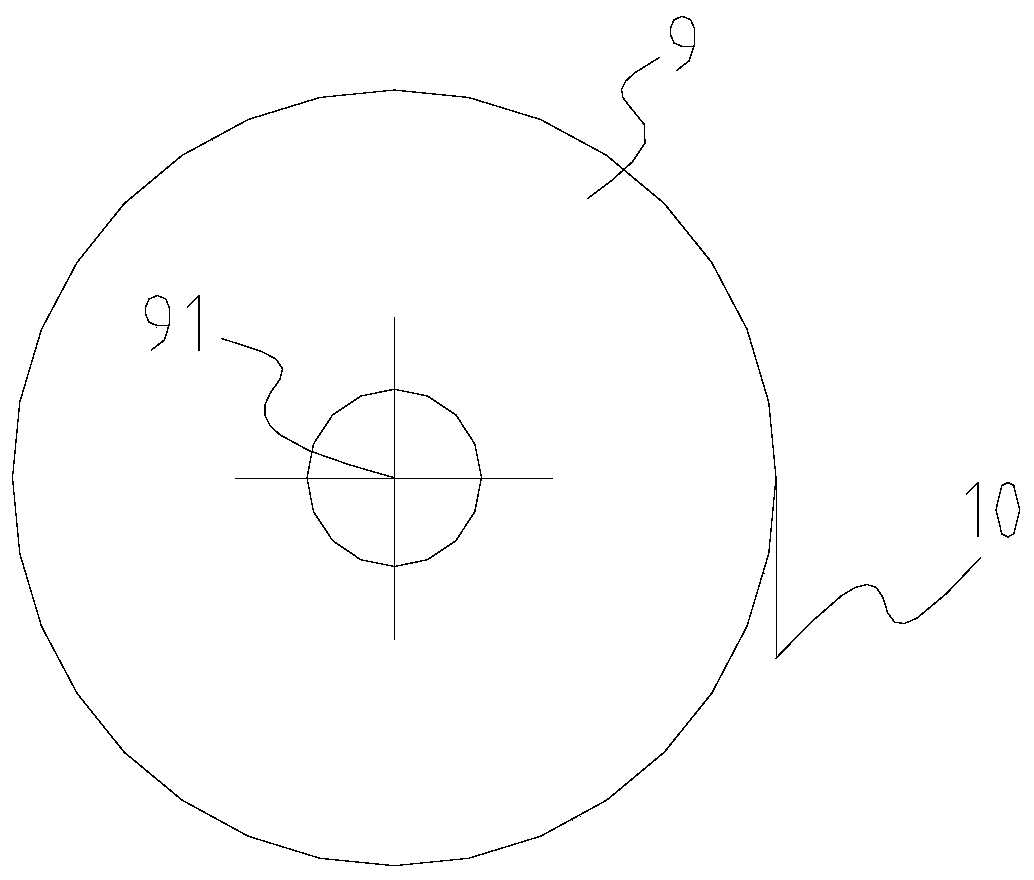

[0036] like Figures 1 to 4 As shown, a fully automatic feeding method adopts a fully automatic feeding system, which has: a material storage module 1, a material handling module 2, a material head search module 3, a material head traction module 4, an automatic glue application module 5, and an automatic splicing module. A material module 6 and a control module 7; it includes the following process: the material 9 is transported from the material storage module 1 to the handling process of the use station 8; after the material 9 arrives at the use station 8, the material head is searched on the surface of the material 9 10; pulling the material head 10 to the gluing station to complete the process of applying glue on the surface of the material head 10; and pulling the material head 10 to the automatic material receiving module 6 to complete the material receiving process.

[0037] Wherein, in the material storage module 1 , various materials are stored in digital information,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com