Easy-pulled bottle cap pull ring riveting edges gapless cutting and forming method

A molding method and a technology of easy-pull bottle caps, which are applied in molding tools, applications, household appliances, etc., can solve the problems of uneconomical and large material consumption, and achieve the effect of improving flatness and avoiding the impact of matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

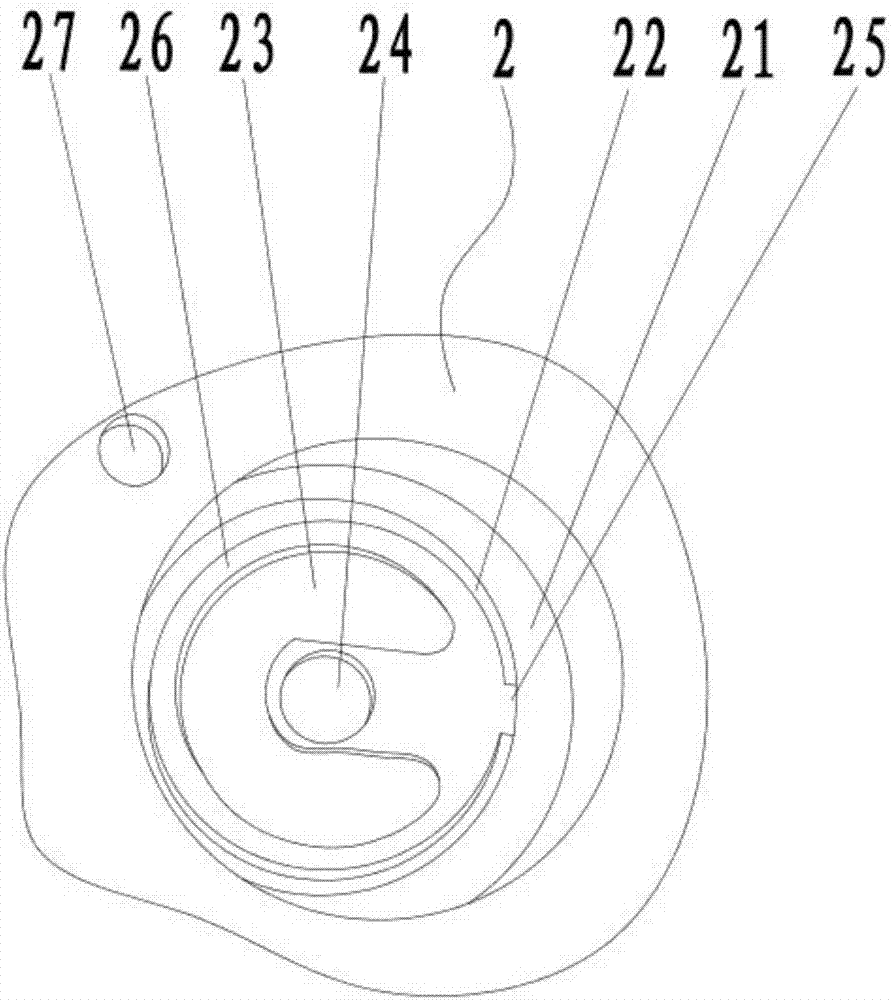

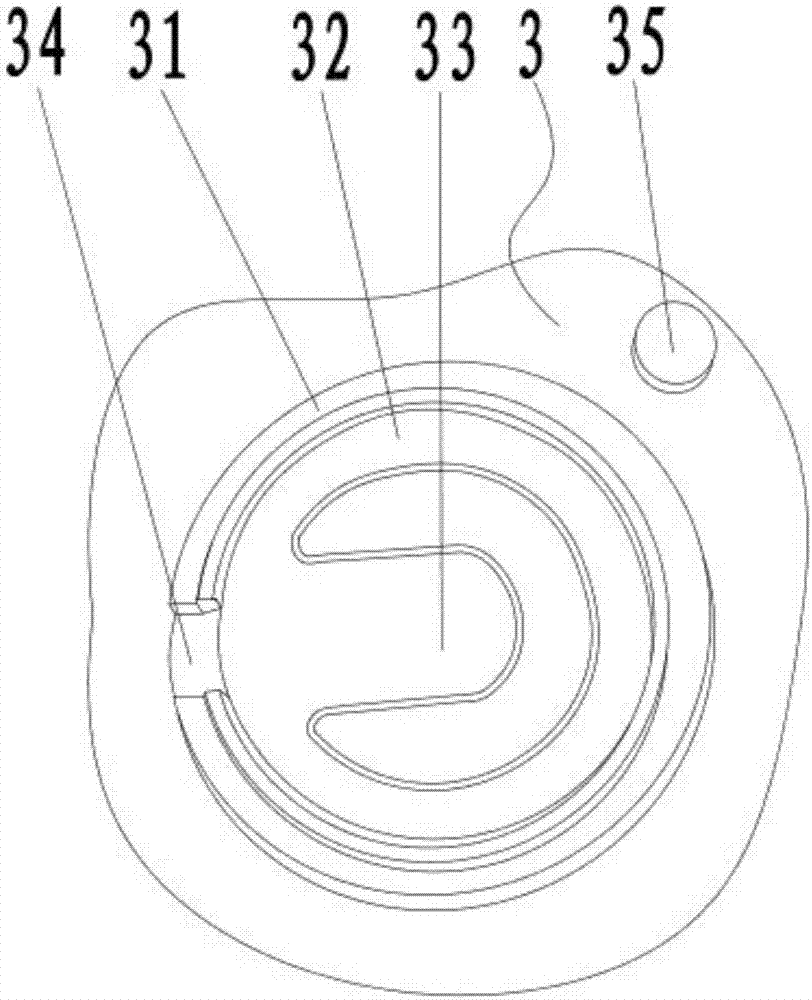

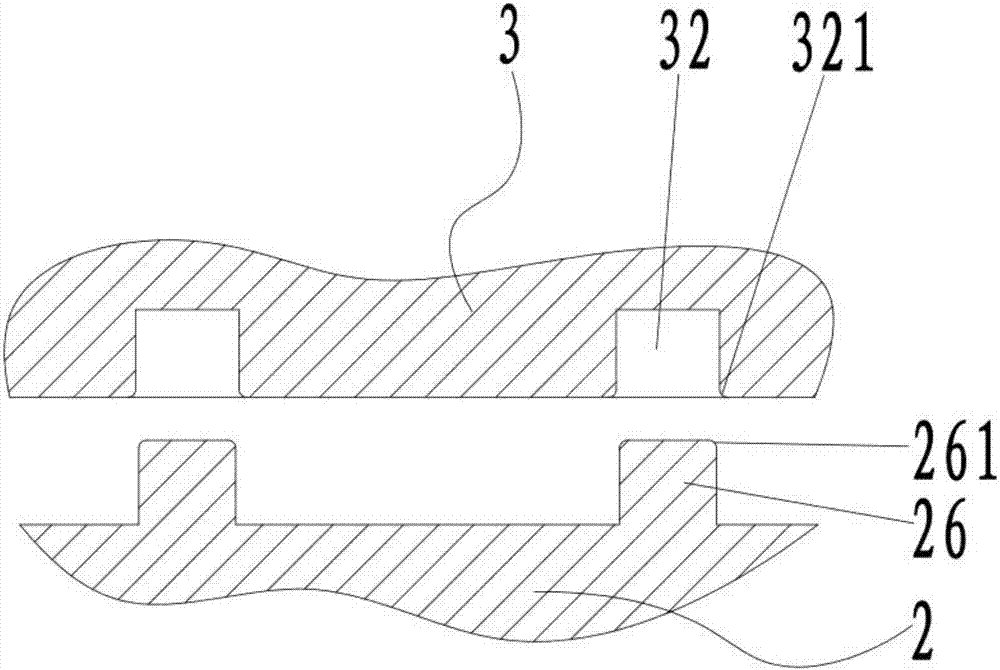

[0019] Such as Figures 1 to 5 As shown in one of the present invention, the riveting edge of the easy-to-open bottle cap has a gap-free cutting material forming method, wherein the pull ring has a ring-shaped handle part 14 and is connected to the inner side of the ring-shaped handle part 14 and is used for riveting and matching with the bottle cap. The riveting part 12, the specific molding method is as follows: place the tab blank 1 formed by trimming the outline between the upper mold 3 and the lower mold 2 of the stamping die, and press the upper mold 3 to make the tab blank 1 Folding the trimmed edge of the contour to form the bent portion 141, 121;

[0020] The lower mold 2 has an annular handle profiling protrusion 26 and a riveting part profiling protrusion 24 adapted to the shape of the pull ring, and there is a Contoured concave cavity 23, when the tab blank plate 1 is aligned and placed on the lower die 2, the contour trimming edges of the ring handle part 14 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com