Hybrid excitation system of power generation electric welding machine and method thereof

A hybrid excitation and electric welding machine technology, applied in the field of excitation, can solve the problems of low no-load voltage, difficult to arc, bulky and other problems, and achieve the effects of smooth excitation current, reduced burr, and stable magnetic field.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

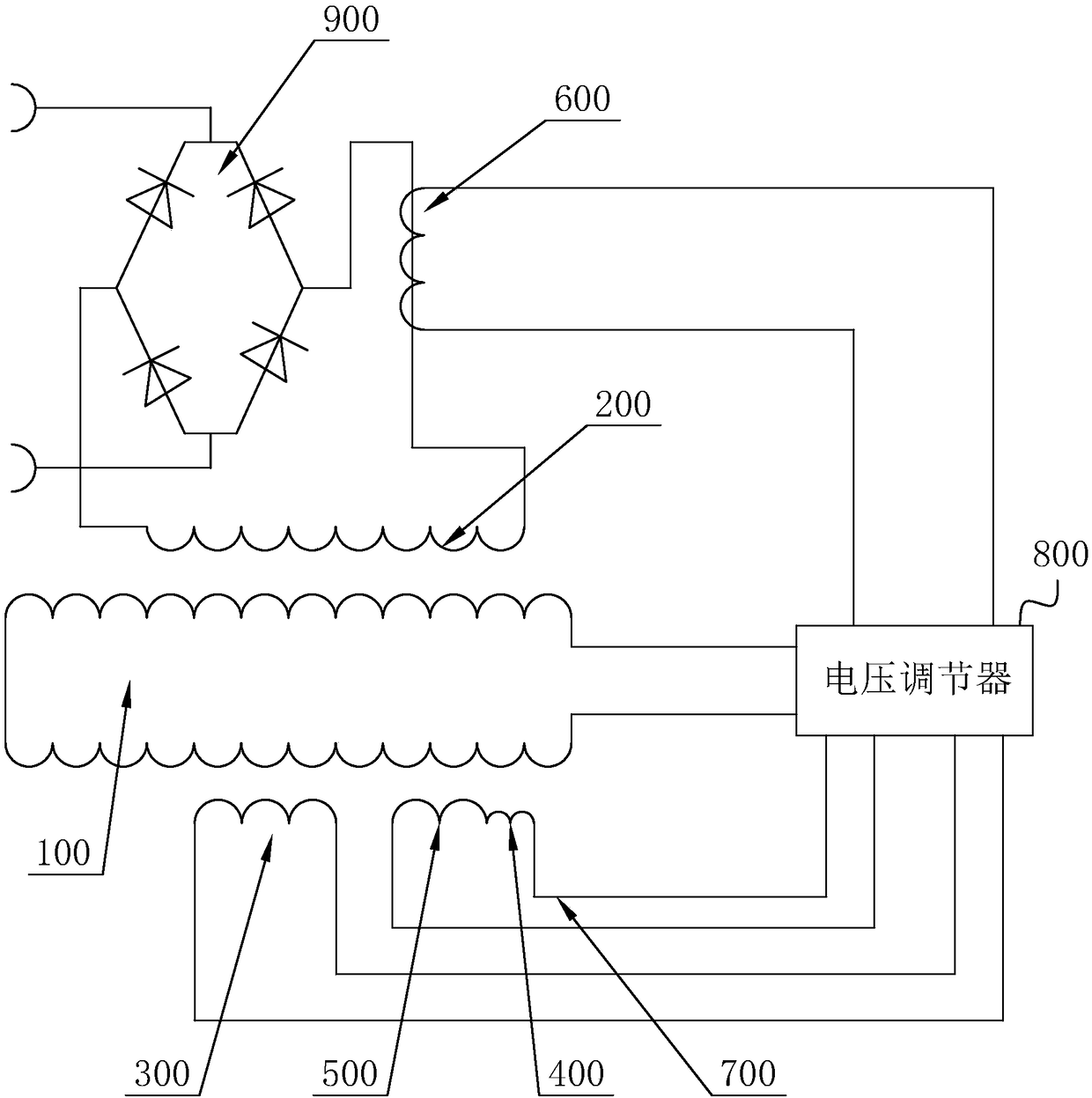

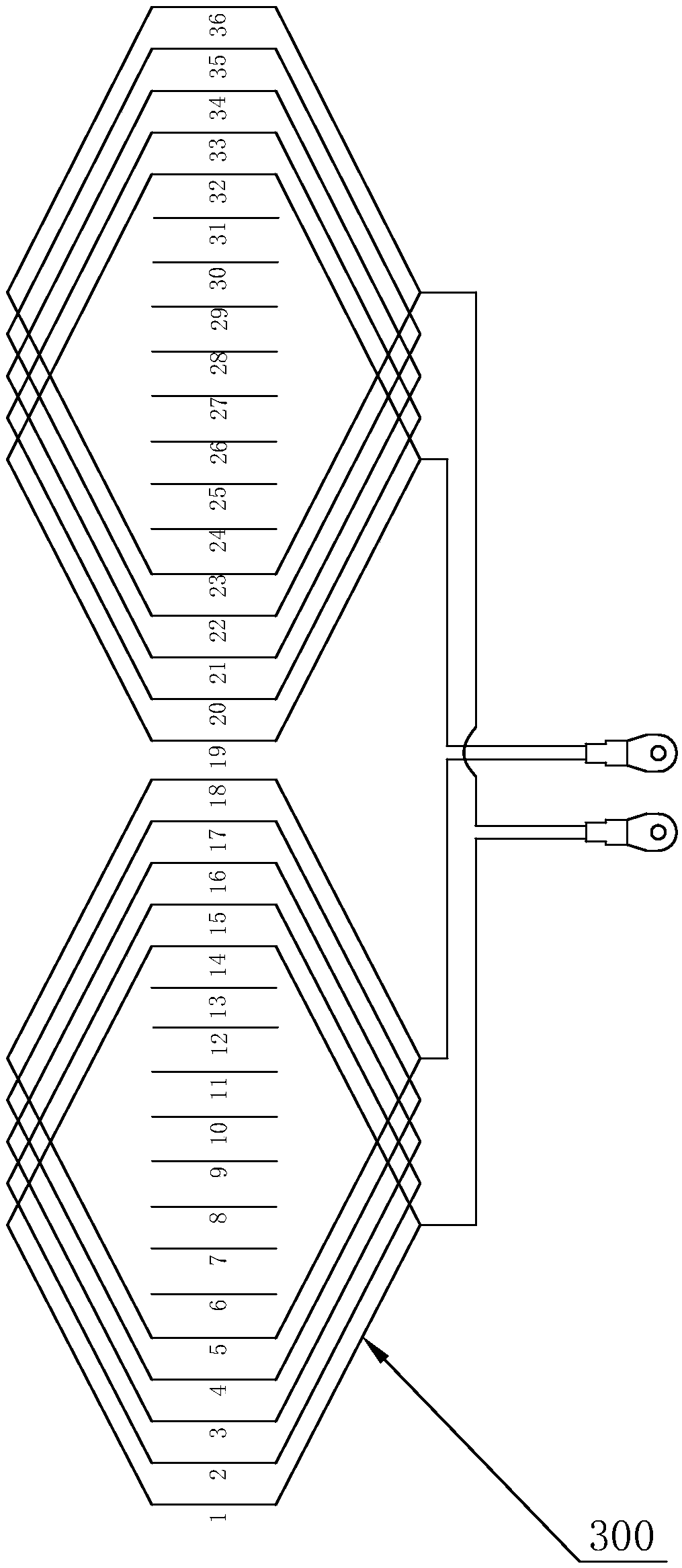

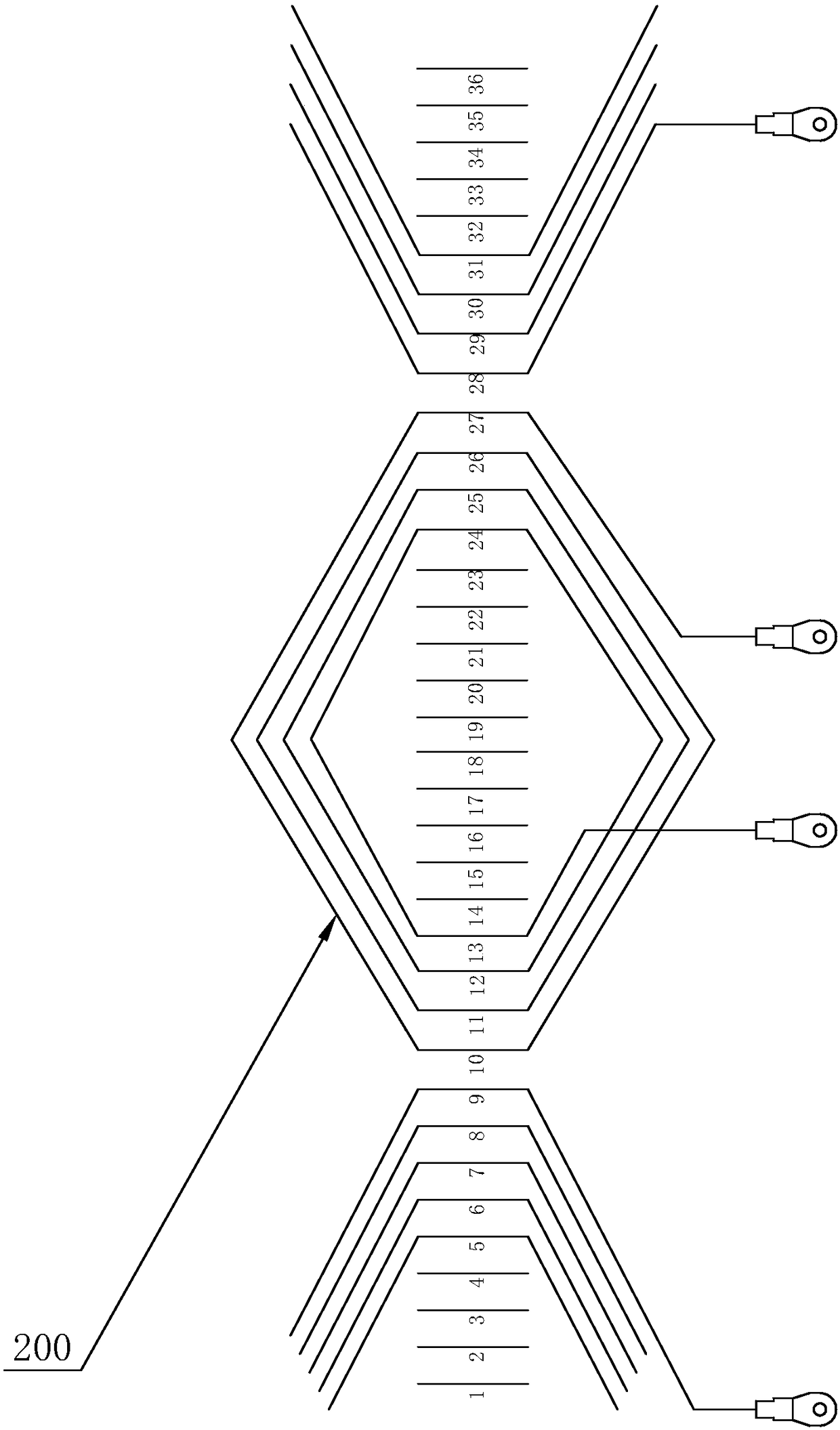

[0039] A hybrid excitation system for a generating electric welding machine, such as figure 1 As shown, it includes a motor rotor and a motor stator wound with an excitation winding 100. The motor stator is sequentially wound with a welding output winding 200 with a coaxial center line, a user power winding 300, a harmonic winding 400 and a fundamental wave winding 400. Winding 500, such as figure 2 As shown, the welding output winding 200 is used to provide welding power, and the welding output winding 200 is electrically connected with a current transformer 600 for inductive welding output current and a rectifier 900 for rectification, such as image 3 As shown, the user power winding 300 is used to provide user power, and the harmonic winding 400 and the fundamental winding 500 are used to provide excitation current to the excitation winding 100 .

[0040] Such as figure 1 and Figure 4As shown, the harmonic winding 400 is a third harmonic coil, and the number of turns ...

Embodiment 2

[0044] Combining the above-mentioned inventive idea of the technical solution of the present invention, a hybrid excitation method of a power generation electric welding machine, such as Figure 5 shown, including the following steps:

[0045] Step S1: Wind the welding output winding 200 on the motor stator, wind the excitation winding 100 on the motor rotor, and wind the user power supply winding 300 outside the welding output winding 200; after the motor rotor rotates, fix the magnetic field on the motor rotor to cut the welding output The winding 200 and the user power winding 300, the welding output winding 200 is used to provide welding power, and the user power winding 300 is used to provide user power.

[0046] Step S2: Determine the turns of the fundamental winding 500 and the harmonic winding 400; wherein, the harmonic winding 400 is a third harmonic coil. Determining the number of turns of the fundamental winding 500 and the harmonic winding 400 can improve the ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com