Ultrathin PI cover film and preparation method thereof

A cover film, ultra-thin technology, applied in the field of ultra-thin PI cover film and its preparation, to achieve the effects of increasing flatness, improving alignment efficiency, improving product qualification rate and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

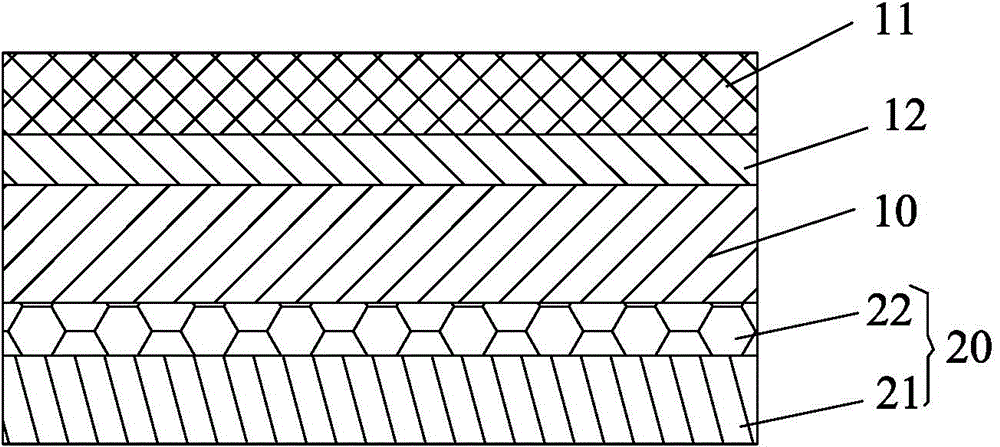

Image

Examples

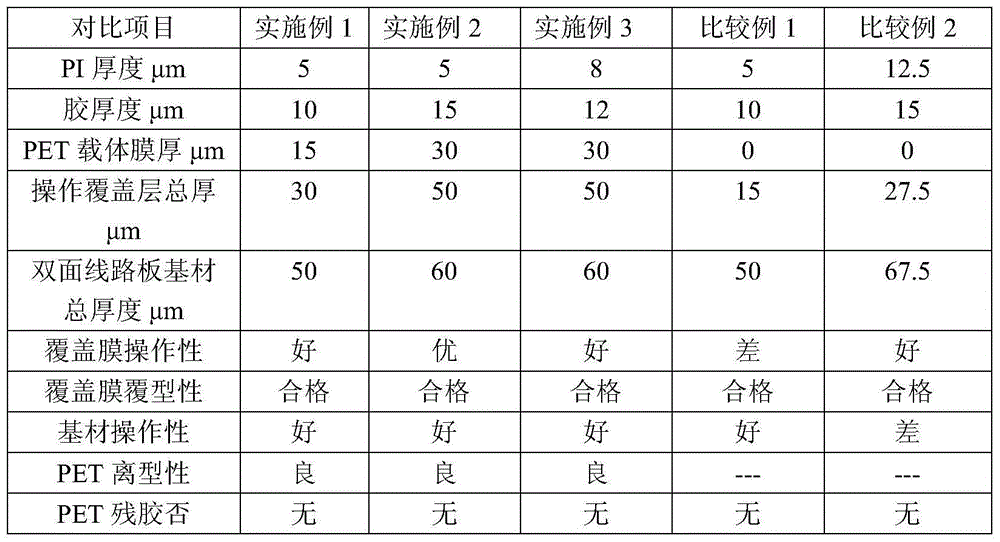

Embodiment 1

[0029] A kind of preparation method of ultra-thin PI covering film, comprises the steps:

[0030] (1) Preparation of low-viscosity PET carrier film:

[0031] Prepare low-viscosity agent, described low-viscosity agent comprises the following components by weight: 30 parts by weight of carboxyl-terminated nitrile rubber; 100 parts of bisphenol A epoxy resin 1001, wherein solid content 60%; dicyandiamide 18 parts of amine, dissolved in DMF solution, wherein the concentration of DICY dicyandiamide is 10%; 0.05 part of 2-ethylmethylimidazole; 120 parts of butanone. Dissolve the carboxy-terminated nitrile rubber in methyl ethyl ketone, add bisphenol A epoxy resin 1001, dicyandiamide 1, and 2 ethylmethylimidazole and mix well to obtain a low-viscosity adhesive;

[0032] Take a 25μm PET film for corona treatment, and then apply the low-viscosity agent on the corona-treated PET film. Curing for 1-2 hours, the obtained low-viscosity PET carrier film, the low-viscosity PET carrier film...

Embodiment 2

[0037] A kind of preparation method of ultra-thin PI covering film, comprises the steps:

[0038] (1) Preparation of low-viscosity PET carrier film: purchase PR-SS50N-01-1CM101 PET film coated with low-viscosity from Dewanli Technology, the release force is 5 g / 25mm, remove the protective film, and obtain low-viscosity PET carrier film;

[0039] (2) Preparation of carrier PI composite film: compound the above-mentioned low-viscosity PET carrier film and 5 μm ultra-thin PI film with a mulching machine, and the composite temperature is 80-120 ° C to obtain a carrier PI composite film;

[0040] (3) Composite of carrier PI composite film and release paper: Coating modified epoxy resin glue solution on the surface of carrier PI composite film, the drying thickness of the coating is controlled at 15 μm, drying, and then compounding with release paper to obtain super Thin PI cover film.

[0041] The above ultra-thin PI cover film was cured at 50°C for 13 hours, and the amount of gl...

Embodiment 3

[0043] A kind of preparation method of ultra-thin PI covering film, comprises the steps:

[0044] (1) Preparation of low-viscosity PET carrier film:

[0045]Prepare low-viscosity agent, described low-viscosity agent comprises the following components by weight: 30 parts by weight of carboxyl-terminated nitrile rubber; 100 parts of bisphenol A epoxy resin 1001, wherein solid content 60%; dicyandiamide 18 parts of amine, dissolved in DMF solution, wherein the concentration of DICY dicyandiamide is 10%; 0.05 part of 2-ethylmethylimidazole; 120 parts of butanone. Dissolve the carboxy-terminated nitrile rubber in methyl ethyl ketone, add bisphenol A epoxy resin 1001, dicyandiamide 1, and 2 ethylmethylimidazole and mix well to obtain a low-viscosity adhesive;

[0046] Take the 18μm PET film for corona treatment, and then apply the low-viscosity agent on the corona-treated PET film, control the thickness of the low-viscosity agent after drying to 5μm, dry at 150°C for 5min, and then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com