Thin film structure and manufacturing method thereof

A film structure and manufacturing method technology, applied in special decorative structures, chemical instruments and methods, decorative art, etc., can solve problems such as time-consuming, poor bonding between elastic fluff layer and plastic substrate, complex process, etc., to achieve improved anti-corrosion Anti-scratch properties, avoid fading, and reduce fixed costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

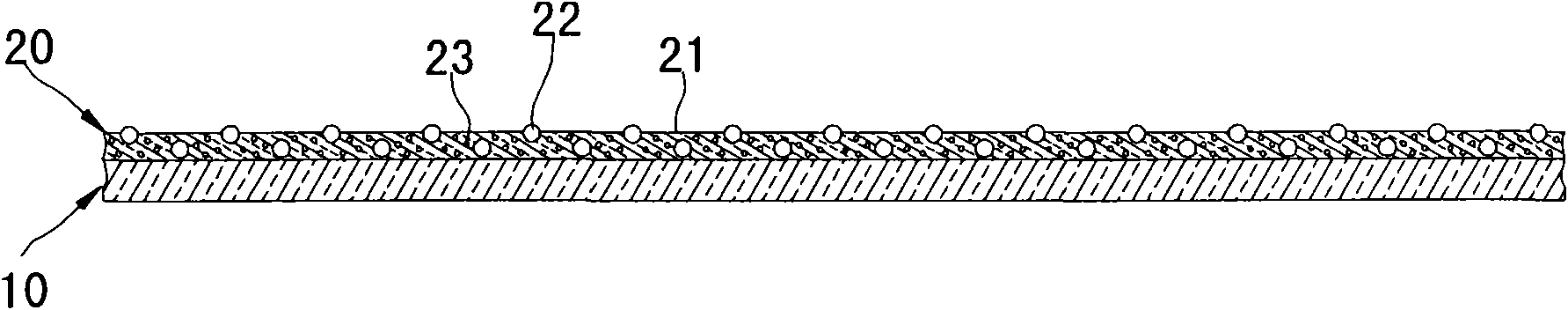

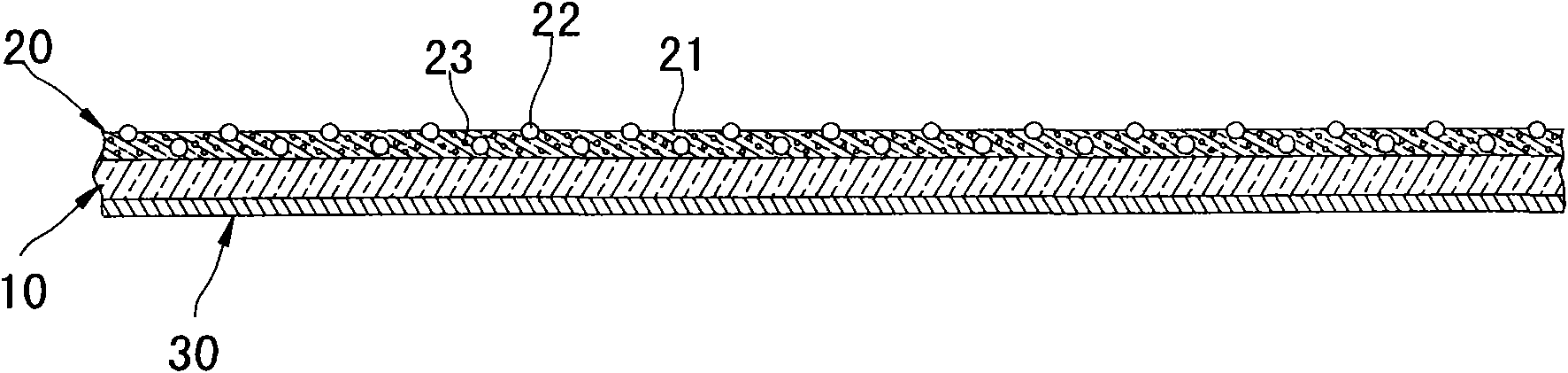

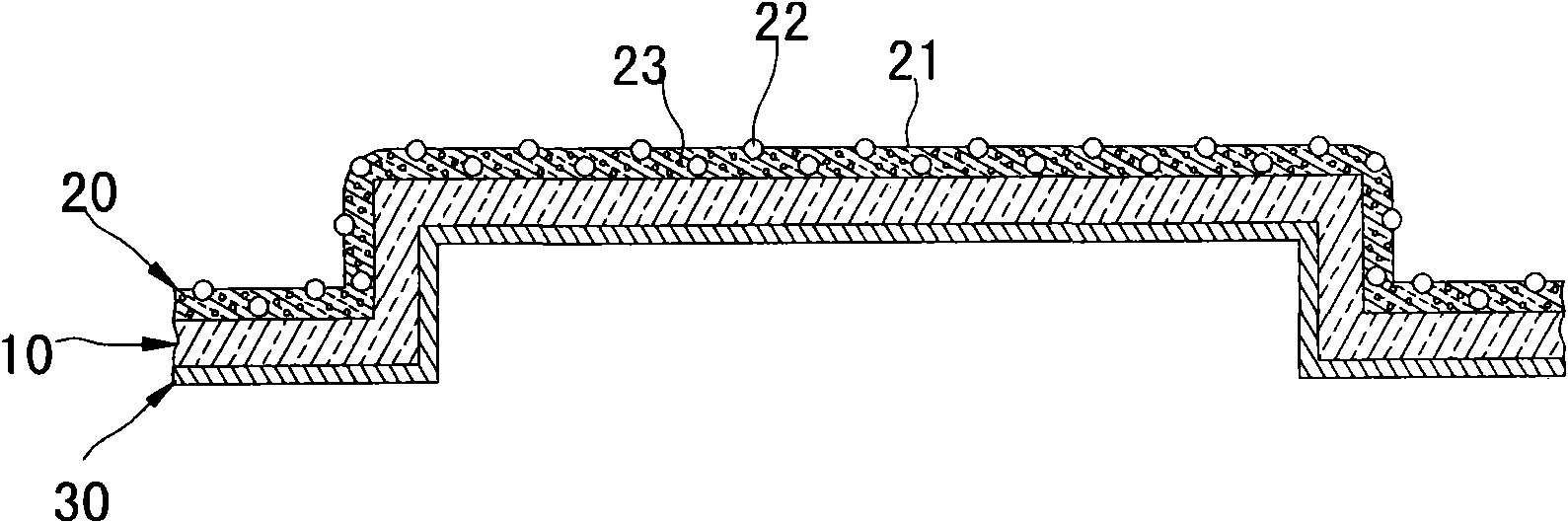

[0028] see Figure 1 to Figure 4 As shown, the film structure of the present invention can be applied to the in-mold decoration (In Mold Decoration, IMD) process, as 3C home appliance casing, automobile interior or audio casing, toy casing, video game joystick, keyboard, mouse, various grips , handle shell... and any high-value-added products that require colorful or 3D decoration technology and a comfortable feel. The film structure includes: a film 10 , a coating 20 , an ink layer 30 and a plastic substrate 40 .

[0029] The film 10 is transparent and its thickness is about 80-500 μm. The material of the film 10 is selected from acrylic (PMMA), polycarbonate (PC), polyethylene terephthalate (PET) , polyethylene (PE), polyvinyl chloride (PVC), polypropylene (PP), polystyrene (PS), methyl methacrylate and styrene copolymer (MS), triacetyl cellulose (TAC) and cyclo One of the olefin copolymers (COC).

[0030] The coating 20 includes a colloid 21 and at least two kinds of flex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com