Tracing method for determining local interference region boundary of free-form surface machining

A technology of local interference and surface processing, applied in the field of tracking, can solve the problems of local interference, low precision, improper selection of processing tool size, etc., to reduce the total length, simplify the operation, and improve the efficiency of surface processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] Example: refer to Figure 5 As shown in , a tracking method for determining the boundaries of local interference areas in free-form surface processing, specifically includes the following steps:

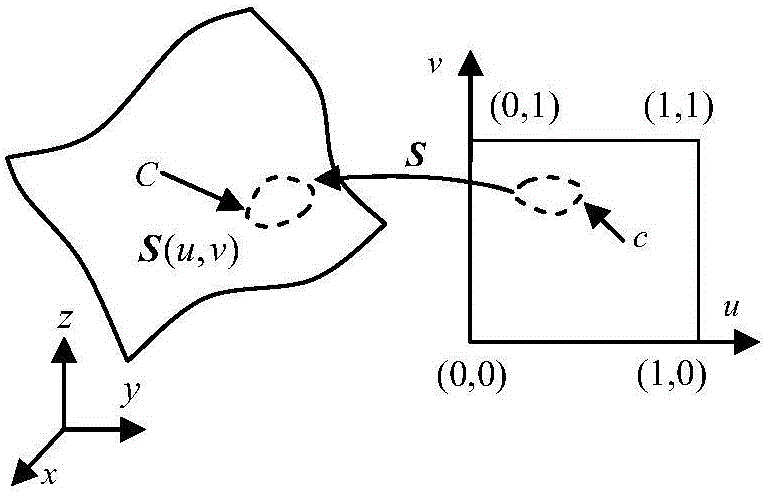

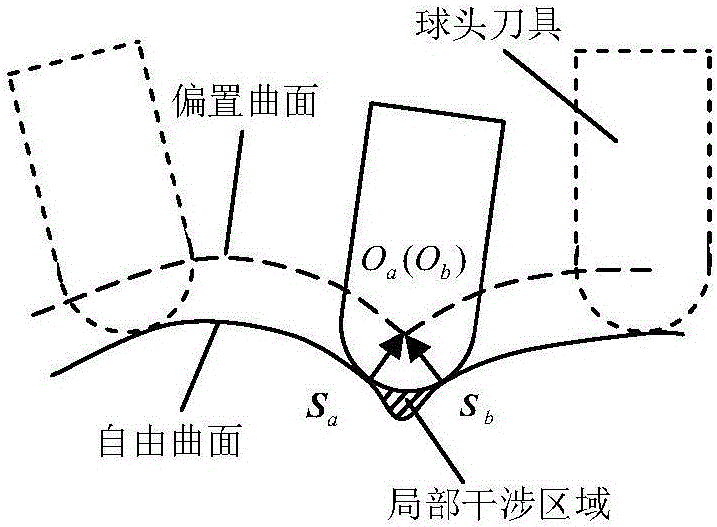

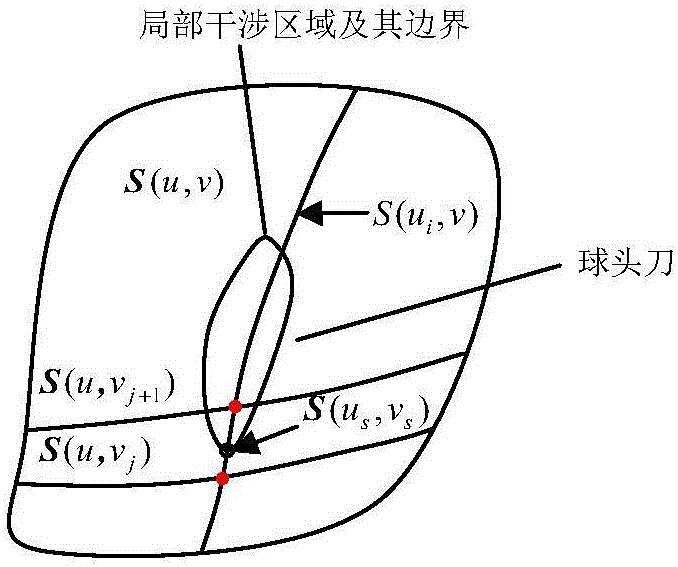

[0045] 1) Establish a free-form surface S based on point fitting of measured values (such as figure 1 shown) and the offset surface S offset , the point in the parameter plane (u 0 ,v 0 ) corresponding to the point S(u on the free-form surface S 0 ,v 0 ) and the offset surface S offset point S on offset (u 0 ,v 0 ) between the corresponding principal curvature relation is: Set the boundary tracking condition of the local interference area: k max (u,v)=k tool ; where: k m is the principal curvature on the free-form surface S; k m_offset is the offset surface S offset on the principal curvature, d is the offset surface S offset Distance to free-form surface S, k max (u, v) is the maximum principal curvature of the point on the free surface S, k tool is the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com