Three-dimensional shape measurement method of coated devices based on white light scanning interference

A technology of white light scanning and measurement method, applied in the field of measurement, can solve the problems of difficult measurement accuracy, limited measurement lateral resolution, and inapplicability of too thick film layers, etc., and achieves the effects of strong anti-noise performance, high calculation accuracy and convenient implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

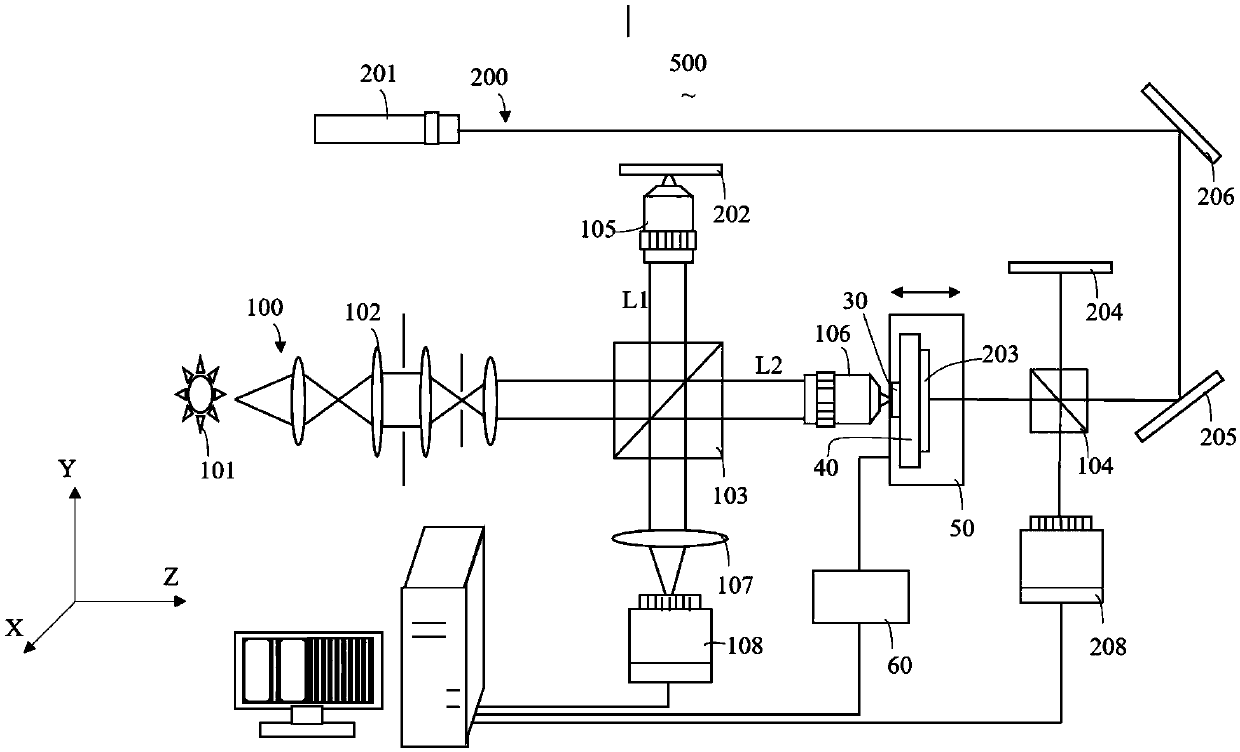

[0018] In this embodiment, a white light scanning interferometry system 500 will be described with reference to the accompanying drawings, which will be used as a hardware part for implementing the method for measuring the three-dimensional shape of a coated device in the second embodiment.

[0019] like figure 1 As shown, the white light scanning interferometry system 500 provided by the first embodiment of the present invention includes a white light scanning module 100, a calibration module 200, a fixed plate 40 for fixing the object to be measured 30, a piezoelectric ceramic micro-displacement platform 50, and a piezoelectric ceramic micro-displacement platform 50. Electroceramic controller 60.

[0020] Wherein the white light scanning module 100 comprises: a white light source 101, a Kohler illumination system 102, a first beam splitter 103 and a first plane mirror 202, a first microscope objective 105 and a second microscope objective 106 , an imaging lens 107 , and a f...

no. 2 example

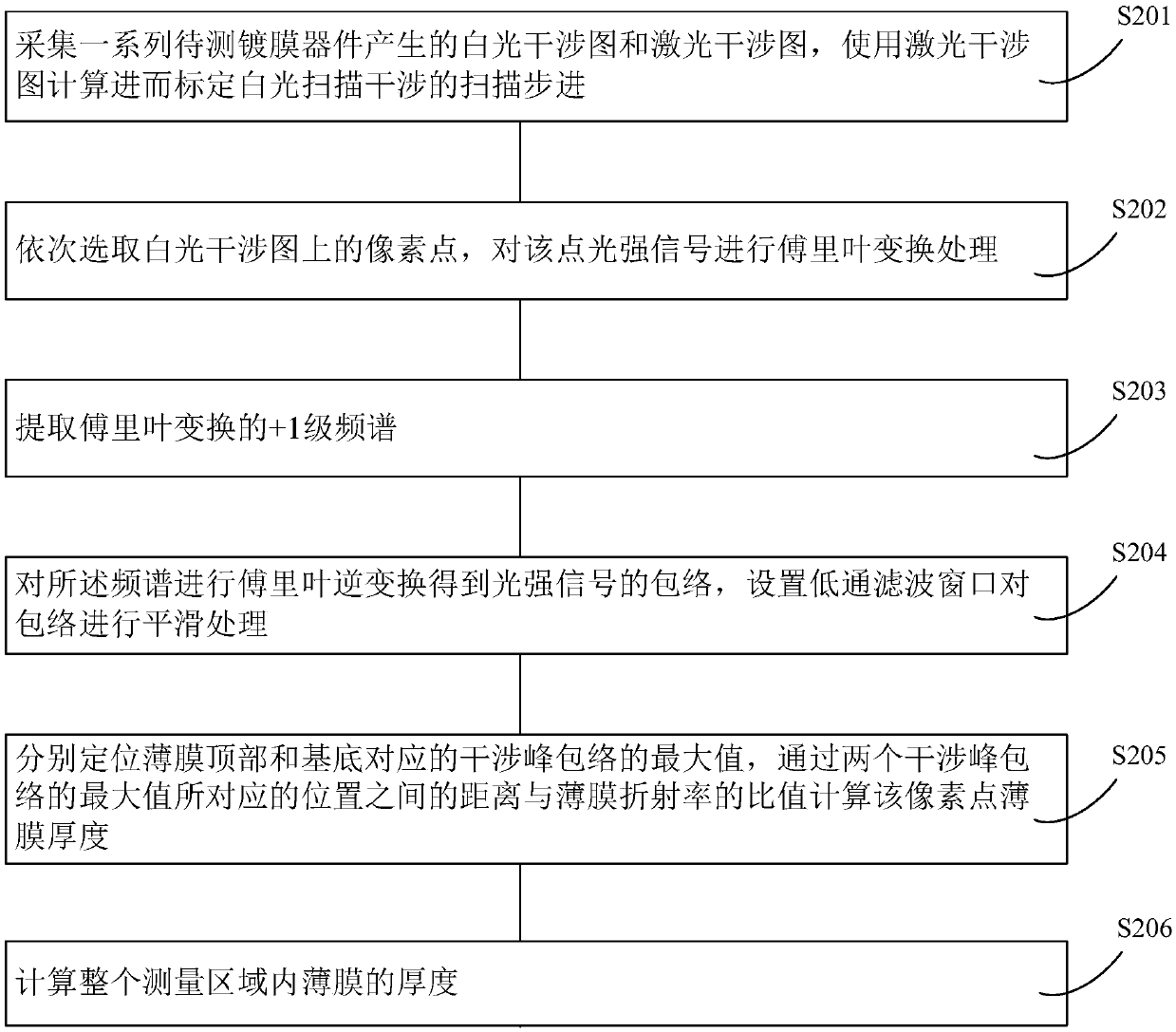

[0038] Please refer to figure 2 , the method for measuring the three-dimensional shape of a coated device based on white light scanning interference will be further described below in conjunction with the accompanying drawings and embodiments. In this method, the white light scanning interferometry system 500 described in the first embodiment is used for measurement, and specifically includes the following steps S201–S206.

[0039] In this embodiment, white light scanning interference is used to measure the topography of the coated device. In the case of different substrate materials of the coated device, the envelope shape of the first interference peak formed by the upper layer of the film is the same, while the second interference peak formed by the substrate The envelope shape of each interference peak will be different. In this embodiment, it is assumed that the substrate is composed of two materials.

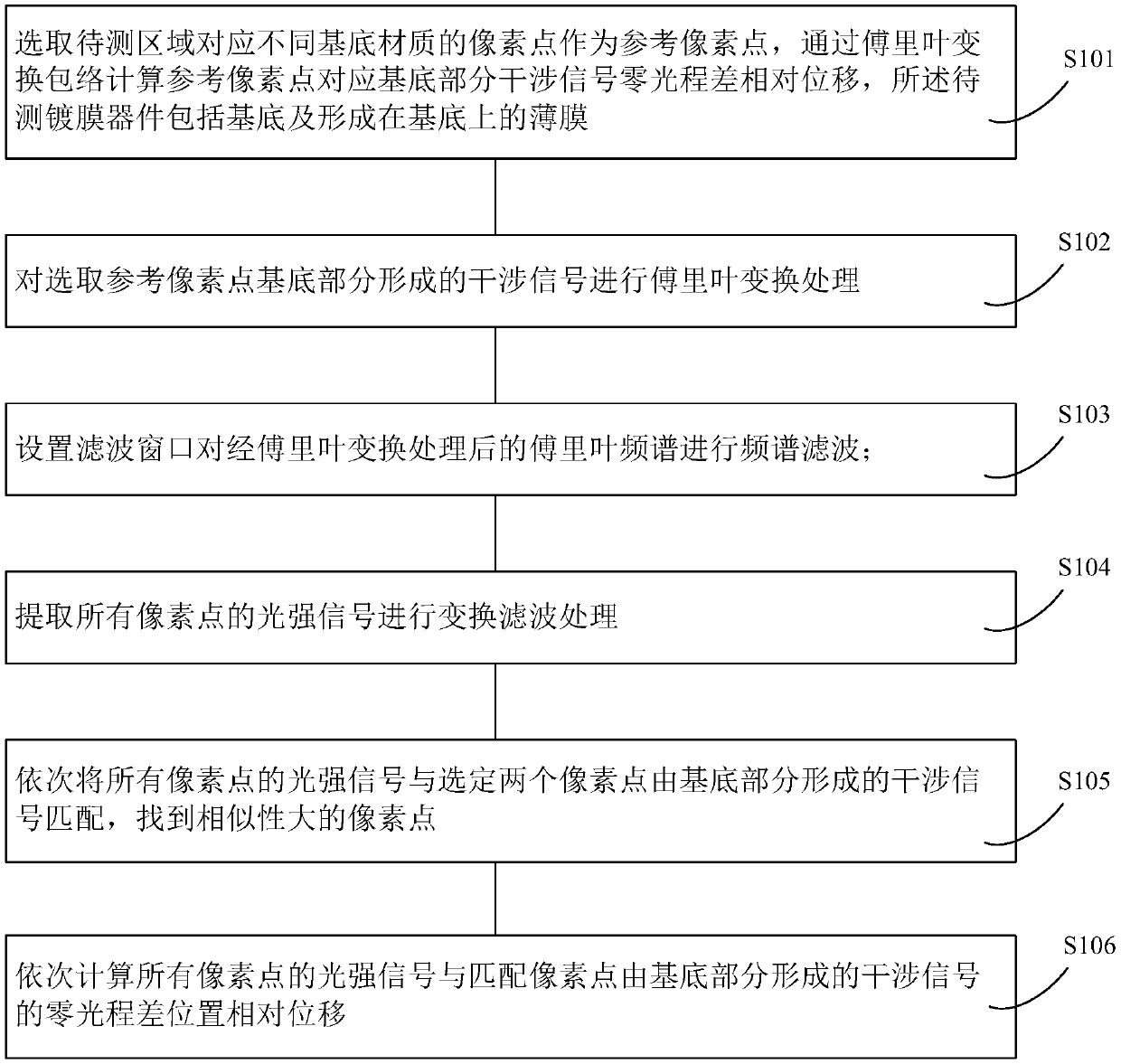

[0040] Step S101, select pixels corresponding to different substra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com