Fixing and clamping equipment for sheet metal machining

A fixed clamping, sheet metal technology, applied in the field of mechanical processing, can solve the problems of reducing sheet metal processing efficiency, increasing operator labor intensity, flexible clamping of sheet metal processing parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

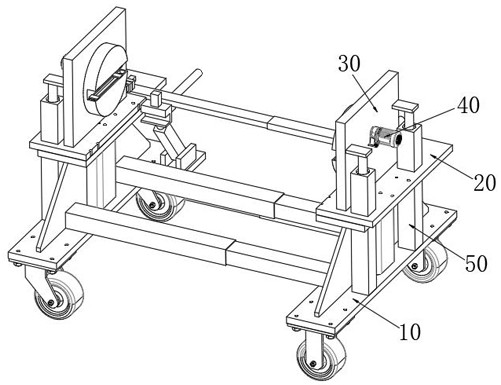

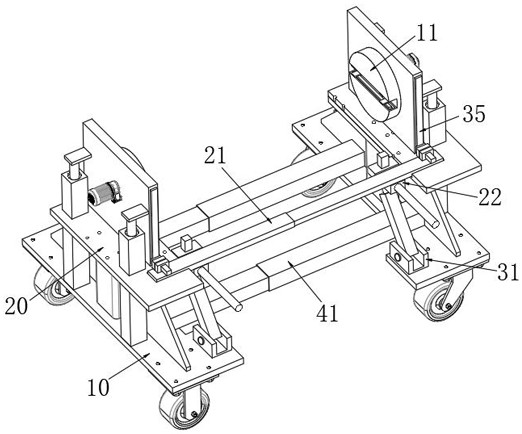

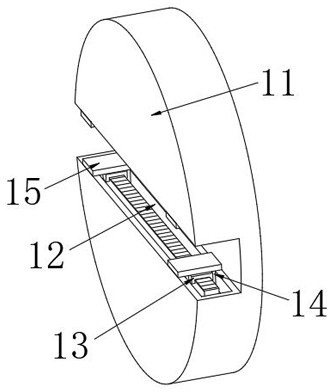

[0034] see Figure 1-Figure 8 shown, a stationary clamping device for sheet metal processing, comprising

[0035] There are two movable racks 10, two movable racks 10 are provided, moving wheels are arranged at the bottom of the two movable racks 10, and a fixed rack 20 is also arranged at the top of the two movable racks 10;

[0036]The side clamping part is used to clamp both sides of the sheet metal workpiece, and at the same time realize the overturning adjustment of the sheet metal workpiece. The mounting brackets 30, the side clamping components arranged on one side of the two mounting brackets 30, the geared motor 40 arranged on the other side of the two mounting brackets 30, and the first servo motor 40 arranged inside the two mounting brackets 20 respectively The electric cylinder 50, the driving ends of the two first servo electric cylinders 50 are respectively connected with one side of the two mounting frames 30, and one end of the output shaft of the two geared m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com