Garbage container transfer robot and method

A garbage container and robot technology, which is applied in the field of automatic transfer equipment, can solve unseen problems, achieve high transfer efficiency, good reliability, and improve the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

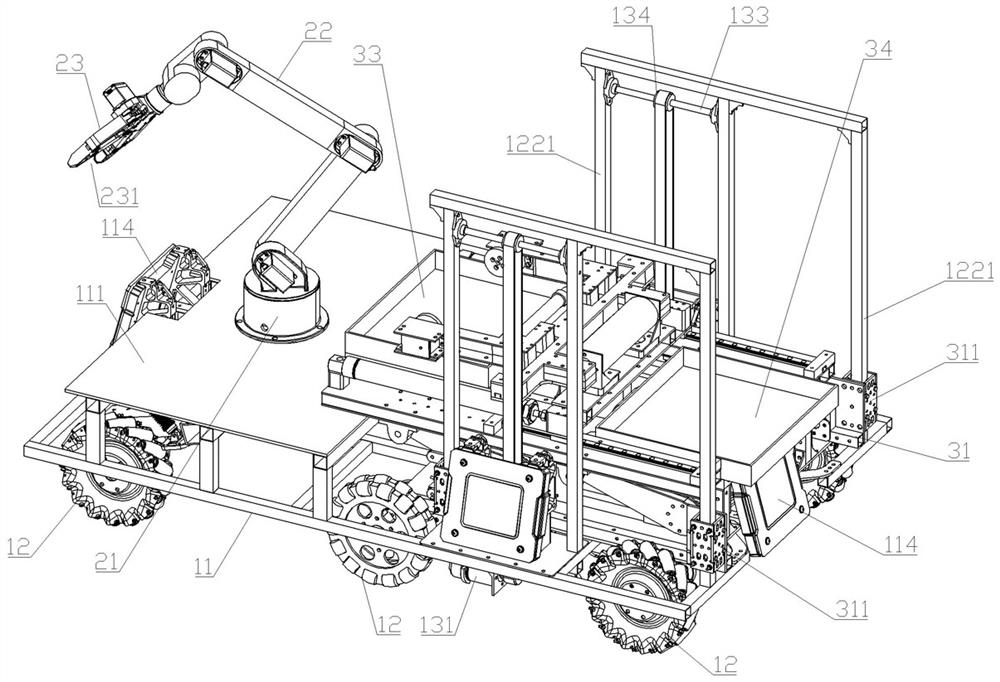

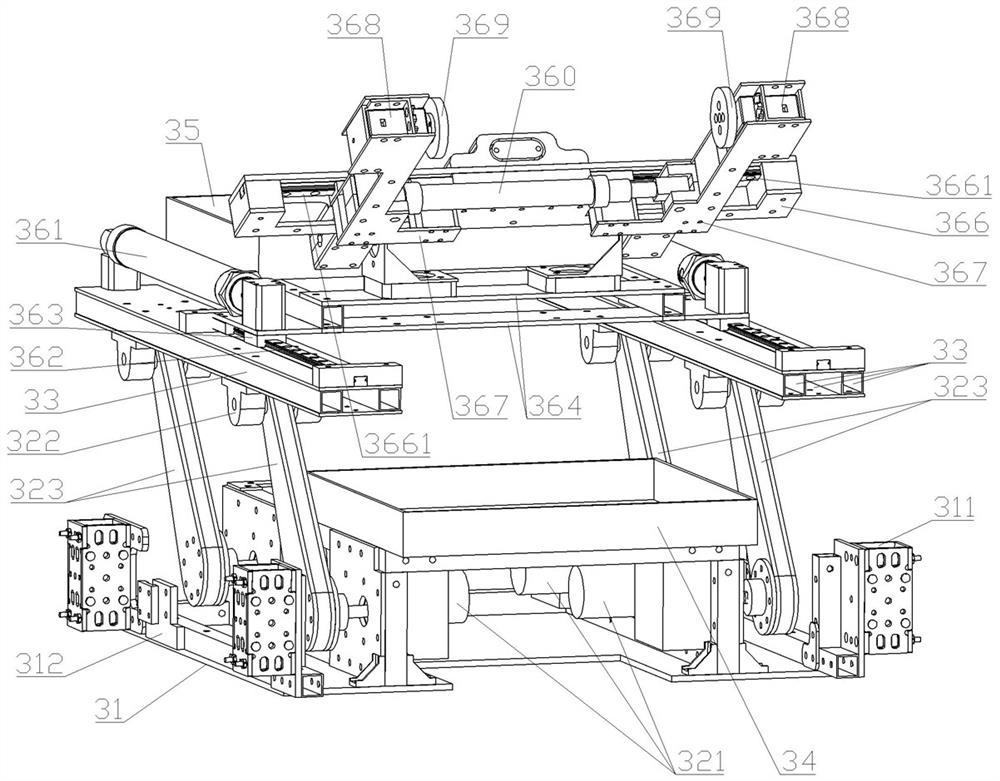

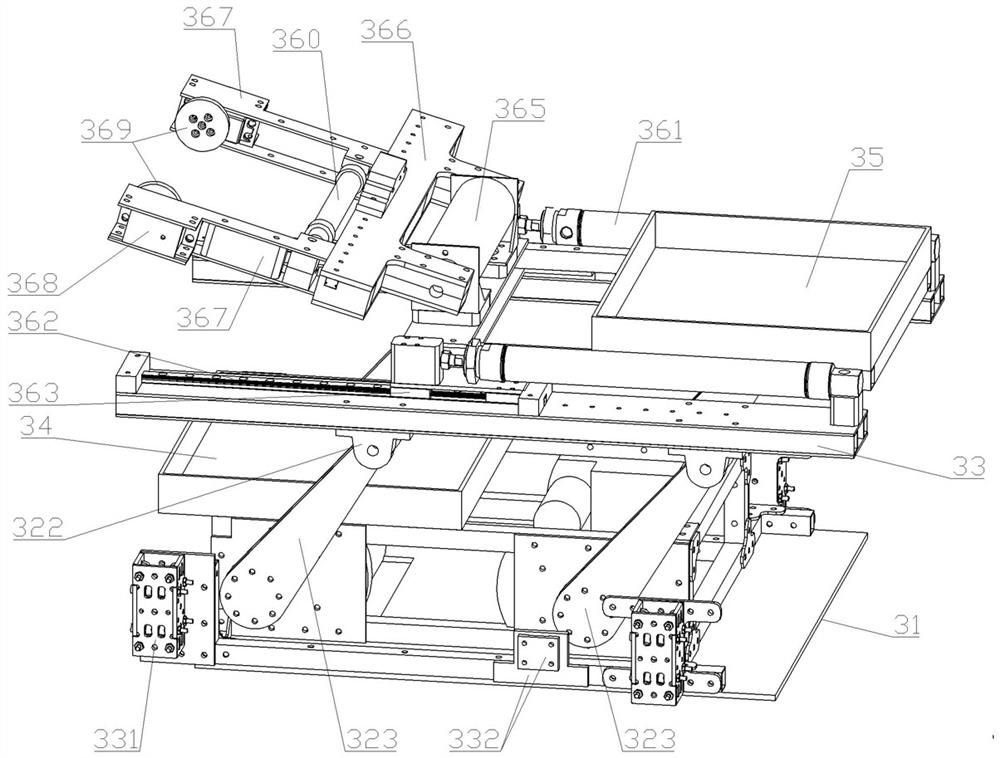

[0104] like Figure 1-4 As shown, the garbage container transfer robot includes a movable frame, a mechanical gripper assembly and a handling assembly.

[0105] The movable frame includes a main body frame 11 , an electric roller 12 and a lift drive assembly. The front end of the main frame 11 is provided with a platform 111 , and the two sides of the rear end are provided with vertical brackets 112 arranged symmetrically. A cargo area 113 is formed between the two vertical brackets 112 , and each vertical bracket 112 is provided with a plurality of vertical brackets. Straightly arranged guide rods 1121. A plurality of electric rollers 12 are symmetrically installed on both sides of the lower end of the main body frame 11 . The two groups of lift drive assemblies are respectively arranged on the two vertical supports 112 . The lift drive assembly includes a motor A131 , a driving pulley 132 , an axle 133 , a driven pulley 134 and a timing belt 135 . The motor A131 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com