Automatic warehousing system containing conveying line and stacking machines

A storage system and stacker technology, applied in the field of automated machinery and equipment, can solve the problems of mutual interference of travel routes, increased enterprise costs, and low efficiency of long-distance operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

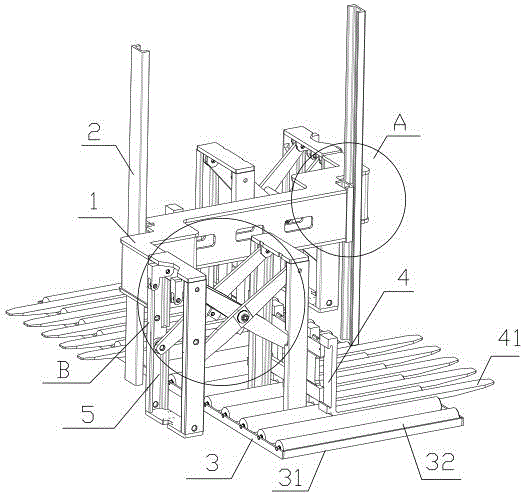

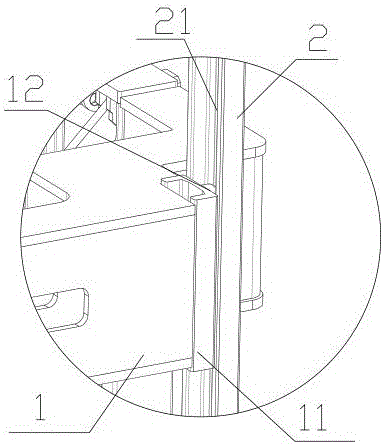

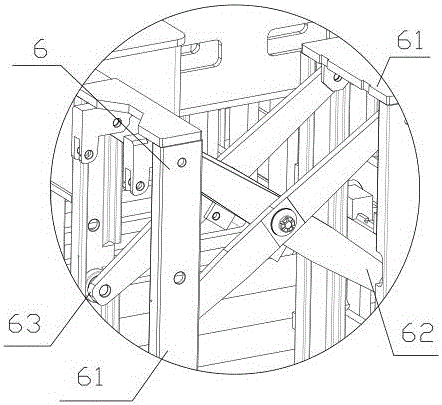

[0037] Example 1, such as figure 1 , figure 2 and image 3 Shown: an automated storage system including a conveyor line and a stacker, including a stacker, a fork assembly 4, laying a conveyor line 3 and guide rails in the roadway, the guide rails are located on both sides of the conveyor line, and the stacker can move along the guide rails Move; stacker comprises pallet fork assembly 4, column 2, is connected with column 2 and can lift main frame 1 in vertical direction, connects main frame 1 and pallet fork assembly 4 and is used to drive pallet fork assembly 4 in A traverse structure 5 that moves horizontally. There are two columns 2 located on both sides of the conveying line 3 . The conveying line 3 includes a plurality of rollers 32 , and the fork assembly 4 is in the shape of forks, including a plurality of forks 41 that are parallel to each other and can move up and down in the gaps between adjacent rollers 32 .

[0038] The stacker includes a fork assembly 4, and...

Embodiment 2

[0047] Example 2, such as Figure 4 As shown, the difference from Embodiment 1 is that the fork assembly 4 traverses in a different manner and in a different structure.

[0048] In this embodiment, the main frame 1 is also connected with a forward moving frame 7 extending in the horizontal direction, the forward moving frame 7 is provided with a forward moving inner guide rail 71, and the fork assembly 4 is provided with a forward moving inner guide rail 71 Sliding front wheels.

[0049] The forward moving inner guide rail 71 in the forward moving frame 7 extends in the horizontal direction, and the forward moving wheel slides on the forward moving inner guide rail 71 to provide guidance for the movement of the fork assembly 4, and the driving parts can be motors or oil cylinders. The forward moving inner guide rail 71 can be on the same horizontal direction as the main frame 1 . The forward moving frame 7 also includes a forward moving frame reinforcing plate 72 for connect...

Embodiment 3

[0050] The difference between embodiment 3 and embodiment 1 is that the number of stackers in one lane is different. In this embodiment, there are multiple stackers working simultaneously in one lane. It also includes a software control system and sensors for avoiding collision and interference with goods when the pallet fork assembly 4 is raised and lowered.

[0051] Since there are multiple stackers working simultaneously on the same conveying line 3 in the same roadway, at this time, the system control software cooperates with the sensor. Control the lifting action of the pallet fork assembly 4 and the speed of the conveying line to avoid collision and interference.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com