Shaft frame of aluminum alloy sightseeing elevator

A sightseeing elevator and aluminum alloy technology, which is applied to vertical pipes, building components, buildings, etc., can solve the problems of increasing installation work, unsightly appearance, and reducing the area of single glass, so as to prevent random disassembly and movement, avoid The effect of collision interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

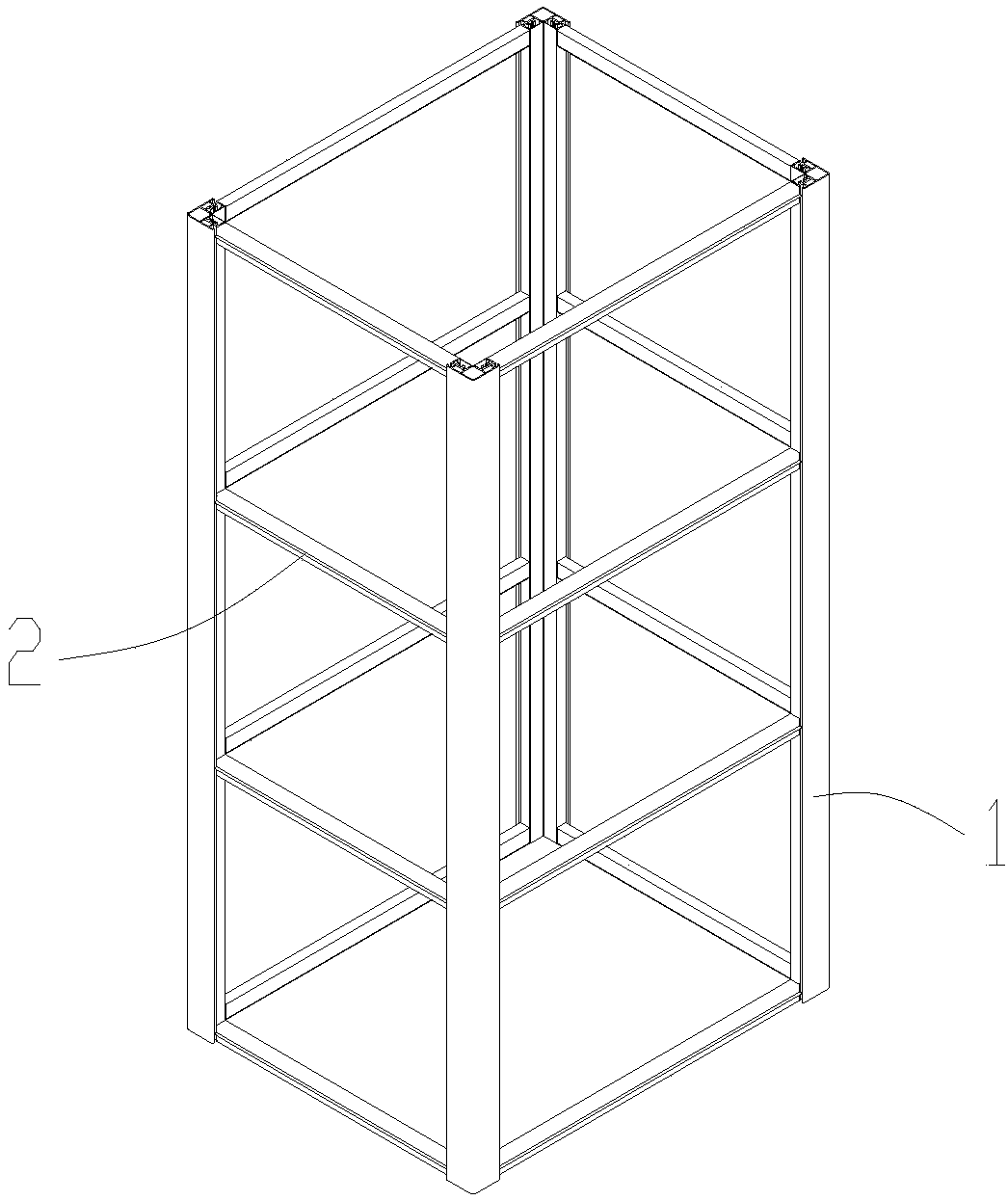

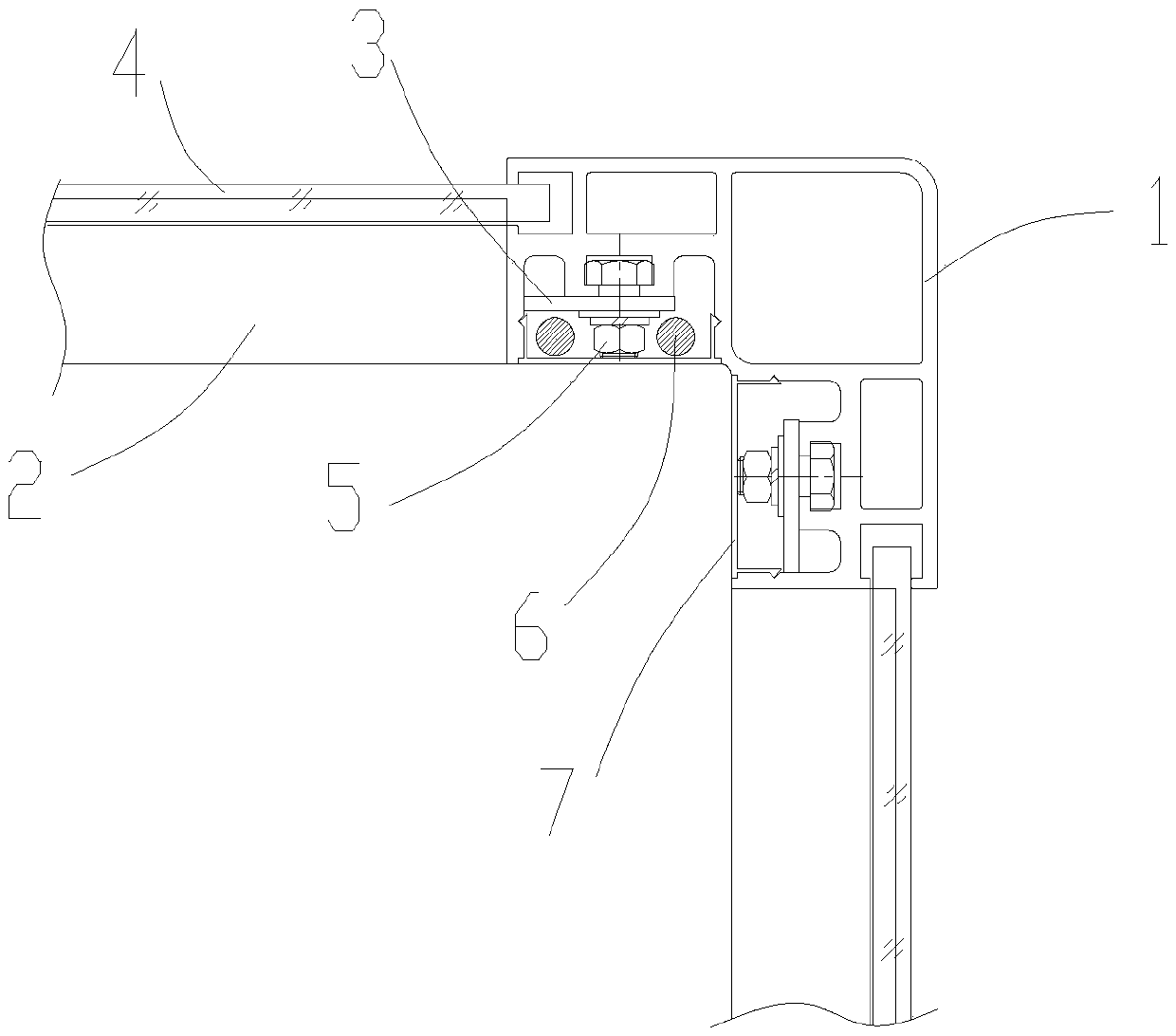

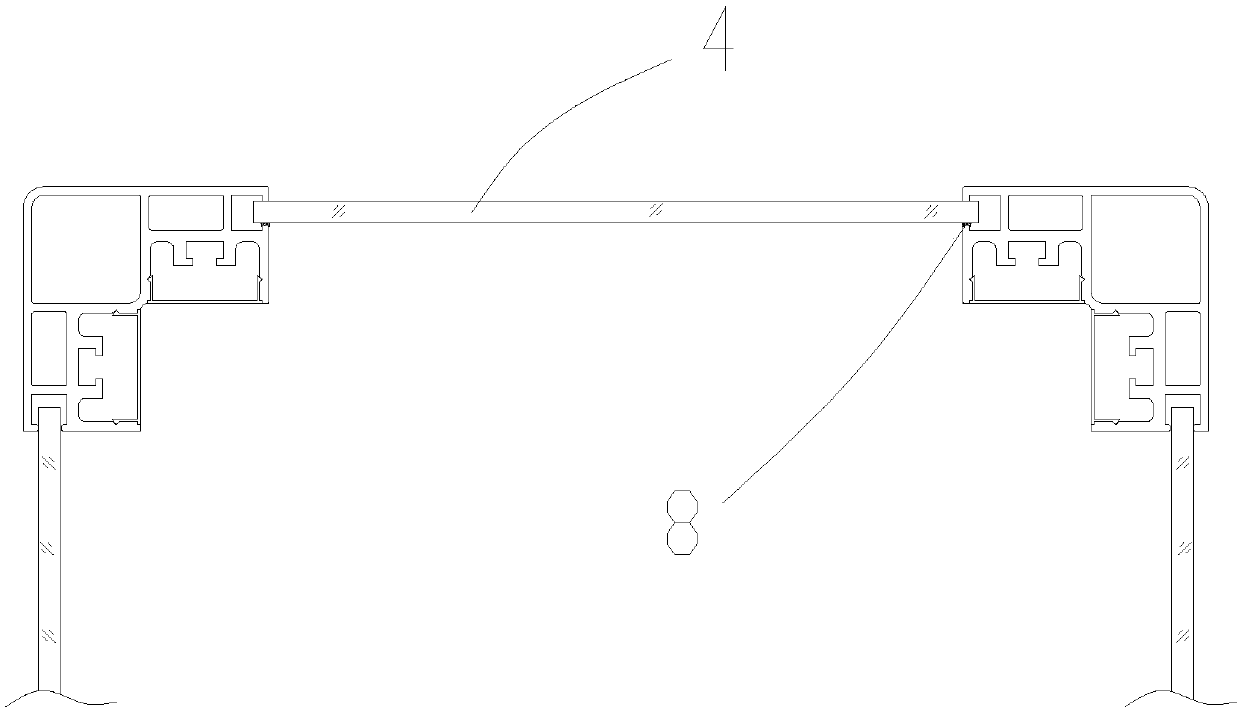

[0036] Embodiment one, such as figure 1 As shown, the application of the middle shaft: four columns 1 and 16 crosspieces 2 form a cuboid shaft. The column 1 and the crosspiece 2 are connected with each other by a T-shaped connecting plate 31 or a right-angled connecting plate 32 with fixing bolts 5 and nuts. And the hoistway cable 6 is arranged in the cable accommodation space 15 and the closed cable tray, and then the cover plate 7 is used to cover all the profile wiring areas. Install exterior glass 4 again, exterior glass 4 is positioned at the gap of crosspiece 2 glass partitions 21 positions up and down with glass glue filling.

Embodiment 2

[0037] Embodiment 2, the application of the entrance shaft: four upright columns 1 and 14 crosspieces 2 form a rectangular parallelepiped shaft. Wherein one side is retained as the gate, and the column 1 and the crosspiece 2 are connected by a T-shaped connecting plate 31 or a right-angled connecting plate 32 with fixing bolts 5 and nuts. And the hoistway cable 6 is arranged in the cable accommodation space 15 and the closed cable tray, and then the cover plate 7 is used to cover all the profile wiring areas. The exterior glass 4 is installed again, and the gap between the top and bottom of the exterior glass 4 and the glass spacer 21 of the crosspiece 2 is filled with glass glue. Install an integrated door cover at the door court.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com