Series-parallel robot for linkage spraying of large surface structure

A surface structure, robot technology, applied in the directions of manipulators, spraying devices, manufacturing tools, etc., can solve the problems of unbalance of the whole machine, poor positioning accuracy and stability of the mechanism, paint damage, etc. Uniform coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] See attached picture.

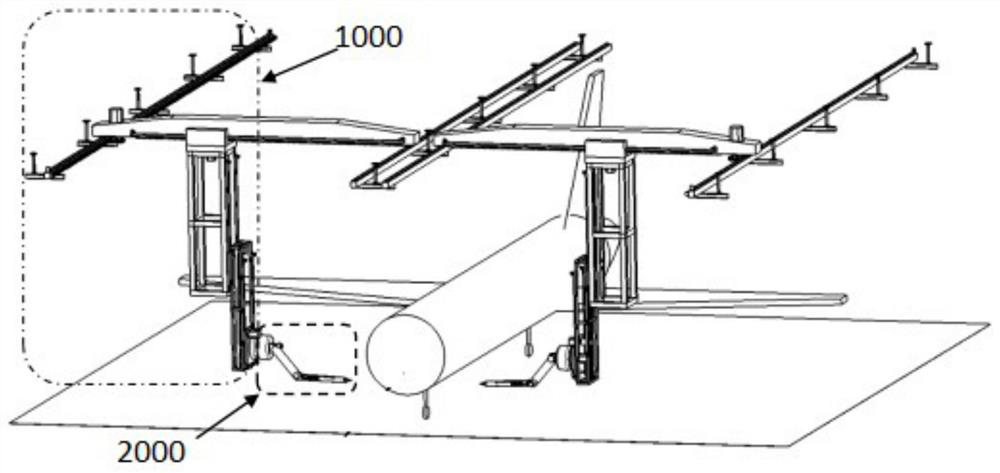

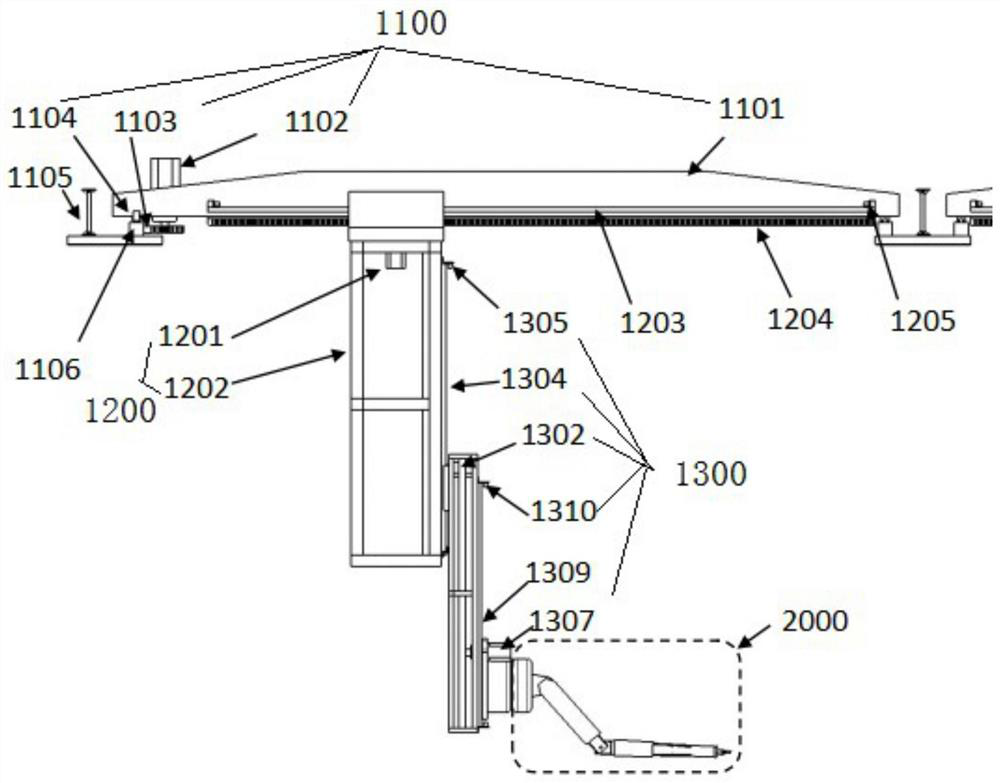

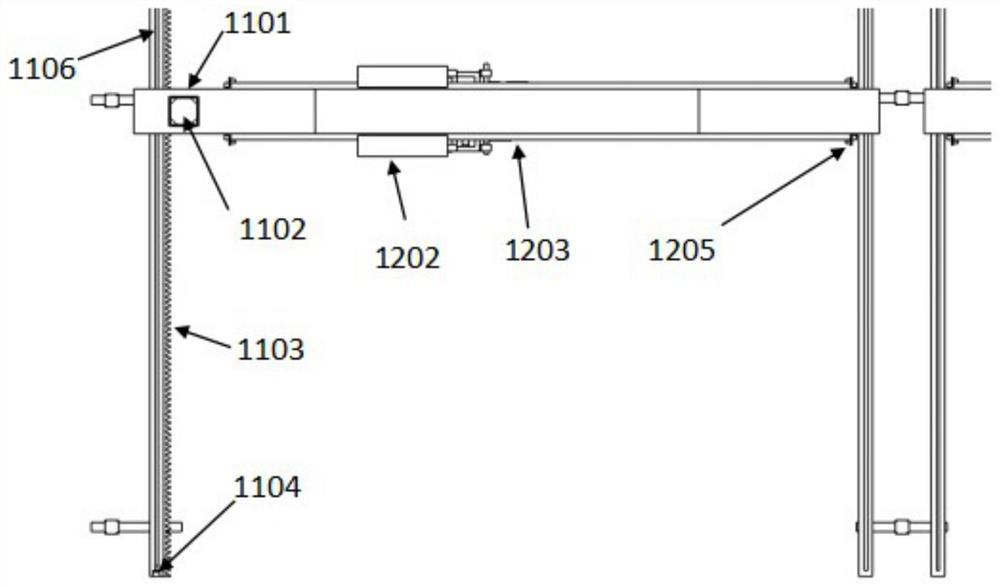

[0056] combine figure 1 and figure 2 , a hybrid robot for spraying large-scale surface structures, including a three-degree-of-freedom moving mechanism in the air 1000 and a spraying robot arm 2000. The base of the painting robot arm 2000 is installed on the Z-direction movement On the manipulator platform 1306, firstly, the base of the spraying manipulator 2000 is used to fix the parallel guide rail slider with screws, and then the guide rail is installed on the Z-direction moving manipulator platform 1306 by screws. The three-degree-of-freedom movement mechanism 1000 in the air drives the spraying robot arm 2000 to achieve translational movement in three directions in space, so that the working position of the spraying robot arm 2000 can be adjusted for different spraying areas to meet the requirements for the movement space of the spraying robot. The three-degree-of-freedom mobile mechanism 1000 in the air is connected and fixed to the stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com