Patents

Literature

163results about How to "Avoid continuity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

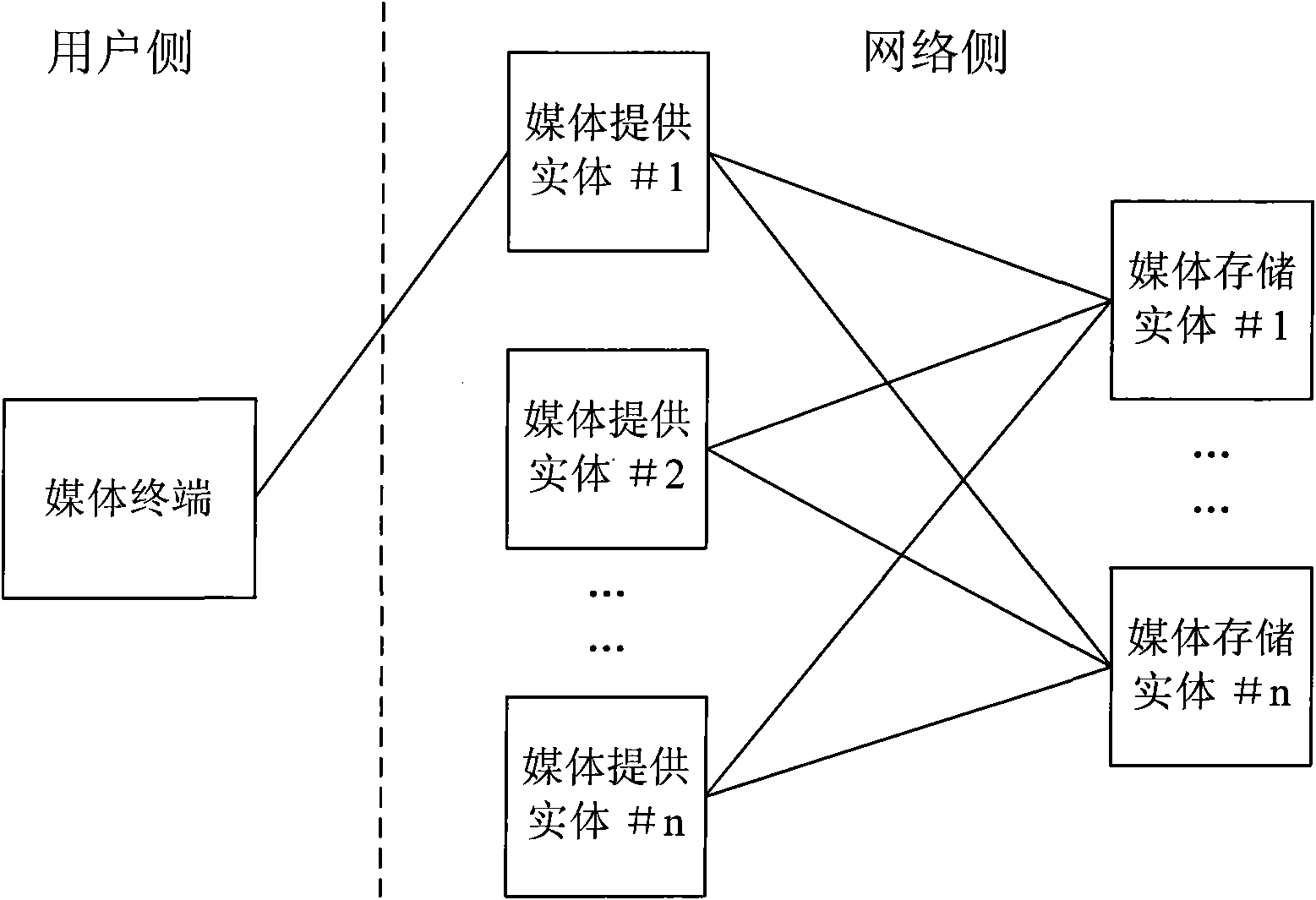

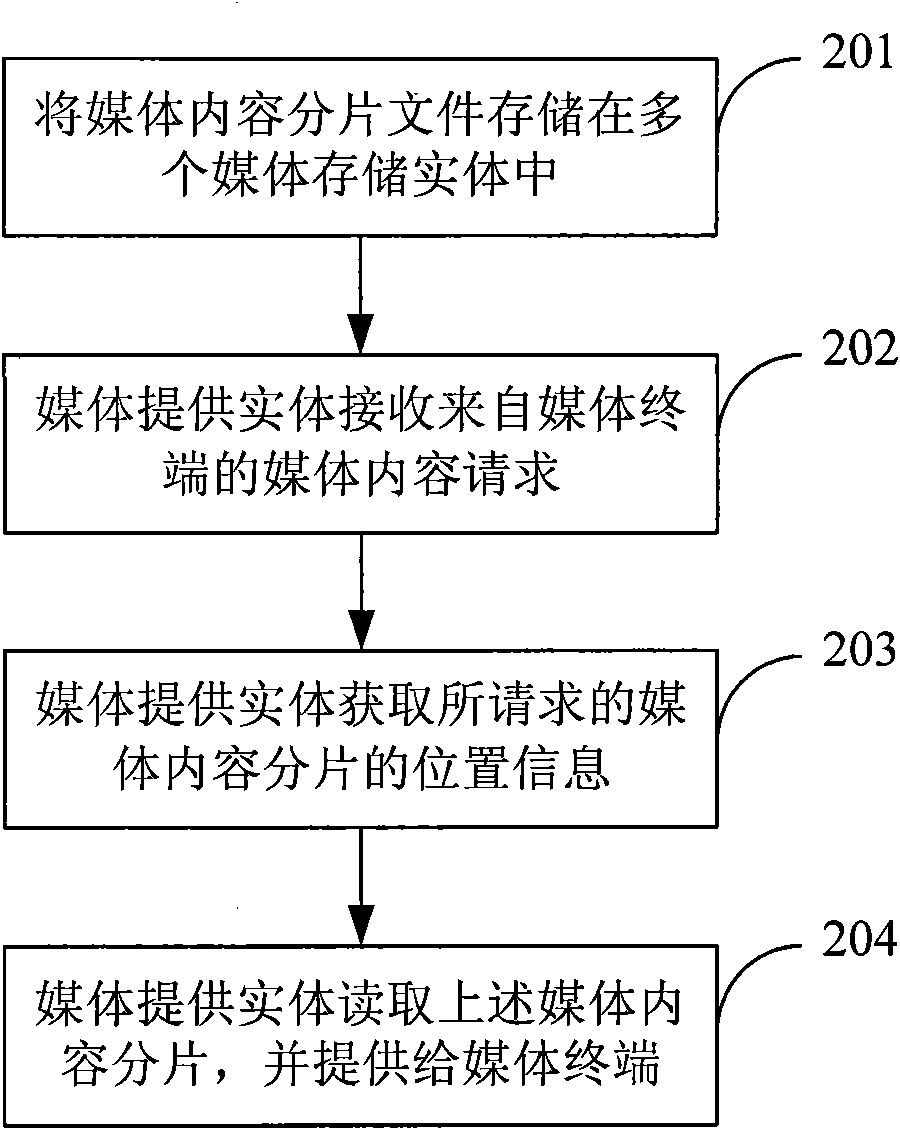

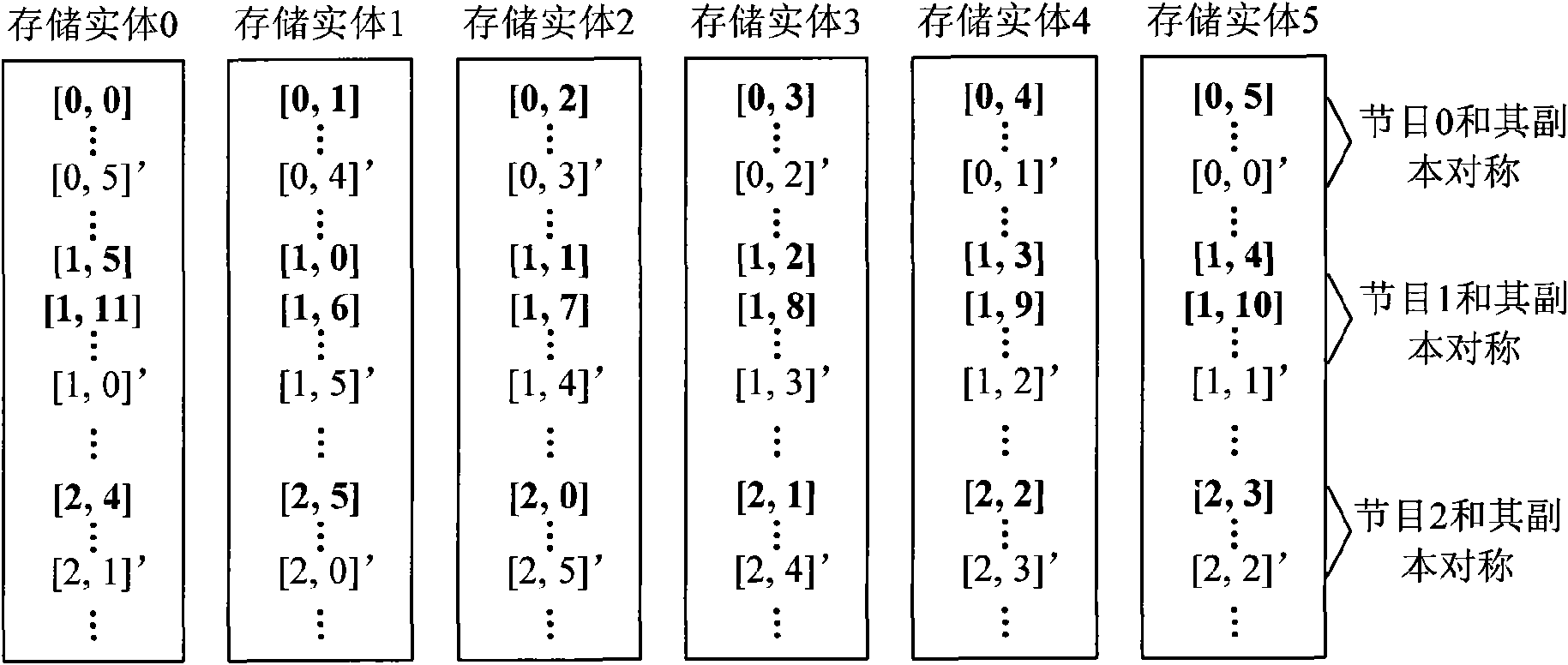

Method, device and system for providing media content

InactiveCN101552800AImprove service qualityImprove business experienceMultimedia data retrievalTwo-way working systemsContent distributionQuality of service

The invention discloses a method, a device and a system for providing media content, which belong to the technical field of multimedia. The method comprises the following steps: receiving media content request from a media terminal; obtaining position information of requested media content slicing files in a plurality of media storage entities according to the media content request; reading the media content slicing files according to the position information and providing the media content slicing files for the media terminal. The device comprises a receiving module, an acquiring module and a providing module. The system comprises a plurality of media storage entities, a media content distribution device and a media content providing device. The invention provides the service quality of the media content, without switching media providing entities, avoids the switching time delay, improves the user service experience, is simpler and can be implemented.

Owner:HUAWEI TECH CO LTD

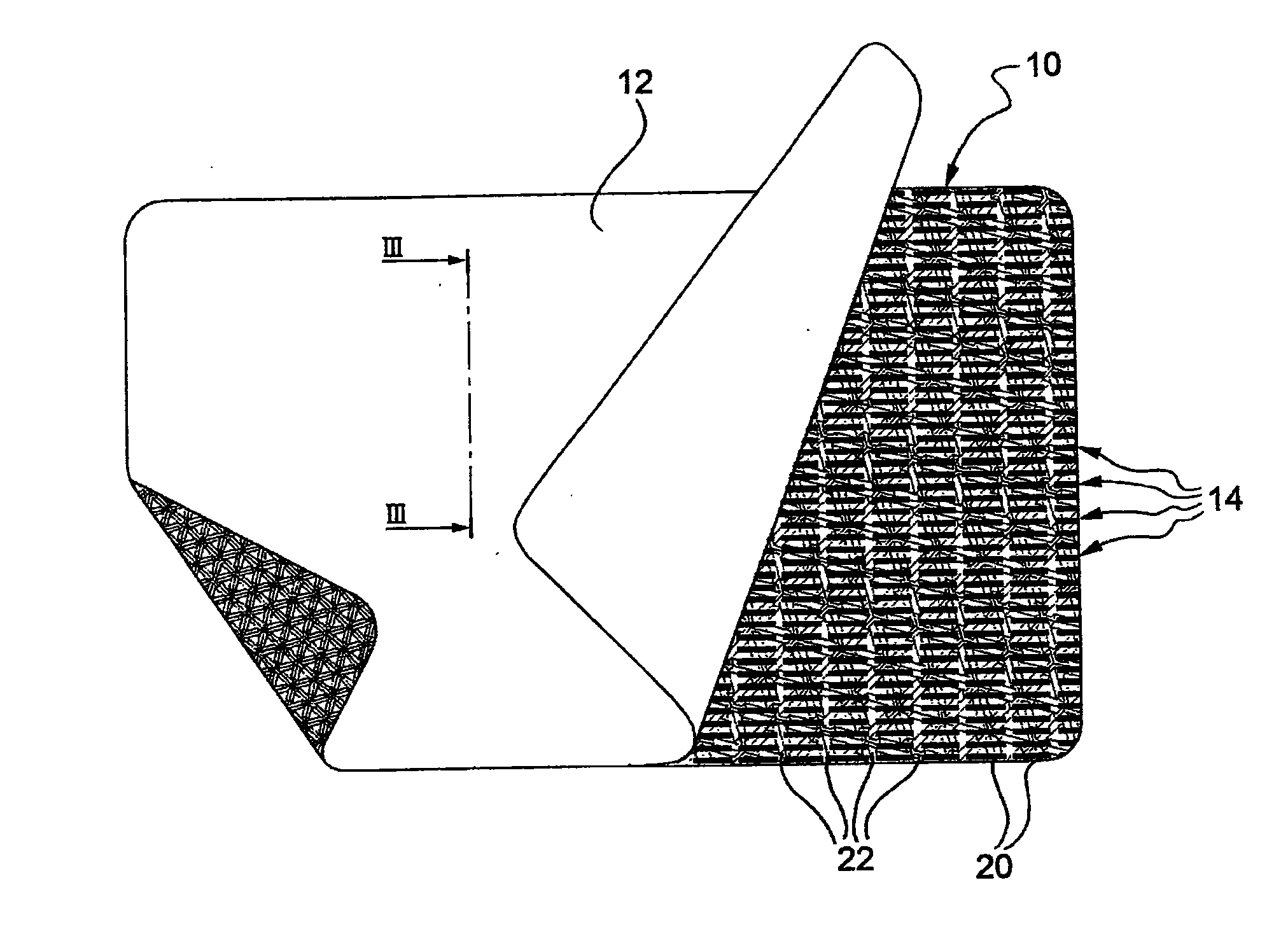

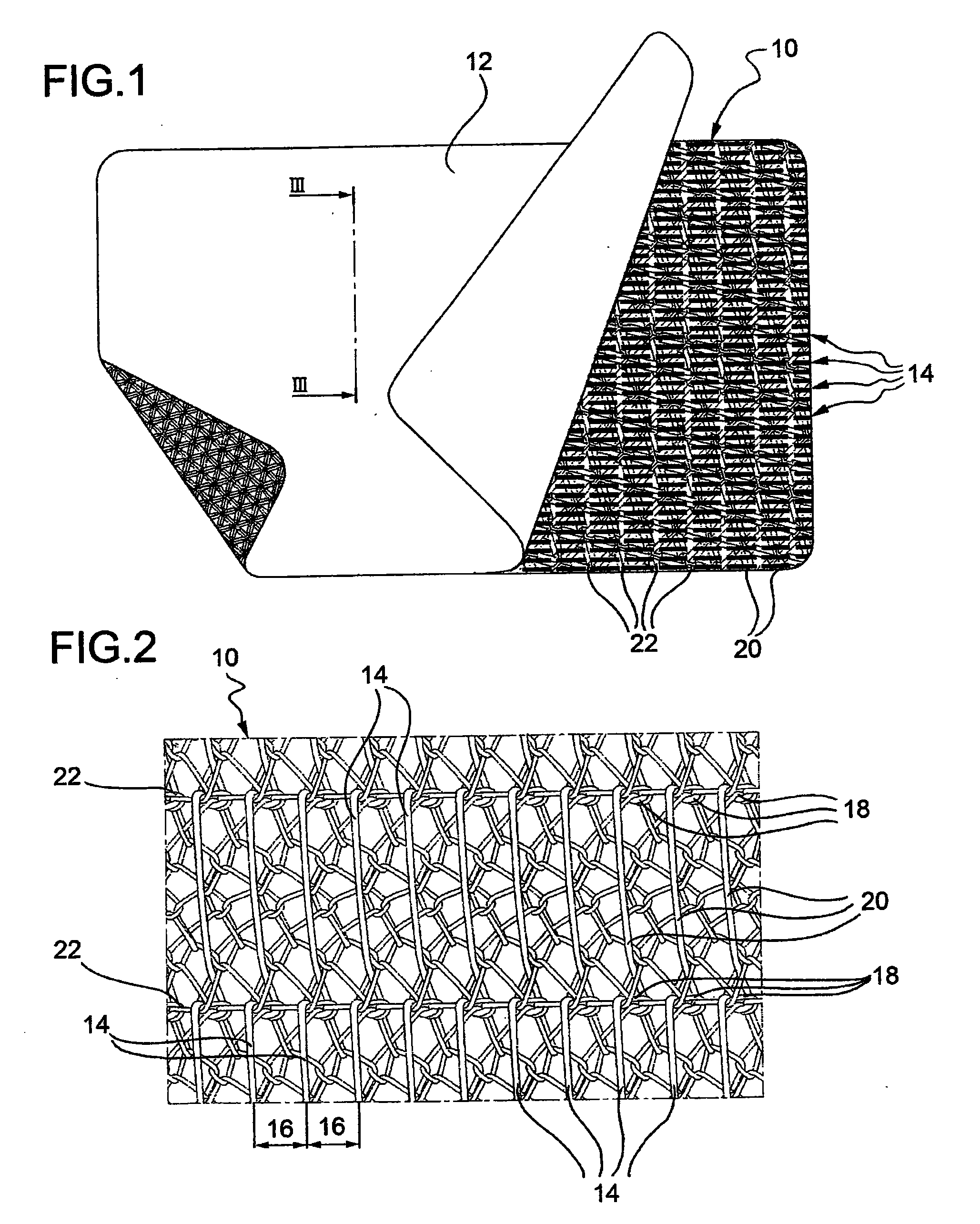

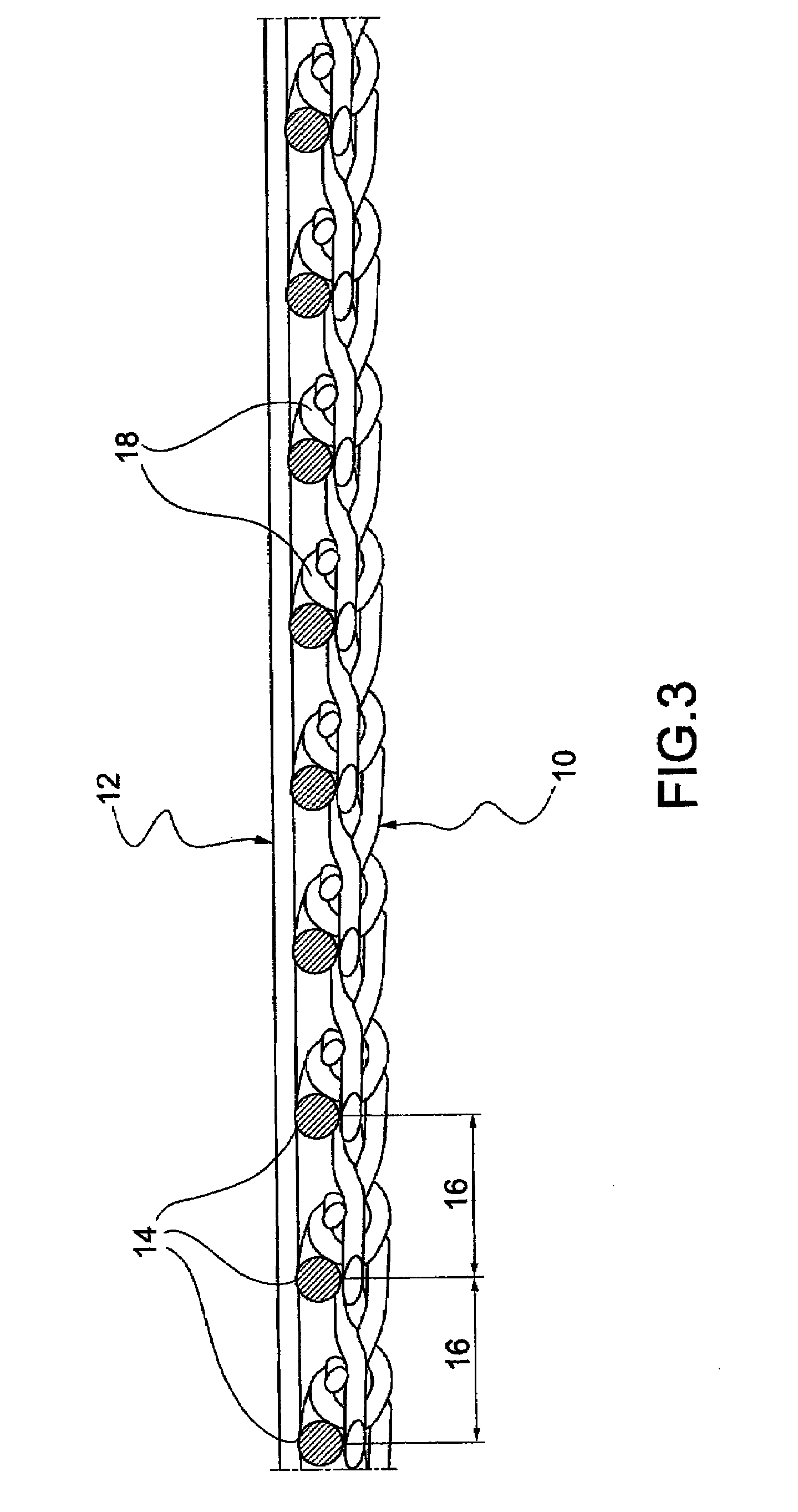

Double layer surgical prosthesis to repair soft tissue

ActiveUS20090276057A1Less thicknessSmall dimensionProsthesisWound clampsIntraperitoneal routeProsthesis

A prosthesis for the treatment of hernias and / or laparoceles via an intraperitoneal route, having a mesh of filaments of non-resorbable and biocompatible polymer material having interstices permitting tissue growth and a sheet of polymer material having barrier properties and low adhesion to sensitive organs and tissues. The sheet is superimposed upon and joined to the mesh so as to form a stratified structure. In particular, the sheet is joined to mesh through a plurality of filaments located alongside each other at a spacing of not more than 5 mm. Each filament has a plurality of attachment sites to the mesh which are not more than 15 mm apart, and each length of filament between two successive attachment sites projects from the surface of the mesh facing sheet and is fused to the sheet.

Owner:HERNIAMESH

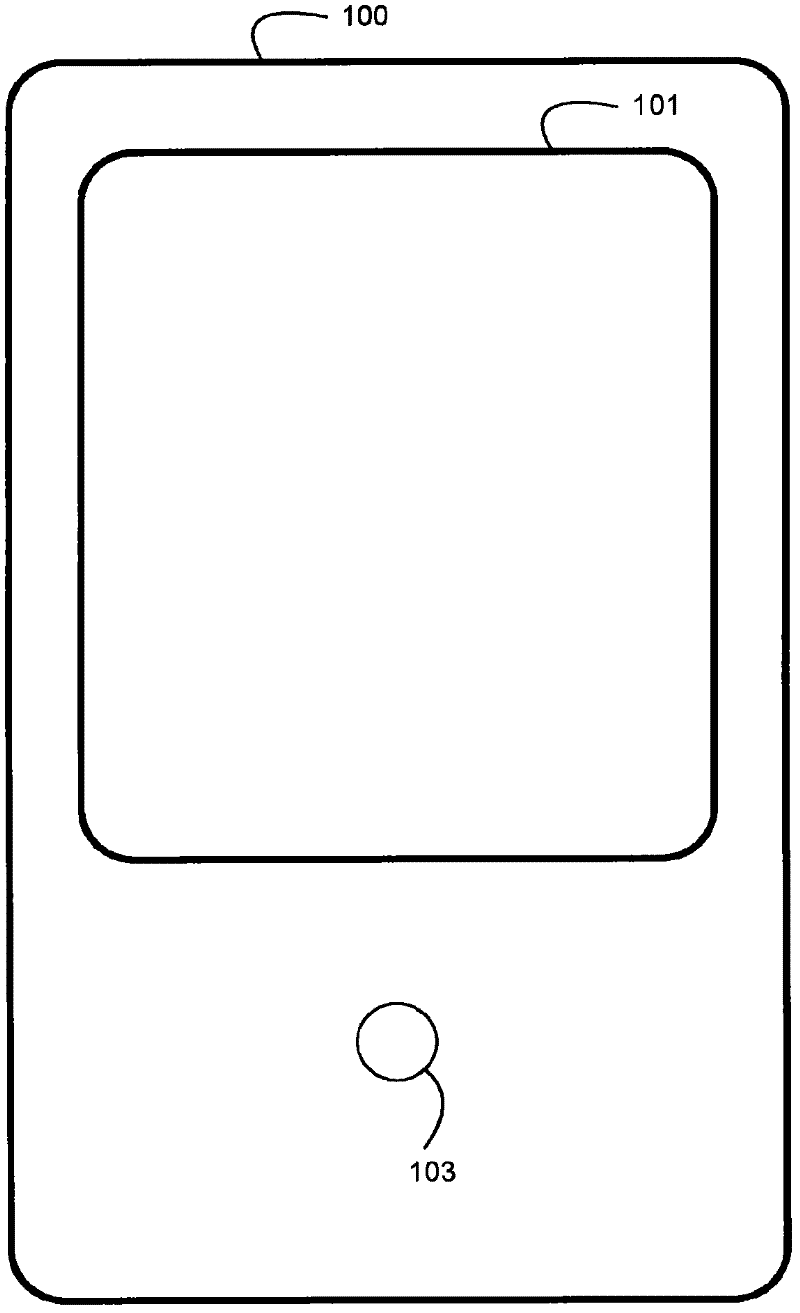

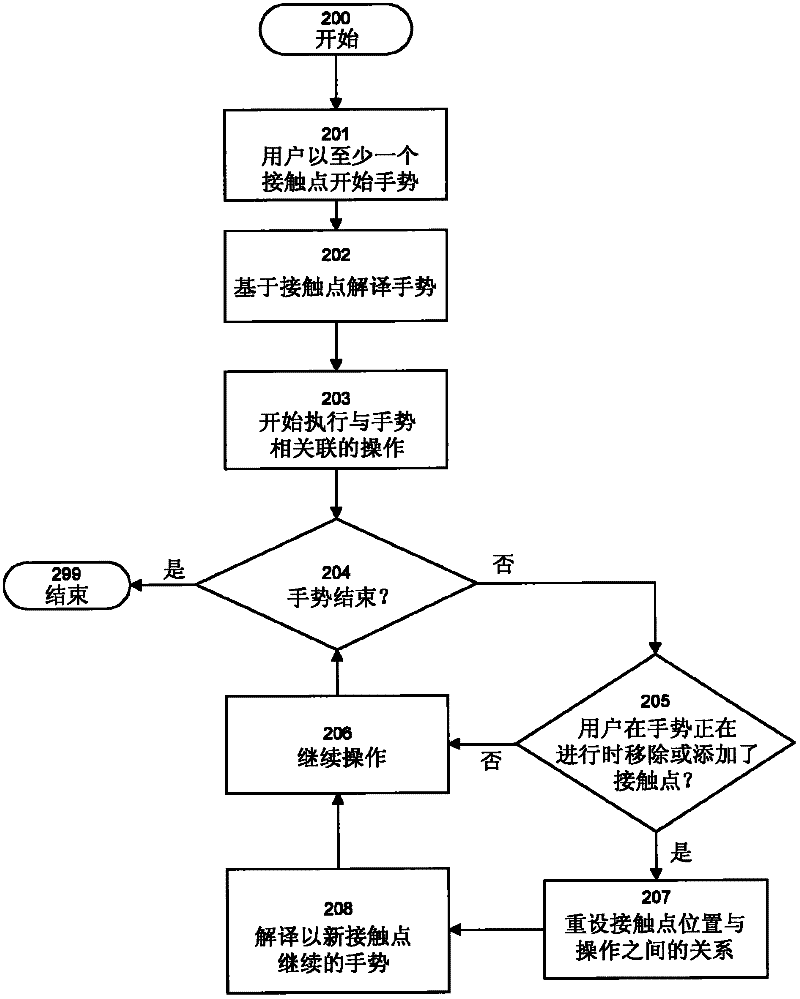

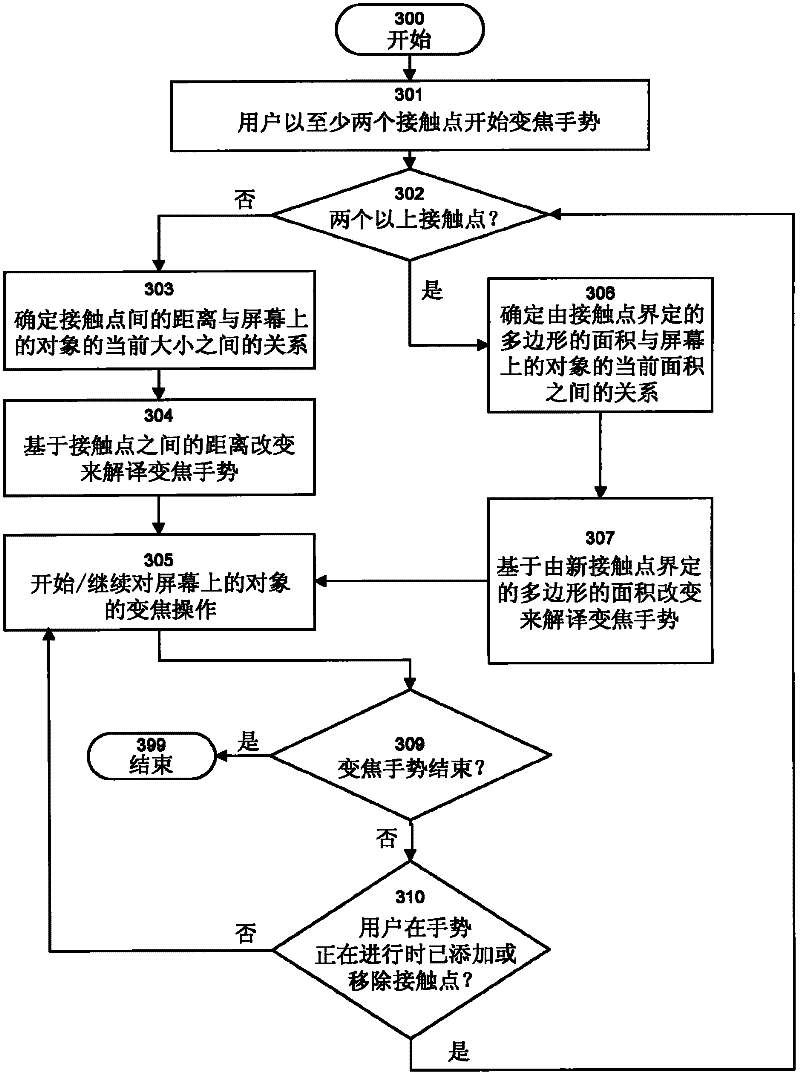

Interpreting gesture input including introduction or removal of a point of contact while a gesture is in progress

InactiveCN102224488AAvoid unpredictabilityAvoid continuityInput/output processes for data processingMulti-touchPoint location

A touch-sensitive device accepts single-touch and multi-touch input representing gestures, and can change a parameter of a gesture responsive to introduction or removal of a point of contact while the gesture is in progress. The operation associated with the gesture, such as a manipulation of an on-screen object, changes in a predictable manner if the user introduces or removes a contact point while the gesture is in progress. The overall nature of the operation being performed does not change, but a parameter of the operation can change. In various embodiments, each time a contact point is added or removed, the system and method of the present invention resets the relationship between the contact point locations and the operation being performed, so as to avoid or minimize discontinuities in the operation.; In this manner, the invention avoids sudden or unpredictable changes to an object being manipulated.

Owner:QUALCOMM INC

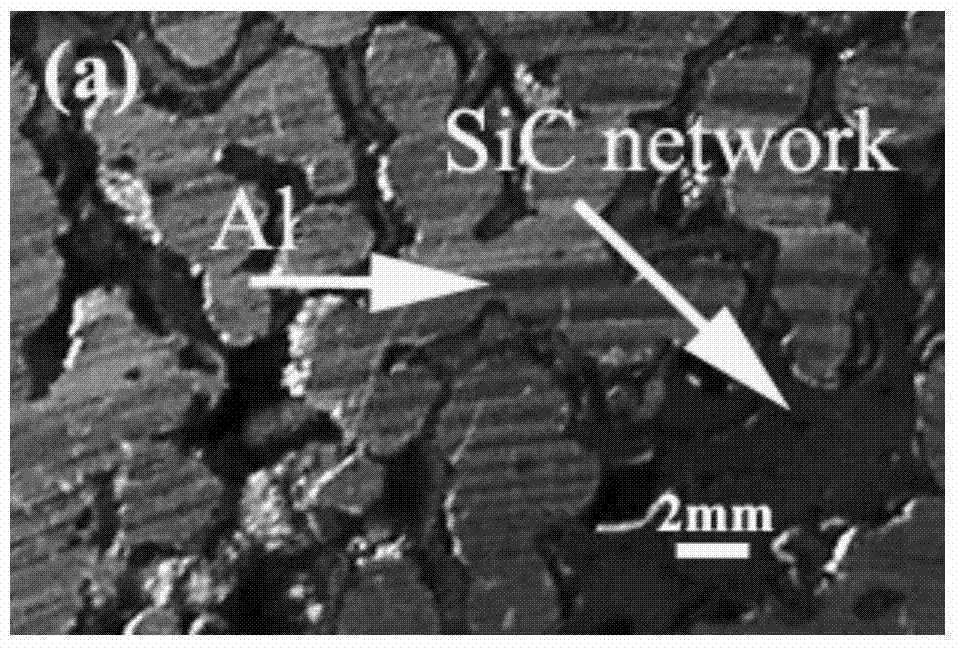

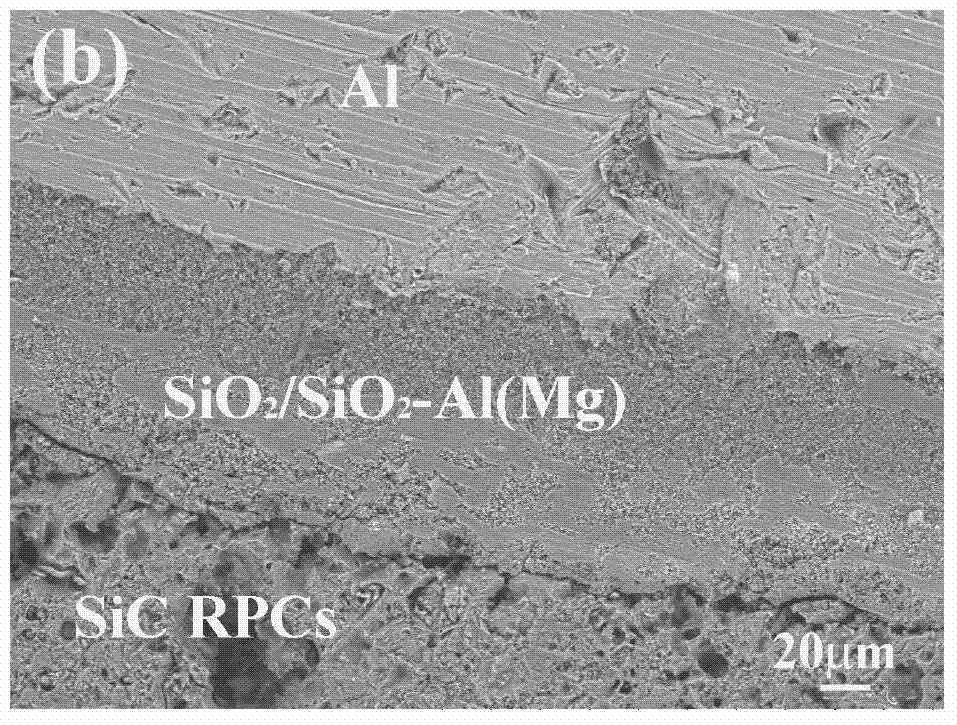

Preparation method of silicon carbide reinforced aluminum base composite material

The invention discloses a preparation method of a SiC / Al composite material. The method comprises the following steps: carrying out ball milling on alumina and / or silicon oxide powder and a dispersant by using a ball milling medium, adding a binder, and continuously carrying out ball milling to obtain a coating slurry, wherein a mass ratio of the powder to the dispersant to water to the ball milling medium to the binder is 1:0.005-0.01:0.1-0.4:2:0.01-0.03; immersing reticulated porous SiC ceramic in the coating slurry for full absorption, centrifuging, and drying; and embedding secondary-coated reticulated porous SiC ceramic into aluminum or aluminum alloy powder, carrying out vacuum pumping heating to fuse the aluminum or aluminum alloy, introducing argon, and carrying out heat insulation and pressure maintenance to obtain the SiC / Al composite material. The SiC / Al composite material obtained through the method is a bicontinuous phase, and the control of an interface structure and an interface reaction is realized through controlling the composition and performances of the coating slurry to realize strong combination between a silicon carbide matrix and the metal Al and uniform continuous distribution in a three dimensional space, so the segregation and the discontinuousness of the silicon carbide reinforcement are avoided, and the performances of the composite material are improved.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Remanufacturing method for scrap titanium chips through ball milling-equal channel angularpressing

InactiveCN105618501AExcellent technical indicatorsSimple process operationCleaning using liquidsGrain treatmentsScrapSwarf

The invention provides a remanufacturing method for scrap titanium chips through ball milling-equal channel angular pressing. The remanufacturing method sequentially comprises the step of recovering and pretreating titanium chips, the step of performing ball milling treatment on the titanium chips, the step of loading the titanium chips into an equal channel angular pressing mold, the step of performing preprocessing at a room temperature through the equal channel angular pressing, the step of curing and processing at a high temperature, and the step of quenching. The ball milling-equal channel angular pressing composite technique provided by the invention is simple and practical to operate and high in controllability. Through remanufacturing, not only can nanometer block titanium materials (smaller than 200nanometers) with full densification be obtained, but also the metallurgical defect of the continuous distribution and gathering of large sliced oxides can be eliminated. In addition, the shapes of the titanium chips are refined and reformed, and anisotropy caused by deformation texture in hexagonal close packed titanium materials is restrained. The yield strength of the remanufactured nanometer titanium materials reaches to the level of 5-grade titanium, the distribution of nanometer particles of the oxides presents a dispersed uniform state, and through the isotropy of the properties of the materials, the remanufacturing of scrap titanium resources for value increase at low cost is realized.

Owner:SHANGHAI DIANJI UNIV

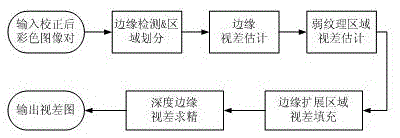

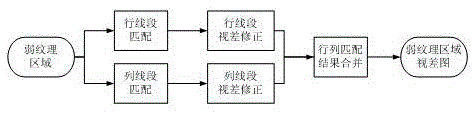

Stereoscopic vision matching method based on weak edge and texture classification

InactiveCN105551035AReduce computationImprove real-time performanceImage analysisPattern recognitionParallax

The invention discloses a stereoscopic vision matching method based on weak edge and texture classification, and solves a technical problem of achieving quick and precise compact matching. The method comprises the steps: carrying out the division and matching of edge and weak texture regions, carrying out parallax error correction and filling, carrying out the refinement of depth edge parallax errors and carrying out compacting of a parallax map. For MADC matching cost, the method carries out the matching according to different properties of regions, carries out mutual parallax error correction or filling according to a matching result, carries out parallax error refinement for a shade region and a parallax discontinuous region, and obtains the complete and compact parallax map. The beneficial effects of the invention are that the method does not need to carry out global optimization, reduces the operation burden of an algorithm, enables a parallax continuity constraint to be matched with the type of the region, and avoids a conflict of common local optimization with the continuity constraint in the prior art. The method is high in universality, and can be widely used for various types of binocular vision and multi-view 3D imaging algorithms.

Owner:深圳市华和瑞智科技有限公司 +1

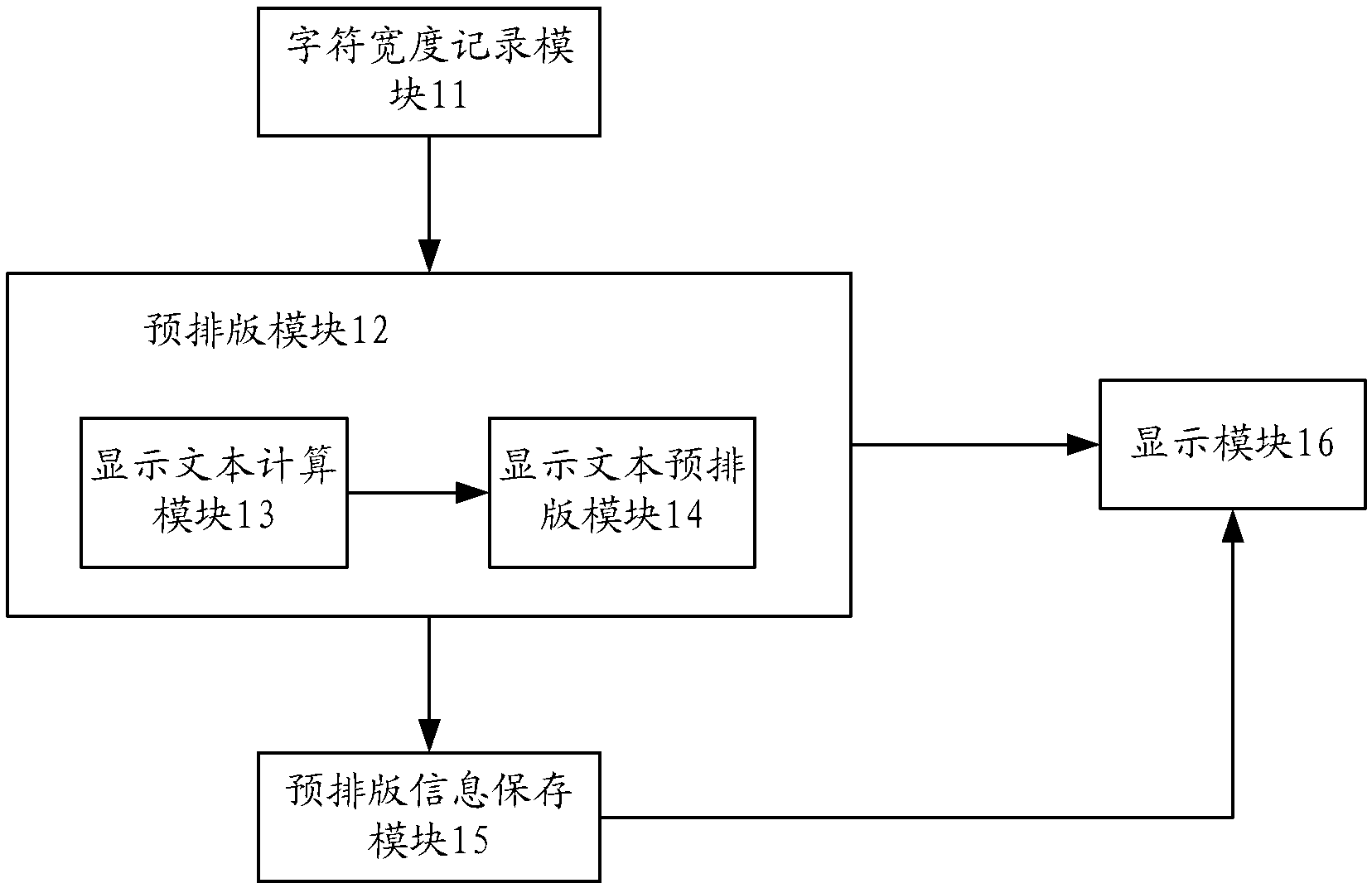

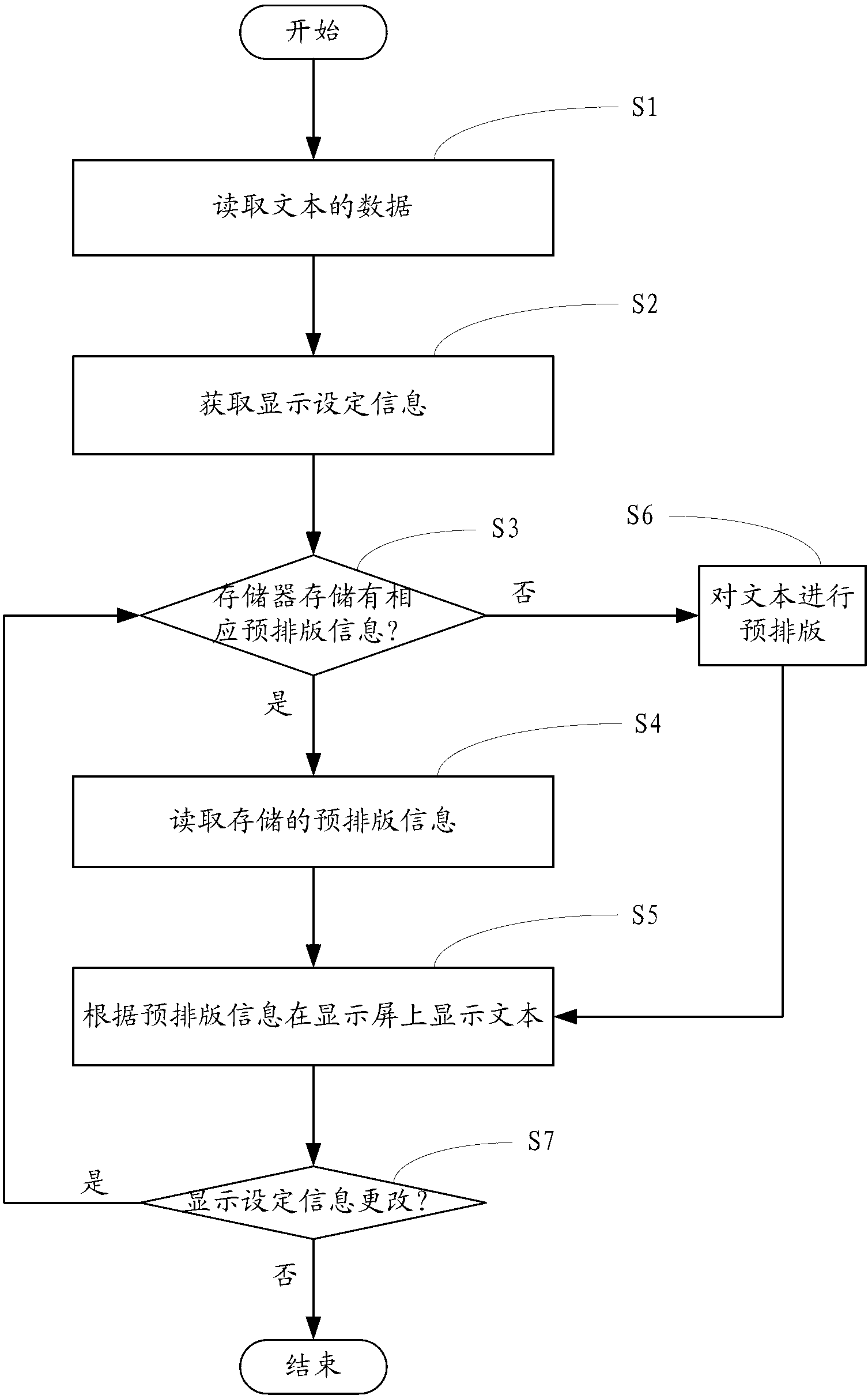

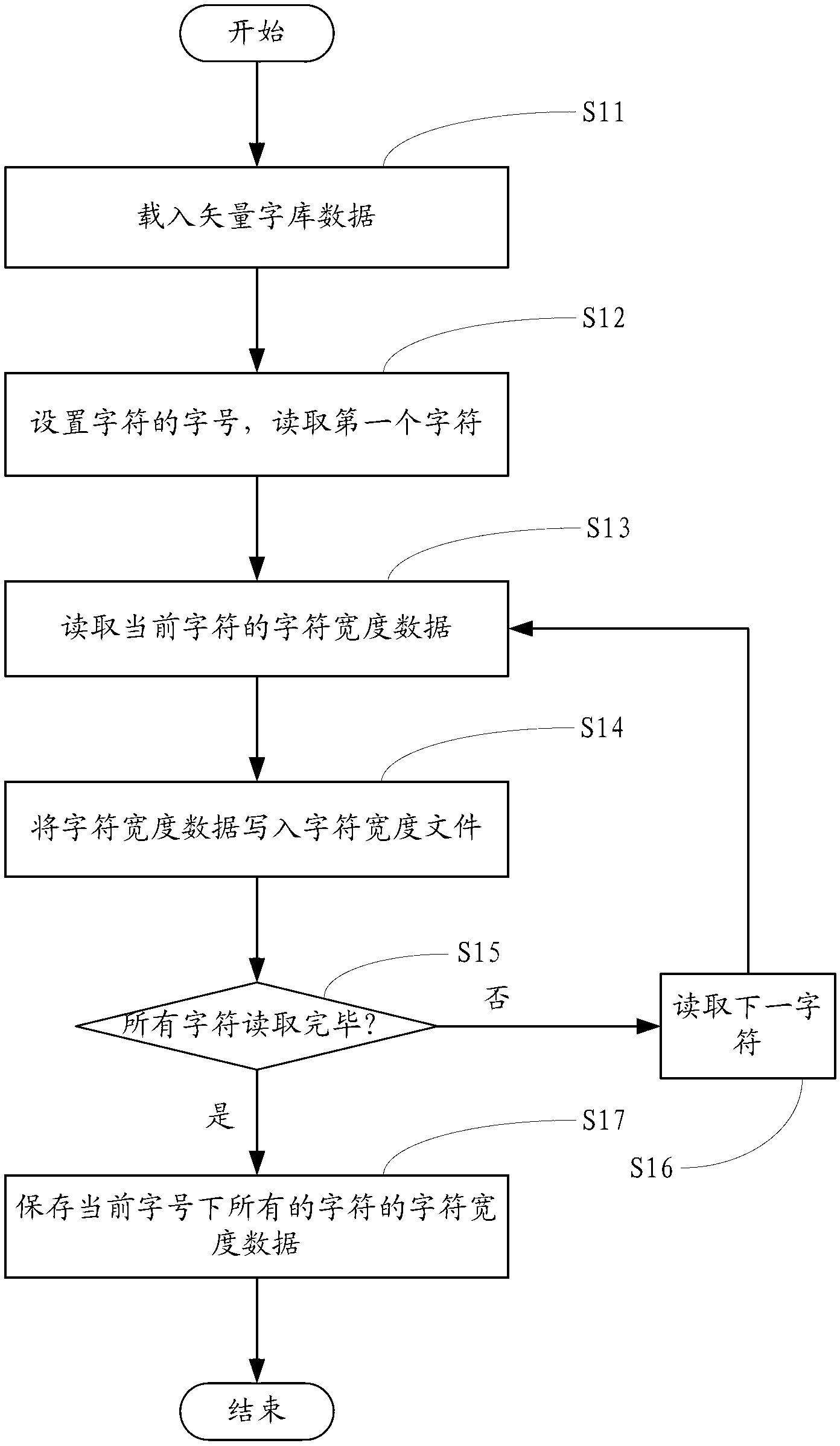

Text display method and text display device for e-book reader

ActiveCN103268185AExact searchNo garbled charactersNatural language data processingSpecial data processing applicationsData segmentText display

The invention provides a text display method and a text display device for an e-book reader. The method includes: recording data about character widths of each character in a vector font library under different font sizes and display setting information of a text, dividing the data of the text into more than one data segment, pre-typesetting each data segment according to the display setting information, determining corresponding starting and ending positions of each display text page displayed on a display screen in the text, searching the starting and ending positions of data corresponding to one received display text page requiring display, reading out the data between the starting position and the ending position, converting the data between the starting position and the ending position into code data, searching corresponding character images from the vector font library according to the code data, and displaying the character images on the display screen according to the display setting information. The device uses the method for displaying texts of e-books. The text display method and the text display device are capable of achieving rapid paging during e-book reading and effectively avoiding content discontinuity or messy codes during paging.

Owner:ALLWINNER TECH CO LTD

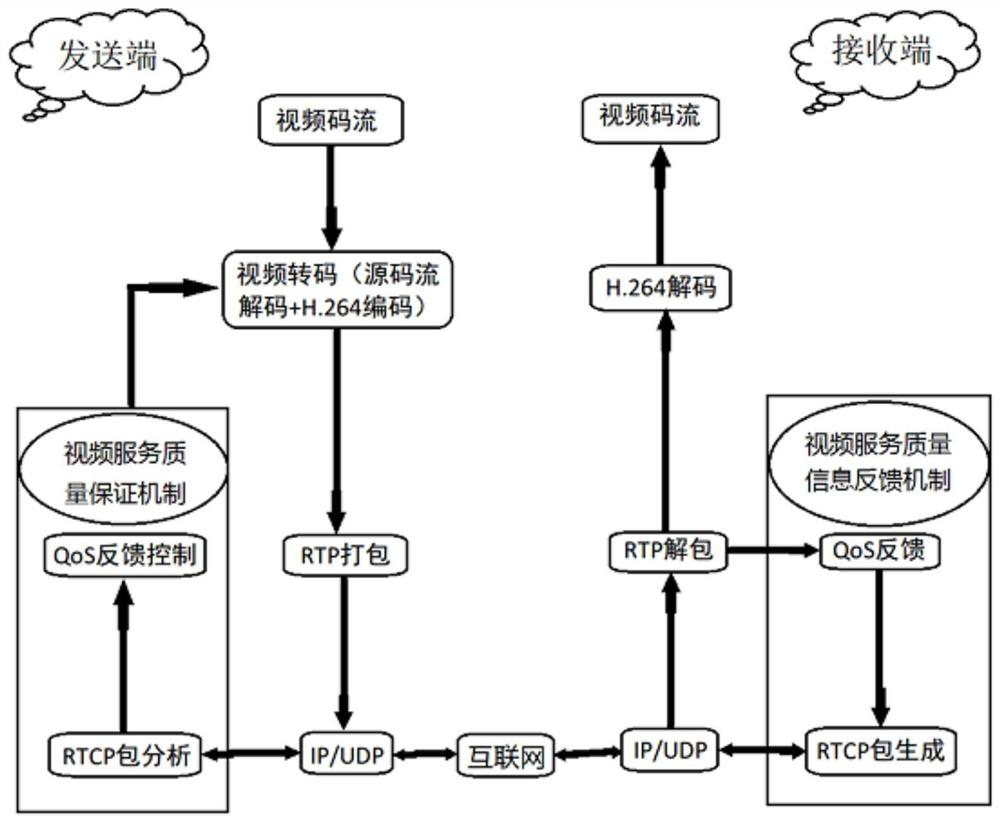

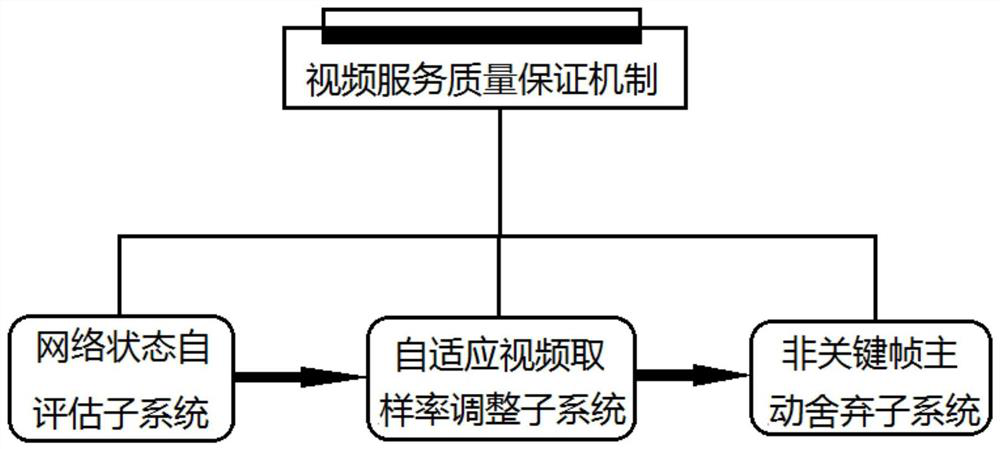

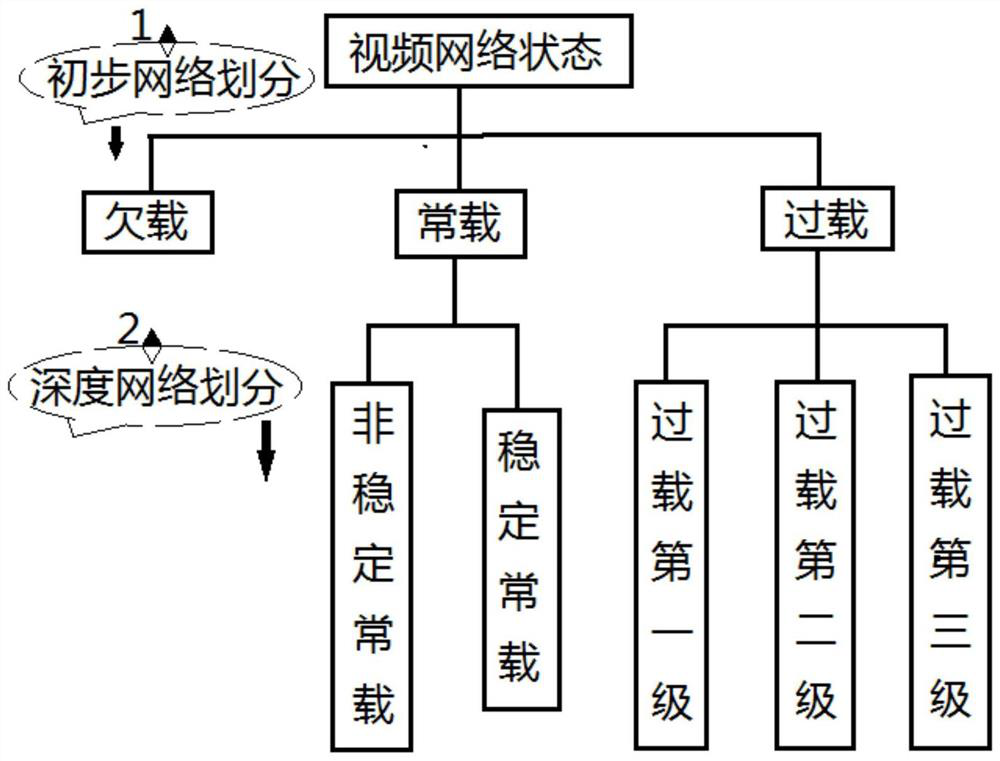

Video coding conversion transmission control system based on network state self-evaluation

ActiveCN111615006APrevent overloadAccurate judgmentSelective content distributionAlgorithmVideo transmission

The invention provides a video coding conversion transmission control system based on network state self-evaluation. Aiming at the problems that the network evaluation algorithm judges the network state only by depending on the packet loss rate, the judgment division is too rough, the limitation of serving as a video transmission rate adjustment basis is large and the like, the invention providesa method for combining the packet loss rate, the network delay and the delay jitter as network state evaluation factors, and the judgment of the network state is more scientific and accurate. Aiming at the problem that effective pre-control measures cannot be taken under the condition that a network has an overload trend but is not overloaded, a network overload pre-control method is added, and the network overload problem is skillfully processed at any time. Aiming at the problems that the network overload is too serious and overload control cannot be carried out by simply adjusting coding parameters, the invention provides a non-key frame active abandoning method, so that the video quality is ensured, the transmission quality is also ensured, a frame loss strategy is carried out before coding, the coding workload is reduced, and the robustness and the high efficiency are higher.

Owner:北京讯众通信技术股份有限公司

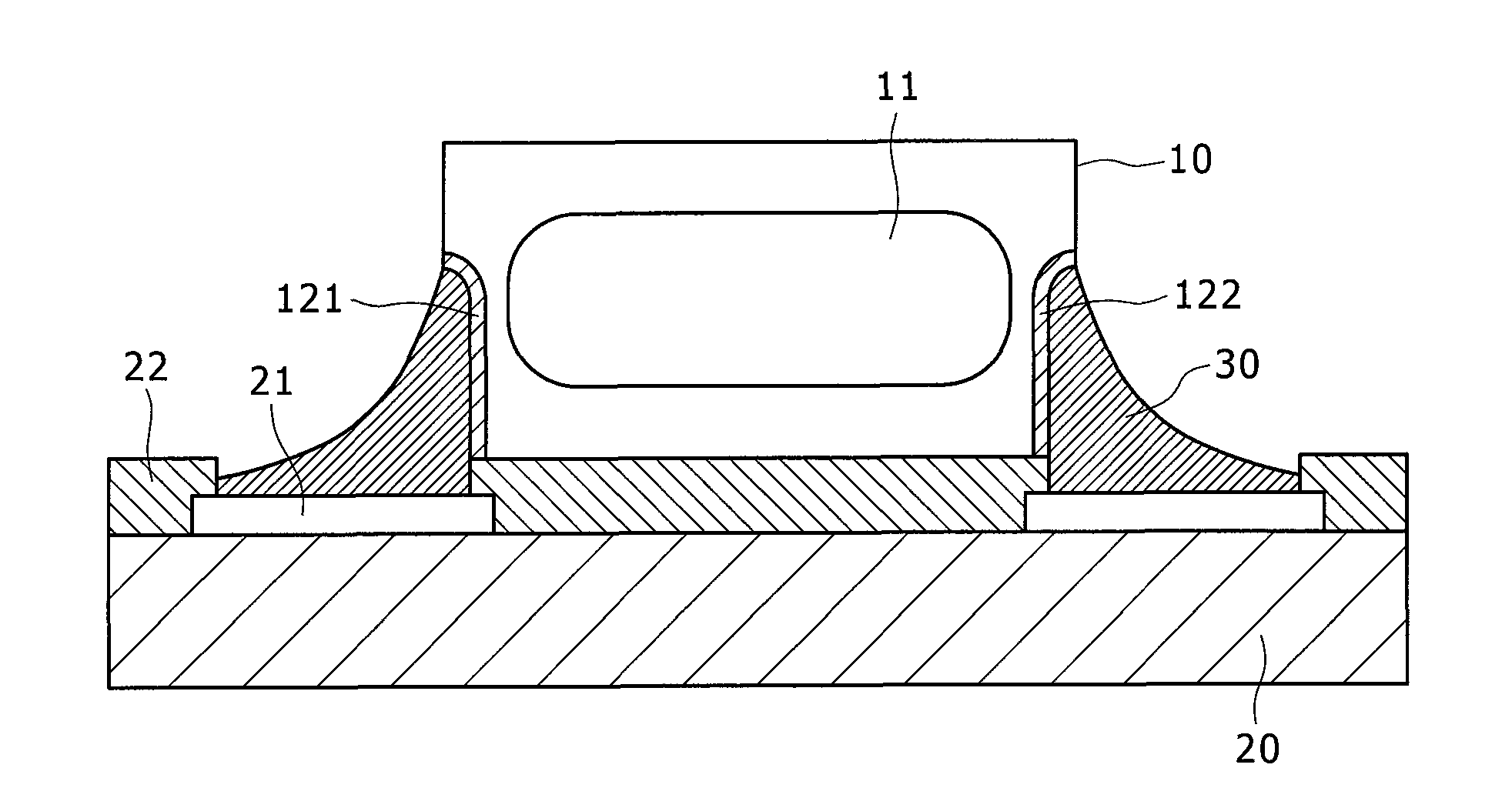

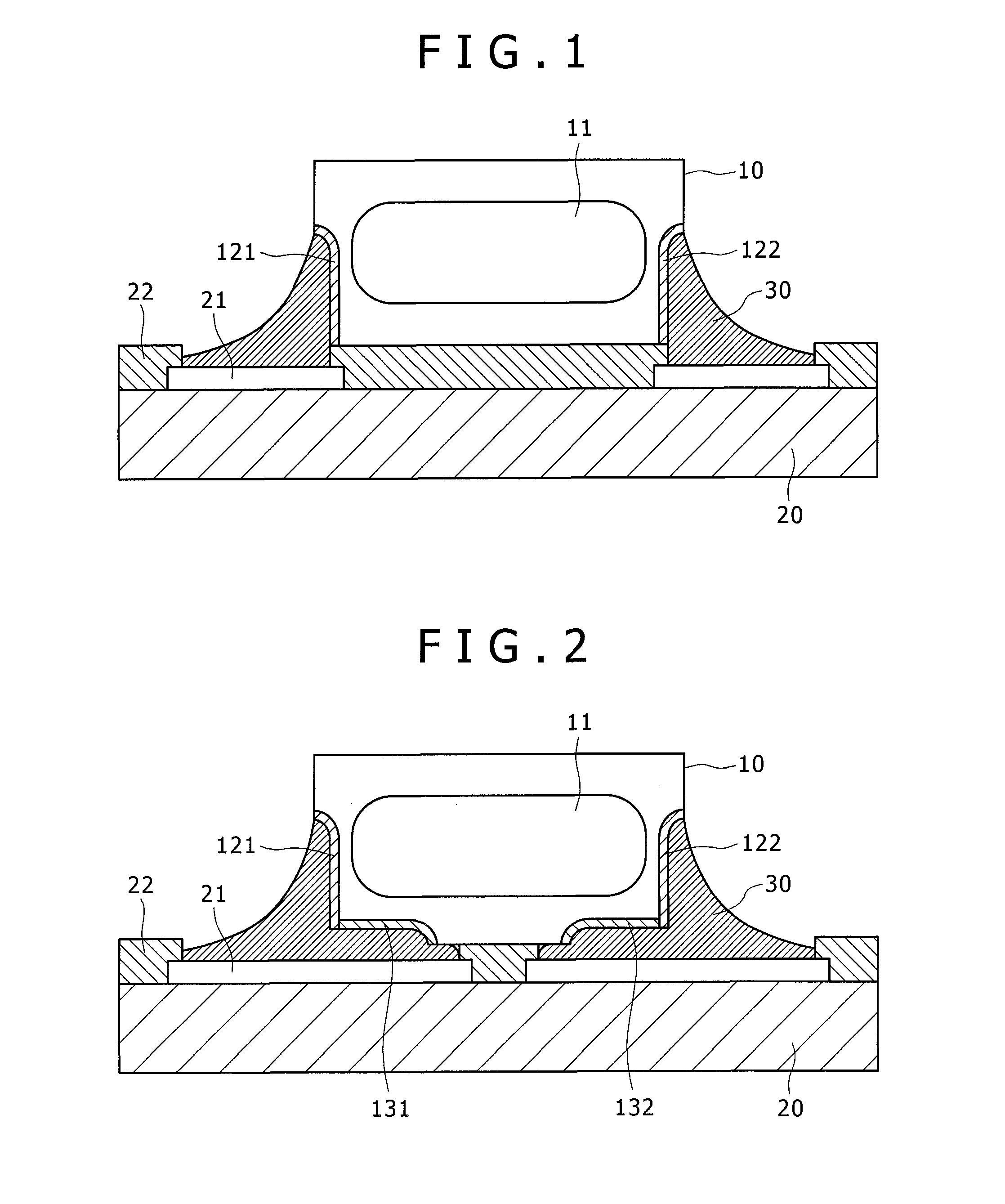

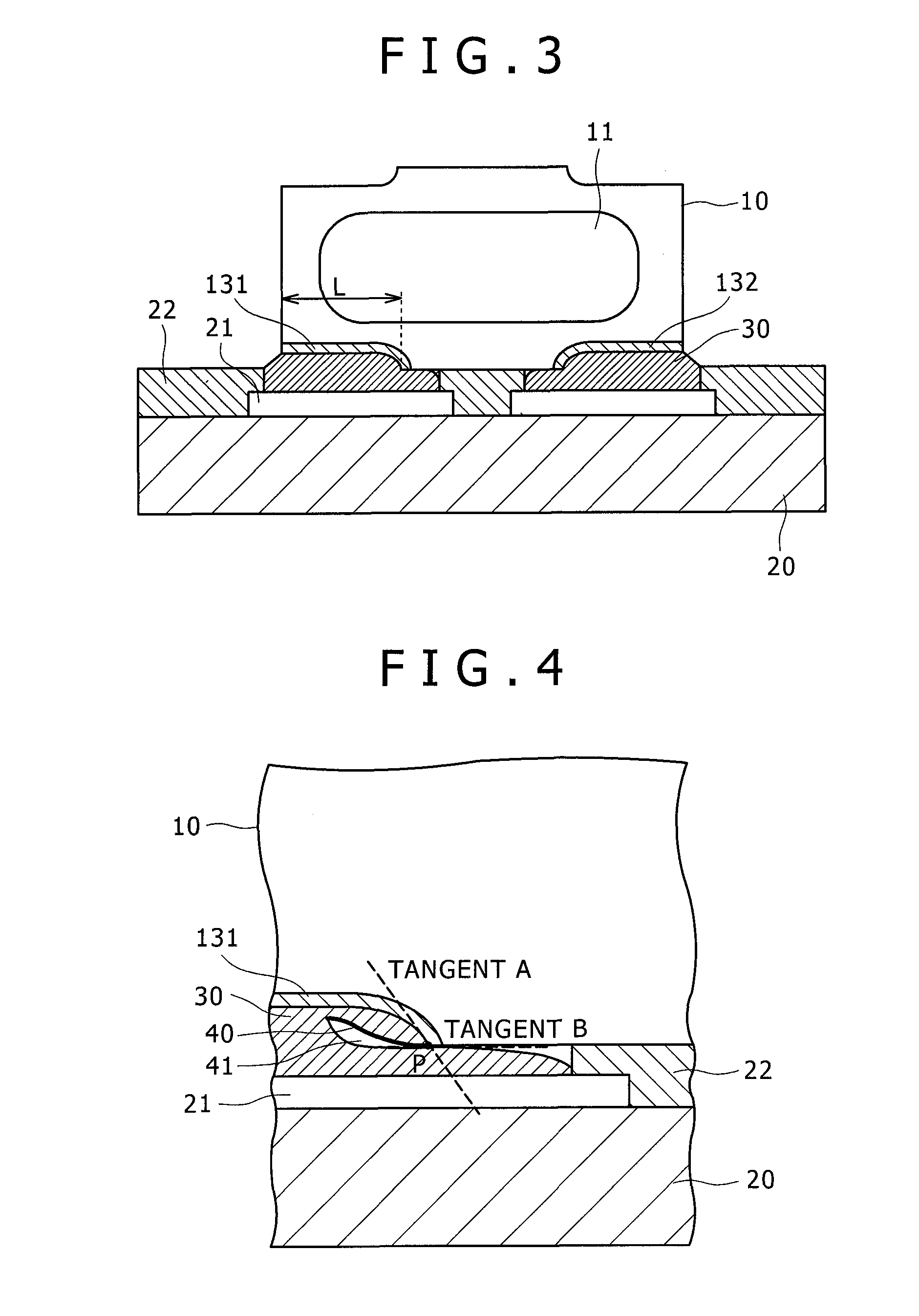

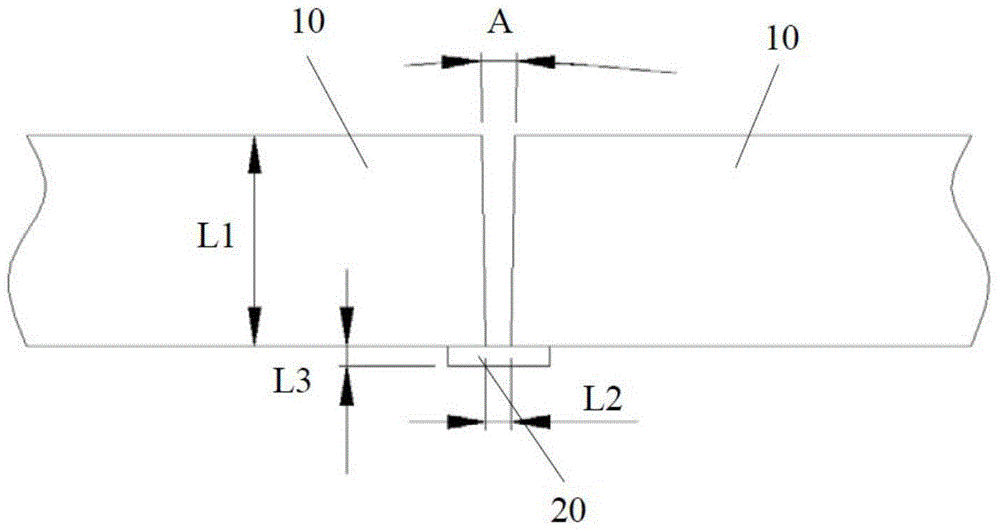

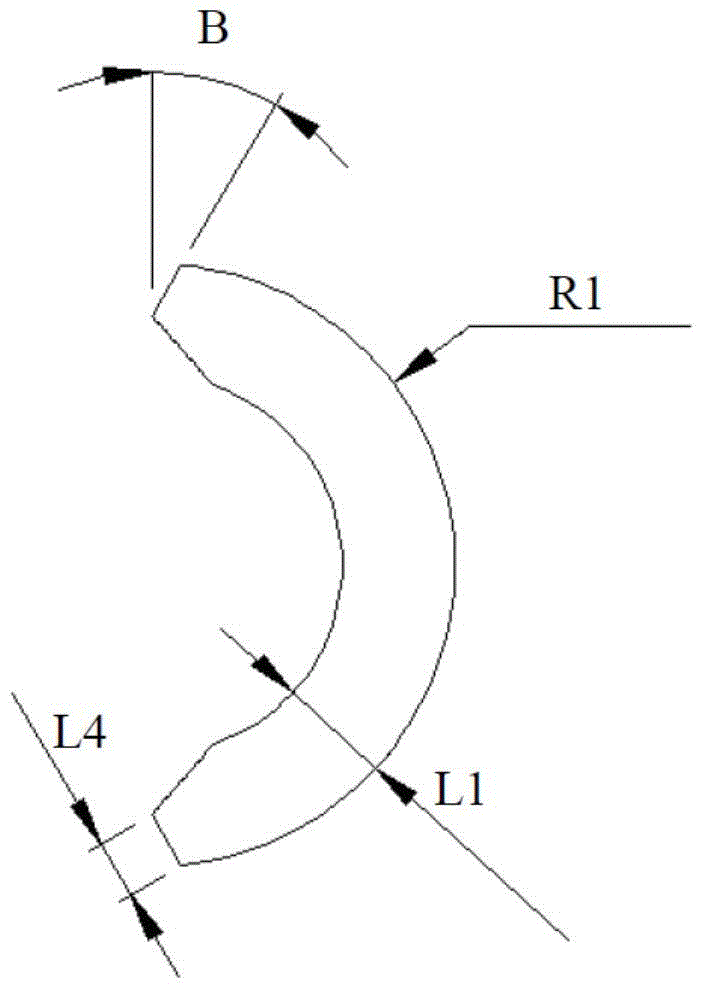

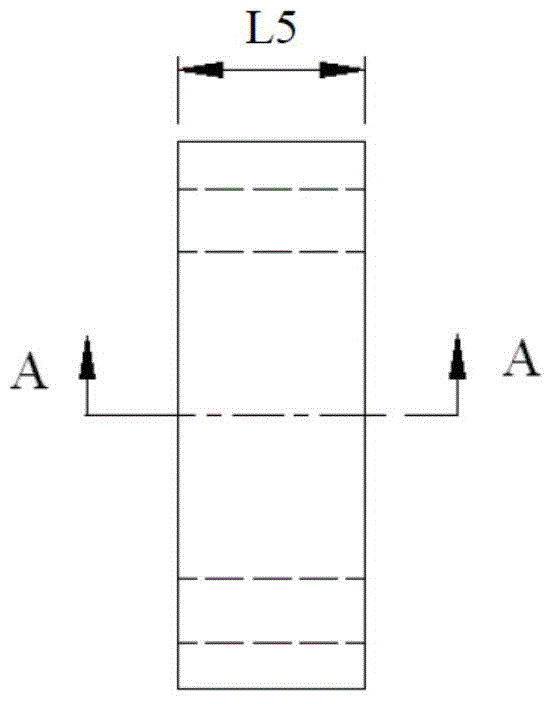

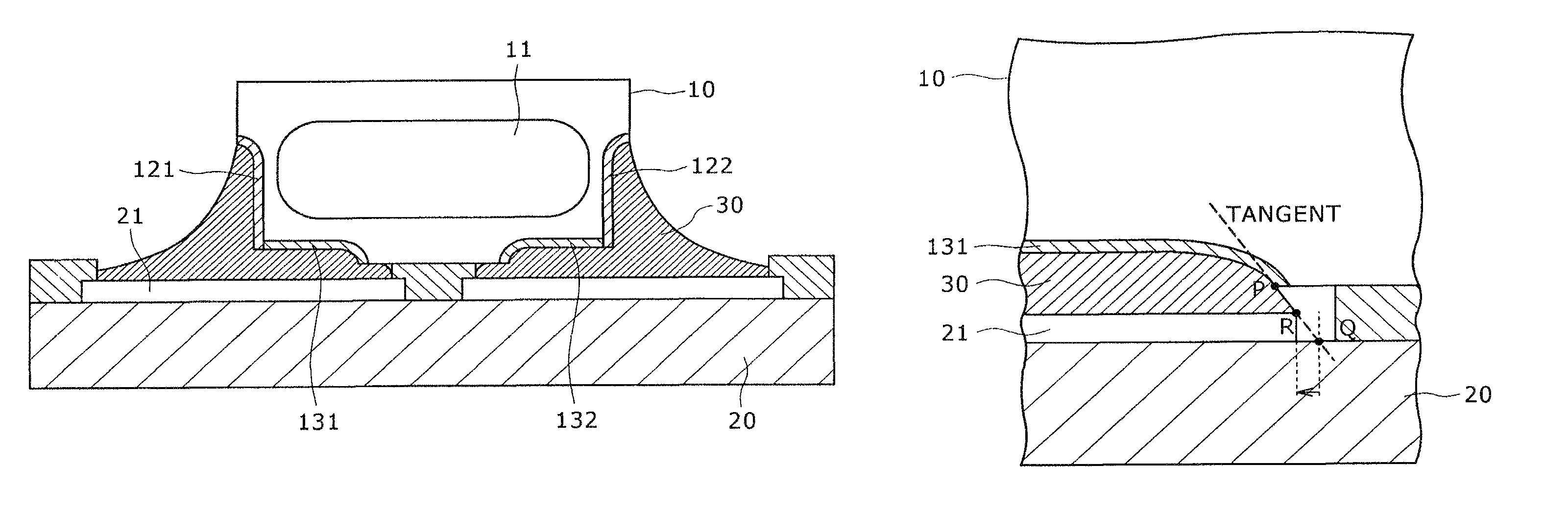

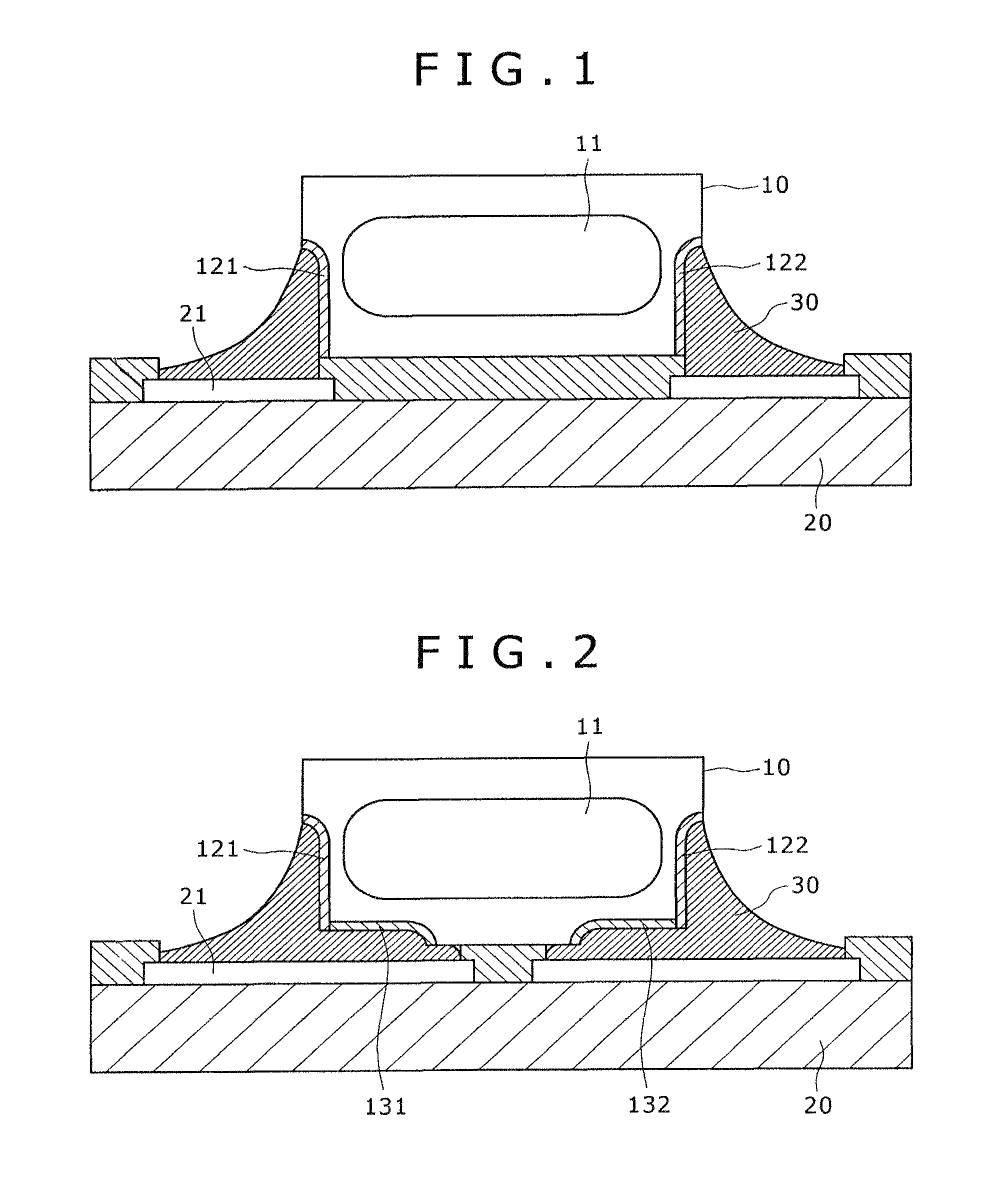

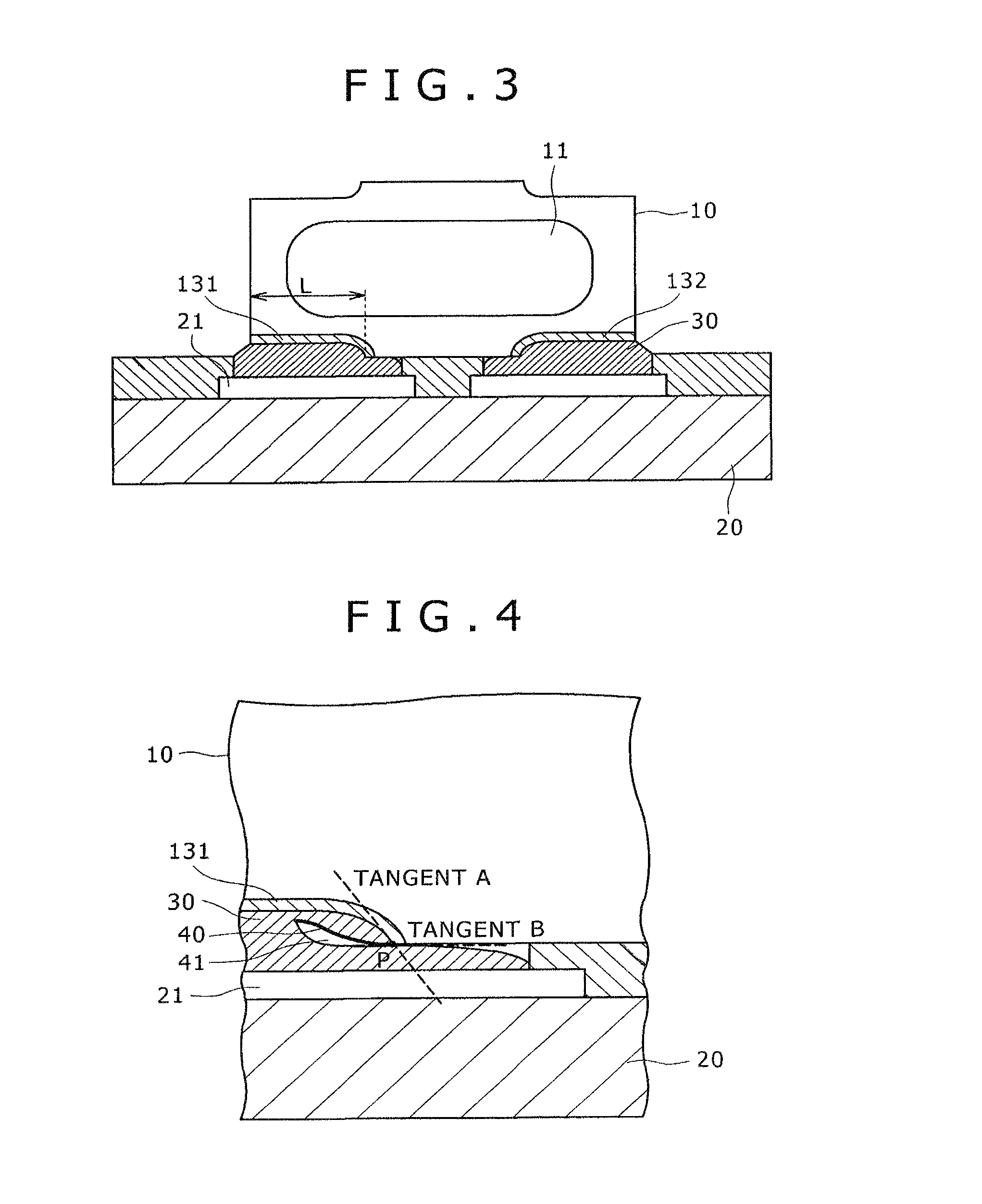

LED Package and LED Package Mounting Structure

InactiveUS20110242450A1Low costImprove fatigue lifeDischarge tube luminescnet screensFinal product manufactureElectrical and Electronics engineeringLed packaging

A highly reliable LED package mounting structure which can realize improvement in solder fatigue life at low costs is provided. An LED package has a light-emitting surface which is perpendicular to a mounting surface of a circuit board, comprises connection terminal portions on the side face or on the side face and the bottom face of the package, and is joined with the circuit board by soldering via the connection terminal portion. Furthermore, the shape of the solder is optimized by defining the relative position relation between the end of an electrode on the central side of the LED package on the bottom face of an LED package body and the end of a component mounting pad on the circuit board.

Owner:MAXELL HLDG LTD

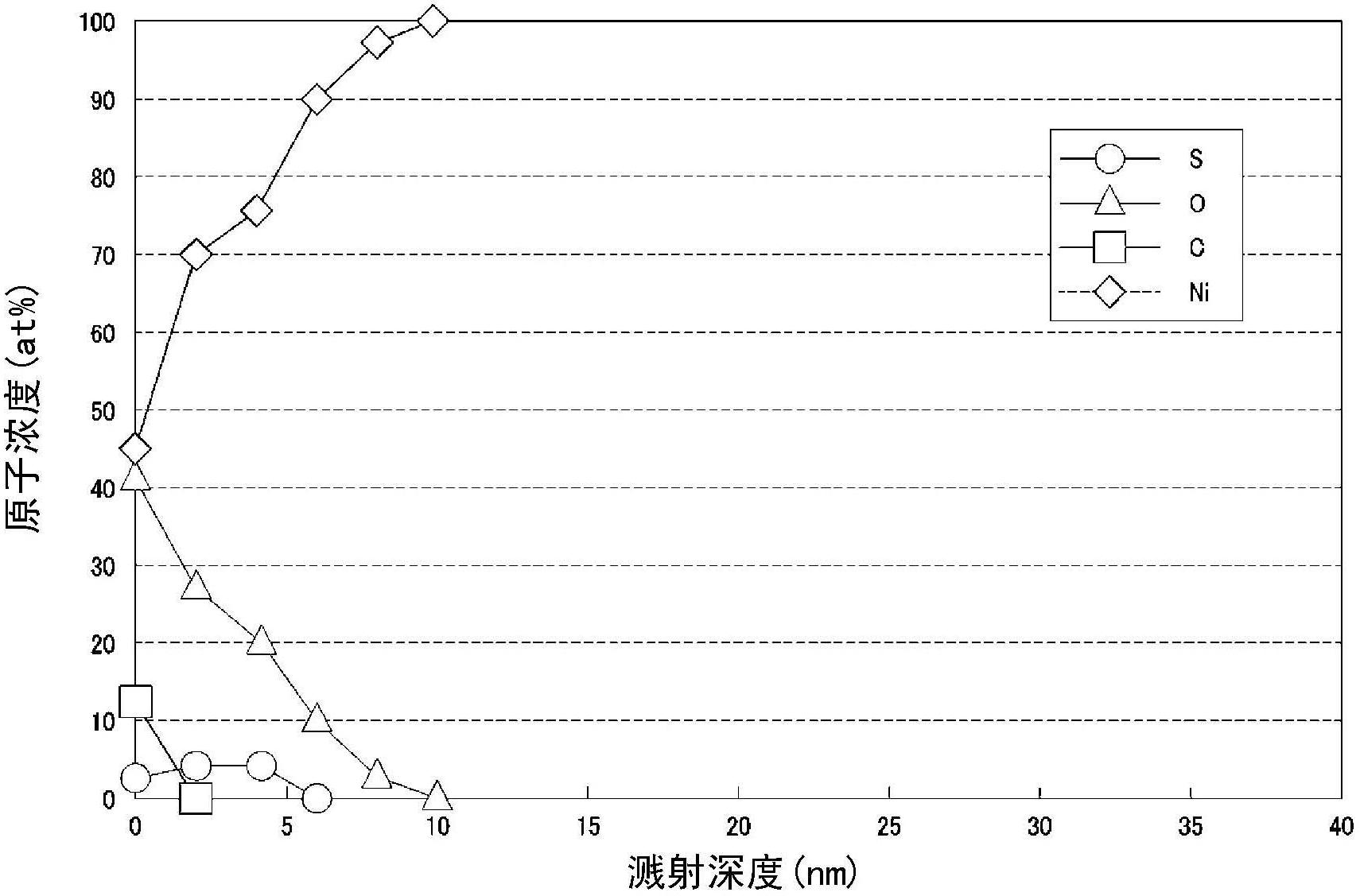

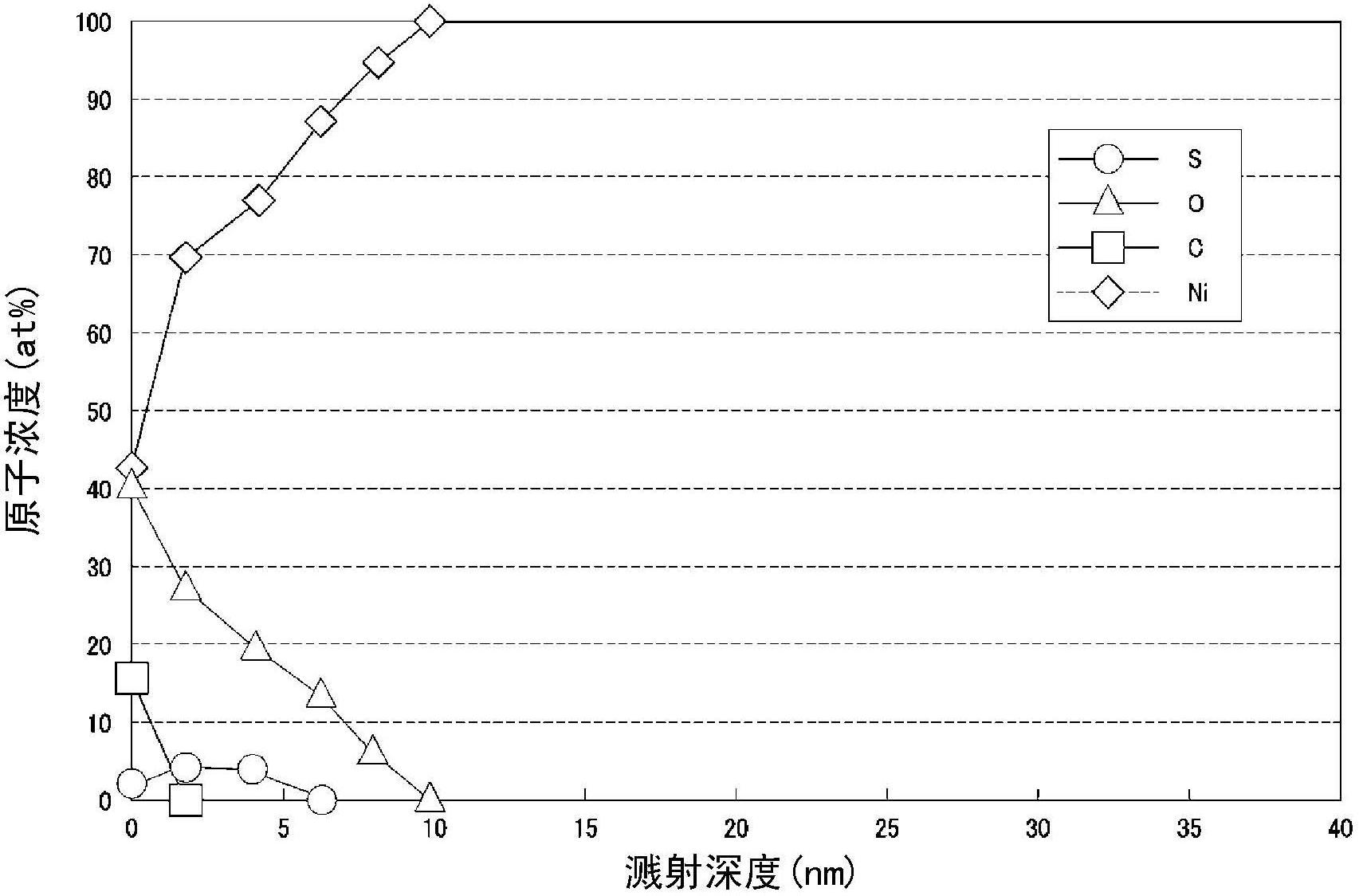

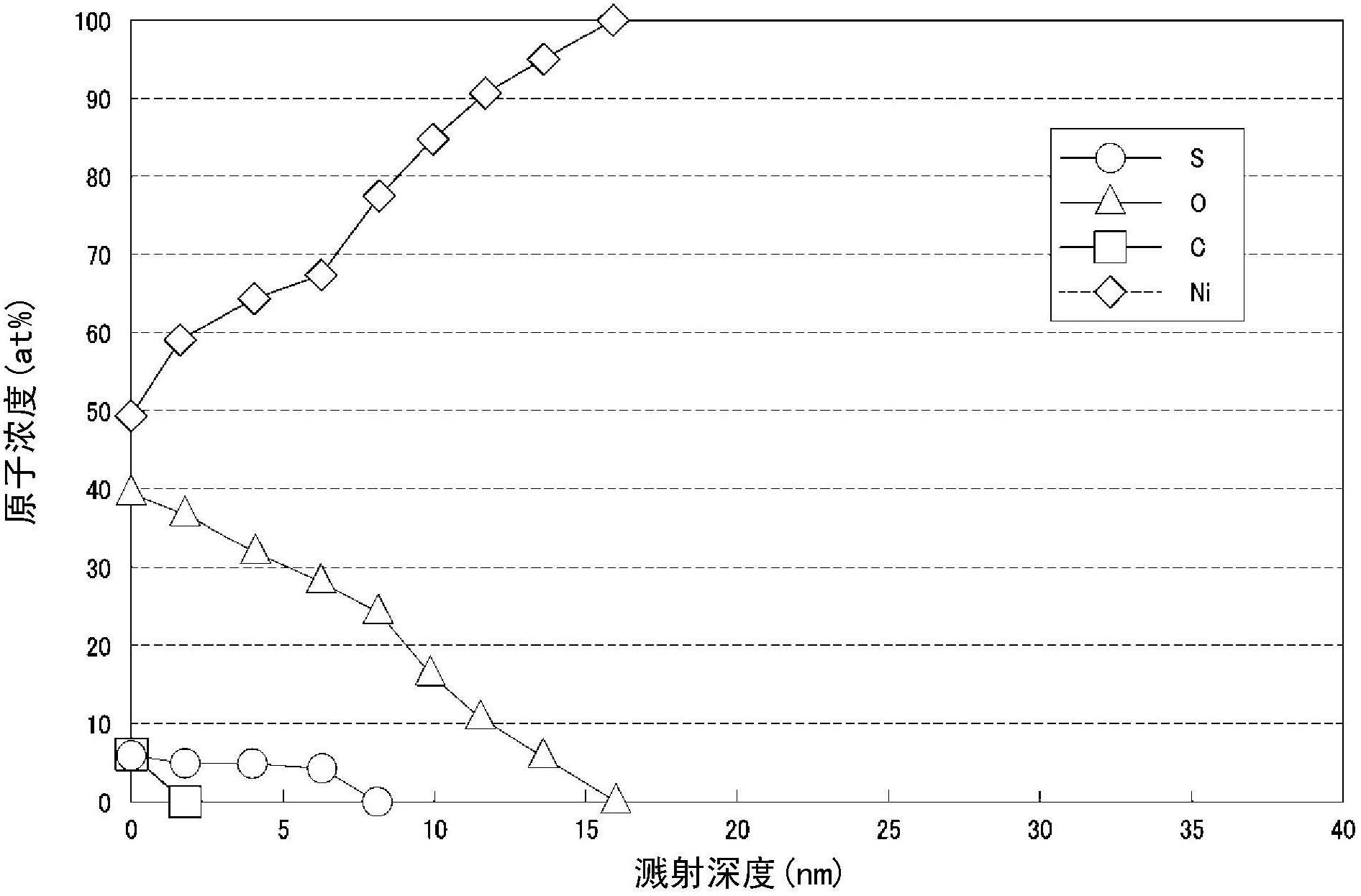

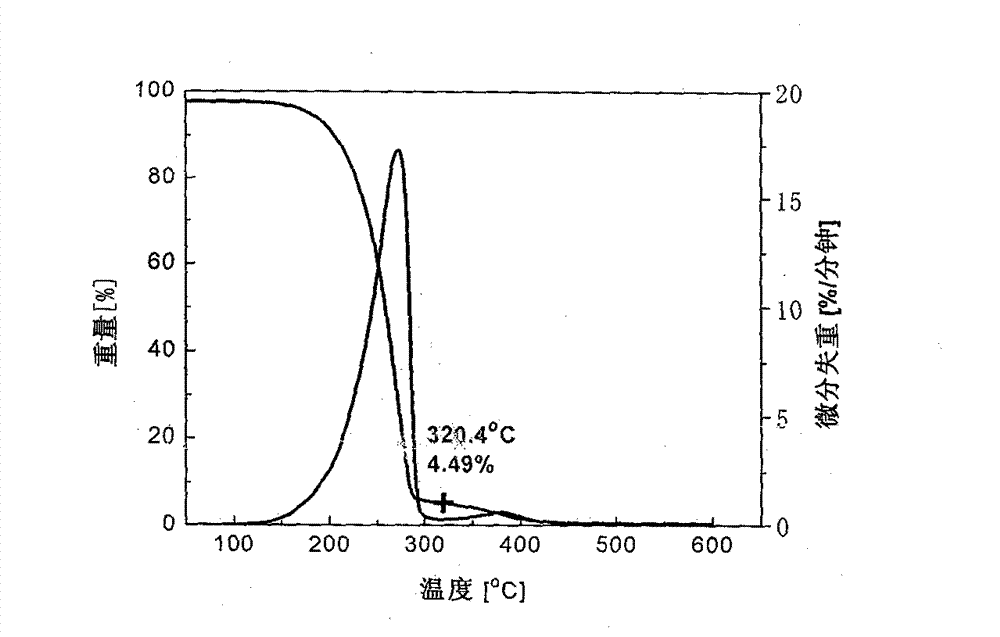

Nickel powder and production method thereof

ActiveCN102665969AHigh purityGood crystallinityTransportation and packagingMetal-working apparatusNickel sulphideOxygen compound

Disclosed is a nickel powder having excellent crystallinity and a high shrink temperature, inhibiting sintering contraction even at high temperatures without affecting the decomposition temperature of the resin binder. Also provided is a production method for the nickel powder. The average particle diameter of the nickel powder is 0.05 - 0.3[Mu]m, crystalline diameter is 60% - 90% of specific surface area diameter, sulphur content is 0.1% - 0.5% by weight, and oxygen content is 0.4% - 1.5% by weight. The powder has a 2 - 15nm thick oxygen-containing surface coating layer with an outermost surface formed from a mixture of a nickel-sulphur compound and a nickel-oxygen compound. Furthermore, in x-ray photoelectron spectroscopy analysis, the outermost layer should preferably have an abundance ratio of 50% - 100% nickel sulphide in the sulphur compound and an abundance ratio of 0% - 50% of nickel hydroxide in the nickel-oxygen compound.

Owner:SUMITOMO METAL MINING CO LTD

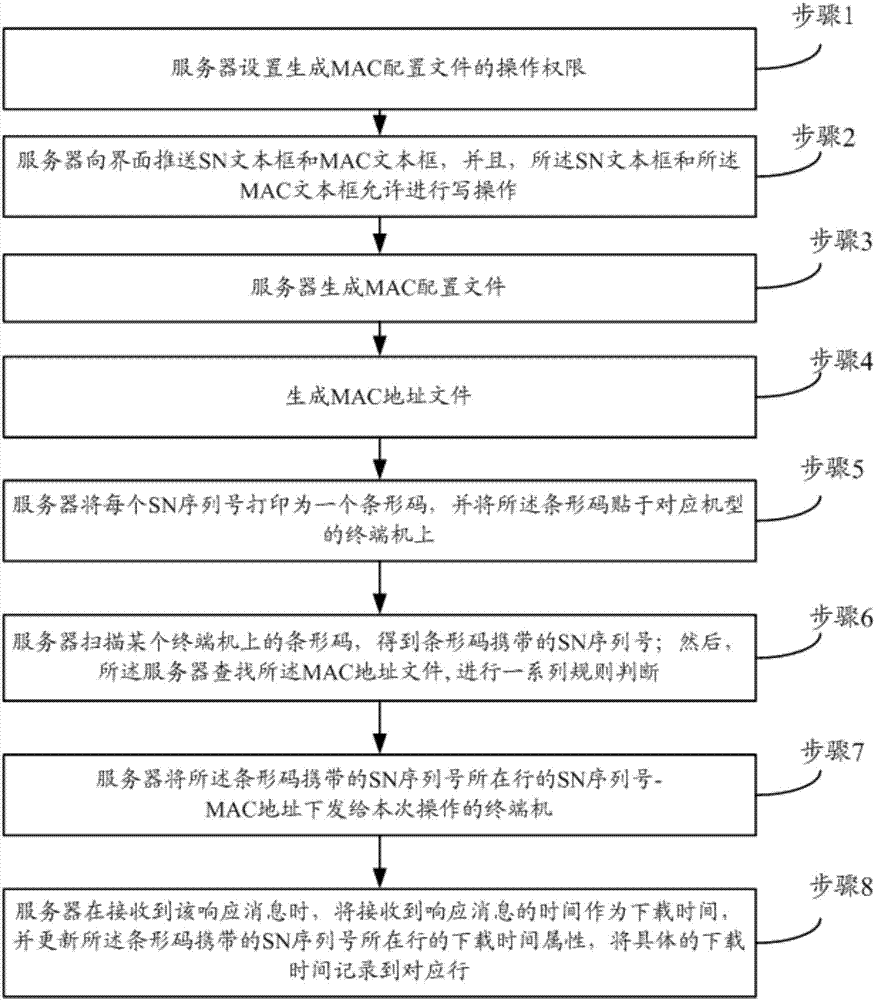

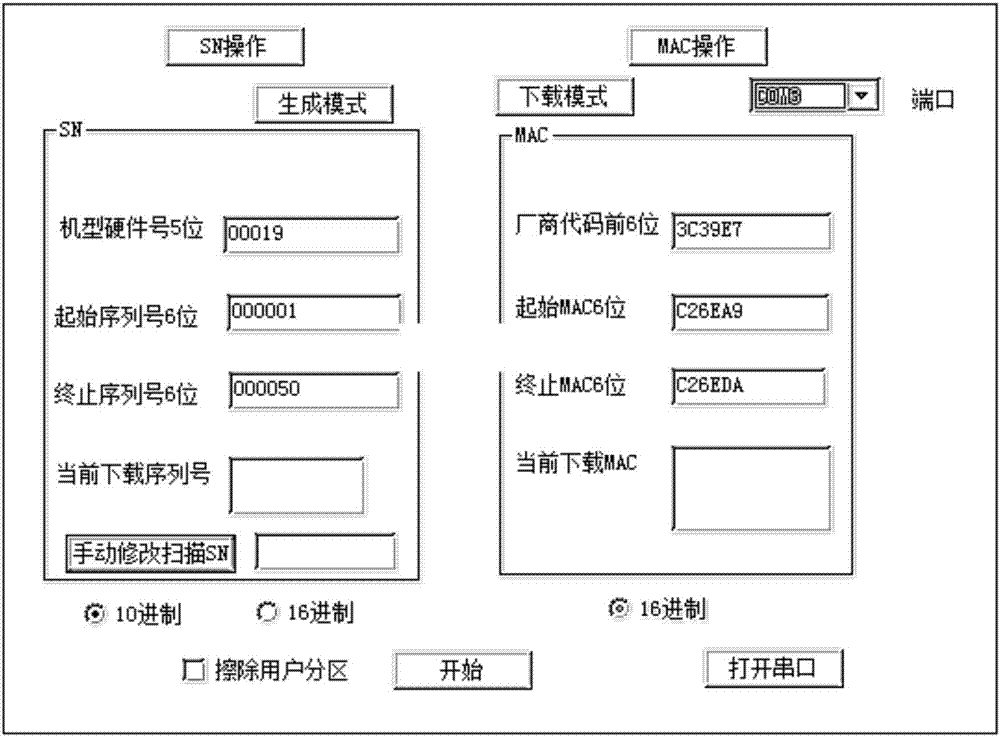

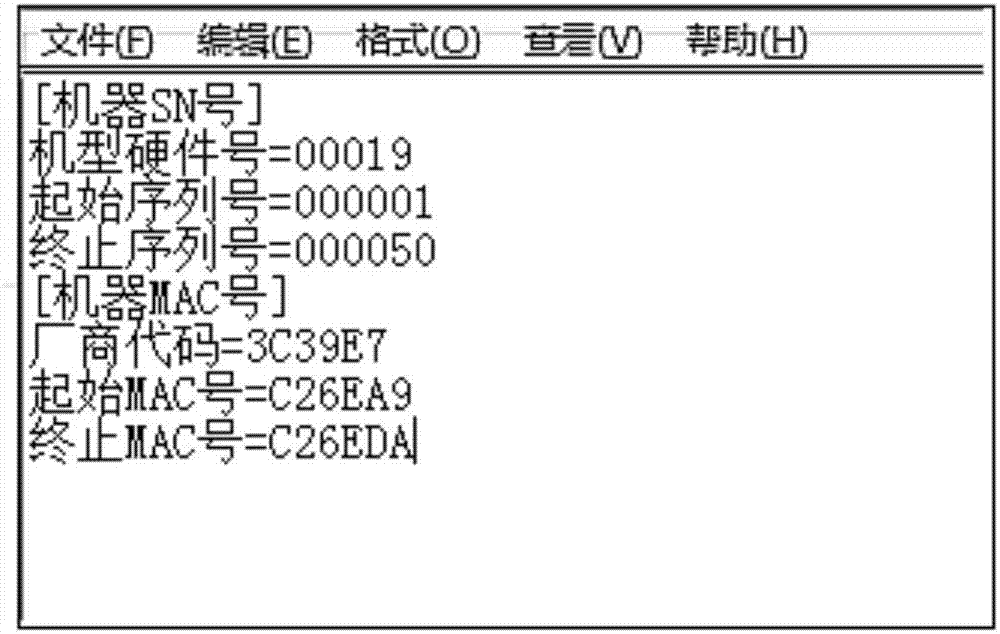

Downloading method of MAC addresses

ActiveCN107205062AGuaranteed validityUniqueness guaranteedData switching networksBarcodeComputer science

The invention provides a downloading method of MAC addresses. The downloading method comprises the following steps: generating an MAC configuration file; generating an MAC address file, wherein the MAC address file consists of multiple specific SNs and MAC addresses; printing, by a server, each SN into a QR code, and sticking the QR codes to terminals of corresponding types; looking up, by the server, the MAC address file according to a rule, so as to obtain the MAC addresses corresponding to the SNs, and after the uniqueness and the effectiveness of the MAC addresses are verified, downloading the MAC addresses to the terminals. The downloading method has the advantages that the downloading method for the SNs and the MAC addresses is simplified; the server is configured to automatically judge the effectiveness and the uniqueness of the SNs and the MAC addresses, so that mistakes caused by a manual judgment procedure are reduced, and MAC fool proofing is effectively realized, namely the problems of repeat, non-continuity and the like of the MAC addresses are prevented, and the uniqueness of the SNs and the MAC addresses of factory terminals is guaranteed.

Owner:AITIWEIER ELECTRONICS TECH BEIJING

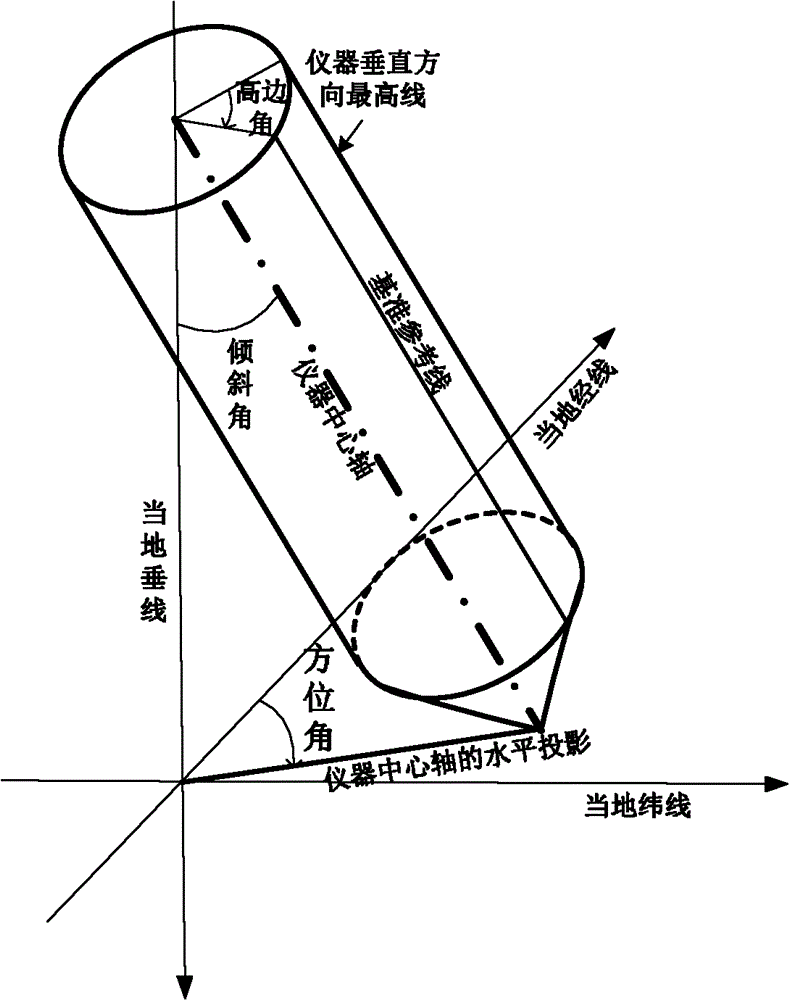

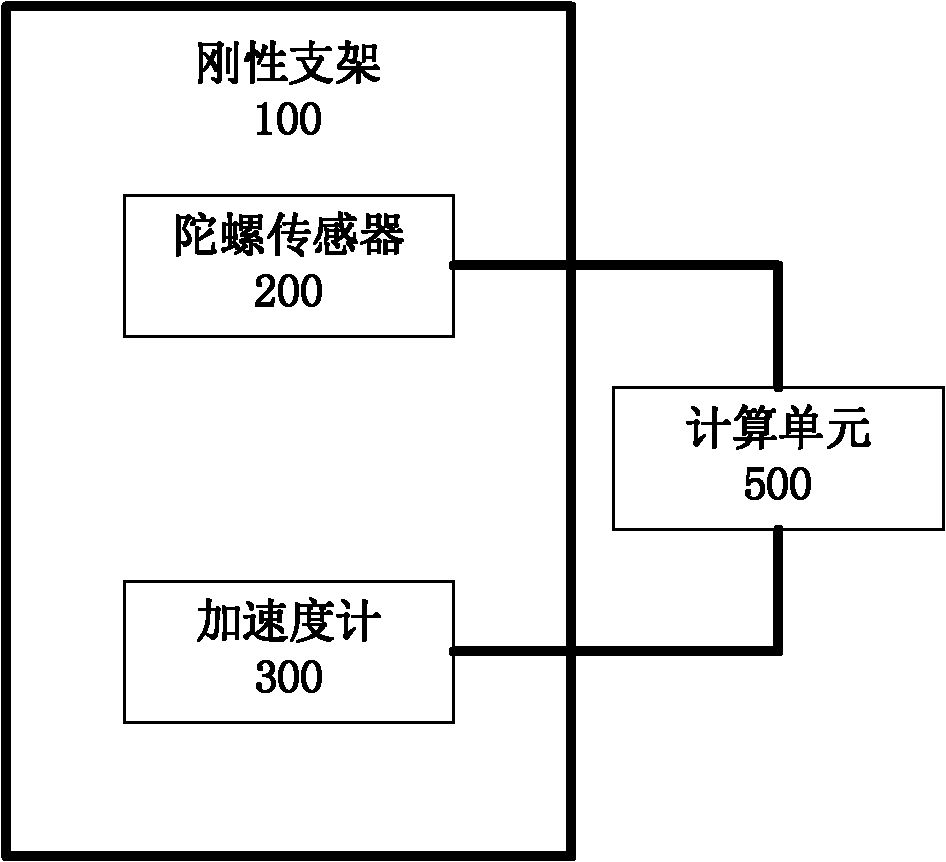

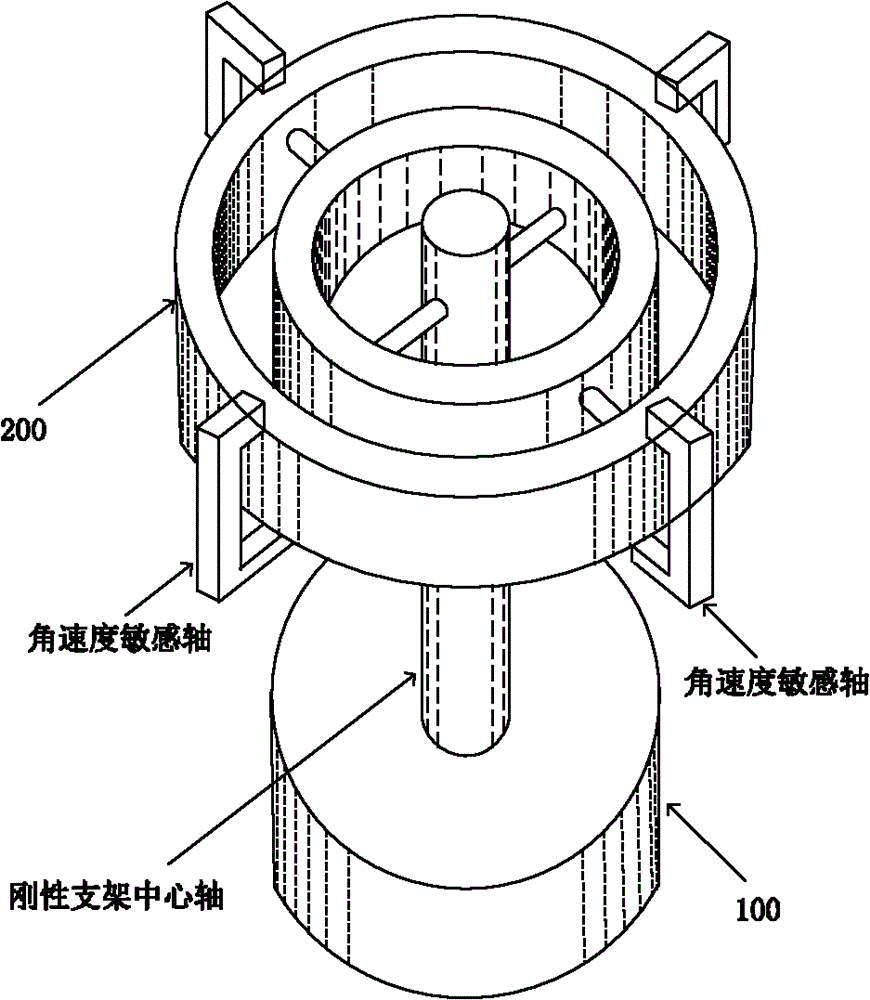

System and method for measuring postures as well as system and method for measuring wellbore track of oil well

ActiveCN102748010AImprove logging efficiencyReduce manufacturing costSurveyContinuous measurementAccelerometer

The invention discloses a system and a method for continuously measuring postures of a rigid bracket (100) at a gravity field by utilizing a two-axis gyroscope as well as a system and a method for measuring a wellbore track of an oil well. The system for continuously measuring the postures by utilizing the two-axis gyroscope comprises a gyroscope sensor (200), an accelerometer (300) and a calculation unit (500). According to the systems and the methods disclosed by the invention, the defects that a gyroscope point measurement operation is complicated and wastes time are overcome, and the disadvantages of continuous measurement of a three-axis gyroscope that the outer diameter is great and the hardware cost is high are avoided; the continuous measurement of the oil field track in a moving process of the rigid bracket (100) can be realized; and the well logging time is shortened, the well logging efficiency is improved and the manufacturing cost of hardware is reduced.

Owner:BEIJING ZEBANON SCI & TECH

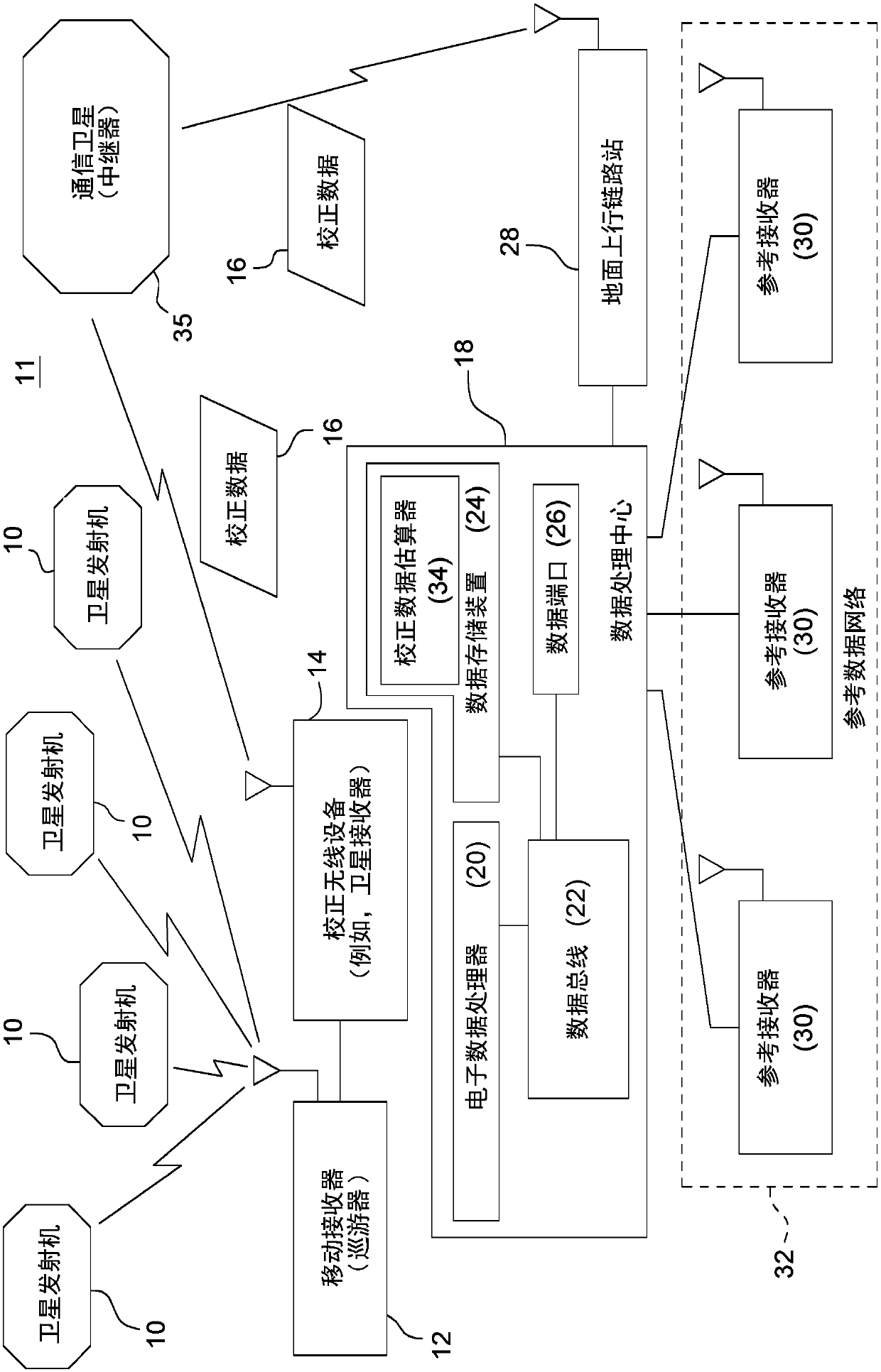

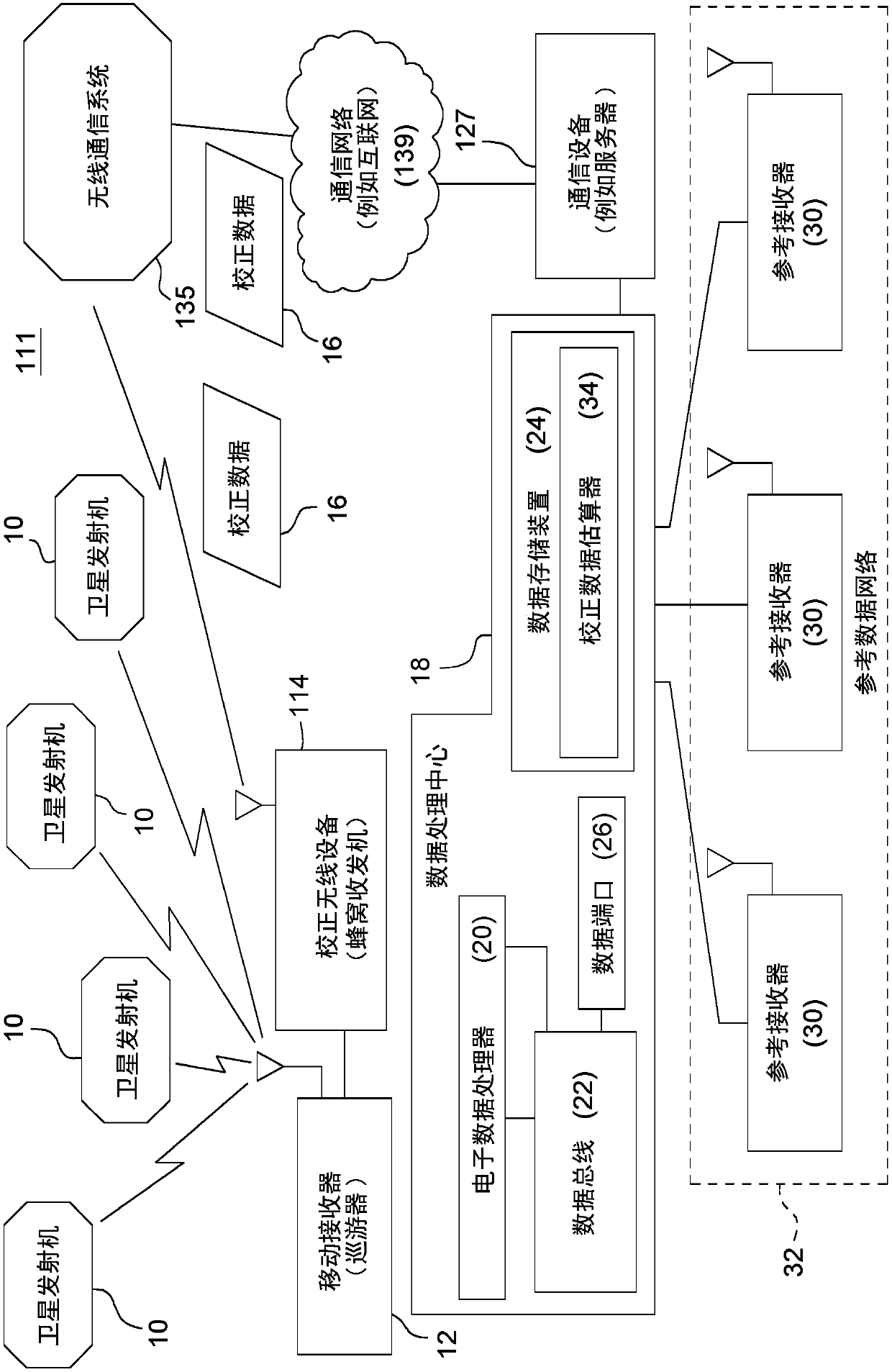

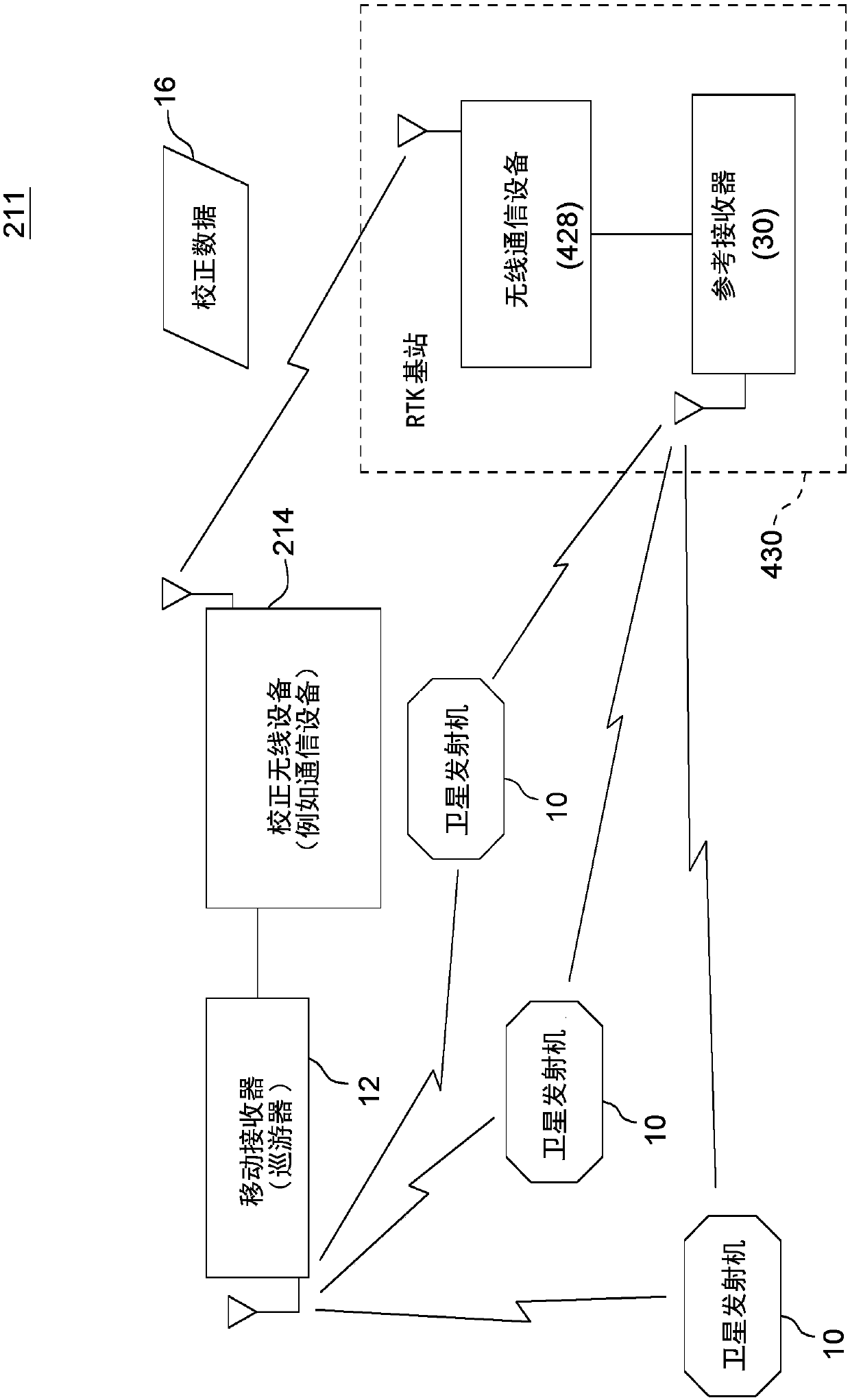

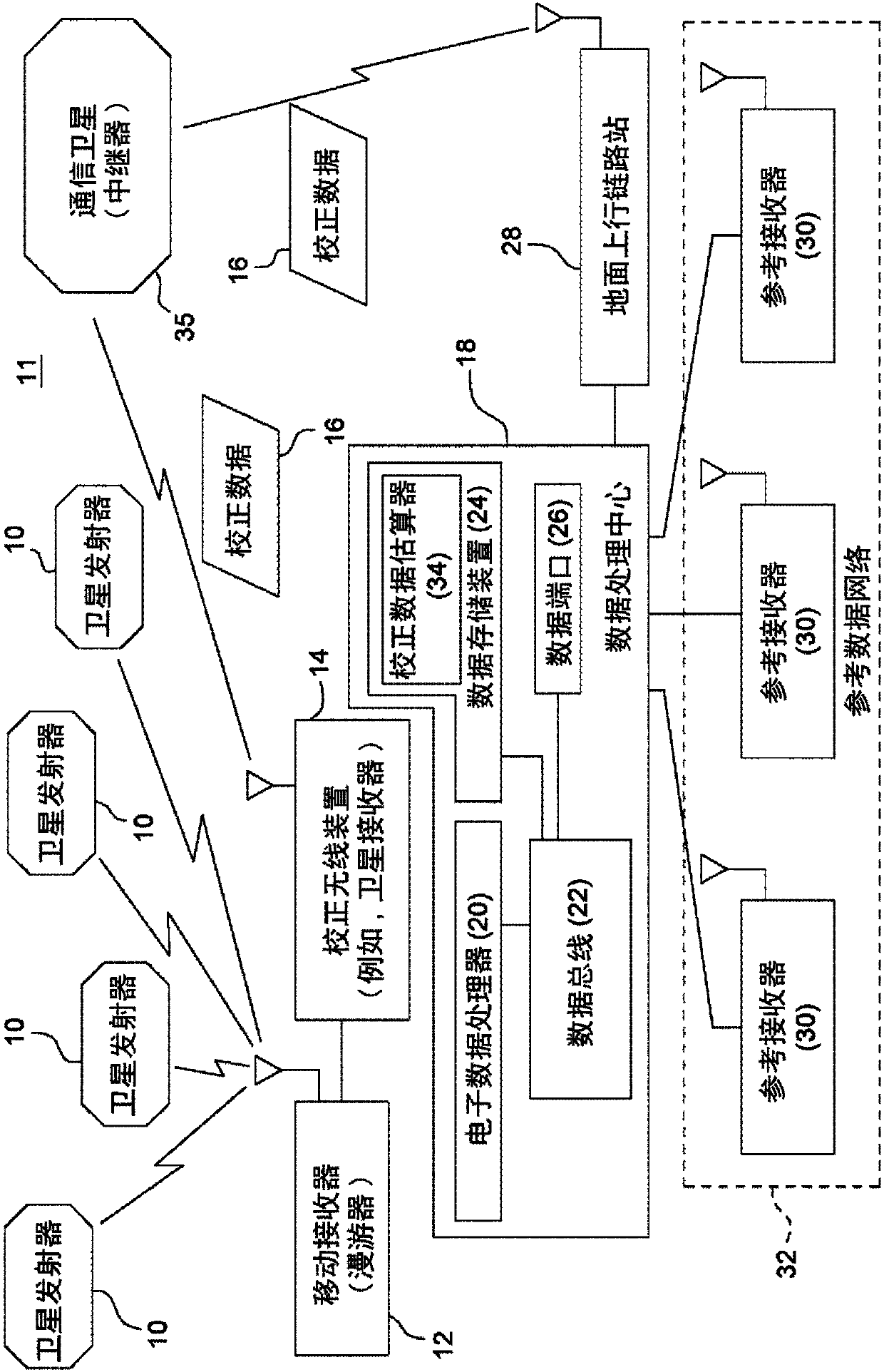

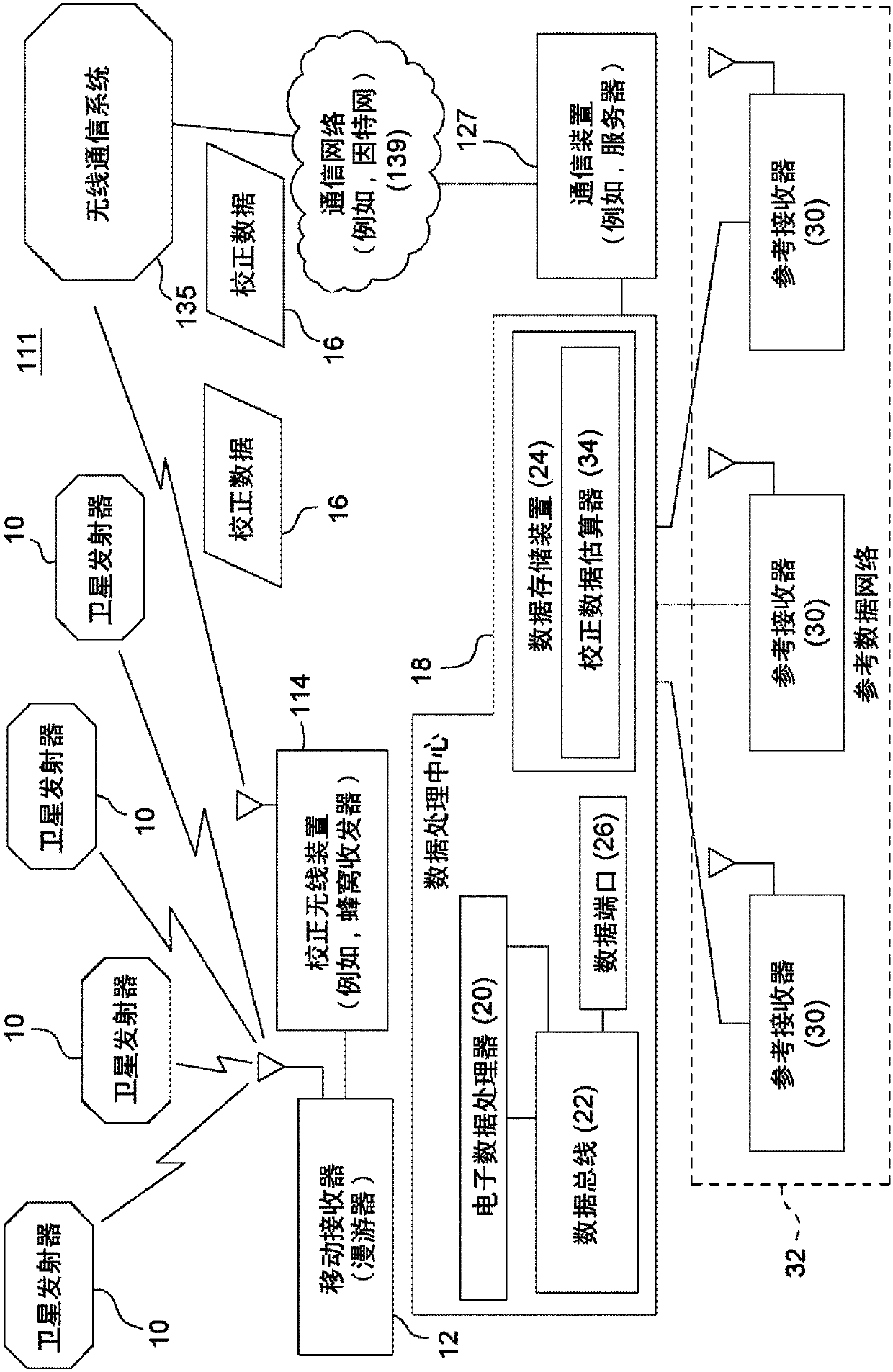

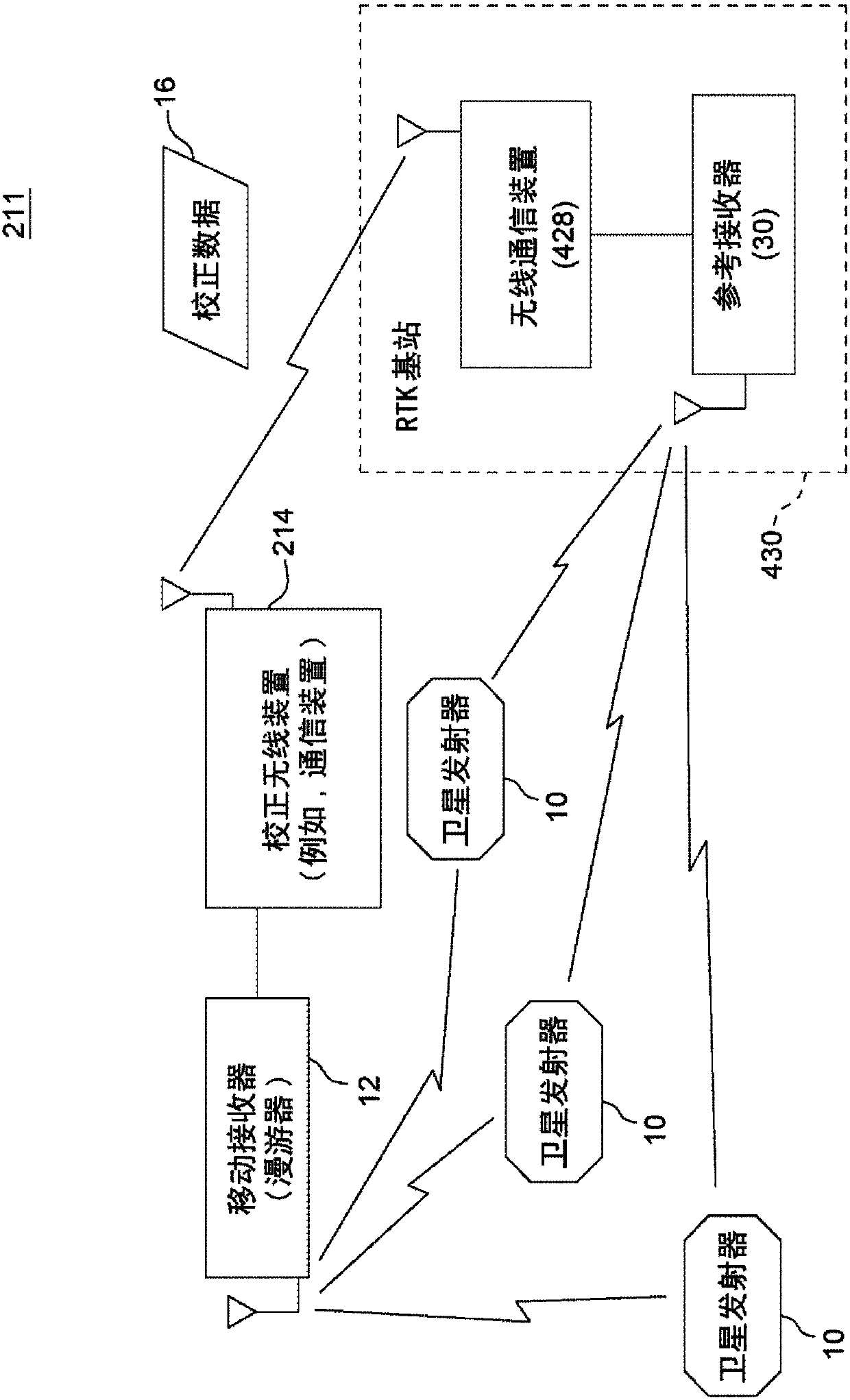

Satellite navigation receiver and method for switching between real-time kinematic mode and relative positioning mode

ActiveCN107710017APrevent jumpingAvoid continuitySatellite radio beaconingReal Time KinematicPrecise Point Positioning

An offset module (130) or navigation positioning estimator (57) determines a reference frame bias between precise point positioning (PPP) reference frame and an RTK reference frame, where the PPP reference frame is associated with relative position estimates generated by the relative position estimator (124) and where the RTK reference frame is associated RTK position estimates generated by the RTK position estimator (122). Upon loss of the RTK correction signal, the navigation positioning estimator (57) or controller switches to a relative position mode based a last available RTK position. The relative position estimator (124) determines an estimated relative position based on time-differenced phase measurements by the mobile receiver (12, 30) in the relative position mode. The relative position estimator (124) or offset module (130) offsets the estimated relative position in the relative position mode.

Owner:DEERE & CO

Heat transfer printing method on object surface

The invention discloses a heat transfer printing method on an object surface. The method comprises the following steps of: cutting and sewing or enclosing a transfer sheet into a tubular shape to cover an object surface; then, applying pressure on the whole object surface and tightly attaching the transfer sheet to the object surface in vacuum; and heating and baking to transfer patterns on the transfer sheet to the object surface. The invention can tightly attach the transfer sheet to the object surface and avoid staggering or breaking transferring patterns, is not limited by object surface shapes and can transfer patterns on an object in any shape or size.

Owner:CLASSIC BUSINESS CONSULTING SHANGHAI

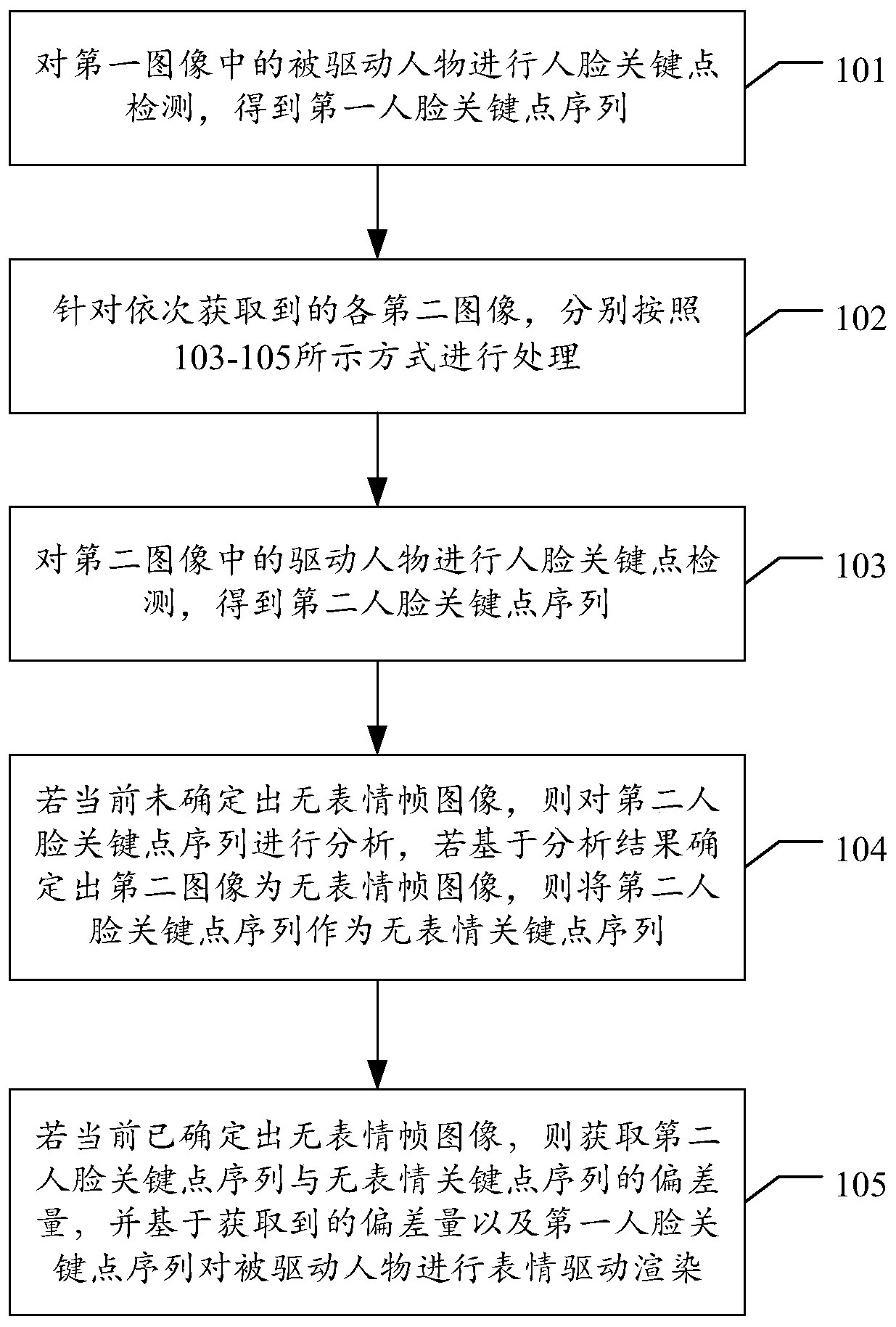

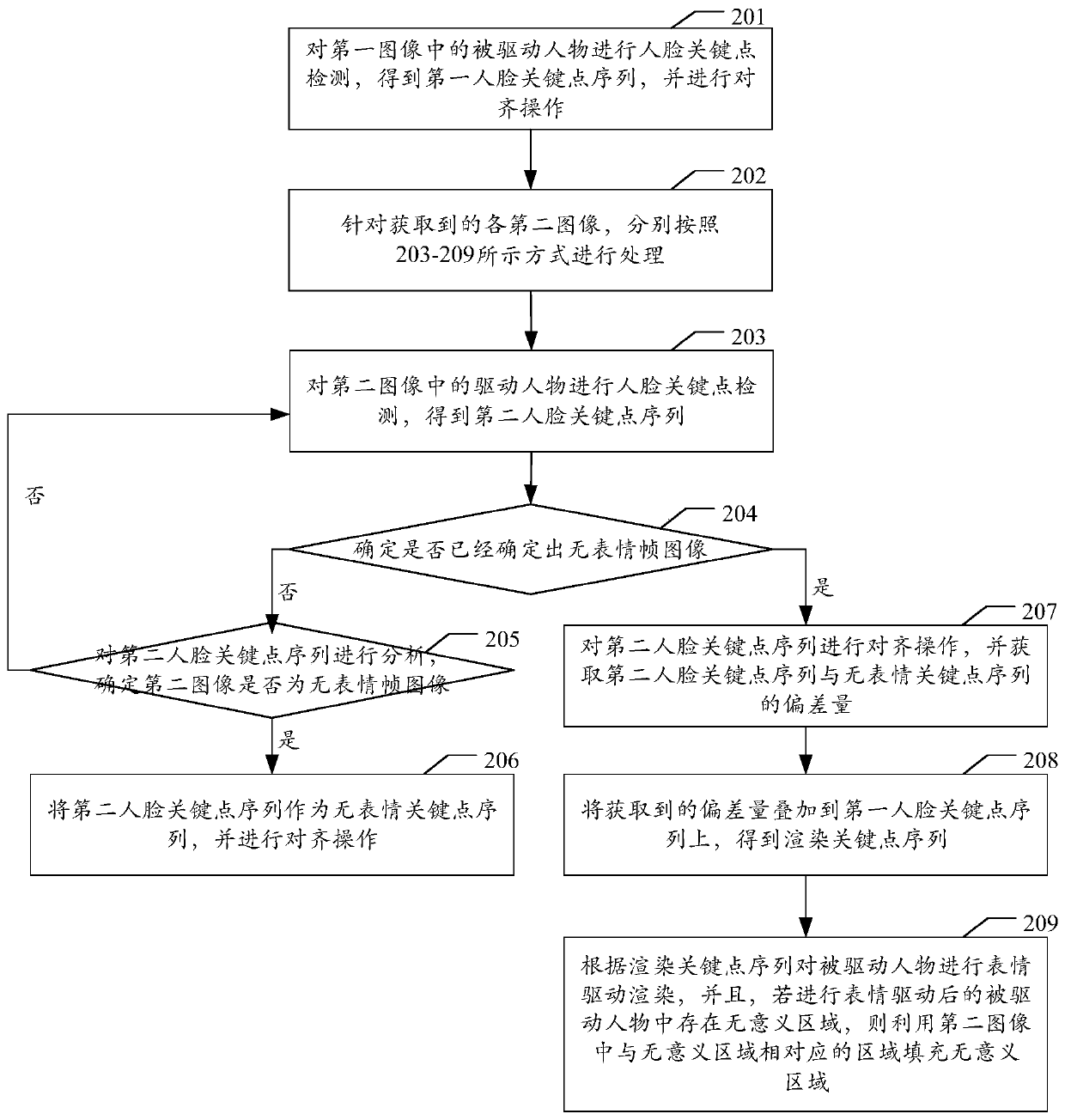

Expression driving method and device, electronic equipment and storage medium

PendingCN110941332AImplementation is flexibleImprove interactivityInput/output for user-computer interactionAnimationEngineeringComputer vision

The invention discloses an expression driving method and a device, electronic equipment and a storage medium, and relates to the field of artificial intelligence, and the method can comprise the steps: carrying out the face key point detection of a driven person in a first image, and obtaining a first face key point sequence; for each second image obtained in sequence, the following processing iscarried out: performing face key point detection on a driving person in each second image to obtain a second face key point sequence; analyzing the second face key point sequence if the no-expressionframe image is not determined currently, and taking the second face key point sequence as a no-expression key point sequence if the second image is determined to be the no-expression frame image basedon an analysis result; and otherwise, obtaining a deviation value between the second face key point sequence and the expression-free key point sequence, and performing expression driving rendering onthe driven person based on the deviation value and the first face key point sequence. By applying the method of the invention, the flexibility, interactivity, accuracy and the like can be improved.

Owner:BEIJING BAIDU NETCOM SCI & TECH CO LTD

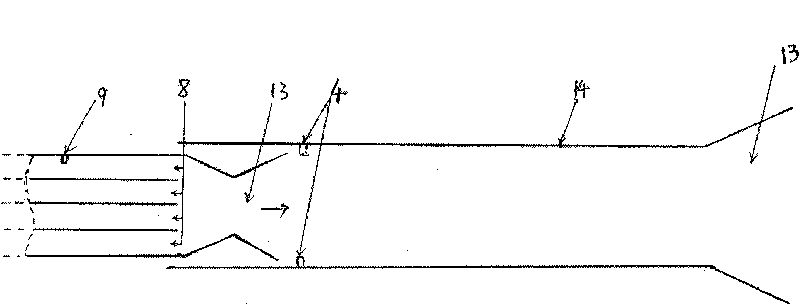

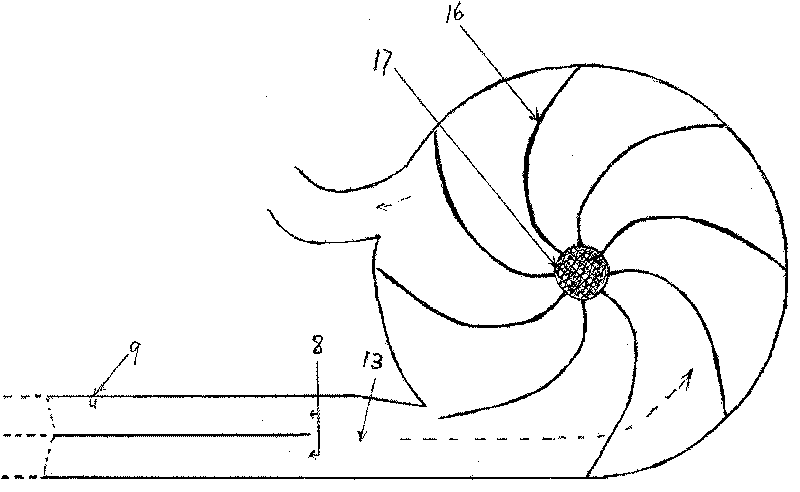

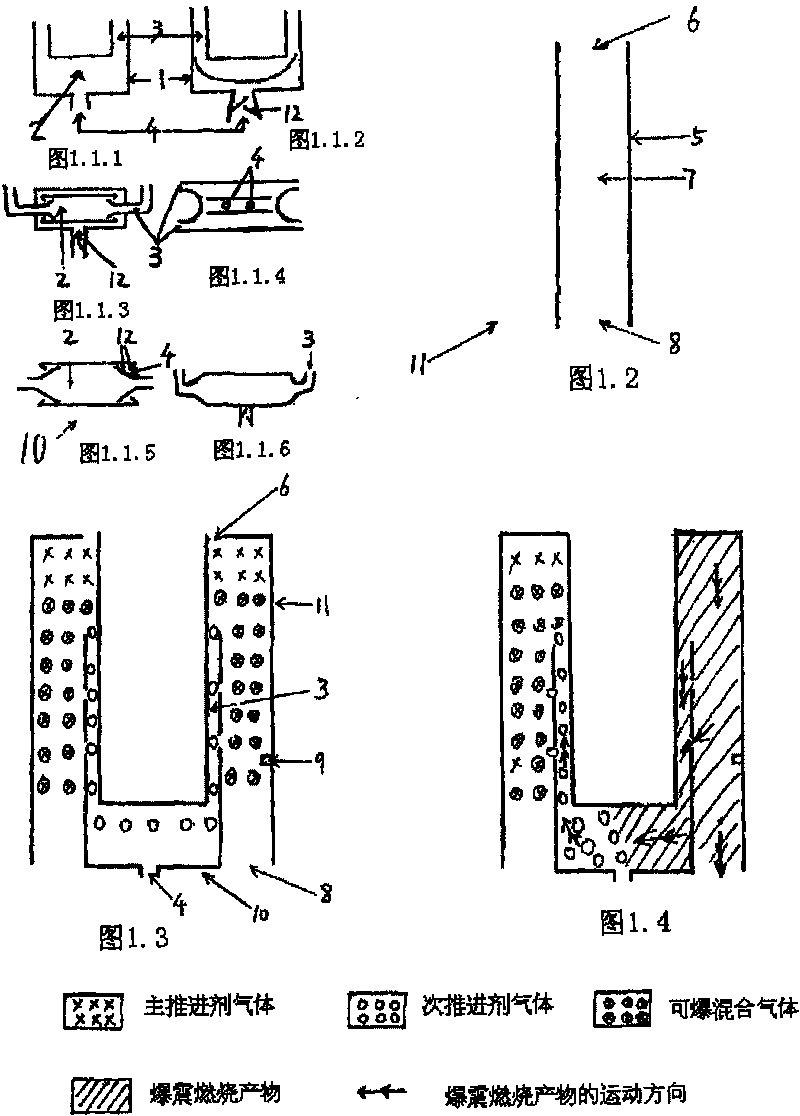

Multitube pulse detonation combustion chamber communicated with jet deflector

InactiveCN101718236AAvoid early ignitionAvoid continuityRocket engine plantsPhysicsCombustion chamber

The invention relates to a multitube pulse detonation combustion chamber communicated with a jet deflector, mainly comprising at least two detonation units, at least one detonation jet deflector and at least one ignition detonating device. Each detonation unit comprises a detonation unit shell and a detonation unit internal cavity, wherein the detonation unit internal cavity mainly comprises a detonation chamber inlet, a detonation chamber and a downstream detonation chamber outlet which are communicated; each detonation jet deflector mainly comprises a detonation jet deflector shell, a detonation jet deflector internal cavity, at least two communicating pipes respectively communicated with the detonation jet deflector internal cavities and at least one propelling agent inlet positioned in the detonation jet deflector; and the detonation jet deflector can temporarily store and transfer a certain quantity of the propelling agent and can also forcibly and alternately complete the propelling agent refilling and dopping and the detonating process of the detonation units by utilizing energy and a substance which are generated by detonation burning. The invention can ensure stable working performance of a pulse detonation motor and improve the cycle efficiency of the pulse detonation motor.

Owner:周林

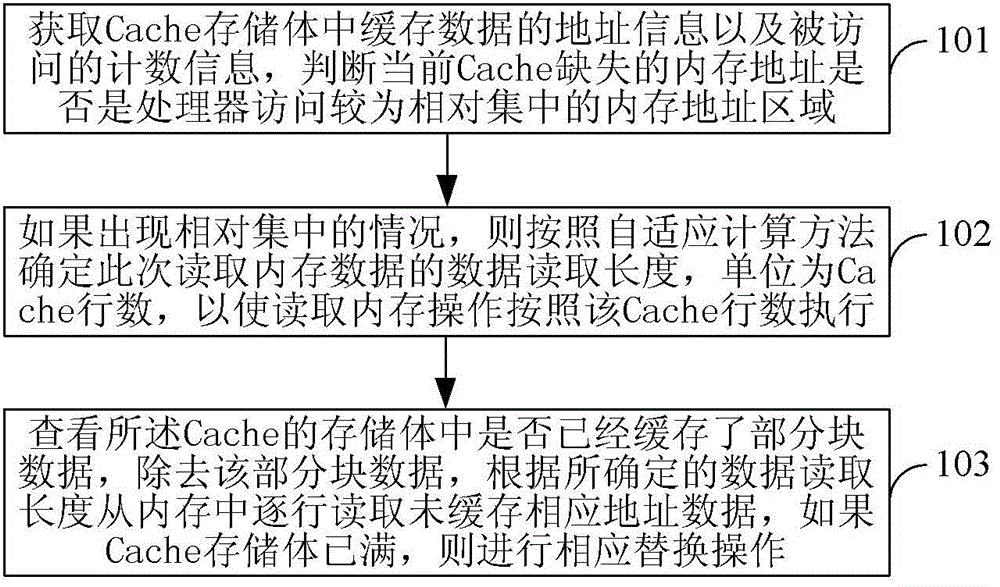

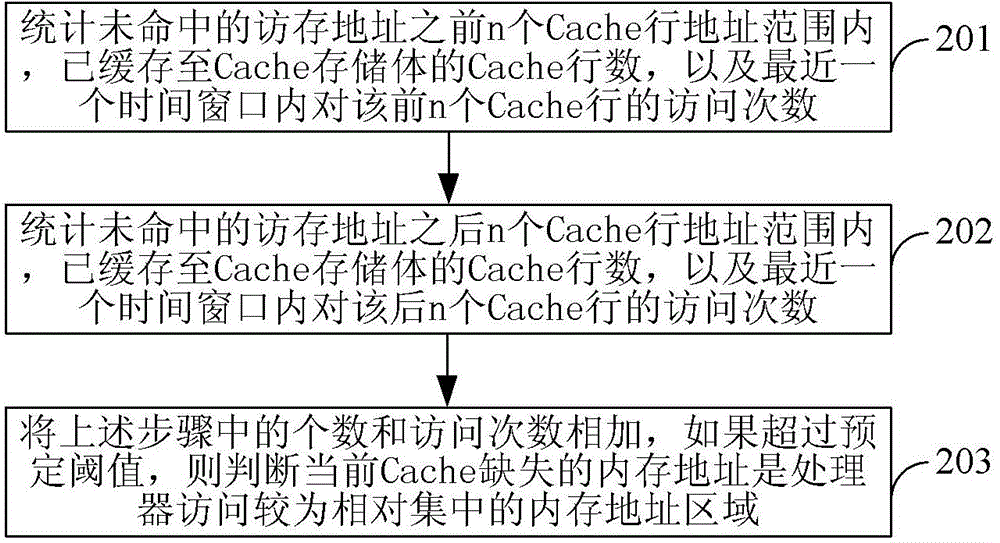

Method and device for reading length of data block of cache memory in self-adaption mode

ActiveCN104156323AReduce the number of read dataImprove hit rateMemory adressing/allocation/relocationData informationConcentration ratio

The invention provides a method and device for reading the length of a data block of a cache memory in a self-adaption mode. The method includes the steps that when the last Cache of a processor is missed, cache data information of the Cache is obtained; whether the missed memory access address and the address of cached data in the Cache are centralized or not is judged according to the cache data information; if yes, the read data length adapting to the data distribution concentration ratio is determined, wherein the line number of the Cache serves as the unit; the processor reads the data to the Cache from the memory with the missed memory access address as the center and according to the determined read data length. The technical problem to be solved through the method and device is to increase the processing speed of a CPU.

Owner:INSPUR BEIJING ELECTRONICS INFORMATION IND

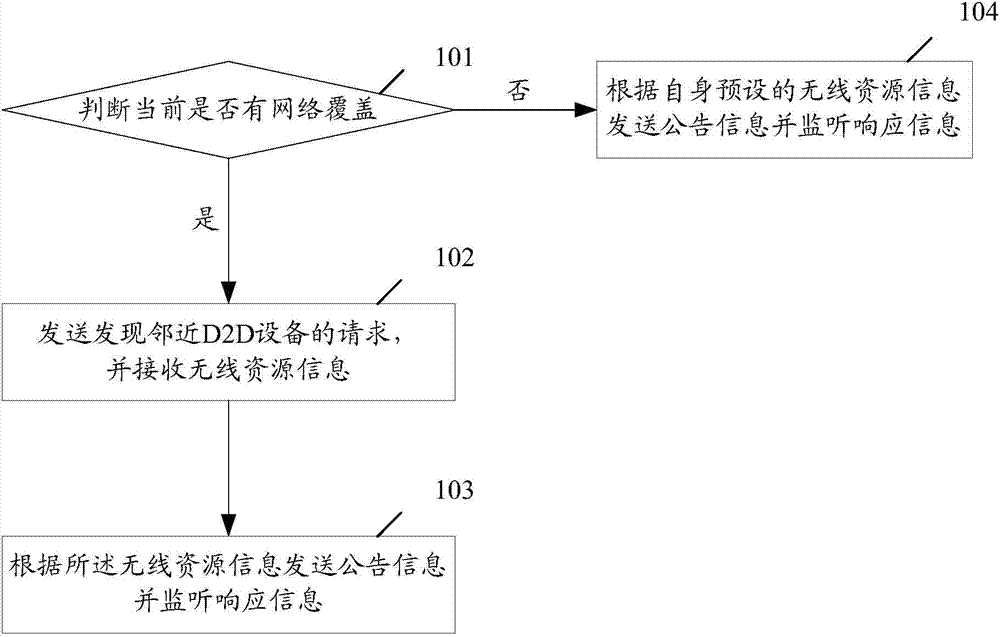

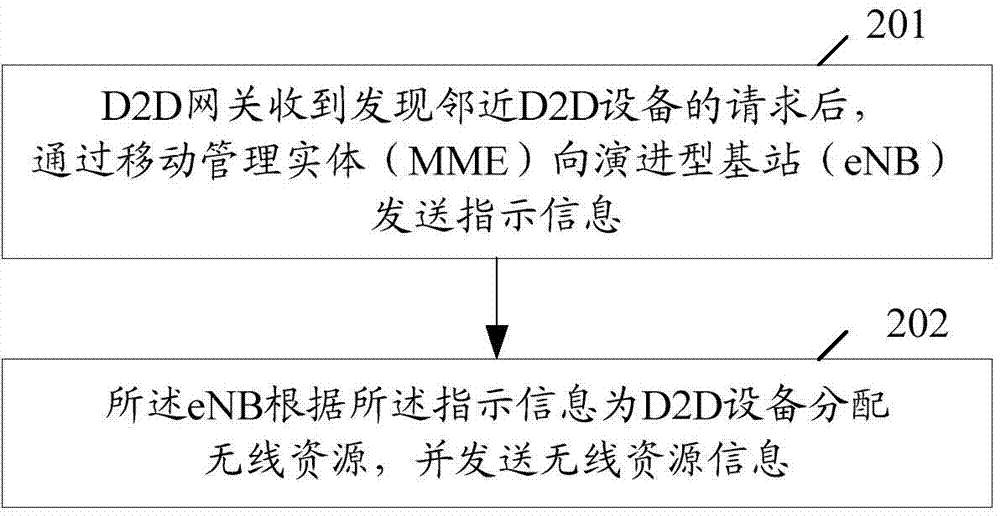

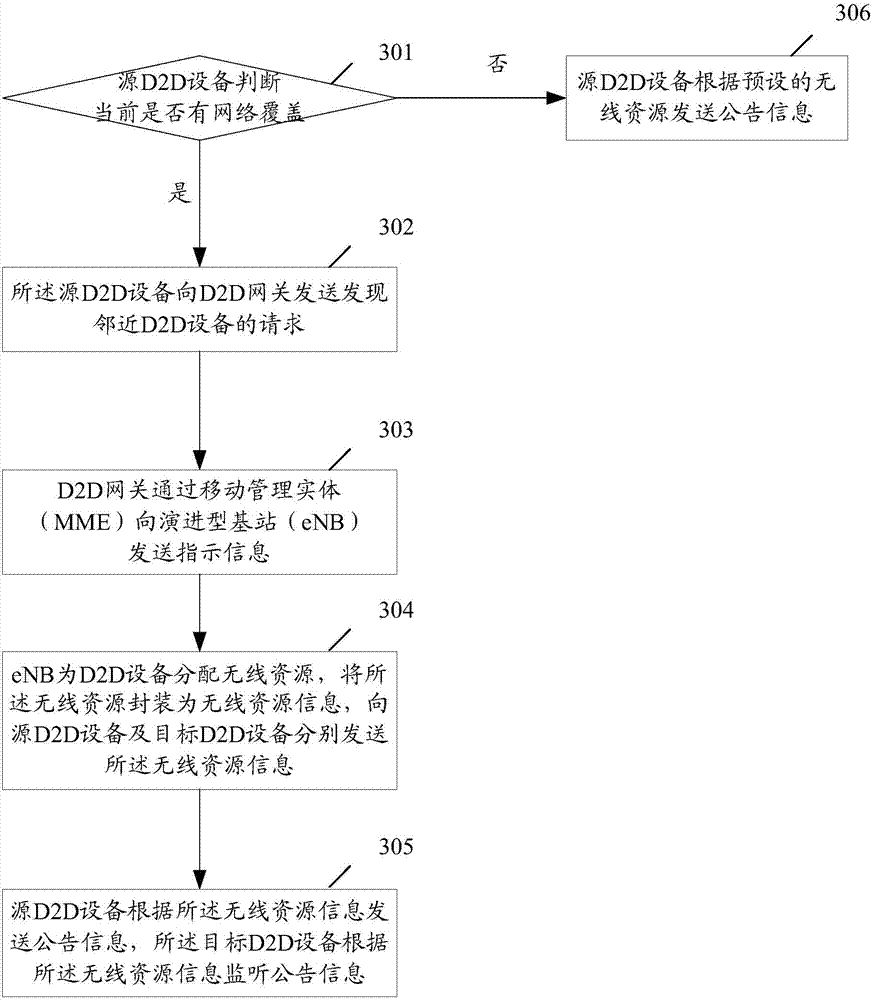

Method, device and system for finding D2D (Device to Device) equipment

InactiveCN104519550AReduce power consumptionImprove discovery efficiencyEnergy efficient ICTPower managementResource informationComputer science

Disclosed is a method for D2D device discovery. The method comprises: a source D2D device determines whether the coverage of a network exists at present, if so, sends a request for discovering an adjacent D2D device, receives wireless resource information, sends bulletin information according to the wireless resource information and monitors response information; and if not, sends bulletin information according to preset wireless resource information in the device and monitors response information. Also disclosed is a system and apparatus for D2D device discovery. The present invention can realize discovery between D2D devices, reduce power consumption of a D2D device, and improve discovery efficiency of a D2D device.

Owner:ZTE CORP

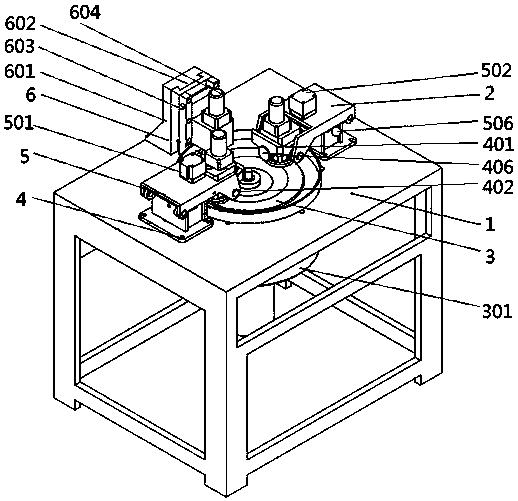

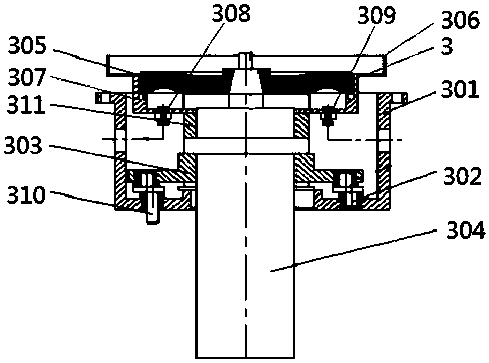

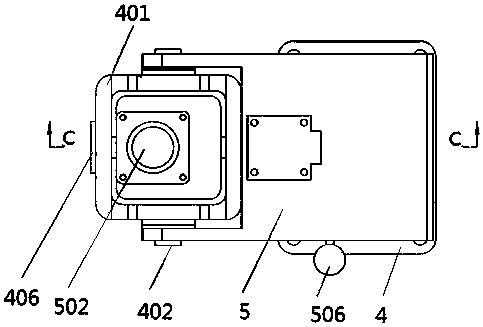

Two-workstation polycrystalline diamond compact polisher

PendingCN107855900AAvoid continuityGuaranteed polishing qualityGrinding machinesGrinding work supportsThermodynamicsPolishing

The invention discloses a two-workstation polycrystalline diamond compact polisher and solves the problem that existing polishers are unreliable in polishing quality and low in polishing efficiency due to unreasonable structure. The polisher comprises a polishing wheel base and a polycrystalline diamond compact clamp seat, a polishing wheel set is arranged in the polishing wheel base and comprisesa driving shell fixedly connected with the polishing wheel base, a plurality of eccentric shafts are arranged on the bottom side of the driving shell, the eccentric shafts are in transmission connection through an eccentric shaft seat, a polishing wheel driving shaft in planet motion is arranged in the eccentric shaft seat, a polishing wheel is fixedly arranged at the upper end of the polishing wheel driving shaft, a waterproof cooling shell is arranged on the periphery of the polishing wheel, a labyrinth sealing structure is arranged between the waterproof cooling shell and the polishing wheel, a closed circulating cooling cavity is formed between the waterproof cooling shell and the polishing wheel, and the polycrystalline diamond compact clamp seat has multiple degrees of freedom. Thetwo-workstation polycrystalline diamond compact polisher is novel in structure and convenient and reliable in polishing and has good popularization and application prospect.

Owner:ZHONGYUAN ENGINEERING COLLEGE

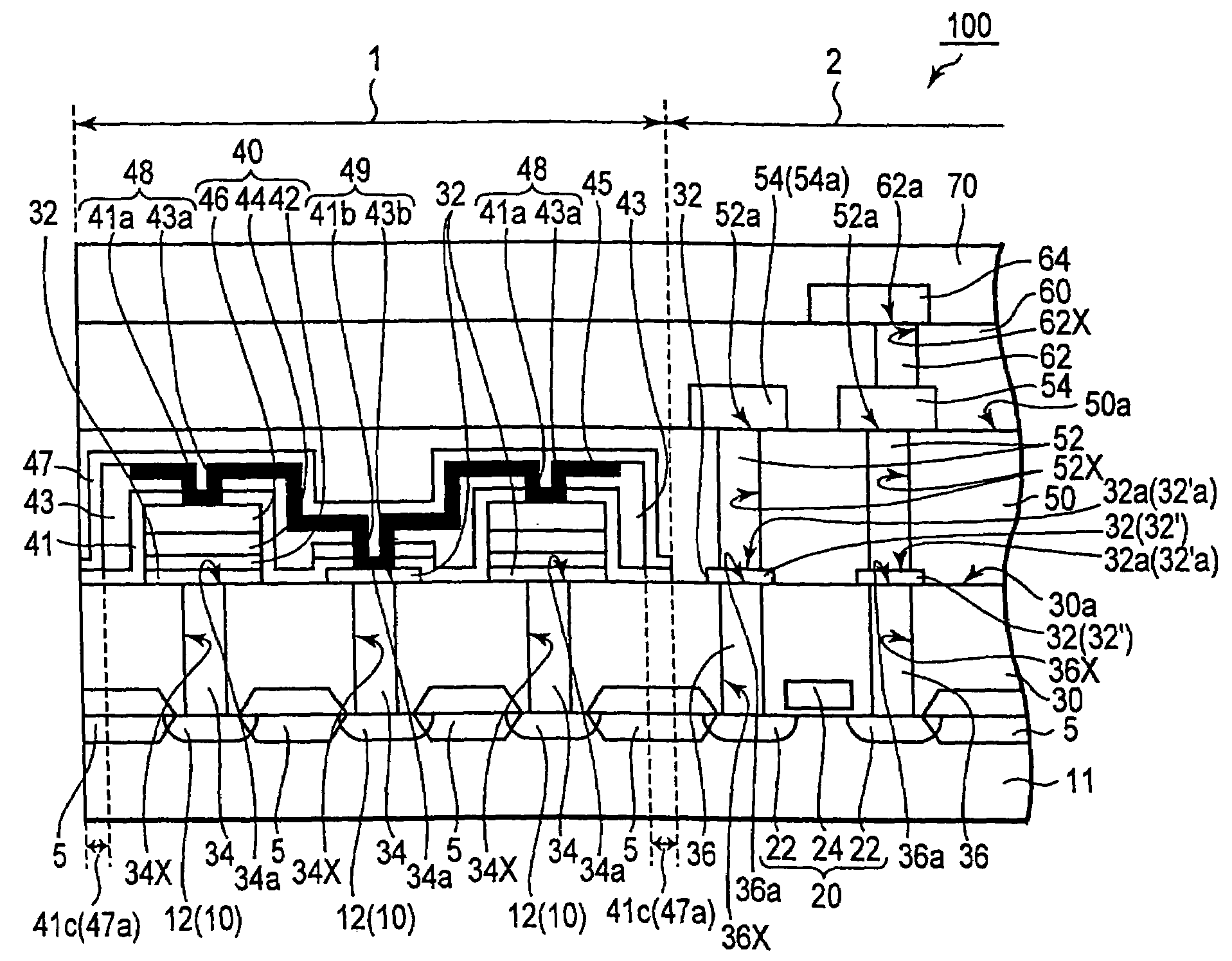

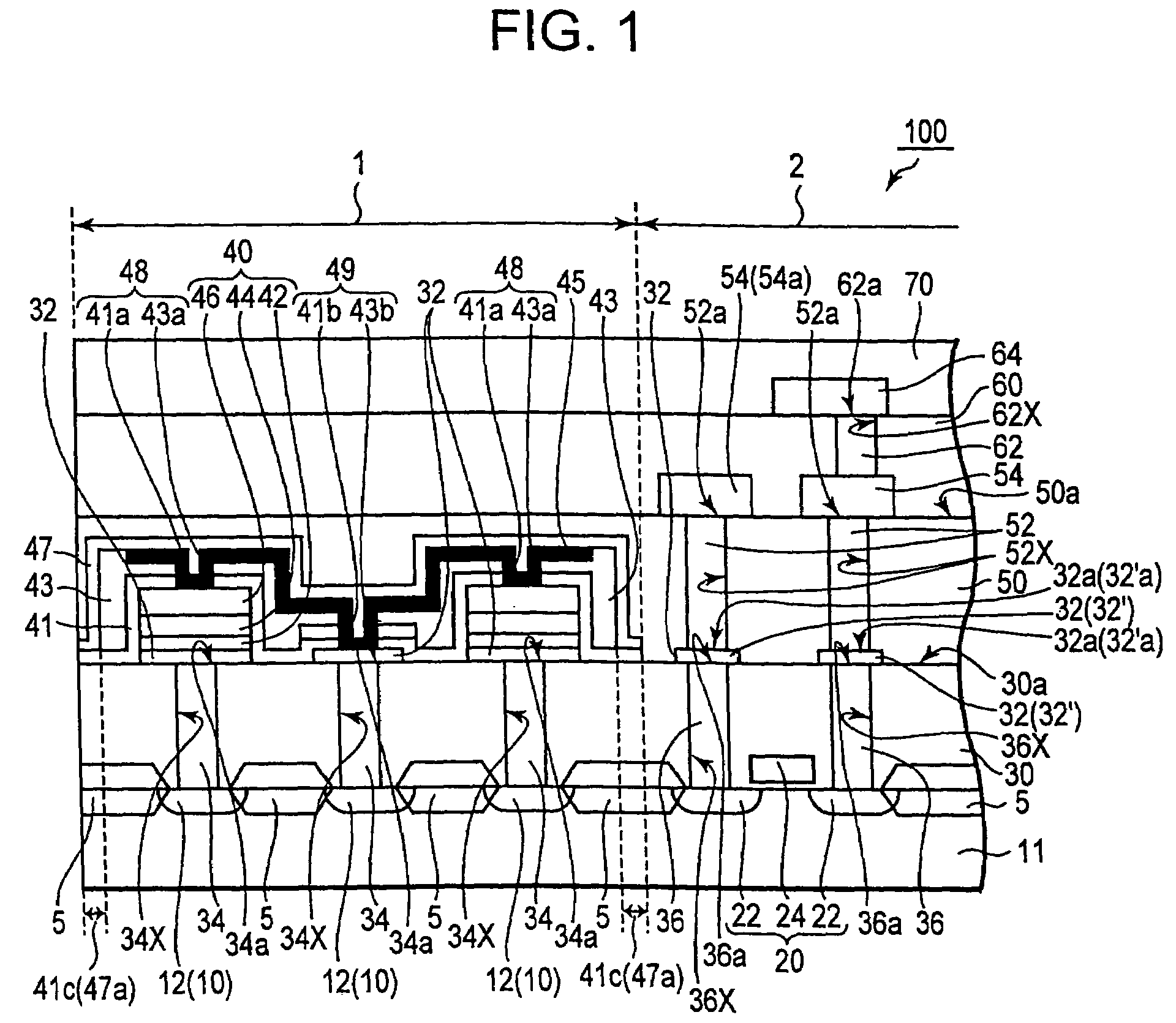

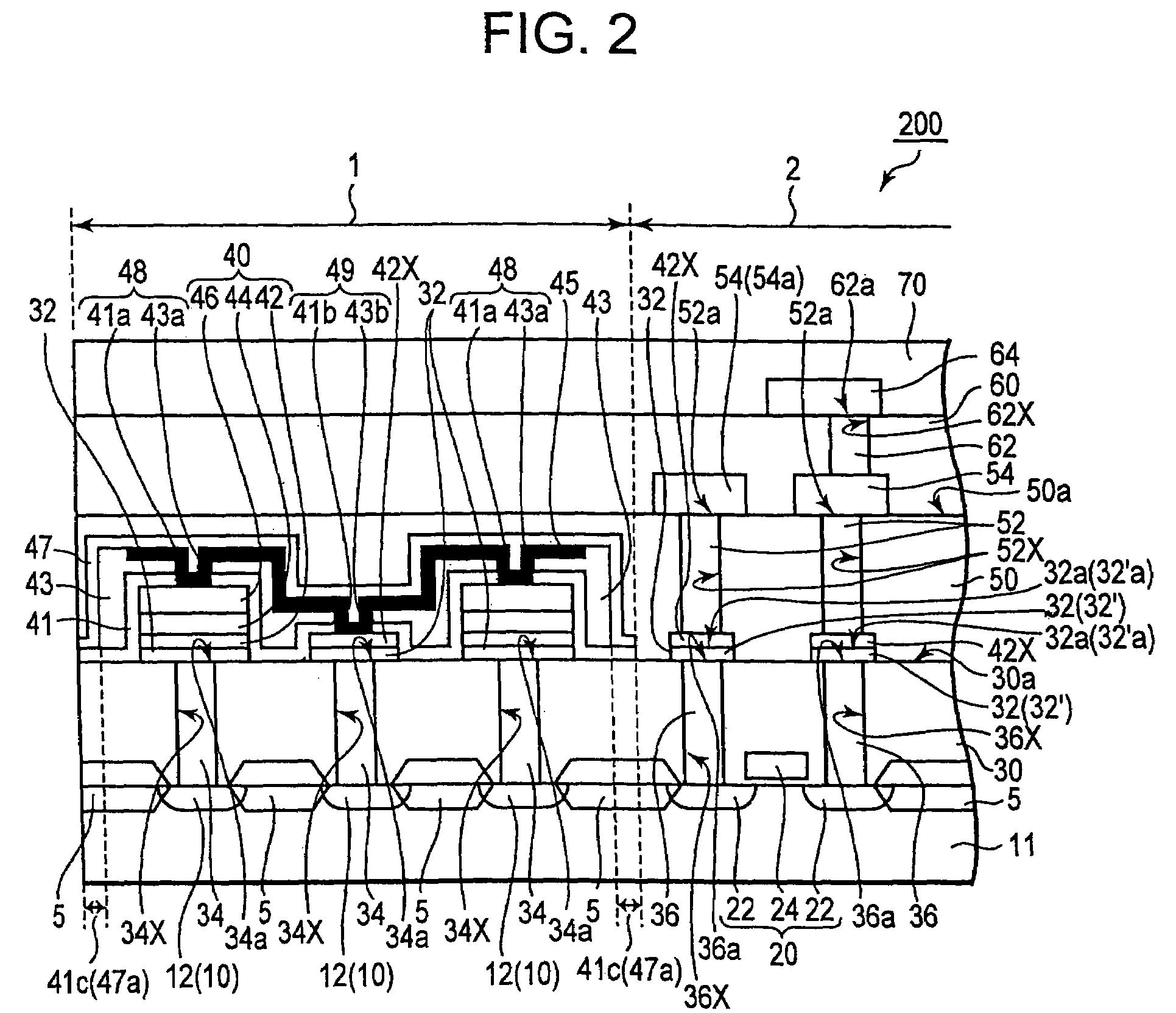

Ferroelectric memory device and manufacturing method thereof

InactiveUS7576377B2Reduced characteristicsAvoid makingTransistorSolid-state devicesHydrogenSemiconductor

A ferroelectric memory device includes a semiconductor substrate, a first insulating film, a plurality of first and second plugs which extend through the first insulating film, conductive hydrogen barrier films, ferroelectric capacitor structural bodies, a first insulating hydrogen barrier film provided so as to cover the ferroelectric capacitor structural bodies, a second insulating film, local wirings extending on the second insulating film, a second insulating hydrogen barrier film which covers the local wirings, a third insulating film, third plugs which extend through the third insulating film so as to connect to their corresponding conductive hydrogen barrier films, and a first wiring layer extending on the third insulating film.

Owner:LAPIS SEMICON CO LTD

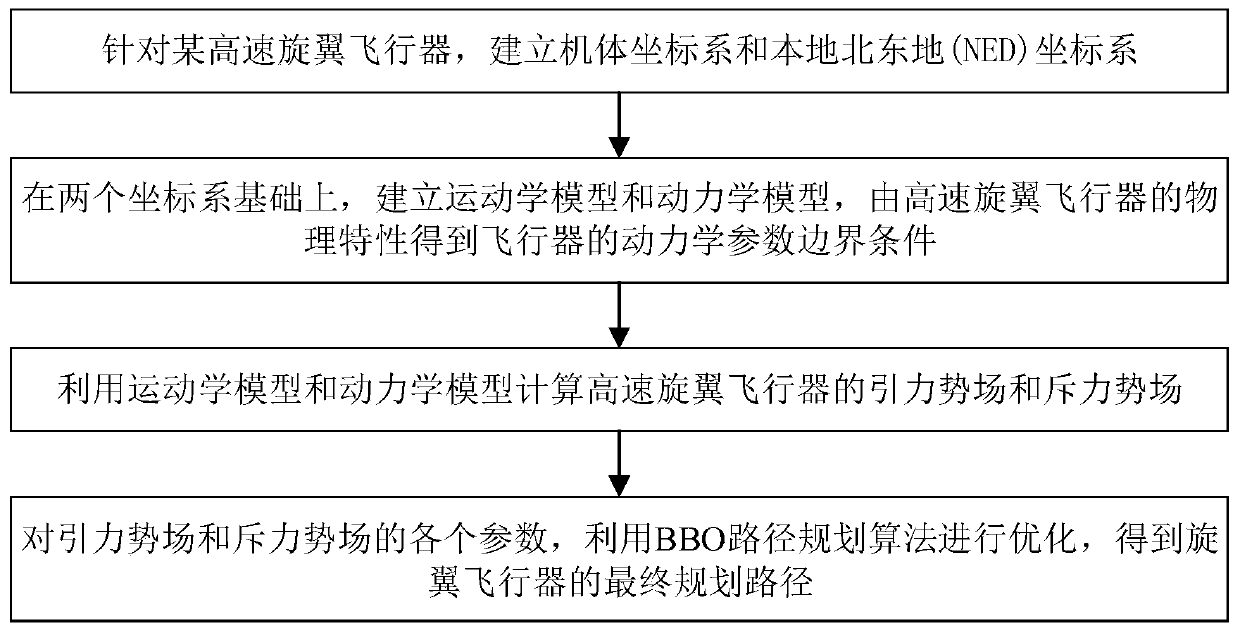

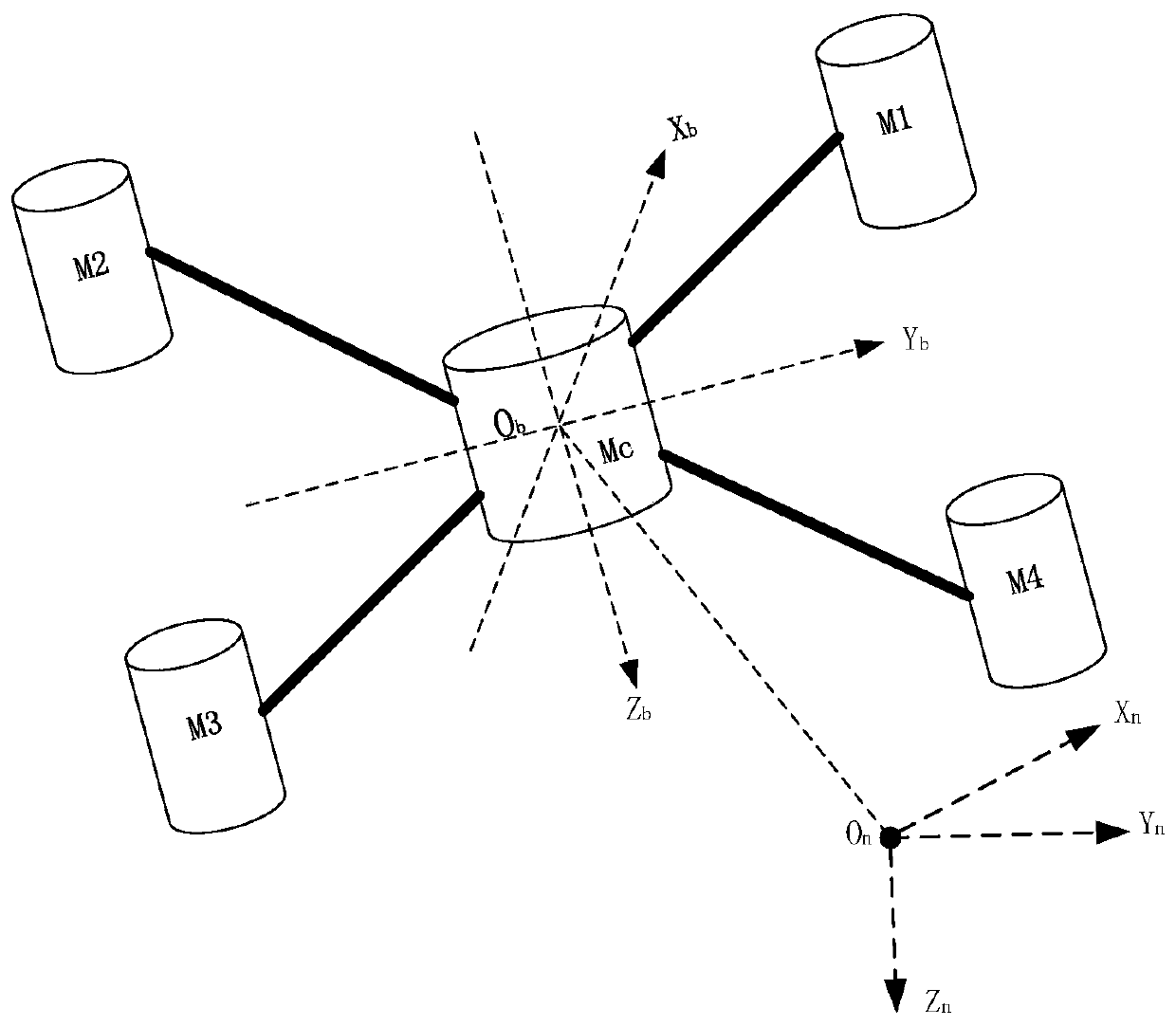

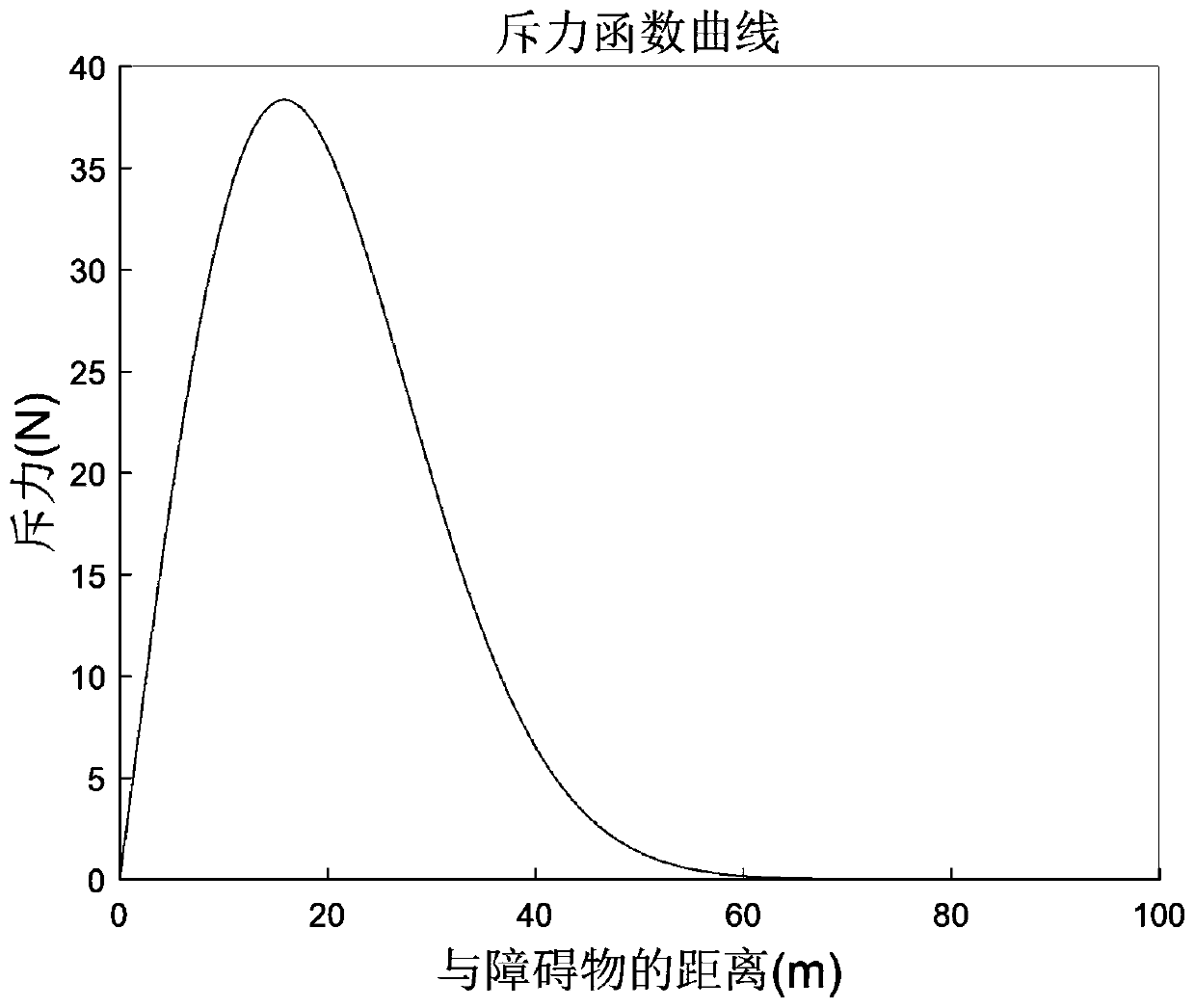

High-speed rotor aircraft path planning method based on BBO optimized artificial potential field

ActiveCN109870906ASimple structureFast operationVehicle position/course/altitude controlAdaptive controlMassive gravitySimulation

The invention discloses a high-speed rotor aircraft path planning method based on a BBO optimized artificial potential field, and belongs to the field of aircraft intelligent task planning. The methodcomprises the following steps of establishing a body coordinate system and a local north-east ground coordinate system for a certain high-speed rotor aircraft, establishing a kinematic model and a kinetic model on the basis of two coordinate systems, and obtaining kinetic parameter boundary conditions of the aircraft through the physical characteristics of the high-speed rotor aircraft; computinga gravitational potential field and a repulsive potential field of the high-speed rotor aircraft by utilizing the kinematic model and the kinetic model; optimizing parameters of the gravitational potential field and the repulsive potential field through a BBO path planning algorithm in order to obtain a final planning path of the rotor aircraft. The algorithm disclosed by the invention is simplein structure and fast in operation speed, the requirements for on-line real-time computation can be well met, the path distance is reduced, the average speed of the aircraft is improved and is close to the limit design speed of the aircraft, and the route planning performance is remarkably improved.

Owner:BEIHANG UNIV

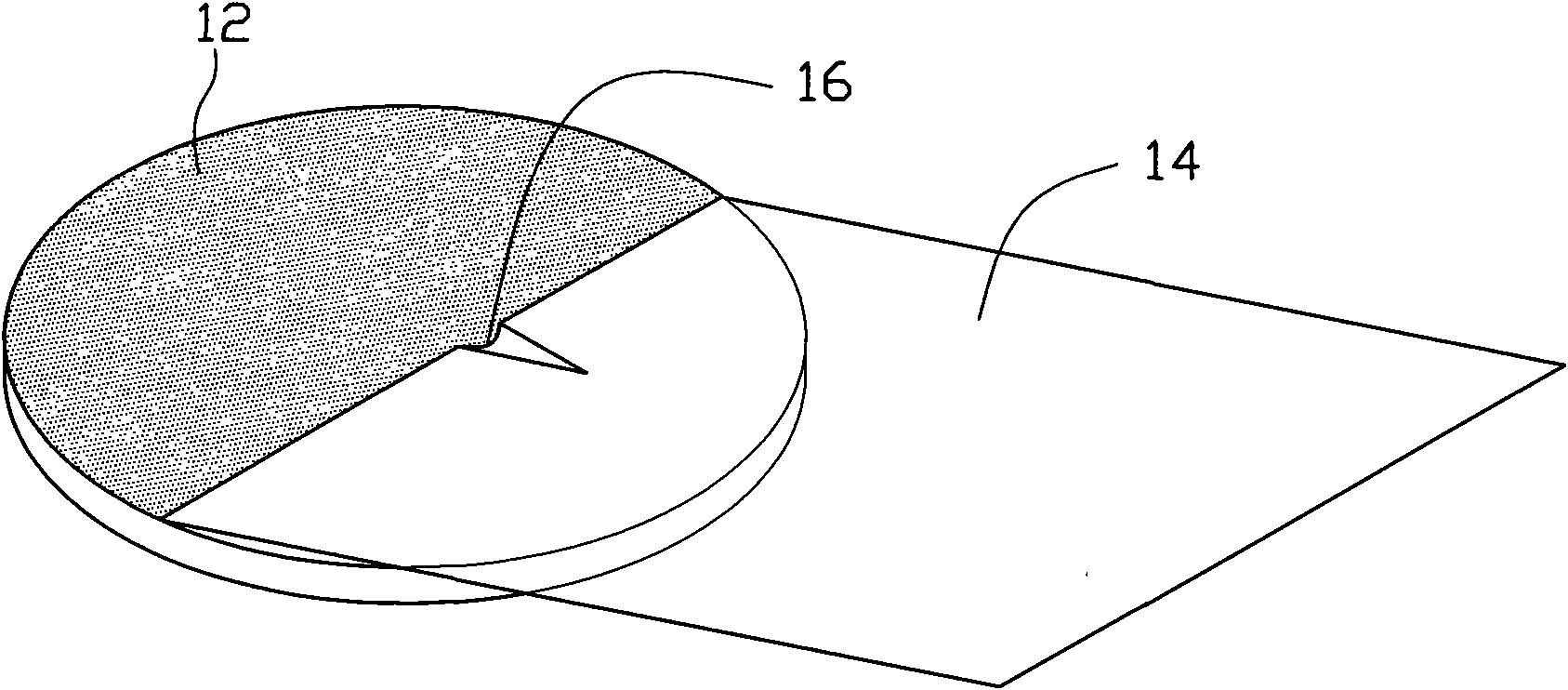

Satellite navigation receiver and method for switching between real-time kinematic mode and precise positioning mode

A receiver (12 or 30) or method uses an offset vector to provide seamless switching between a real-time kinematic (RTK) mode and a precise positioning mode (e.g., precise point positioning, PPP) mode.An offset module (130) or data processor (159) is arranged to determine an offset between precise position and the RTK position estimate. Upon loss of the RTK signal, switching to a precise positionmode is based on a last available RTK position (e.g., if the precise position mode is converged on a position solution with resolved ambiguities of the carrier phase), wherein the next precise position estimate is compensated by the offset or reference frame bias to avoid a jump or discontinuity in the next precise position estimate.

Owner:DEERE & CO

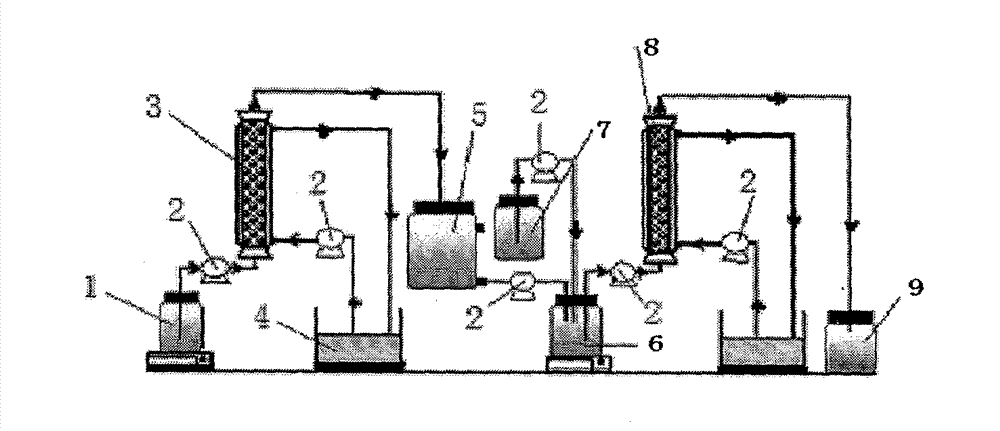

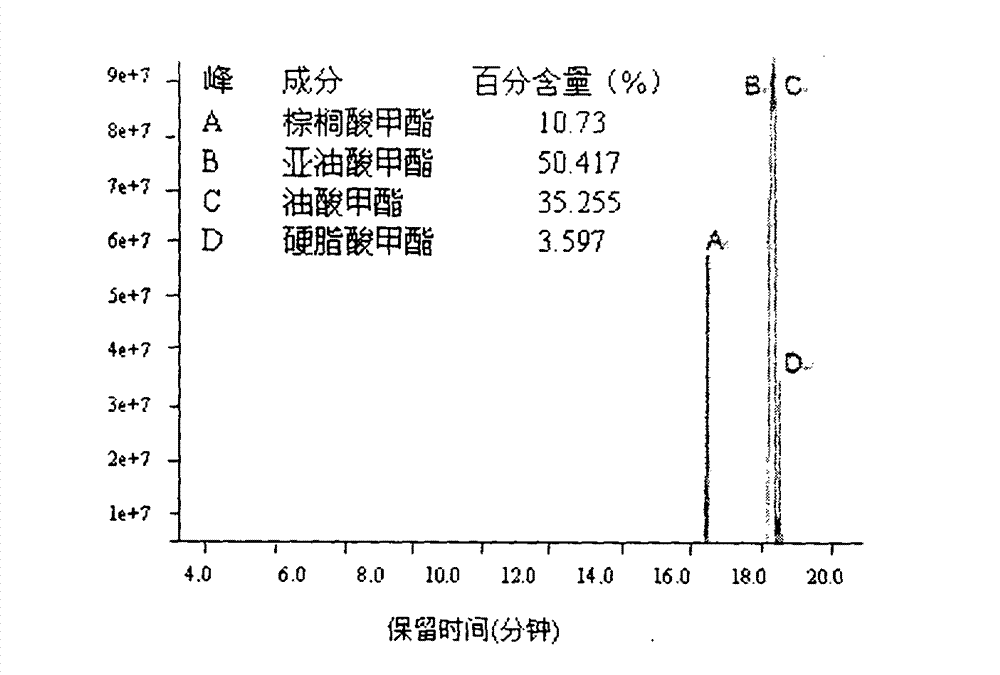

Continuous preparation method of biodiesel

InactiveCN102816645AAchieve separationRealize the transesterification reactionFatty acid esterificationBiofuelsEnvironmental resistanceOil and grease

The invention relates to a continuous preparation method of biodiesel, which uses waste animal and vegetable grease as the raw material and mainly comprises the following steps: (1) removing impurities and moisture in the raw material; (2) performing continuous esterification reaction in a cation exchange resin fixed bed reactor; (3) separating the esterification product; and (4) performing continuous ester exchange reaction and separation in an anion exchange resin fixed bed reactor. The invention overcomes the problems of severe equipment corrosion, difficult product separation, serious environmental pollution caused by waste acid liquid, failure to realize continuous preparation and the like in the homogeneous catalysis process, is low in cost, high in yield and friendly to environment, and has important market application prospects.

Owner:TIANJIN POLYTECHNIC UNIV

Preparation method of jujube health salt

The invention discloses a preparation method of jujube health salt. The preparation method comprises the following steps: 1) jujube pre-treatment, 2) supercritical CO2 extraction: extracting jujube powder by using supercritical CO2 to obtain jujube functional components; and 3) recrystallization: dissolving the jujube functional components, resulting from the step 2, of B, C, and D in a pure water solution at a normal temperature and a normal pressure, adding and dissolving sodium chloride till the solution is saturated, and performing vacuum distillation to obtain jujube health salt crystals. The preparation method of jujube health salt is provided in the invention, and jujube extractives are added into salt, so that a health function of jujubes can be maximally developed, and people's health is prompted while using salt for achieving a purpose of seasoning.

Owner:YULIN SALT IND CO LTD CNSG

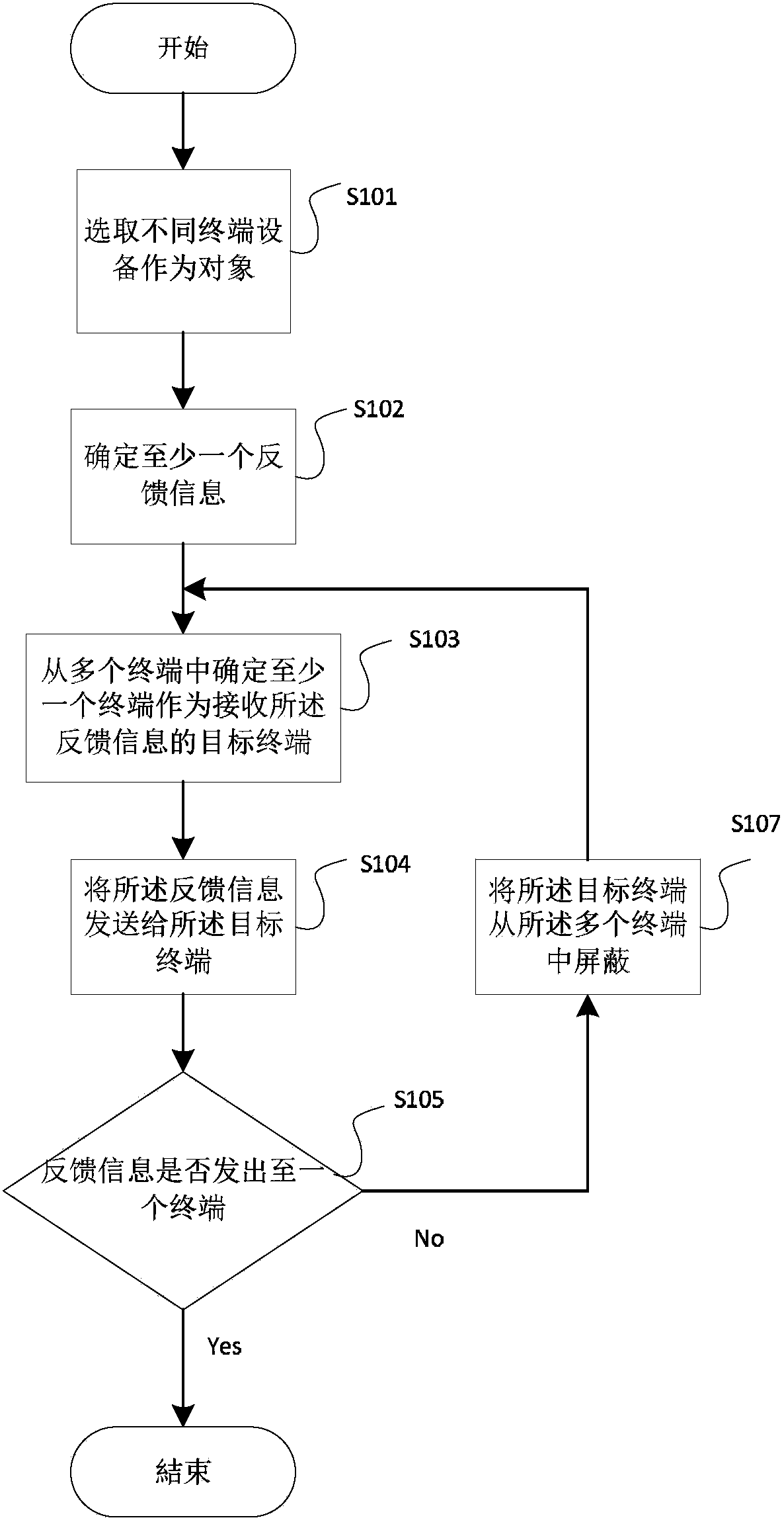

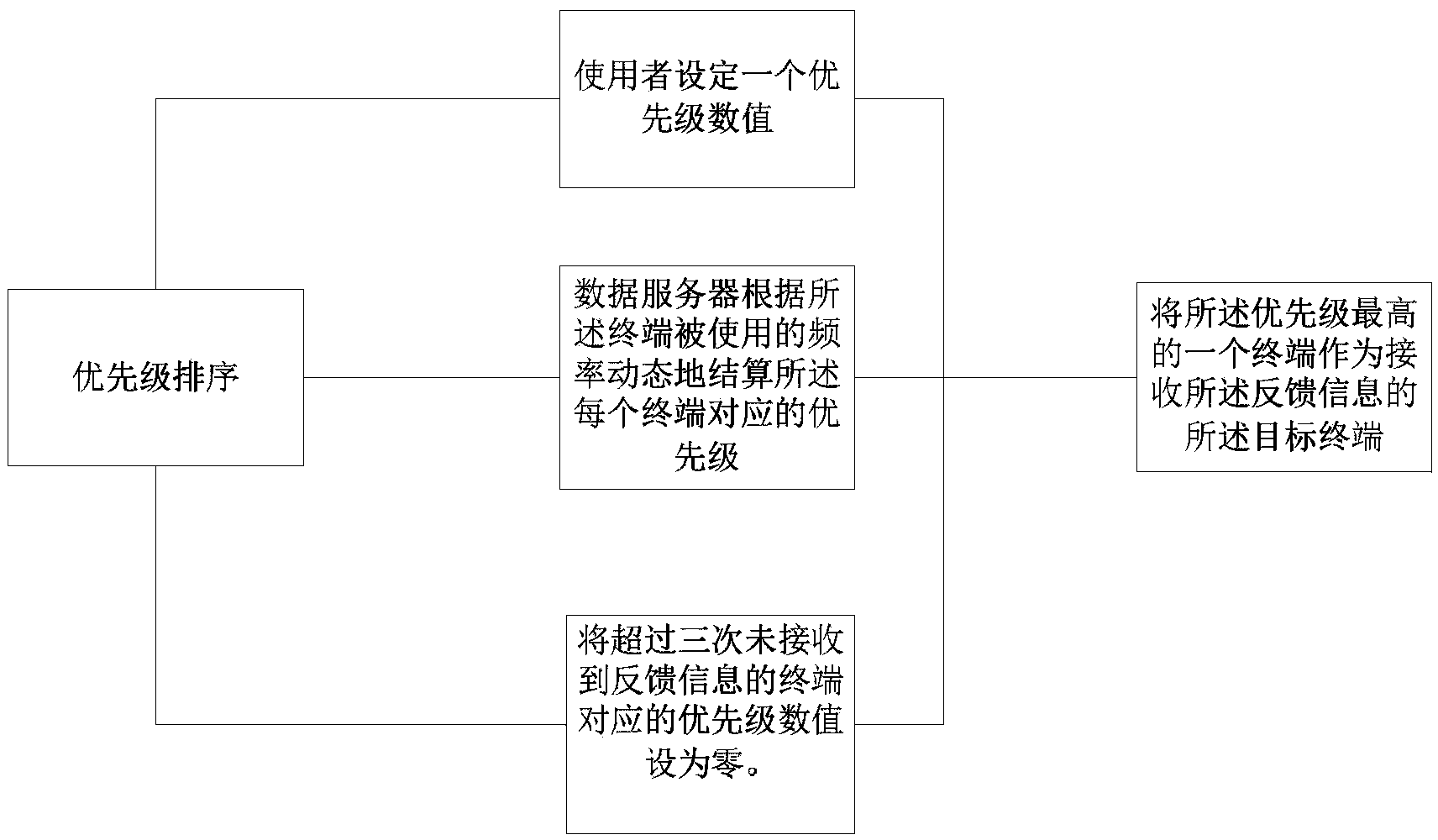

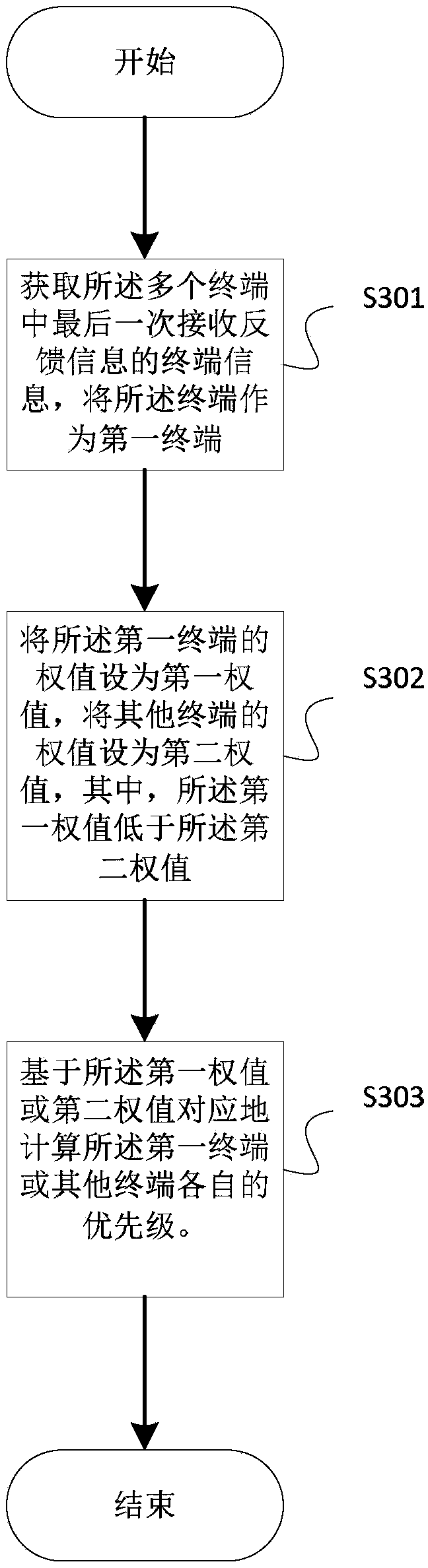

Control method and device for controlling multi-terminal intelligent feedback in information processing system

ActiveCN103955846AAvoid duplicationAvoid continuityTransmissionMarketingInformation processingContinuous feedback

The invention provides a control method for controlling multi-terminal intelligent feedback in an information processing system. The method includes the steps that a, at least one piece of feedback information is determined; b, at least one of multiple terminals is determined to serve as a target terminal for receiving the feedback information, wherein the terminals have relevance and can preferably receive the same feedback information; c, the feedback information is sent to the target terminal. The invention further provides a control device for controlling the multi-terminal intelligent feedback in the information processing system. According to the technical scheme, interaction among multiple terminal devices held by the same user can be achieved, or interaction among multiple terminal devices held by multiple users with the same attribute can be achieved. Through selective feedback of the same feedback information or a series of feedback information, continuous feedback can be obtained by the user on the different terminals, and the problem of feedback information repetition or discontinuity is avoided.

Owner:上海亿动信息技术有限公司

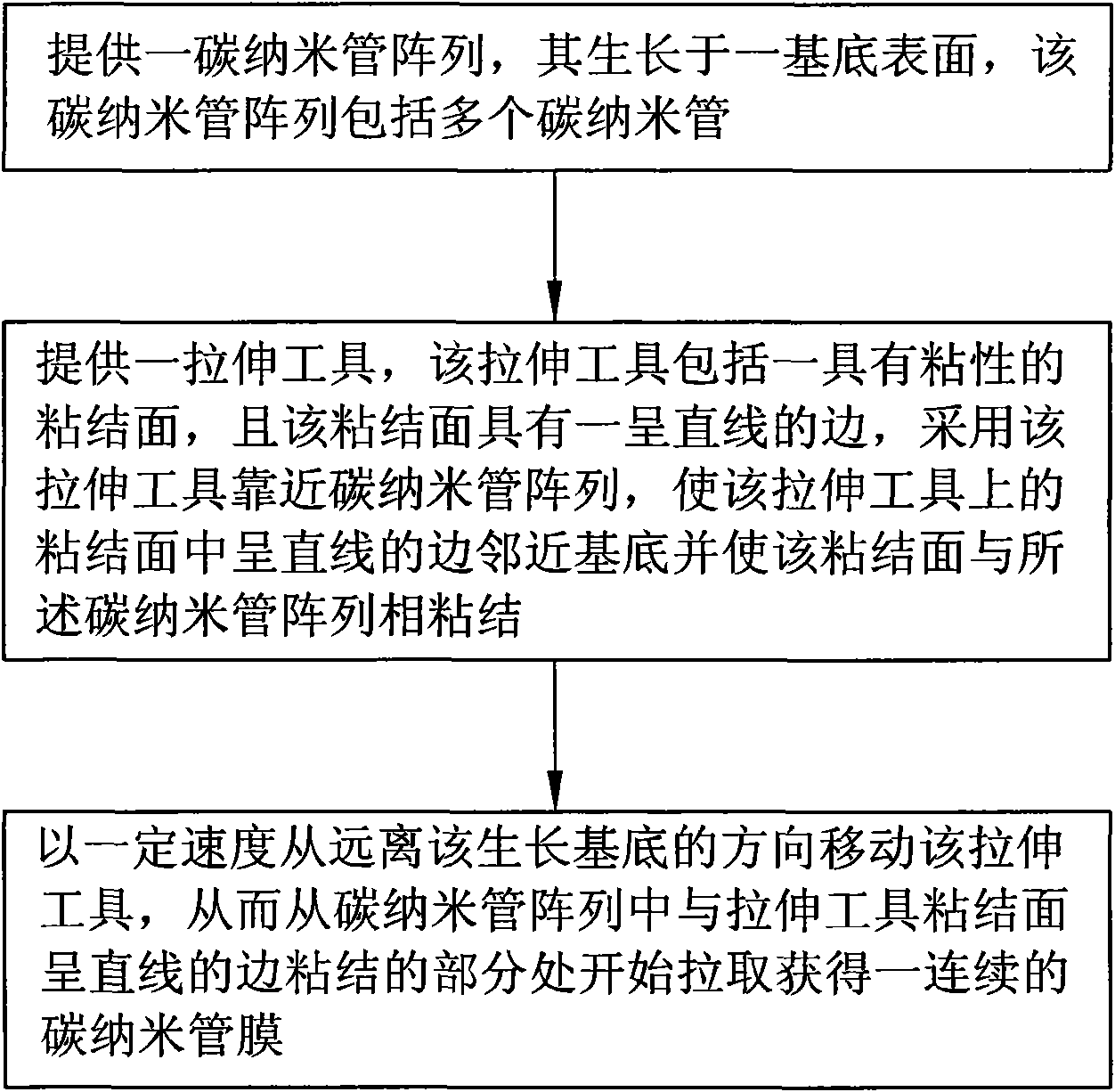

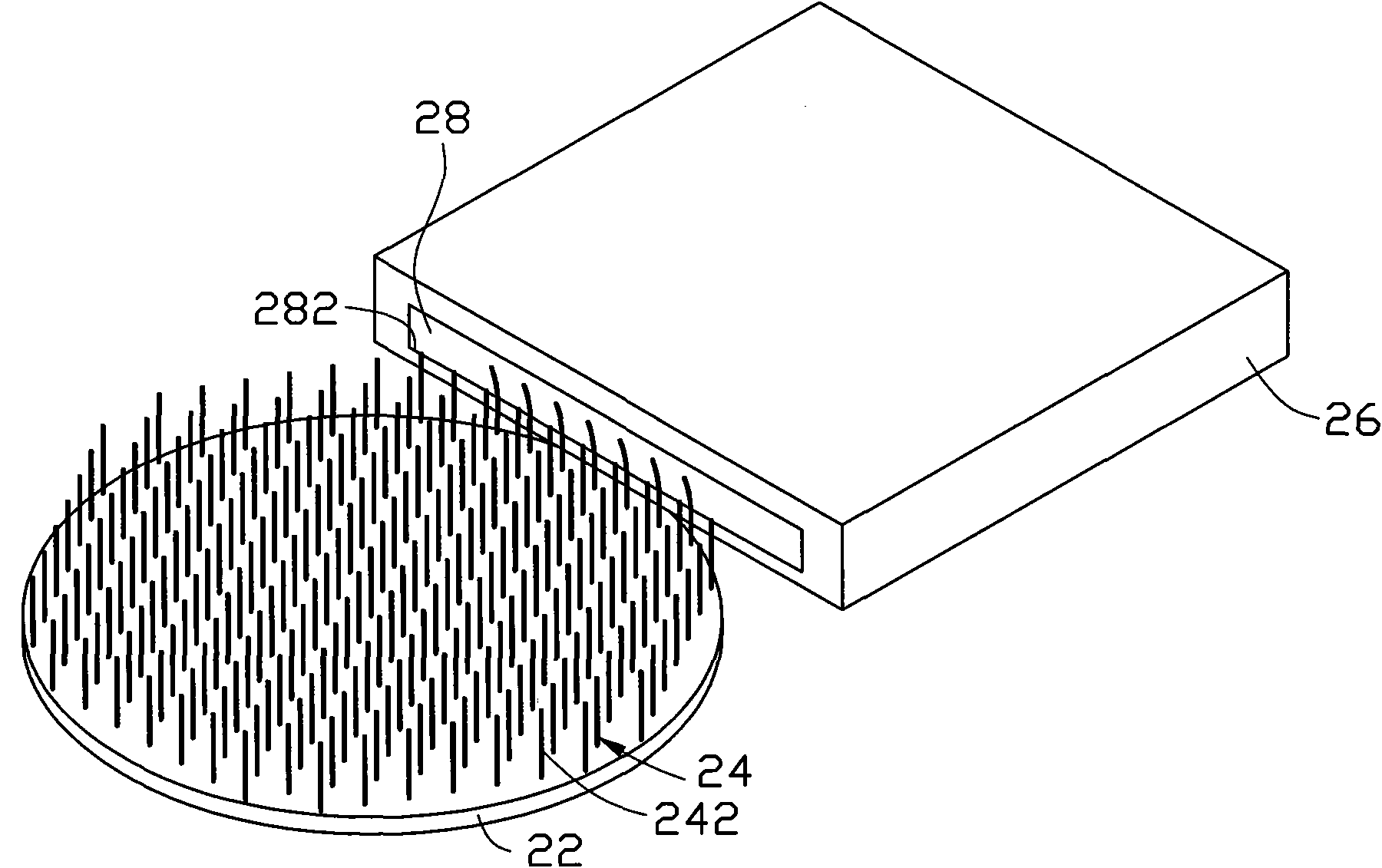

Preparation method of carbon nano tube film

ActiveCN101870465AInhibition thicknessAvoid continuityMaterial nanotechnologyAligned nanotubesCarbon nanotubeNano tube

The invention relates to a preparation method of a carbon nano tube film, which comprises the following steps: providing a carbon nano tube array, wherein the carbon nano tube array grows on the surface of a substrate and comprises a plurality of carbon nano tubes; providing a stretching tool, wherein the stretching tool comprises a viscous bonding surface which is provided with a straight edge; moving the straight edge of the bonding surface of the stretching tool to be close to the substrate to bond the bonding surface with the carbon nano tube array; and moving the stretching tool in a direction away from the growing substrate at a certain speed to obtain a continuous carbon nano tube film by pulling the carbon nano tube array from the part thereof bonded with the straight side of the bonding surface of the stretching tool. By using the preparation method, one continuous carbon nano tube film can be obtained.

Owner:TSINGHUA UNIV +1

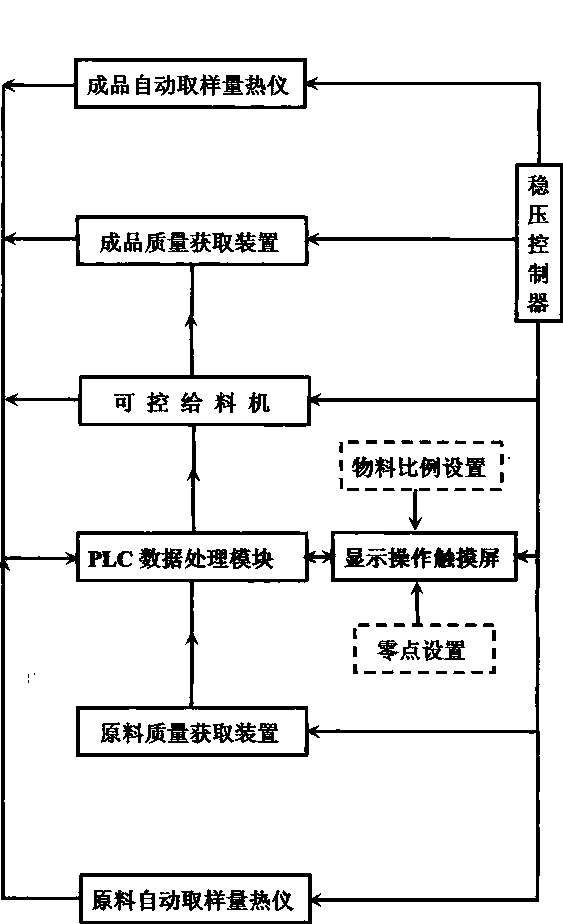

Automatic and continuous batching system

InactiveCN103657510AAvoid continuityAvoid efficiencyMixer accessoriesProgrammable logic controllerProcess engineering

The invention discloses an automatic and continuous batching system which is applicable to a plurality of processes of industrial production of solid materials mixed with materials with certain heat values, wherein the automatic and continuous batching system comprises an automatic raw material sampling calorimeter, a raw material quality acquiring device, a PLC (Programmable Logic Controller) data processing module, a controllable feeder, a finished product quality acquiring device, an automatic finished product sampling calorimeter, a constant-pressure controller and a display operation touch screen, wherein two parameter settings including a material proportion setting and a zero point setting are designed on the display operation touch screen. The automatic and continuous batching system has the advantages that due to the system, full-automatic and high-precision continuous batching in a batching link in the industrial production process is realized; the defects of discontinuous container measurement feeding and low efficiency are avoided; meanwhile, the error in manual operation in the links of producing and batching is eliminated; the influences on the batching precision caused due to a plurality of factors are avoided; the feeding precision is greatly improved; the materials of production enterprises are saved; the automatic and continuous batching system protects the environment; the batching labor is reduced; the capacity is improved.

Owner:CHENGDU VONXAN AUTOMATION SCI & TECH

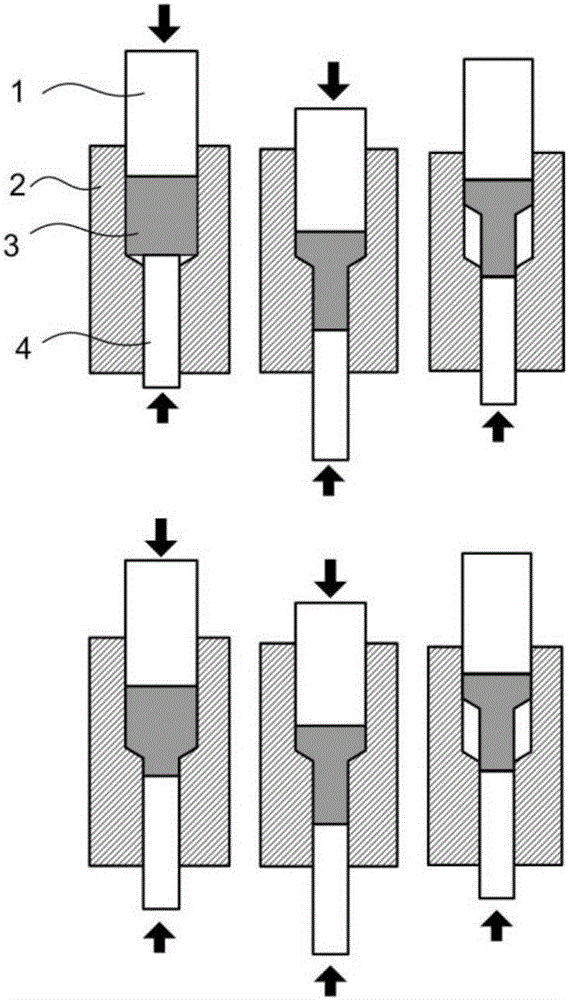

Ball grinding-diameter shrinkage reciprocating extruding method for circular curing of waste titanium chips

InactiveCN106392085ASuppress coarseningEasy to operateRecycling and recovery technologiesGrain treatmentsRoom temperatureSteel ball

The invention proposes a ball grinding-diameter shrinkage reciprocating extruding method for circular curing of waste titanium chips. The method comprises the following steps: (1) the titanium chips are recovered and preheated; (2) the ball grinding is performed for the titanium chips; (3) the titanium chips are covered and packed; (4) the covered and packed titanium chips are coldly extruded at room temperature; (5) diameter shrinkage reciprocating extrusion high-temperature curing: a mold is heated to reach 570-600 DEG C; an upper punch applies the extruding force of 0.9-1.0 GPa; a lower punch applies the back pressure of -200 MPa; in the same pair of reciprocating extrusion molds, the room-temperature cold extruded titanium chips perform the diameter shrinkage extrusion, the ejection, the compression upsetting and the secondary diameter shrinkage extrusion deformation; and (6) quenching: massive titanium obtained in the diameter shrinkage reciprocating extrusion step is quenched and cooled to reach the room temperature through a water cooling mode. Through ball milling, oxides on the surfaces of the chips are totally crushed under collision and grinding of steel balls; and on the basis, the high-temperature extrusion curing is performed to cure the titanium chips as large-size massive titanium.

Owner:SHANGHAI DIANJI UNIV

Ultra-narrow gap TIG (tungsten inert gas) hot wire welding method

InactiveCN104942410ATime-consuming to solveAvoid continuityArc welding apparatusWorking environmentEconomic benefits

The invention provides an ultra-narrow gap TIG (tungsten inert gas) hot wire welding method. The method comprises steps as follows: S1, a groove of a window plate test plate is subjected to machining and assembly work before welding; S2, the window plate test plate is preheated; S3, backing-welding weld bead configuration for the ultra-narrow gap TIG hot wire welding is performed; S4, backing welding parameters are set, and backing welding is performed. According to the ultra-narrow gap TIG hot wire welding method, the problem that the backing welding is difficult and consumes long time during ultra-narrow gap TIG hot wire welding of the window plate is emphatically solved, and the welding defects of incomplete side wall fusion, discontinuity of weld beads, poor weld seam formation and the like generated in the welding process easily are overcome. Therefore, high-efficiency and high-quality ultra-narrow gap backing welding of the window plate is realized; the welding quality and the welding efficiency are improved, the working environment is improved, the preheating frequency is reduced, the production cost is reduced, and high use value and economic benefits are achieved.

Owner:SHANGHAI ZHENHUA HEAVY IND

LED package and LED package mounting structure

InactiveUS8716741B2Improve fatigue lifeAvoid continuityDischarge tube luminescnet screensFinal product manufactureEngineeringElectrical and Electronics engineering

A highly reliable LED package mounting structure which can realize improvement in solder fatigue life at low costs is provided. An LED package has a light-emitting surface which is perpendicular to a mounting surface of a circuit board, comprises connection terminal portions on the side face or on the side face and the bottom face of the package, and is joined with the circuit board by soldering via the connection terminal portion. Furthermore, the shape of the solder is optimized by defining the relative position relation between the end of an electrode on the central side of the LED package on the bottom face of an LED package body and the end of a component mounting pad on the circuit board.

Owner:MAXELL HLDG LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com