Patents

Literature

447results about "Aligned nanotubes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

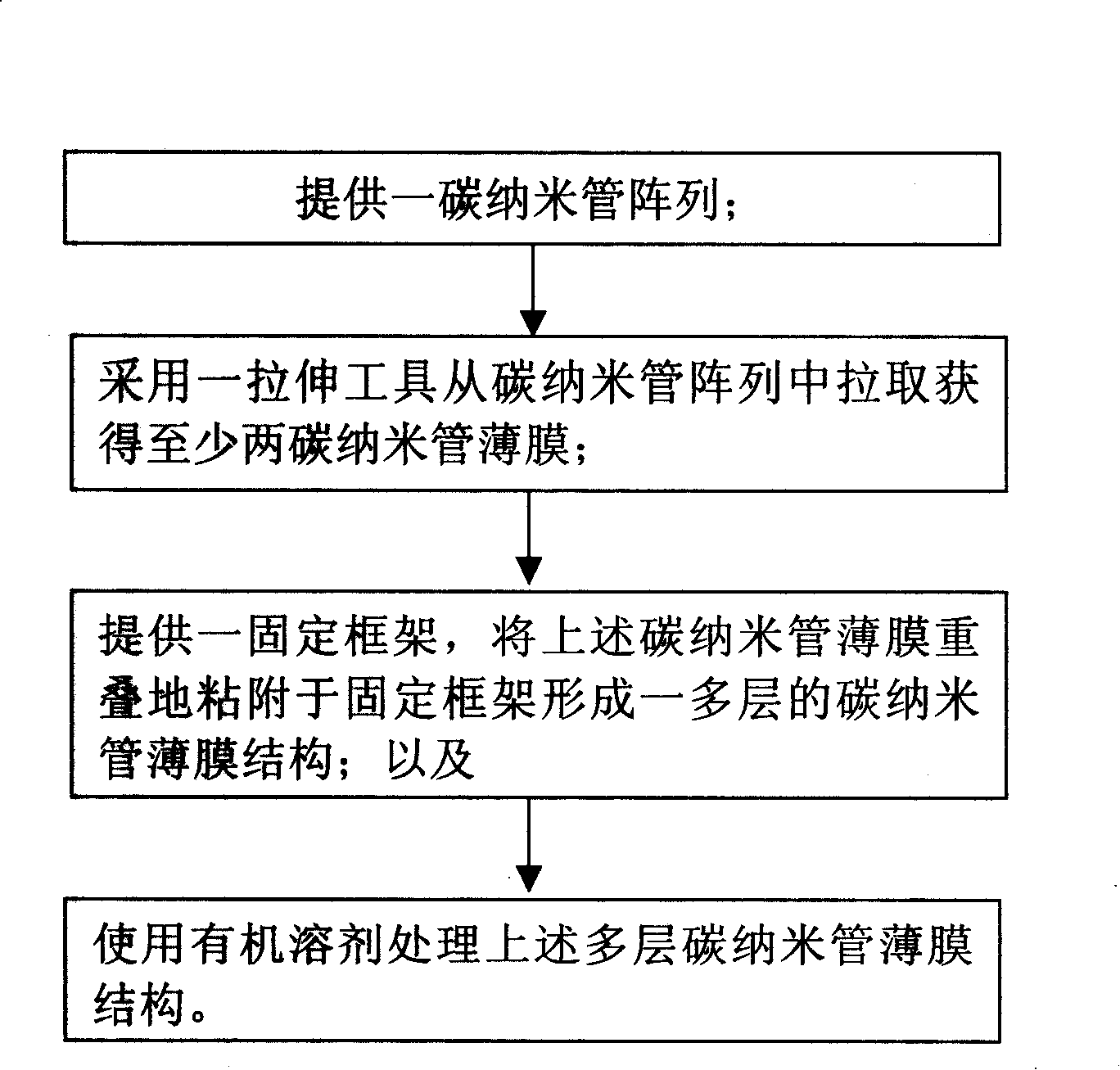

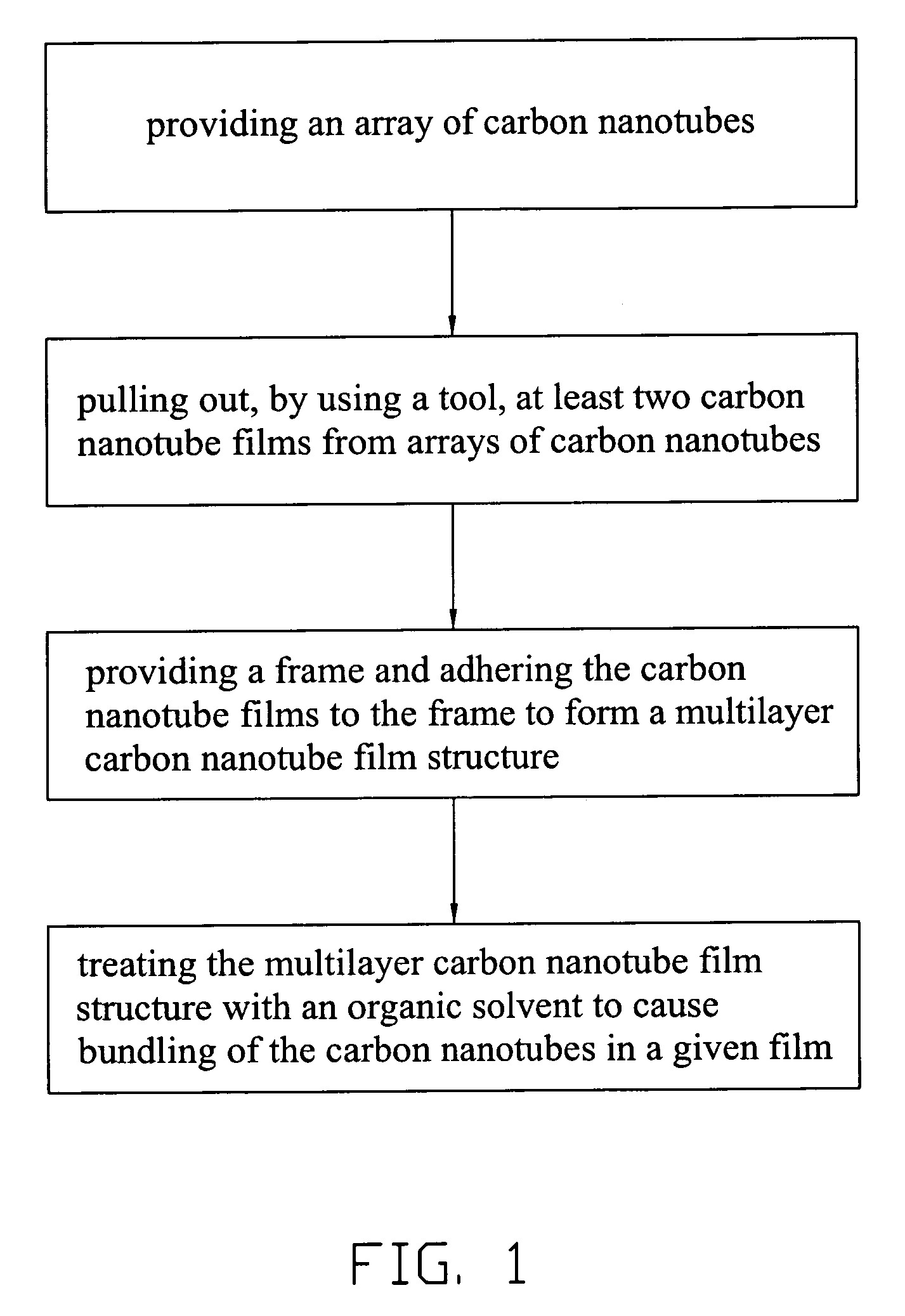

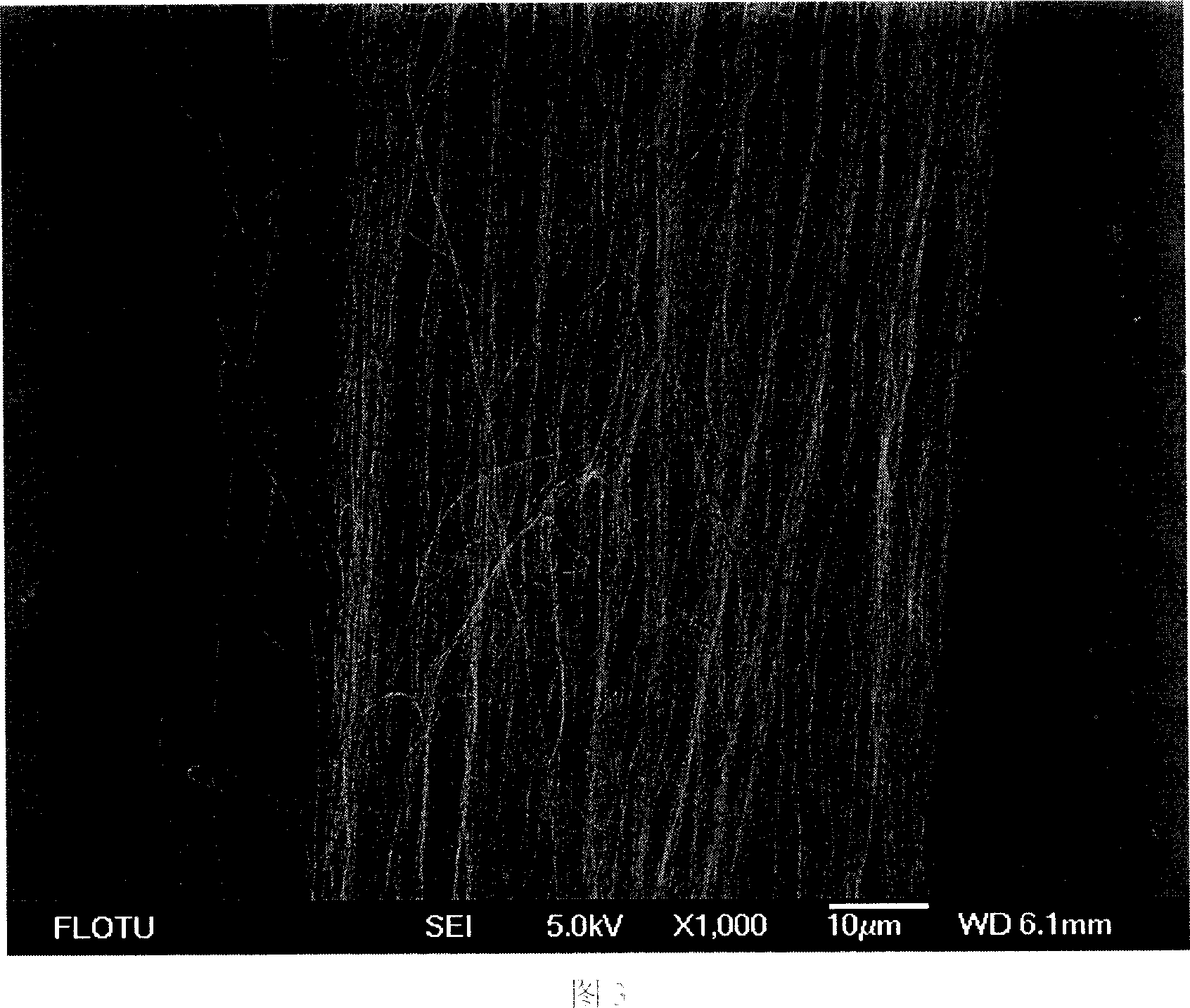

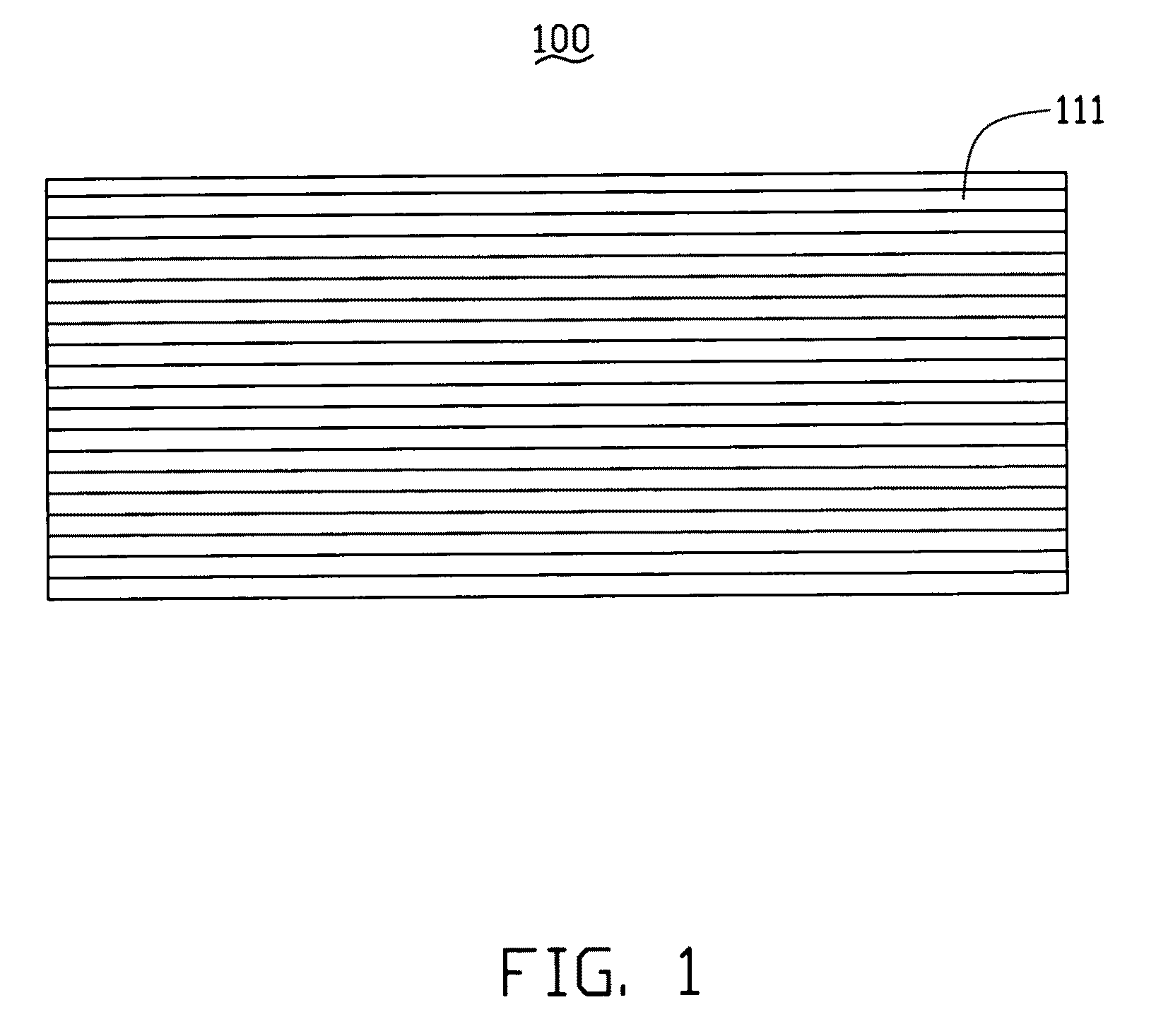

Carbon nano-tube thin film structure and preparation method thereof

ActiveCN101239712ASmall surface to volume ratioNon stickyMaterial nanotechnologyLamination ancillary operationsOrganic solventFixed frame

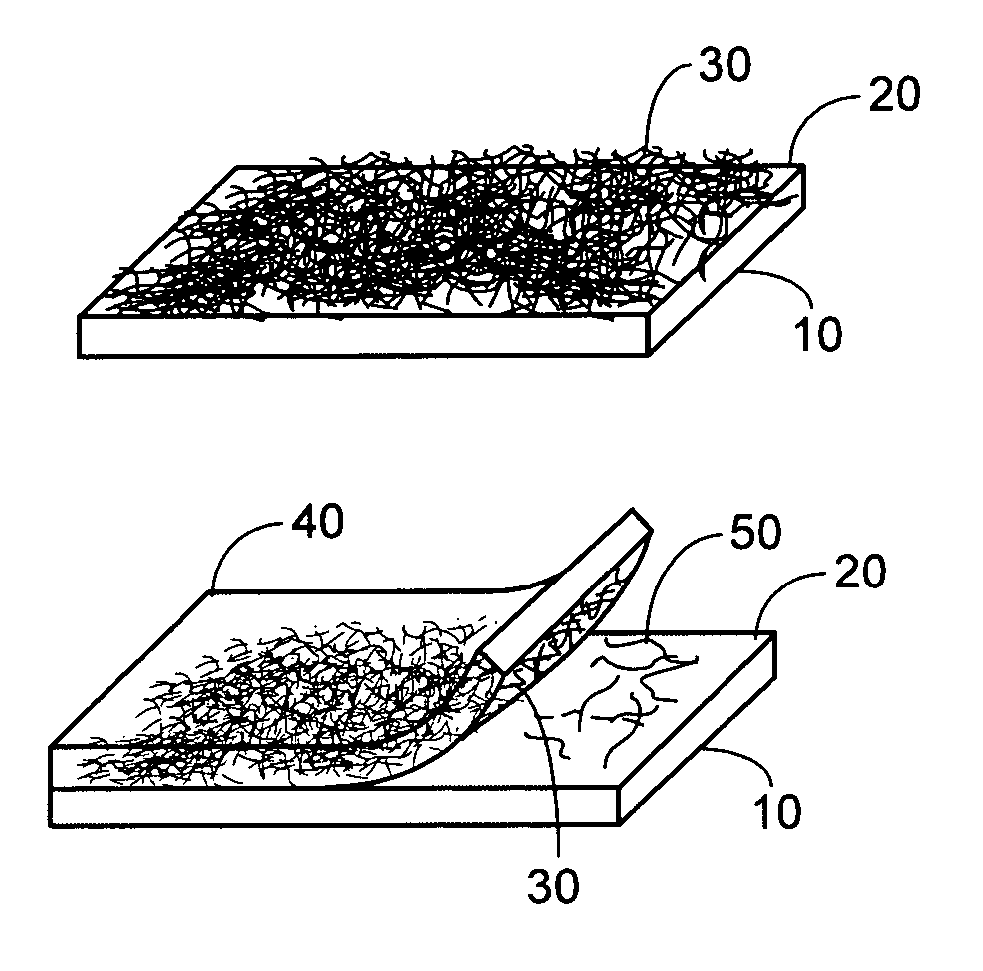

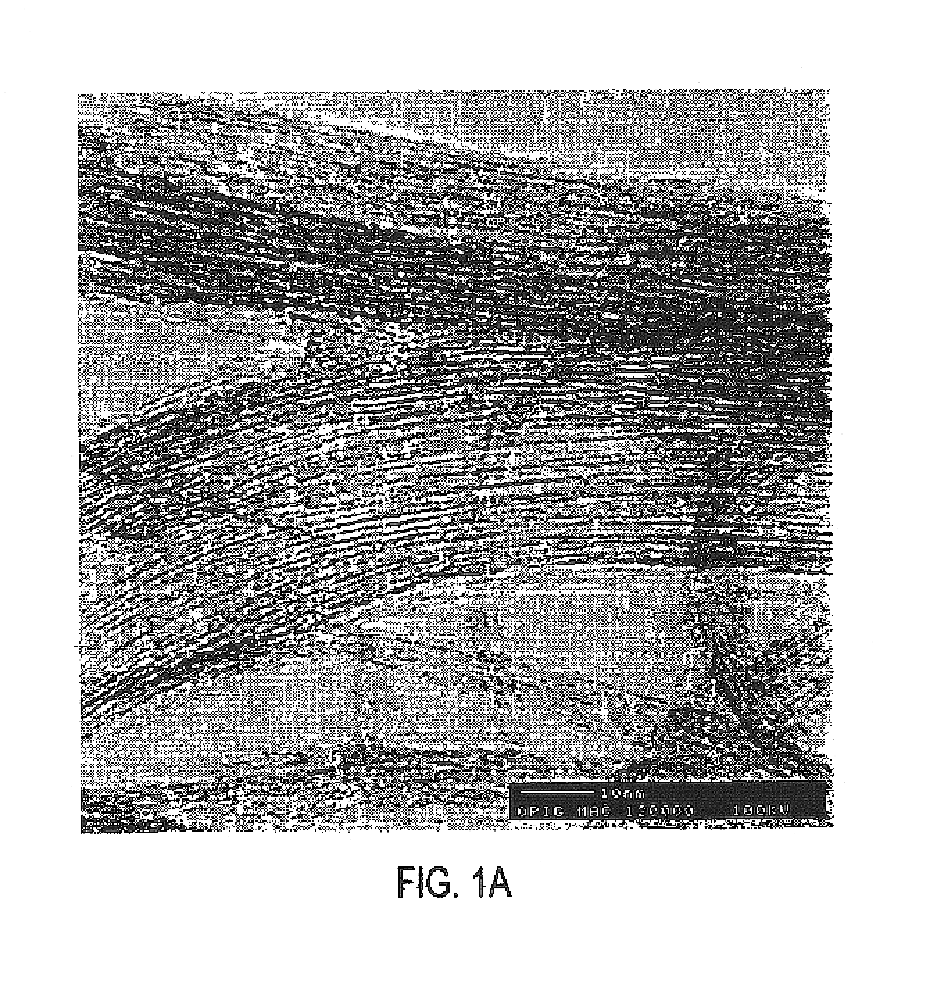

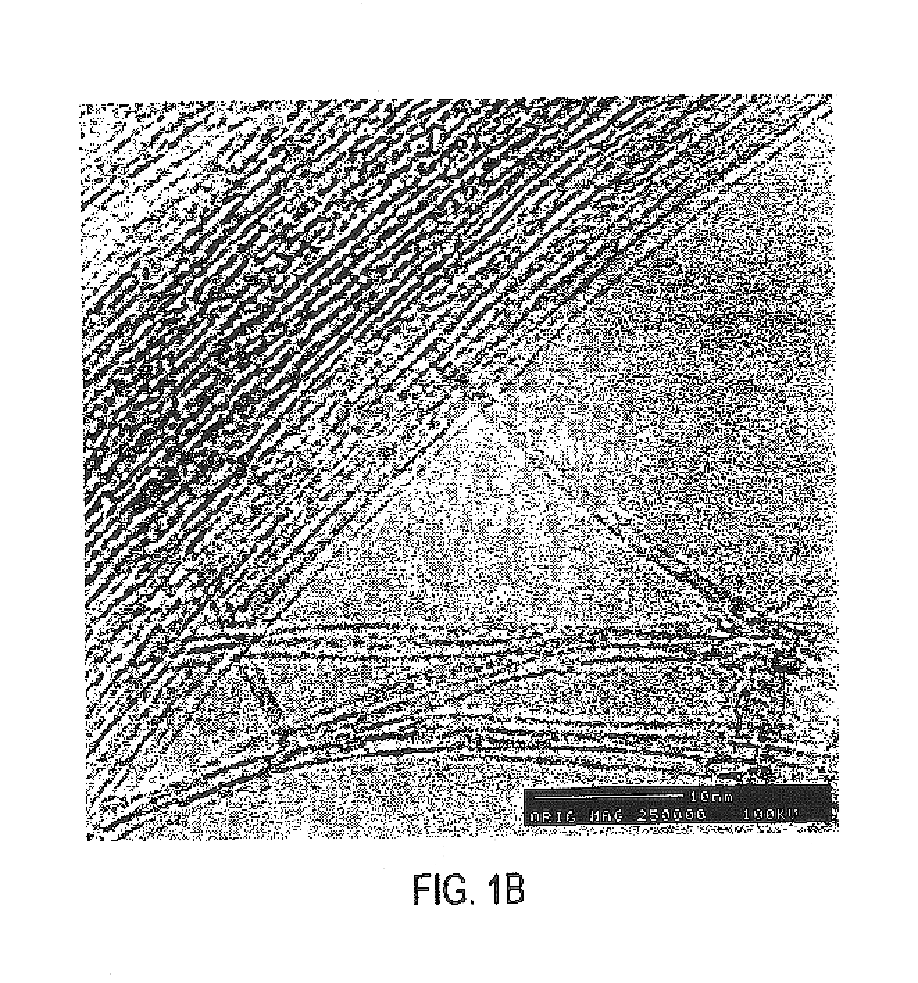

The present invention provides a preparing method of carbon nanotube film structure, including following steps: providing a carbon nanotube array; adopting a pulling tool to acquire at least two carbon nanotube films from the carbon nanotube array; providing a fixed frame, forming a multiple-layer carbon nanotube film structure by overlap adhereing the carbon nanotube film in the fixed frame; and treating the multiple-layer carbon nanotube film by an organic solvent. The carbon nanotube film structure prepared by the method includes at least two layers overlapped and cross-over installed carbon nanotube film, which includes multiple carbon nanotube bundle end to end and arranged in the direction, the multiple-layer carbon nanotube film further includes millipore crosswise formed by multiple carbon nanotube bundles.

Owner:TSINGHUA UNIV +1

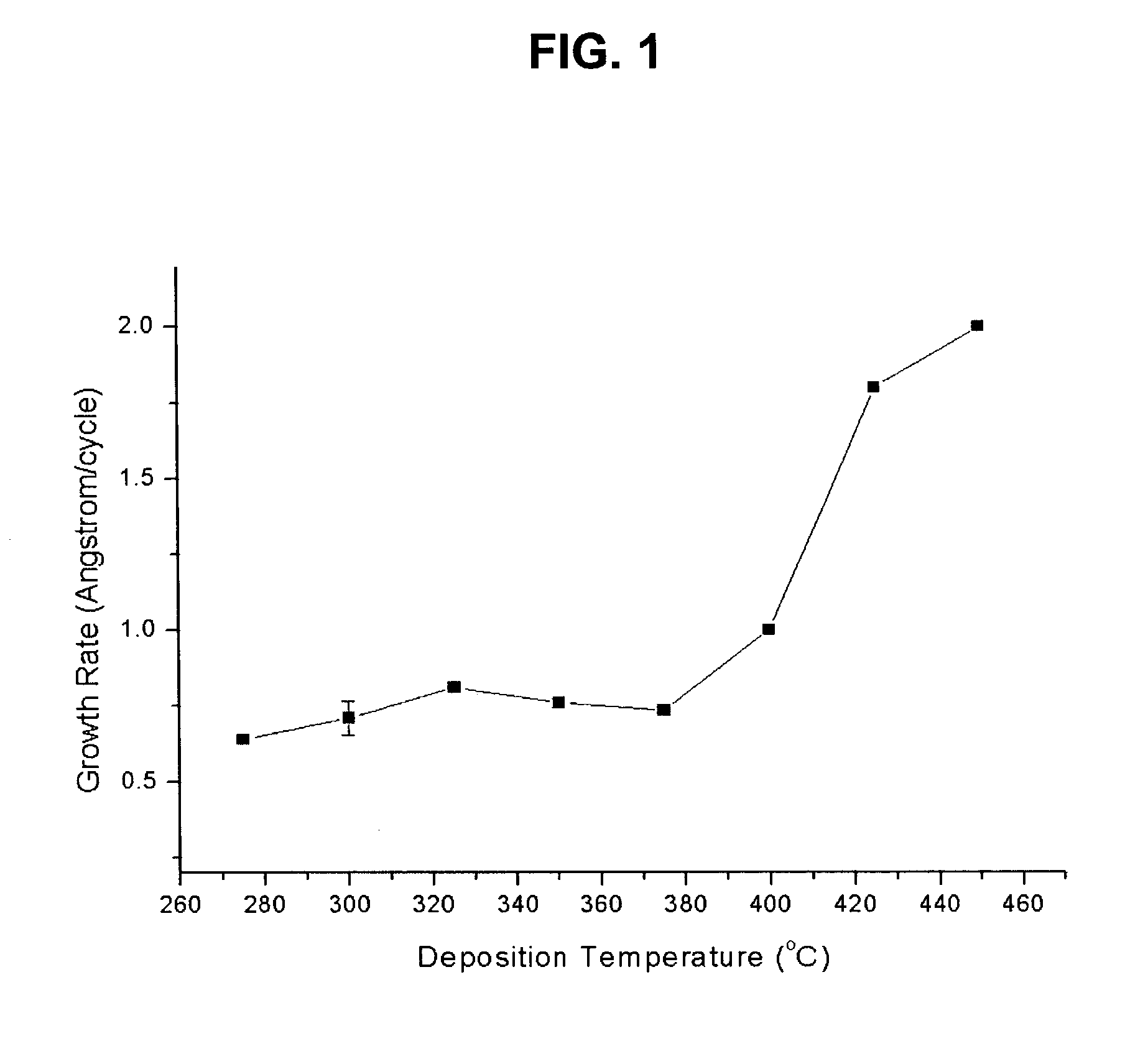

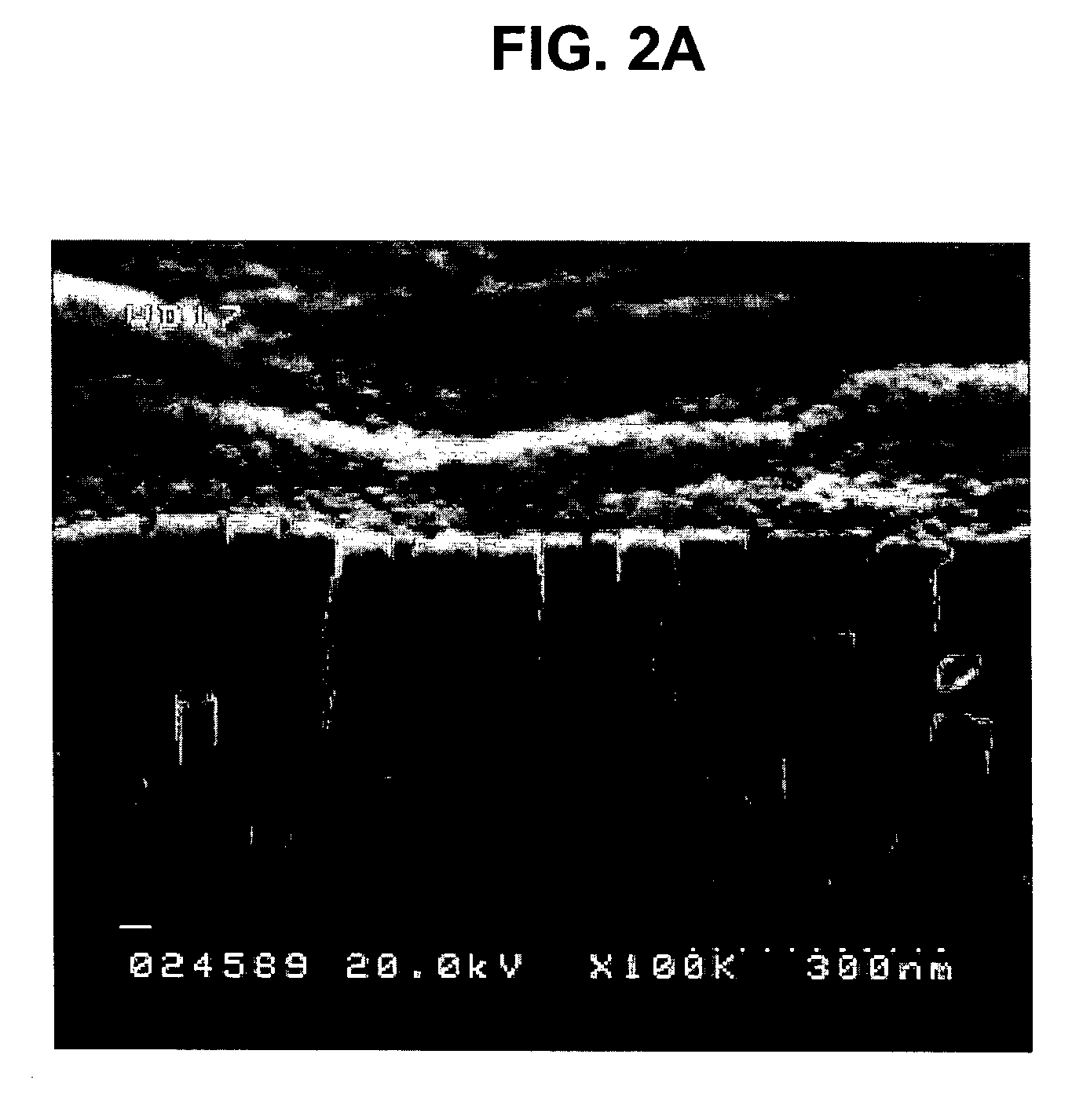

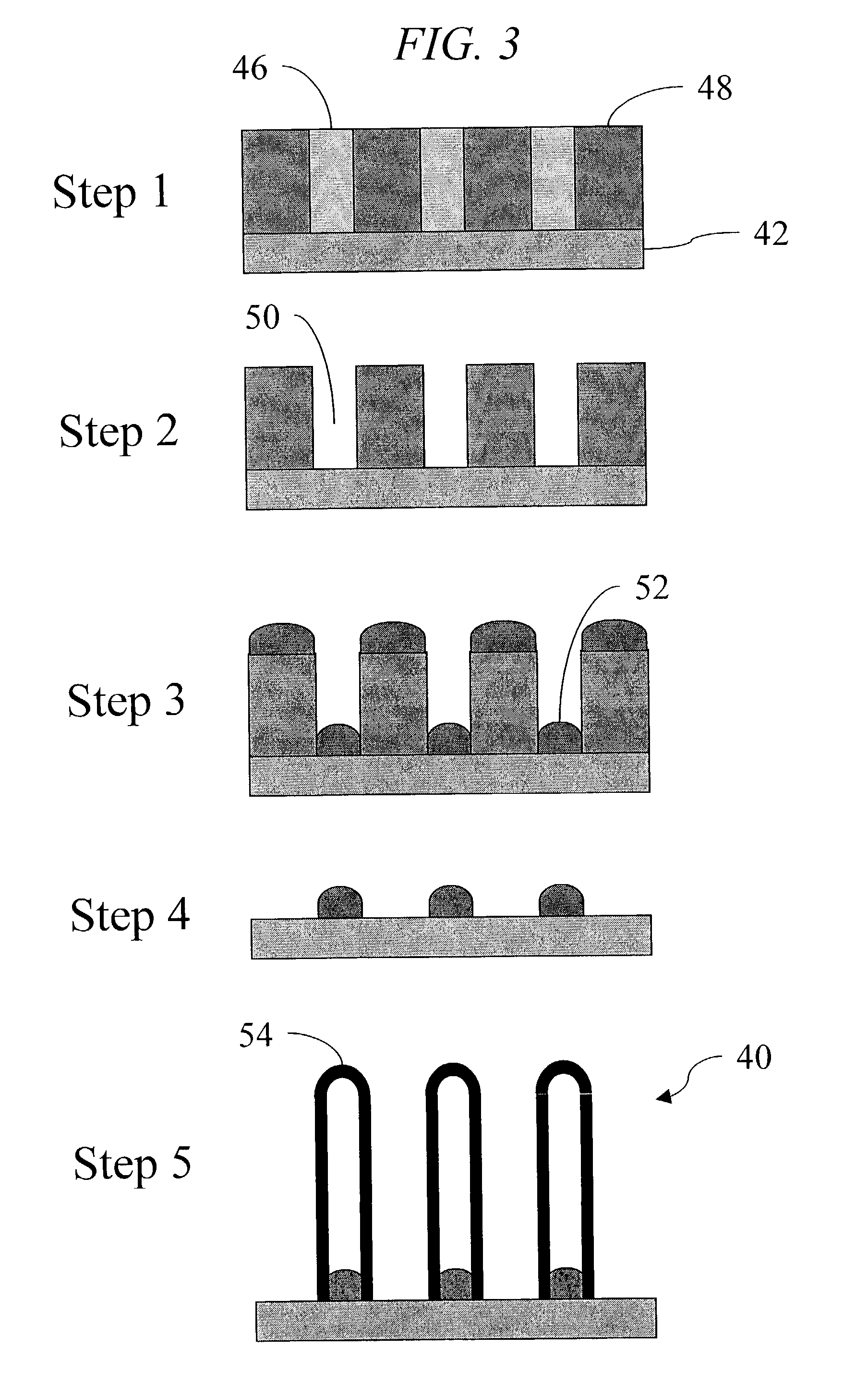

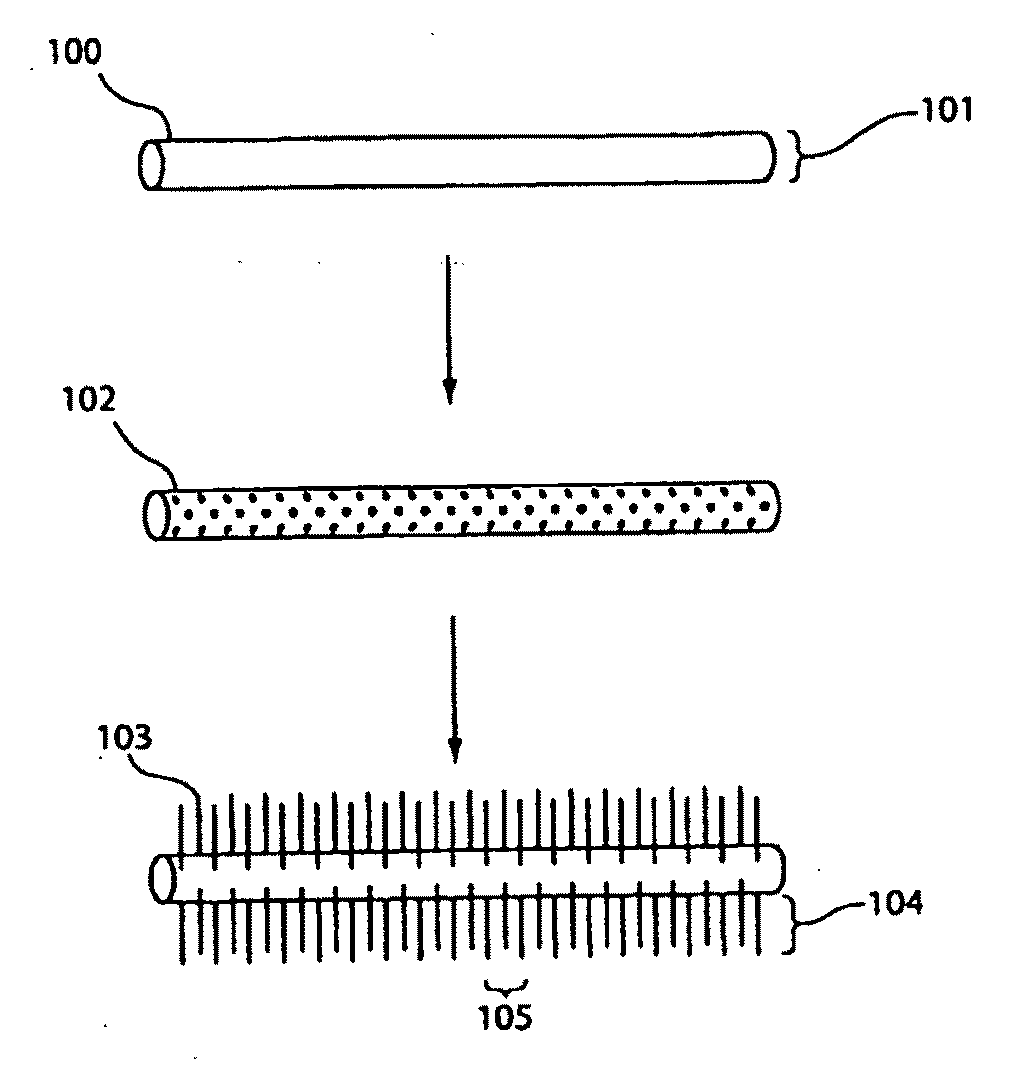

Method of manufacturing inorganic nanotube

InactiveUS7005391B2Material nanotechnologyPolycrystalline material growthInorganic materialsAtomic layer deposition

A method of manufacturing an inorganic nanotube using a carbon nanotube (CNT) as a template, includes preparing a template on which a CNT or a CNT array is formed, forming an inorganic thin film on the CNT by depositing an inorganic material on the template using atomic layer deposition (ALD), and removing the CNT to obtain an inorganic nanotube or an inorganic nanotube array, respectively.

Owner:SAMSUNG ELECTRONICS CO LTD

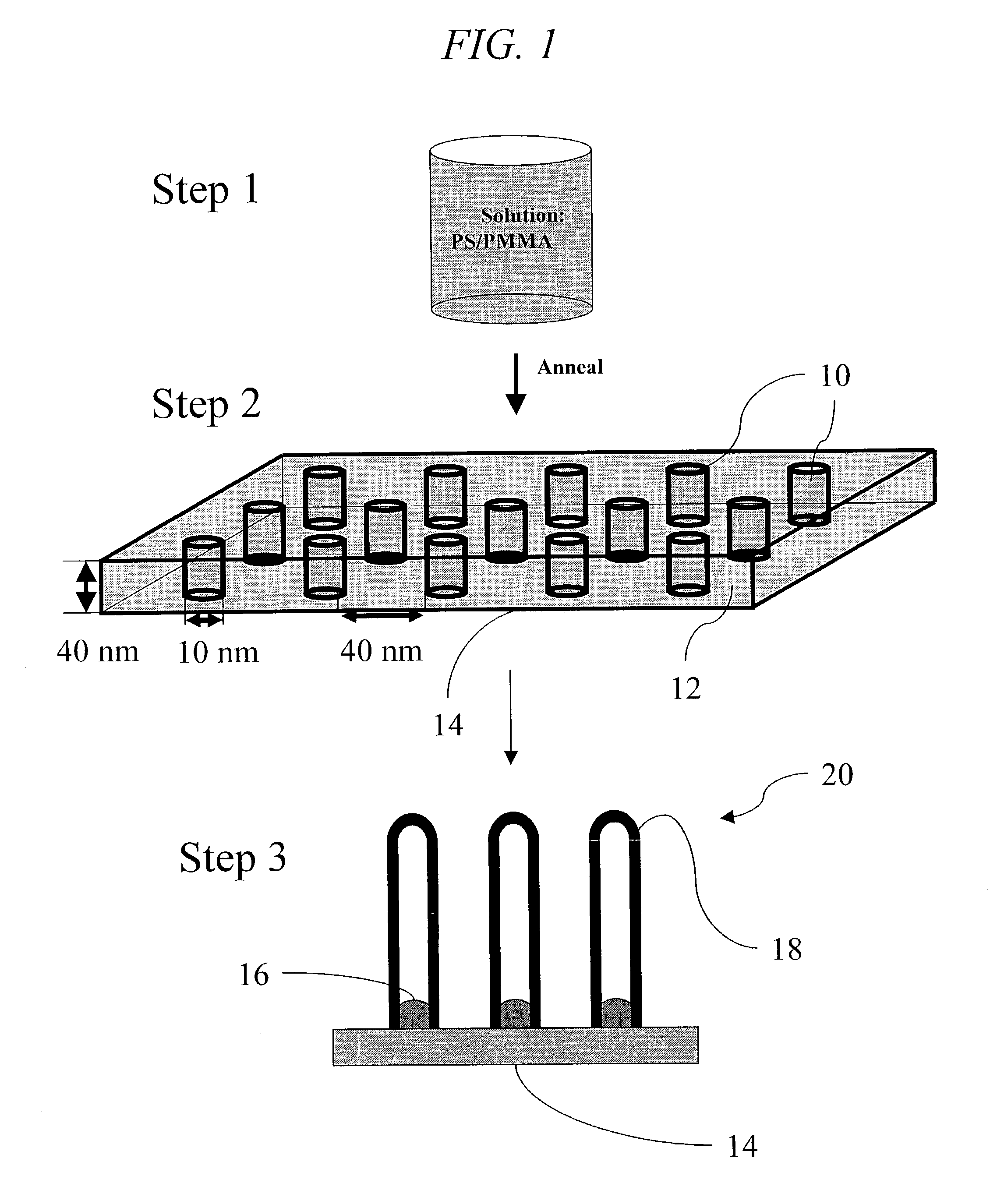

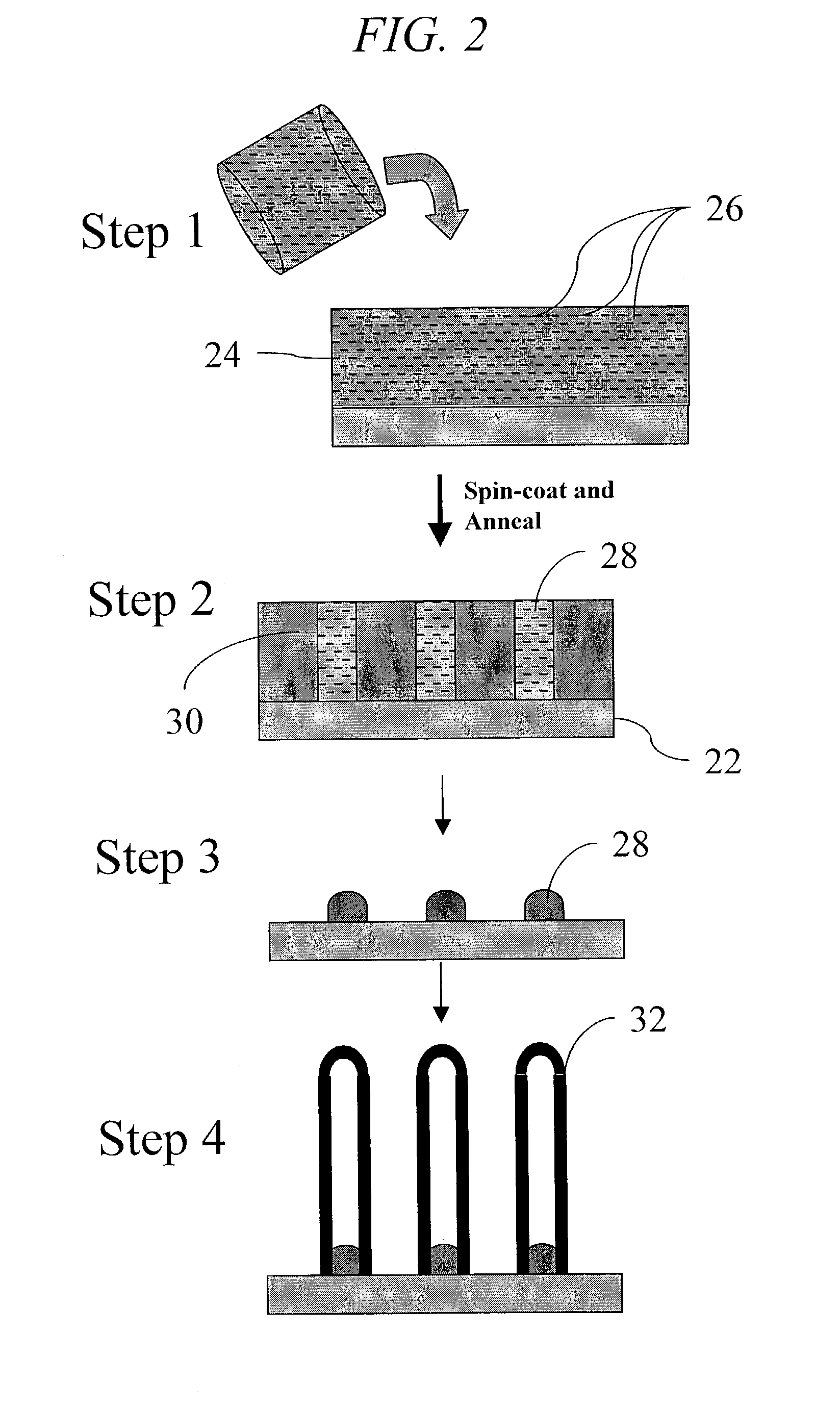

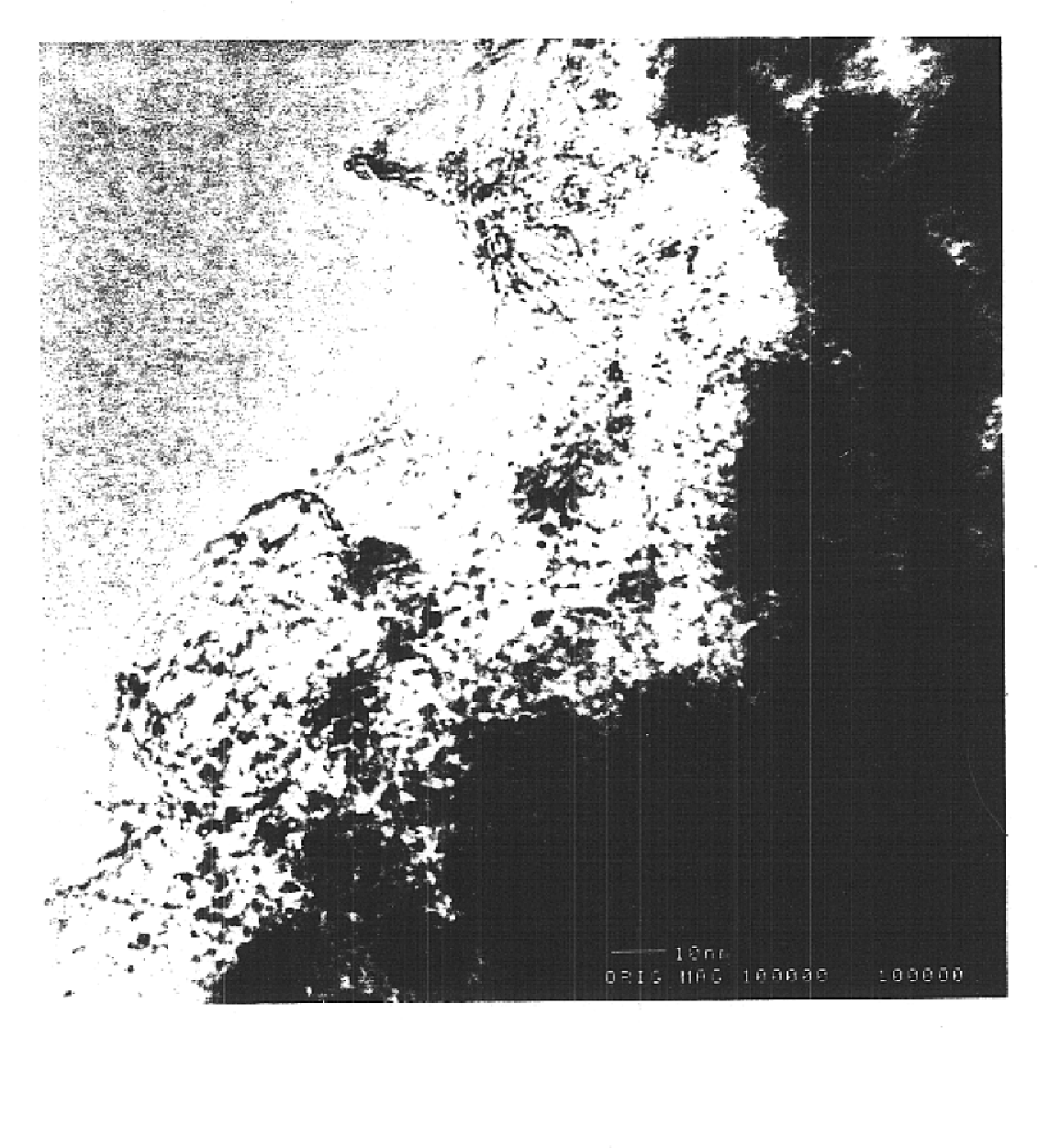

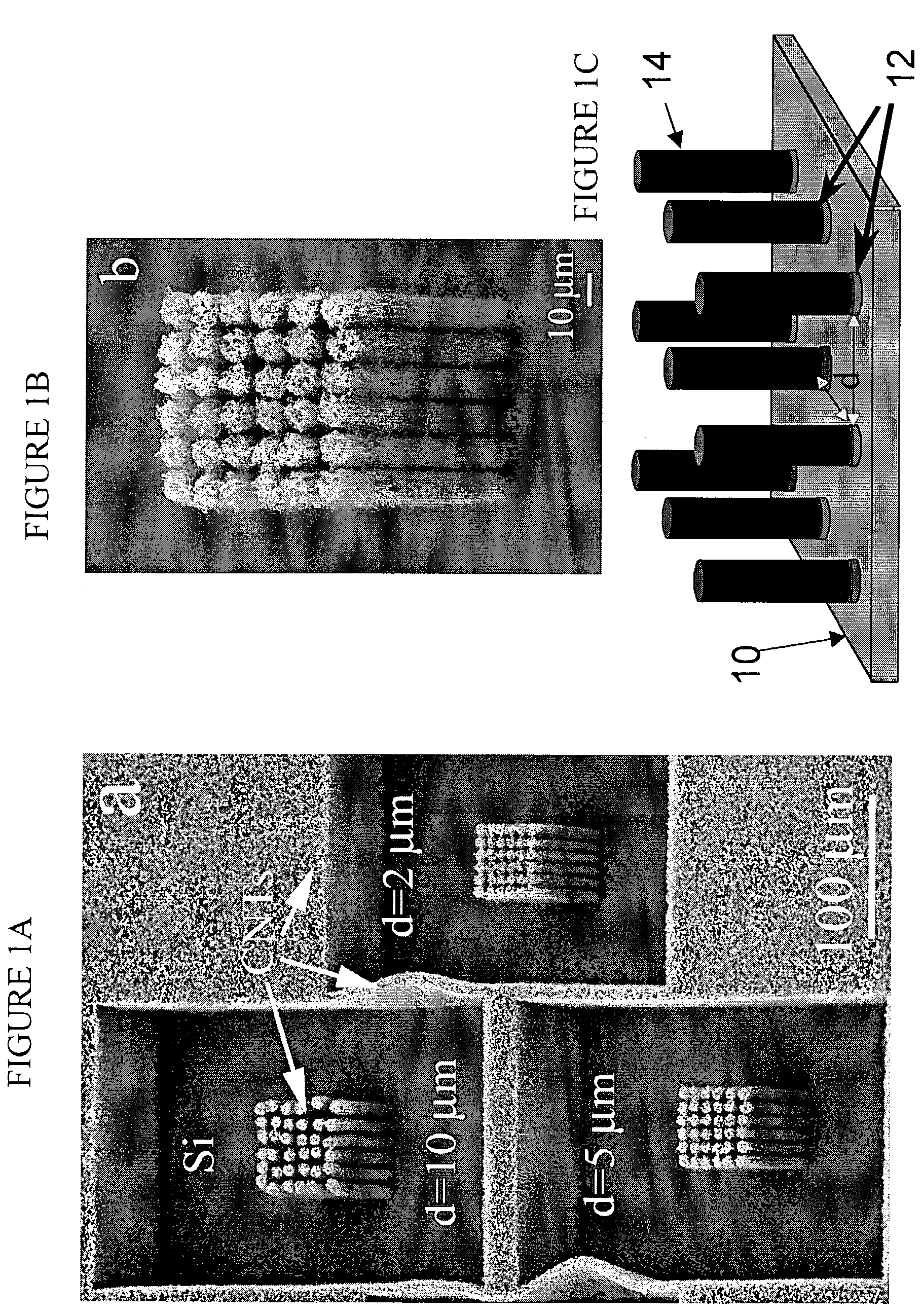

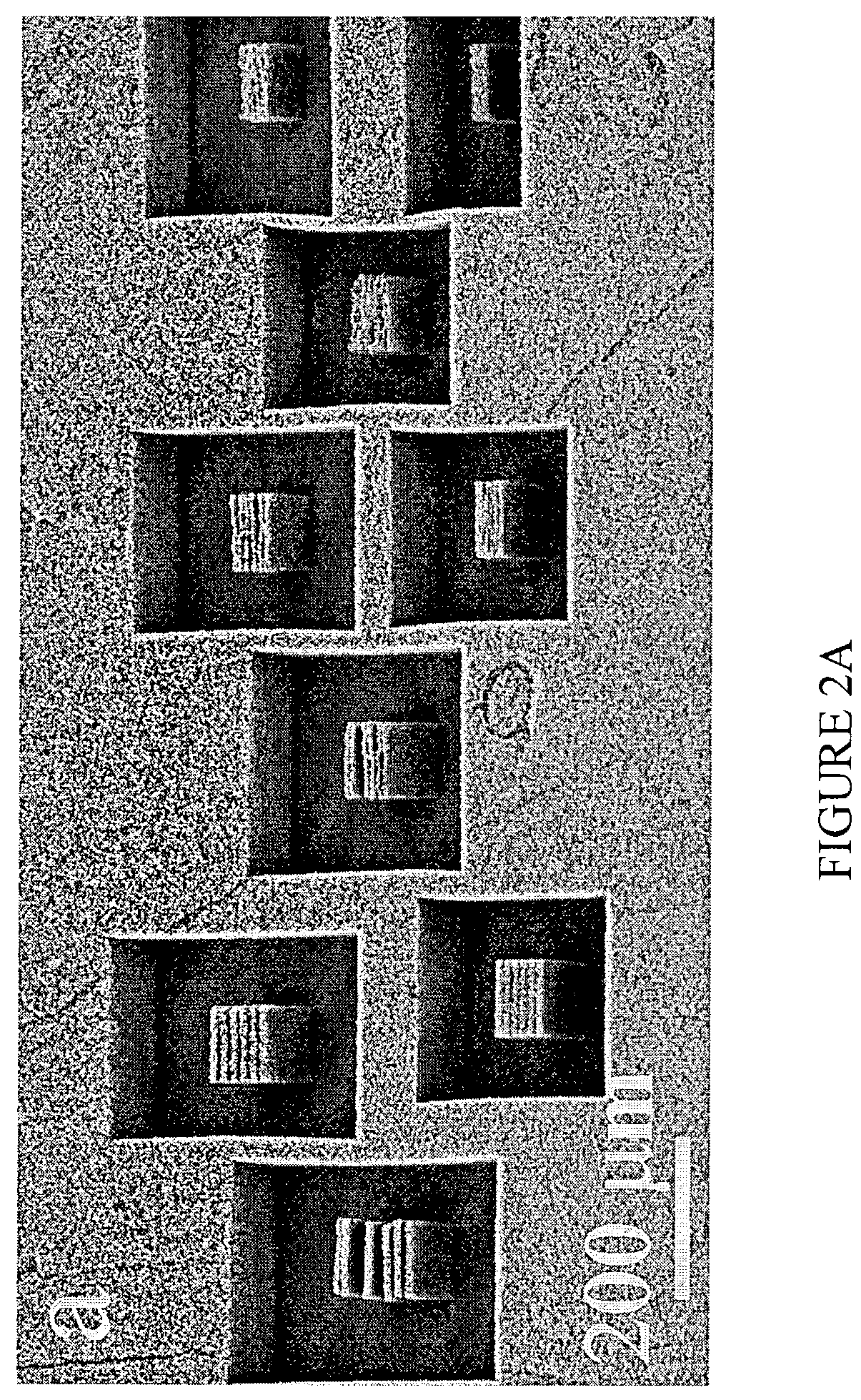

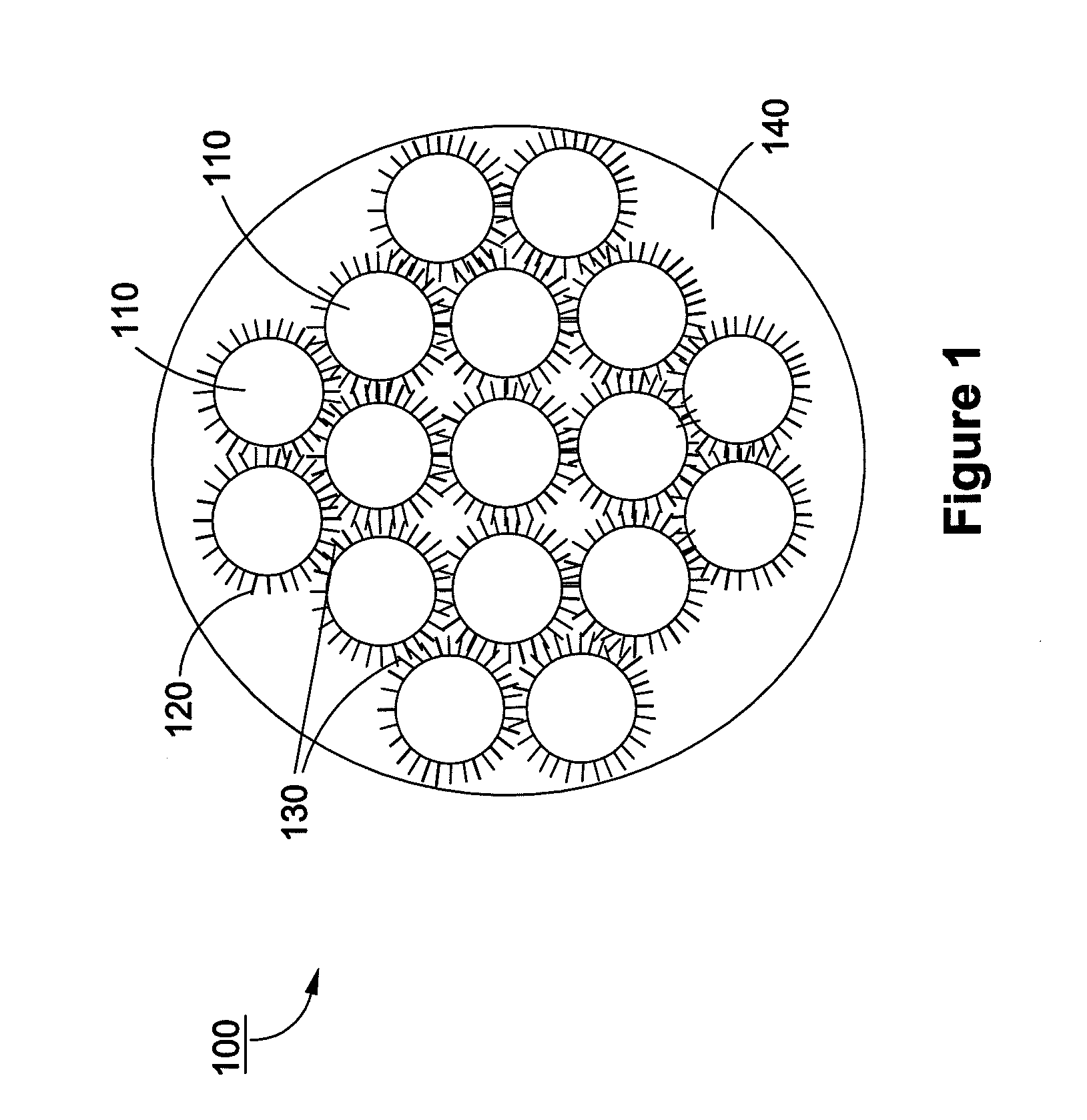

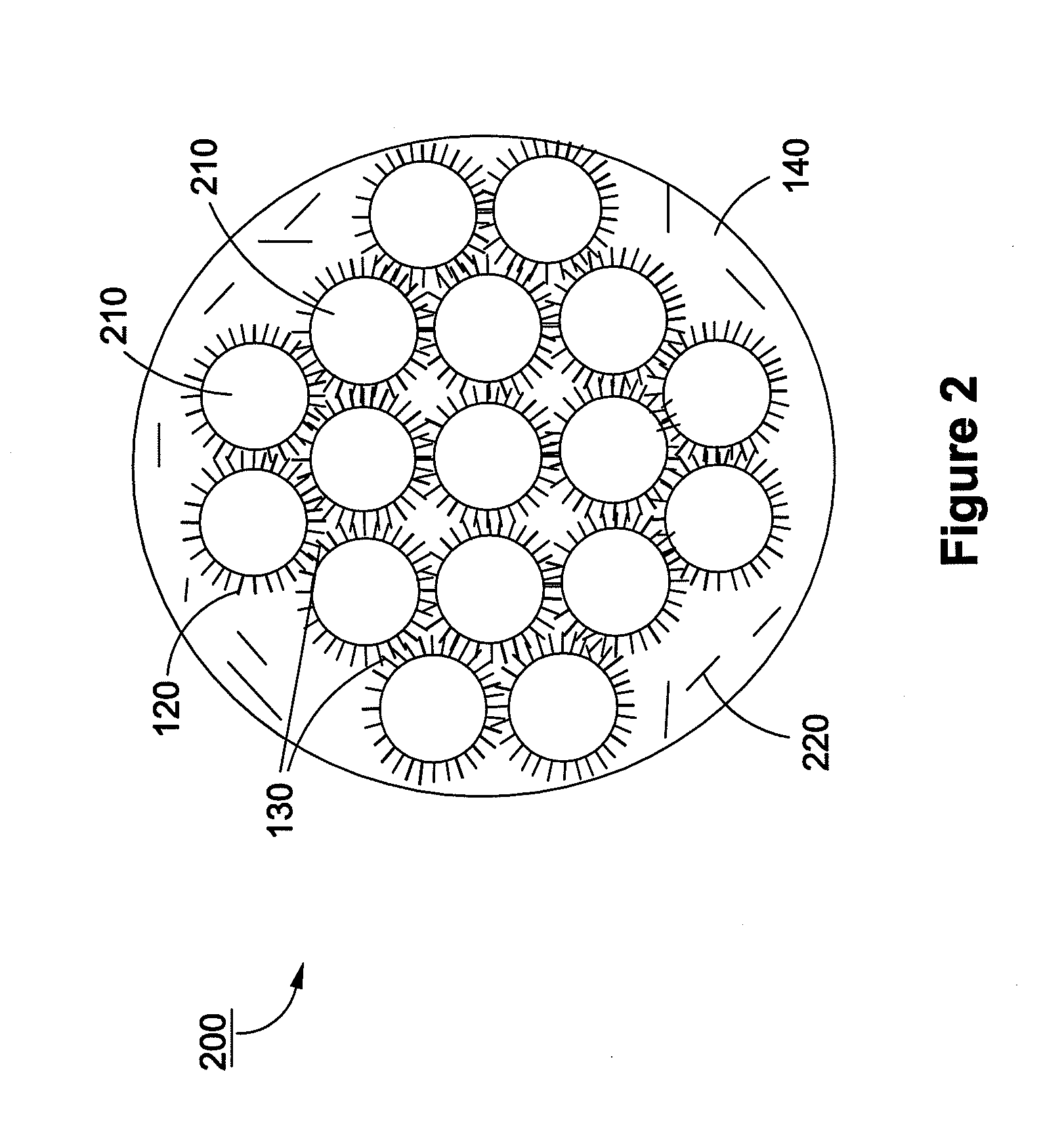

Method of producing regular arrays of nano-scale objects using nano-structured block-copolymeric materials

A method of forming a periodic array of nano-scale objects using a block copolymer, and nano-scale object arrays formed from the method are provided. The method for forming the arrays generally includes the steps of depositing a block copolymer of at least two blocks on a substrate to form an ordered meso-scale structured array of the polymer materials, forming catalytic metal dots based on the meso-scale structure, and growing nano-scale objects on the catalytic dots to form an ordered array of nano-scale objects.

Owner:CALIFORNIA INST OF TECH

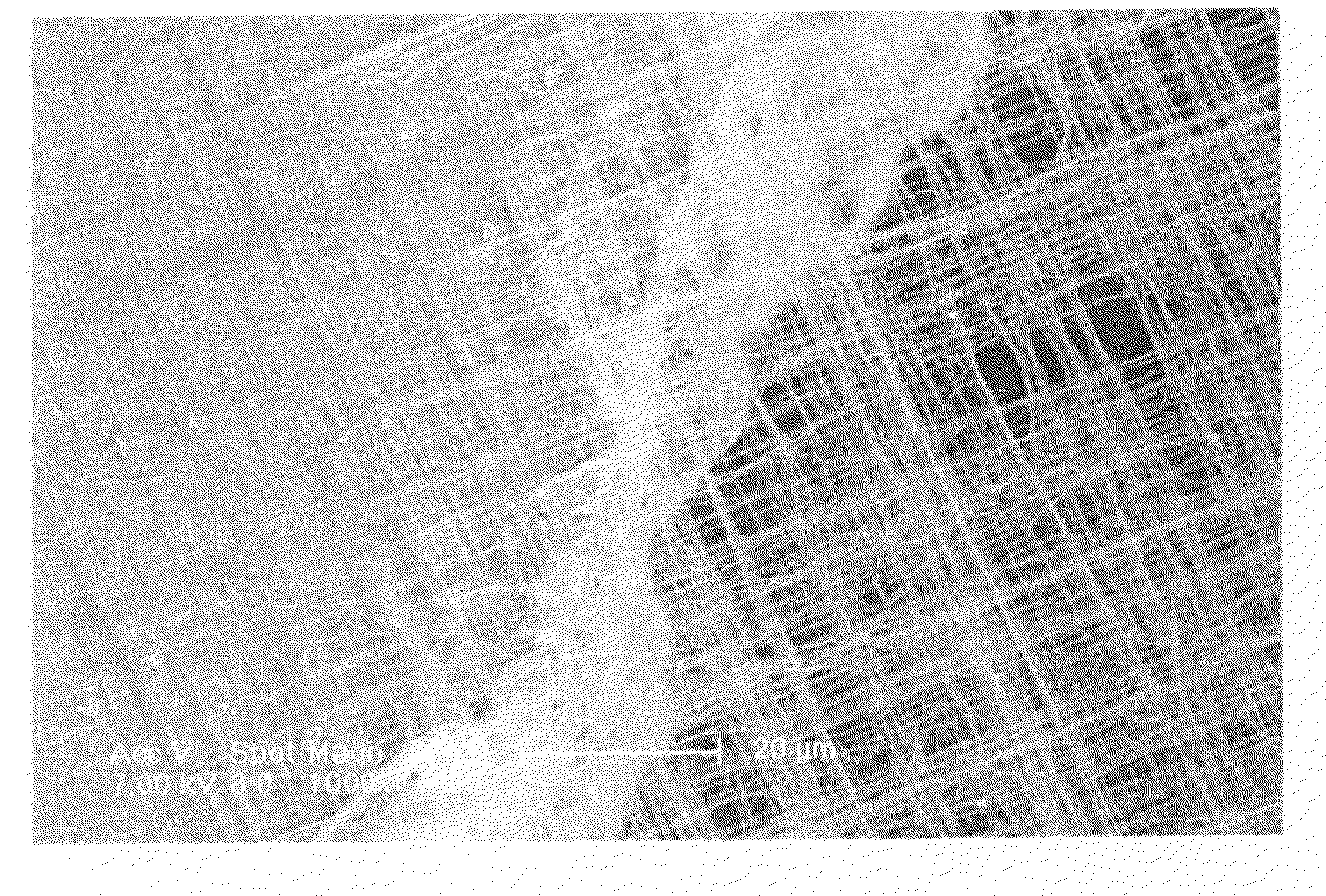

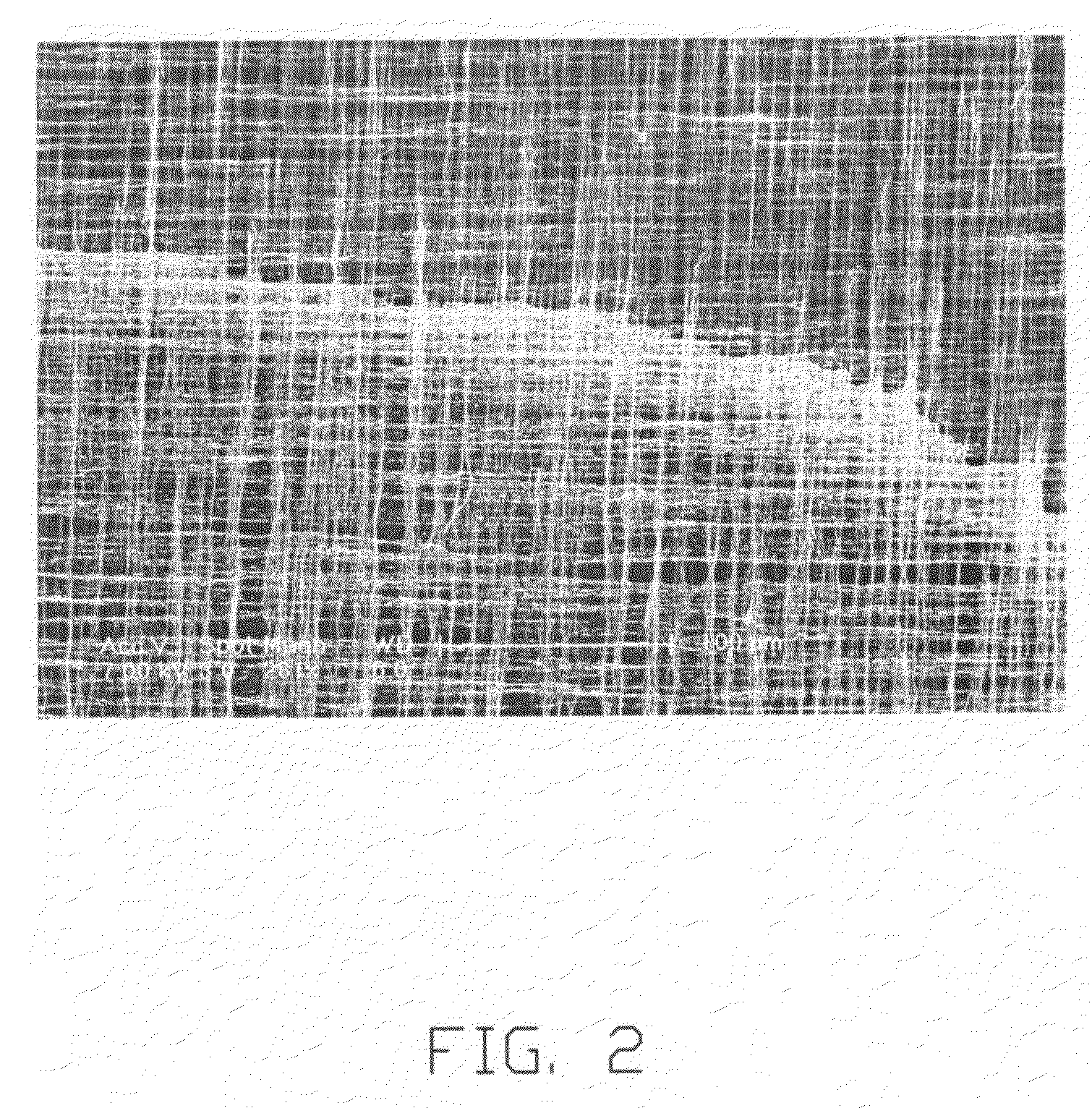

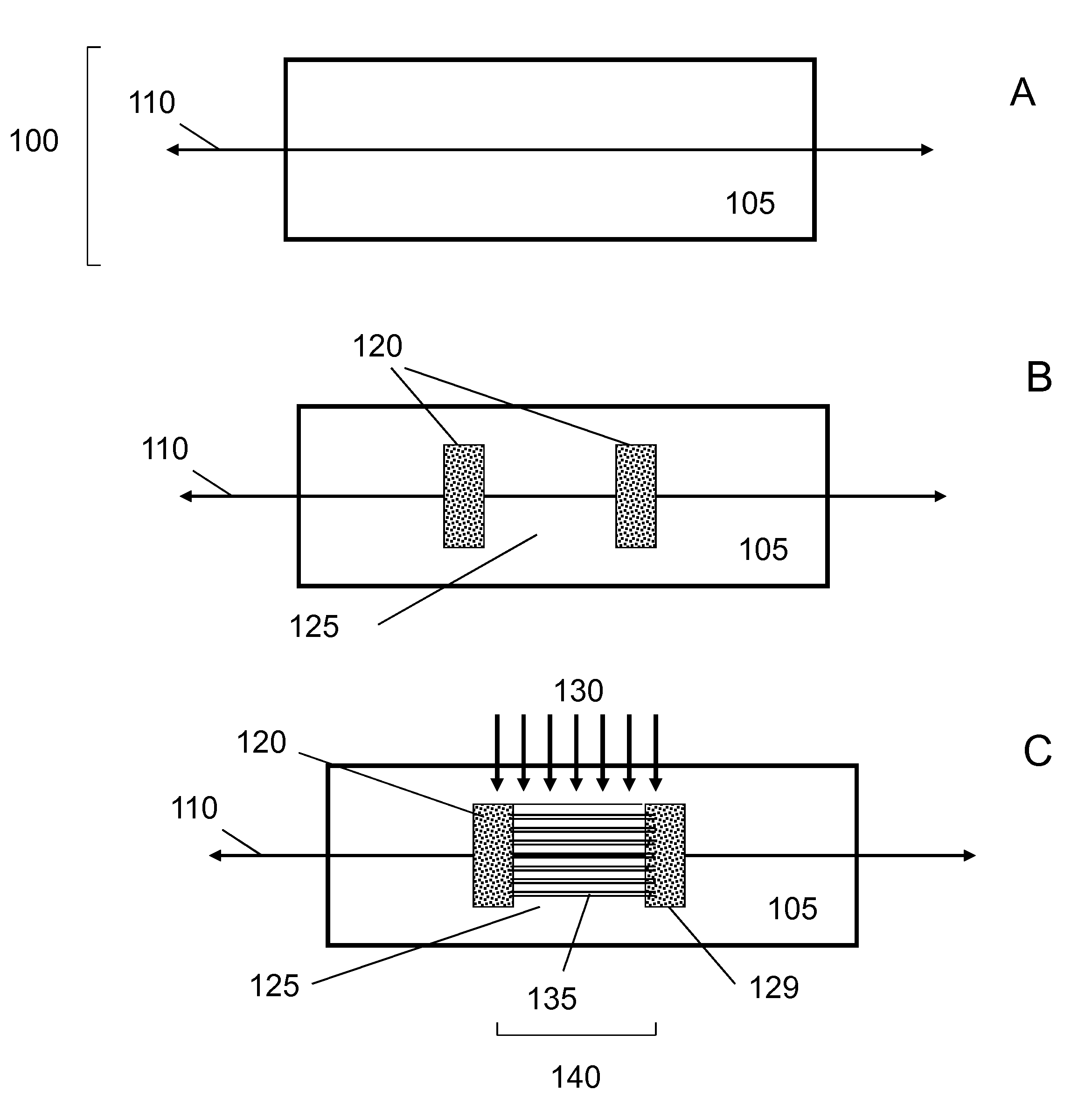

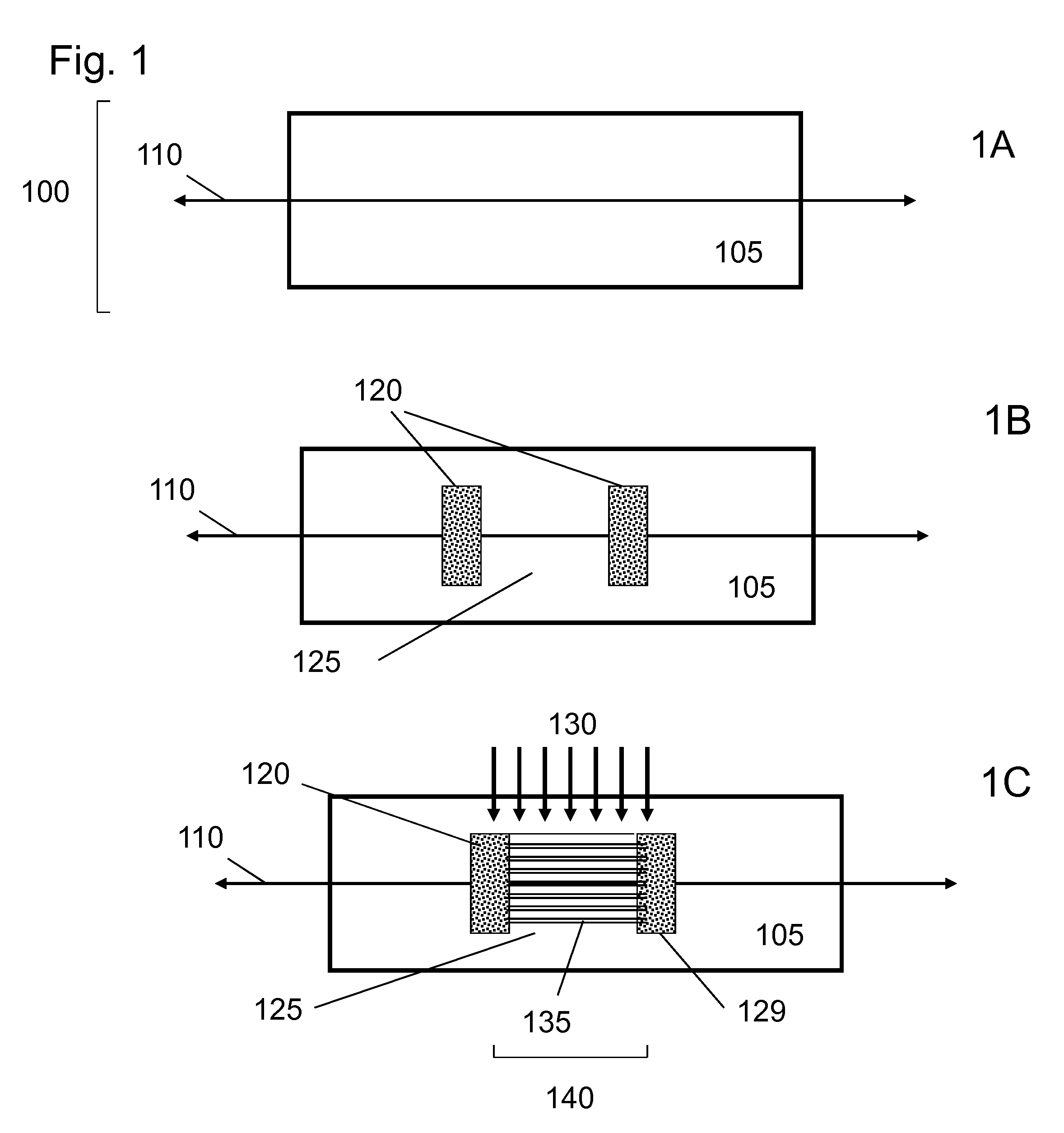

Carbon nanotube film structure and method for fabricating the same

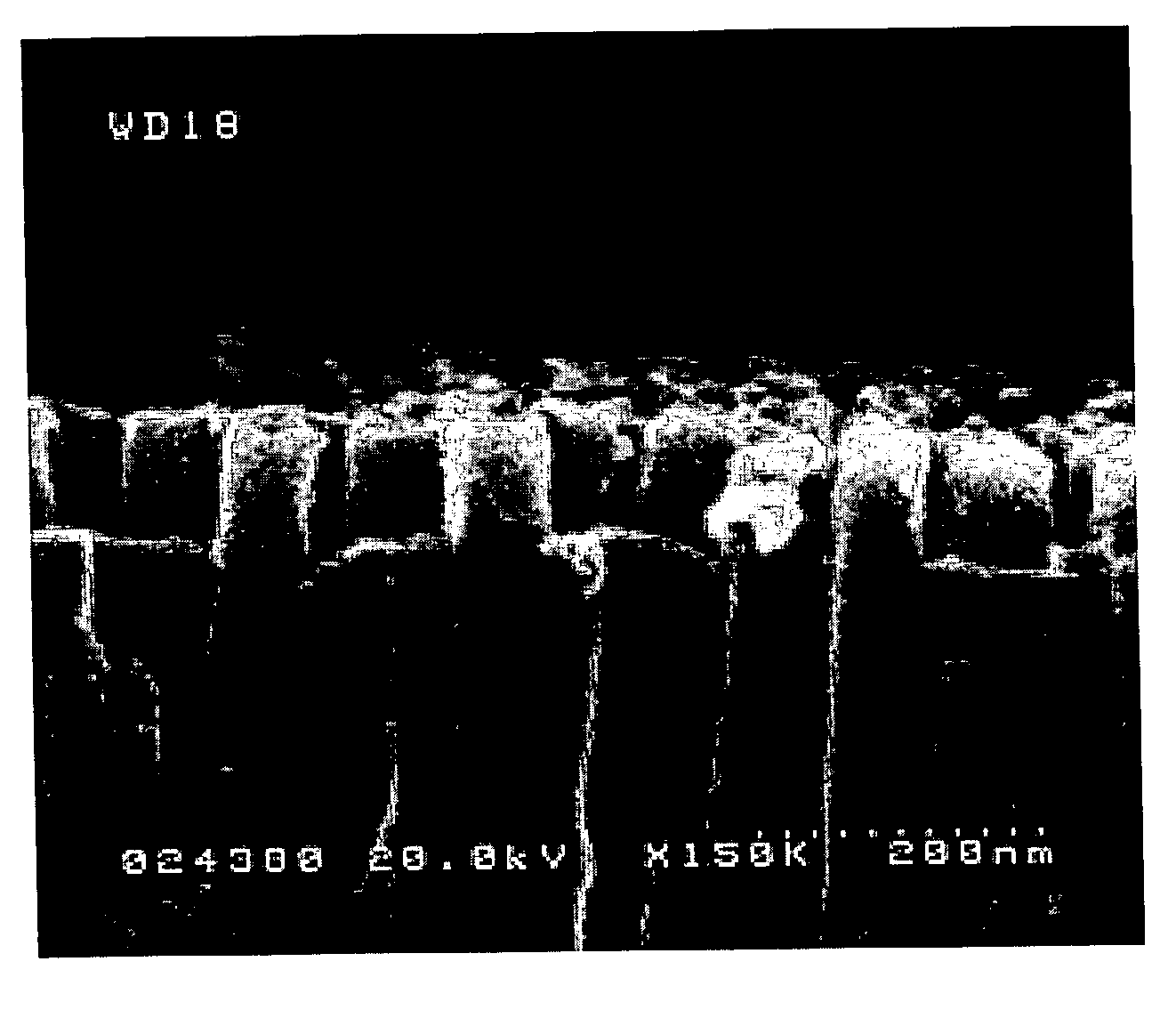

A carbon nanotube film structure includes at least two overlapped carbon nanotube films, with adjoining films being aligned in different directions. Each carbon nanotube film includes a plurality of successive carbon nanotube bundles aligned in the same direction. The carbon nanotube structure further includes a plurality of micropores formed by / between the adjoining carbon nanotube bundles. A method for fabricating the carbon nanotube film structure includes the steps of: (a) providing an array of carbon nanotubes; (b) pulling out, using a tool, one carbon nanotube film from the array of carbon nanotubes; (c) providing a frame and adhering the carbon nanotube film to the frame; (d) repeating steps (b) and (c), depositing each successive film on a preceding film, thereby achieving at least a two-layer carbon nanotube film; and (e) peeling the carbon nanotube film off the frame to achieve the carbon nanotube structure.

Owner:TSINGHUA UNIV +1

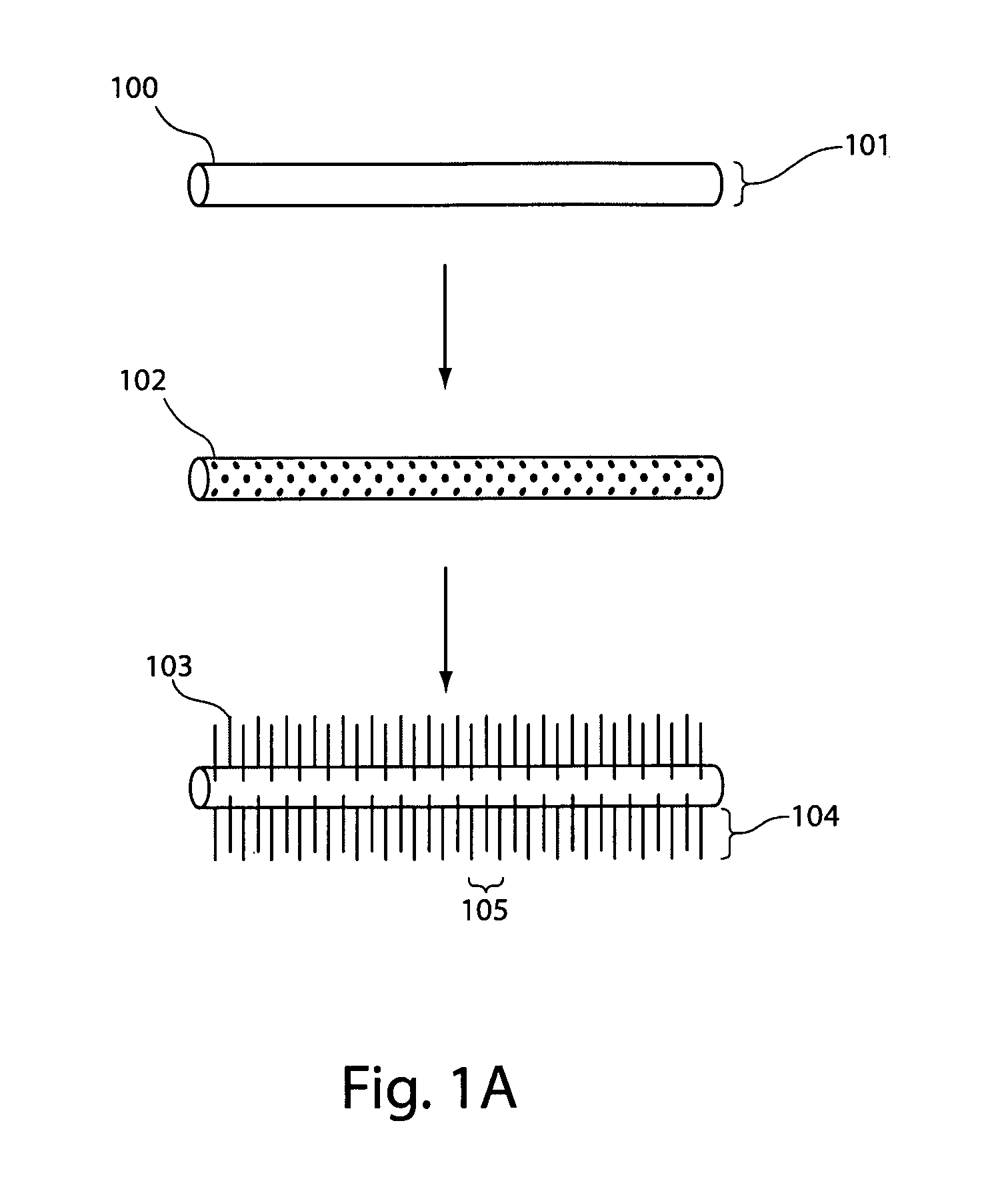

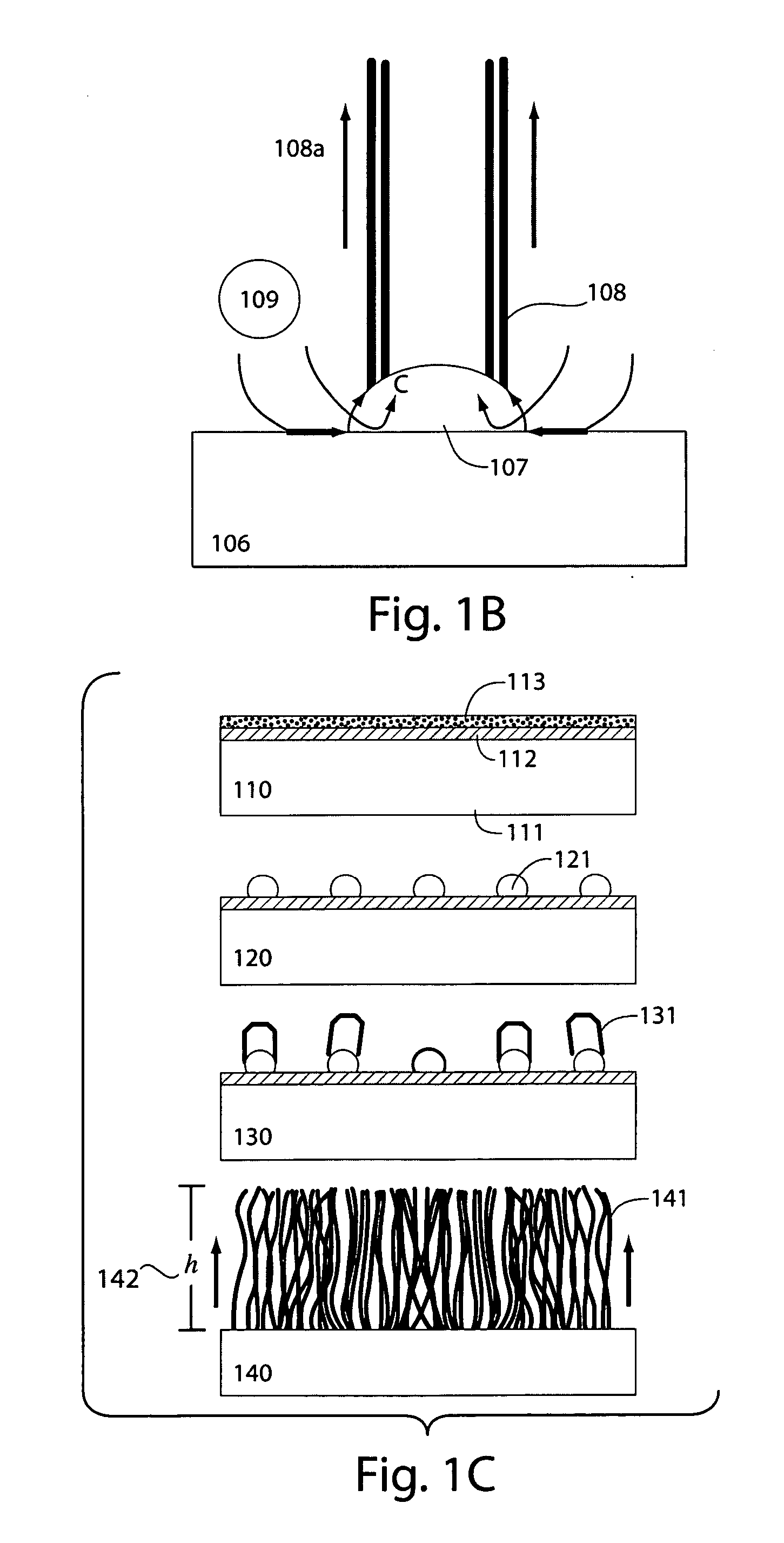

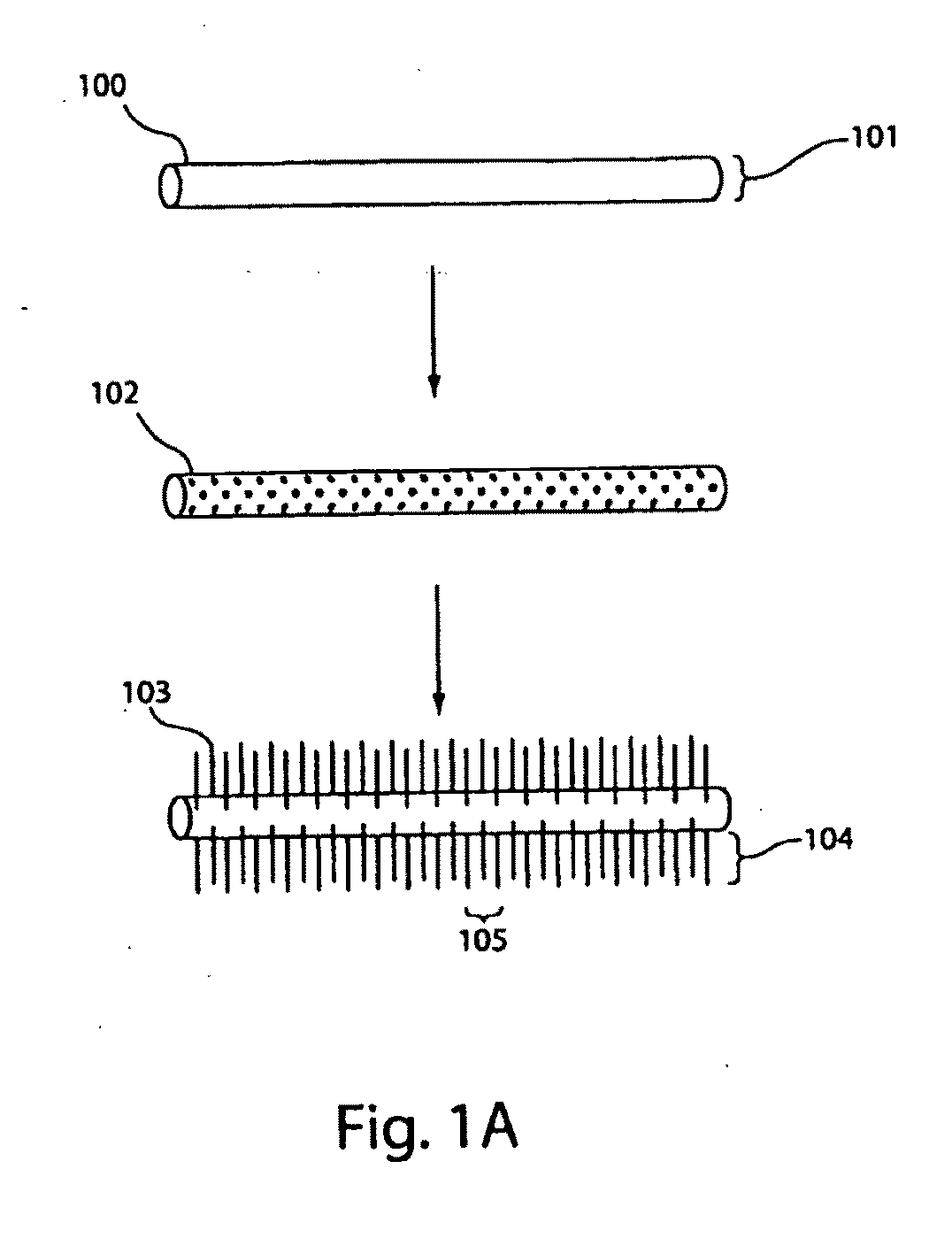

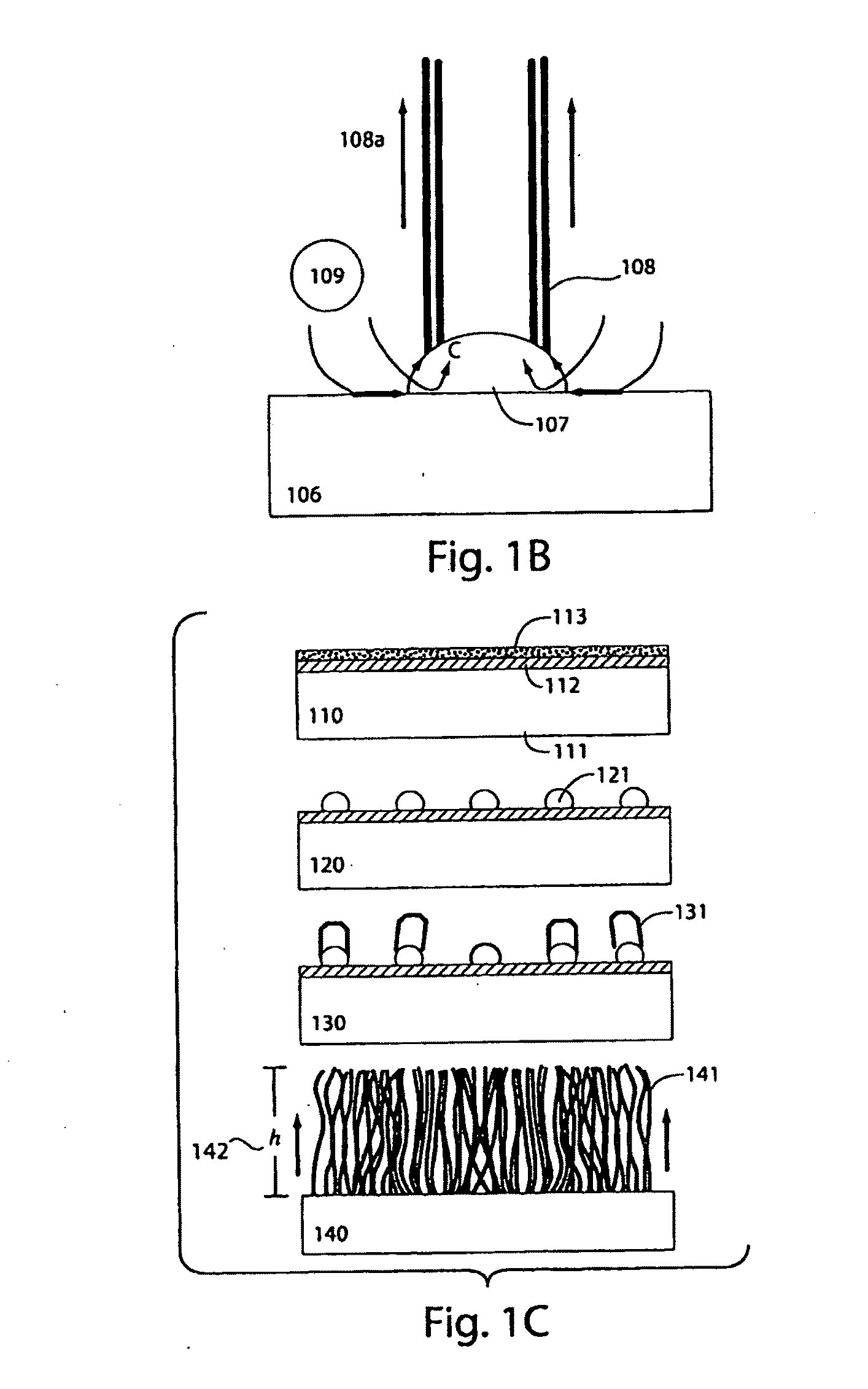

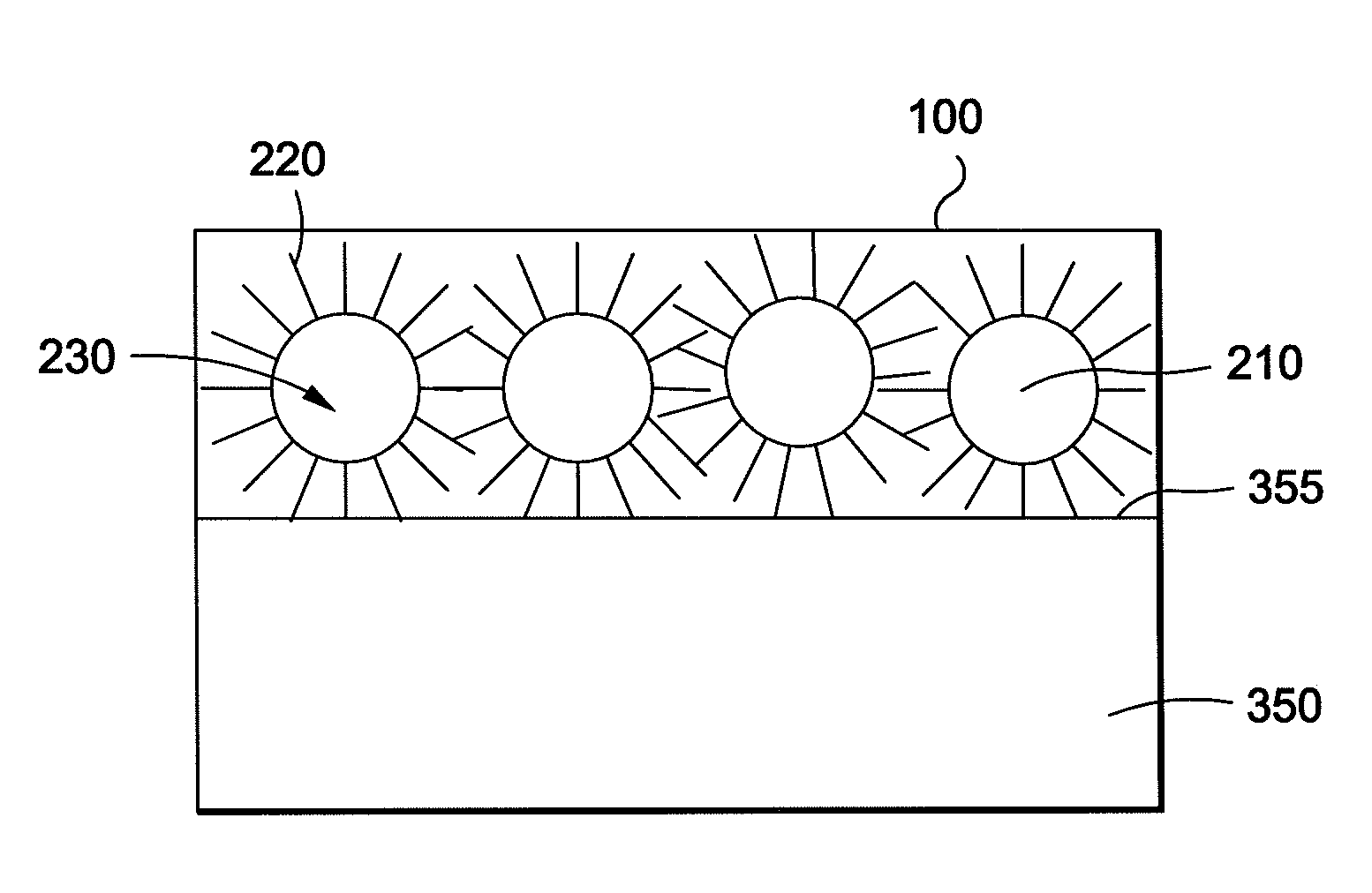

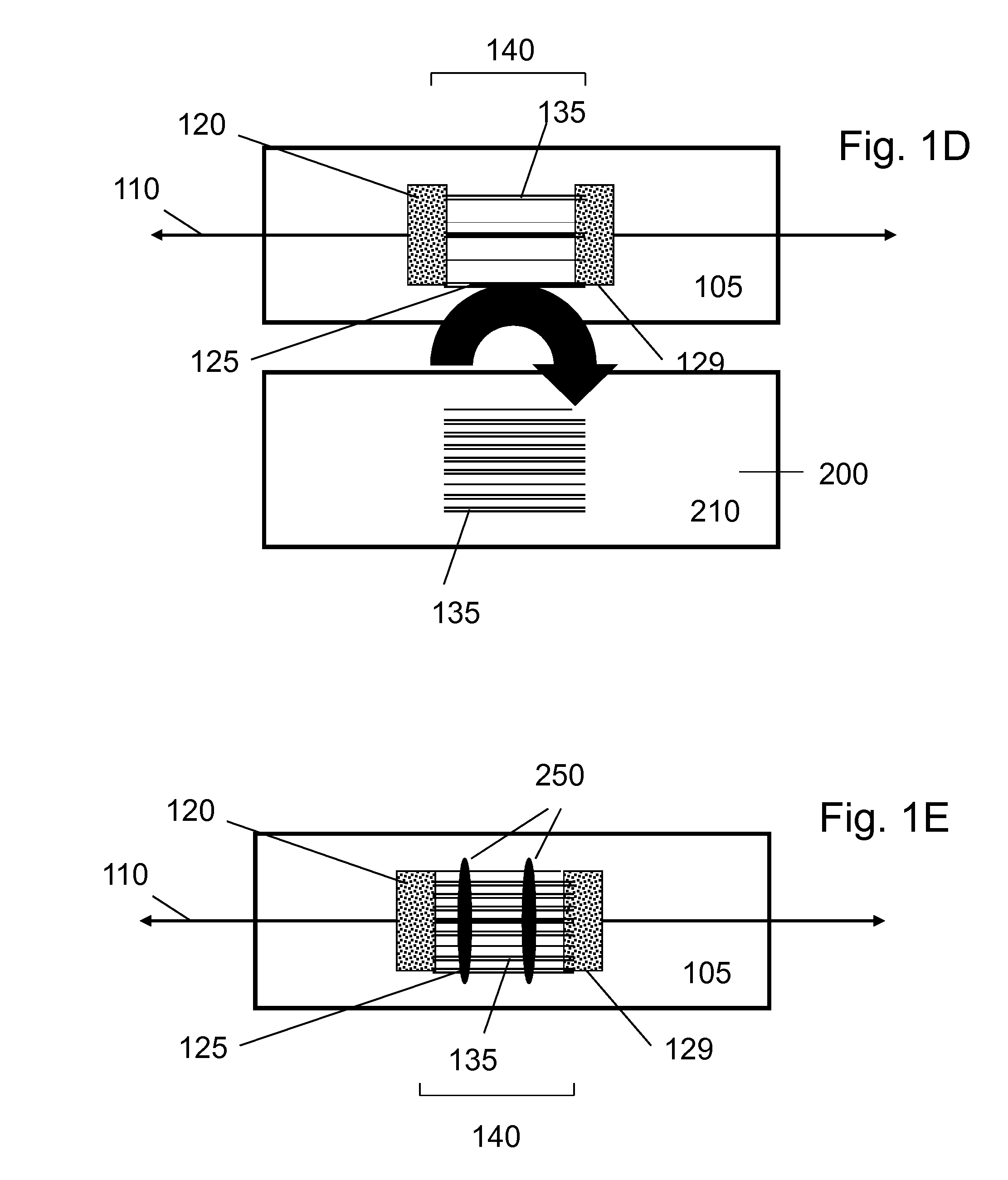

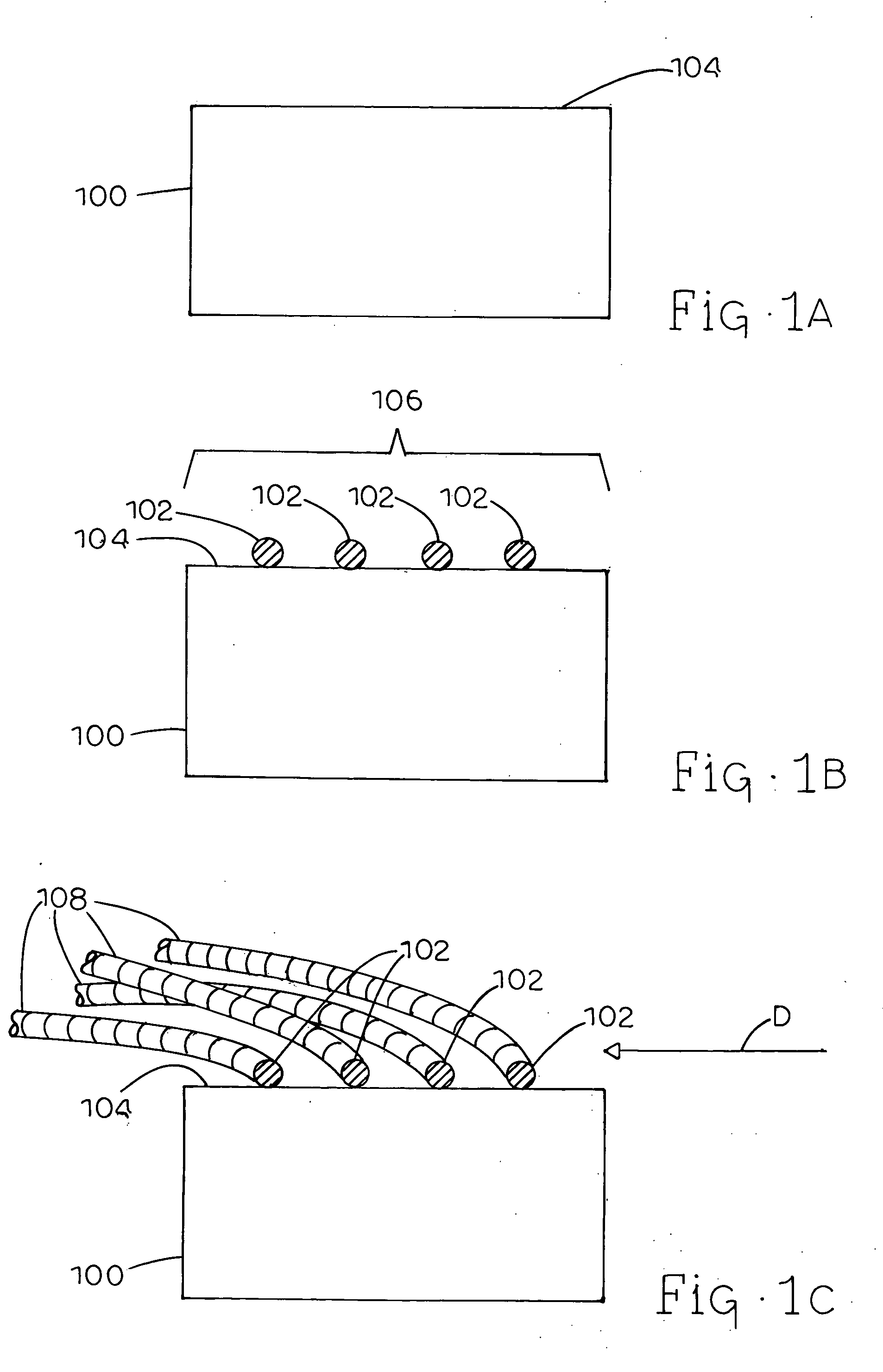

Nanostructure-reinforced composite articles and methods

ActiveUS20080075954A1Material nanotechnologyIndividual molecule manipulationElectronic propertiesNanostructure

The present invention provides methods for uniform growth of nanostructures such as nanotubes (e.g., carbon nanotubes) on the surface of a substrate, wherein the long axes of the nanostructures may be substantially aligned. The nanostructures may be further processed for use in various applications, such as composite materials. For example, a set of aligned nanostructures may be formed and transferred, either in bulk or to another surface, to another material to enhance the properties of the material. In some cases, the nanostructures may enhance the mechanical properties of a material, for example, providing mechanical reinforcement at an interface between two materials or plies. In some cases, the nanostructures may enhance thermal and / or electronic properties of a material. The present invention also provides systems and methods for growth of nanostructures, including batch processes and continuous processes.

Owner:MASSACHUSETTS INST OF TECH

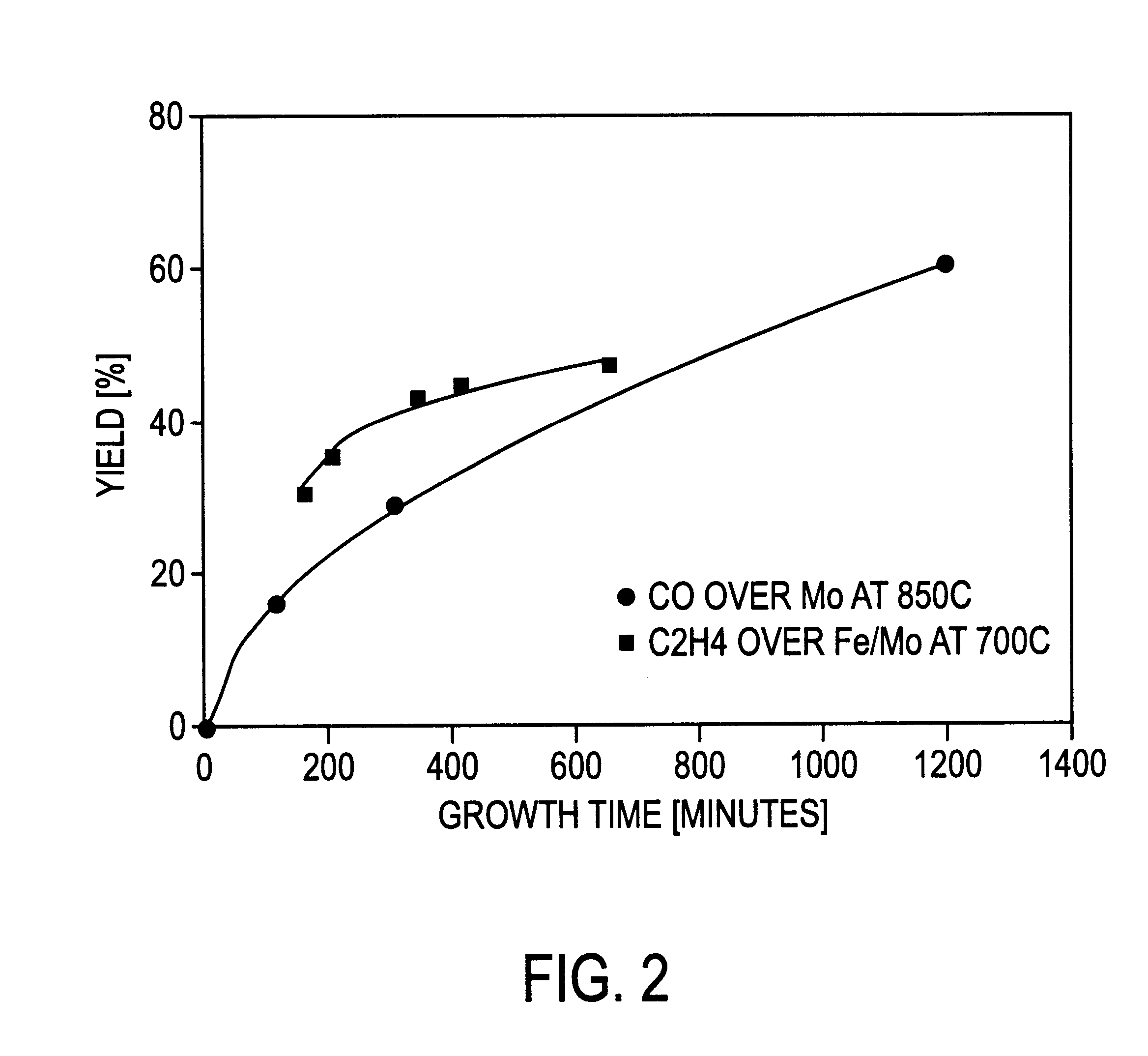

Catalytic growth of single-wall carbon nanotubes from metal particles

InactiveUS6692717B1Material nanotechnologyFibre chemical featuresMetal catalystCatalytic decomposition

Owner:RICE UNIV

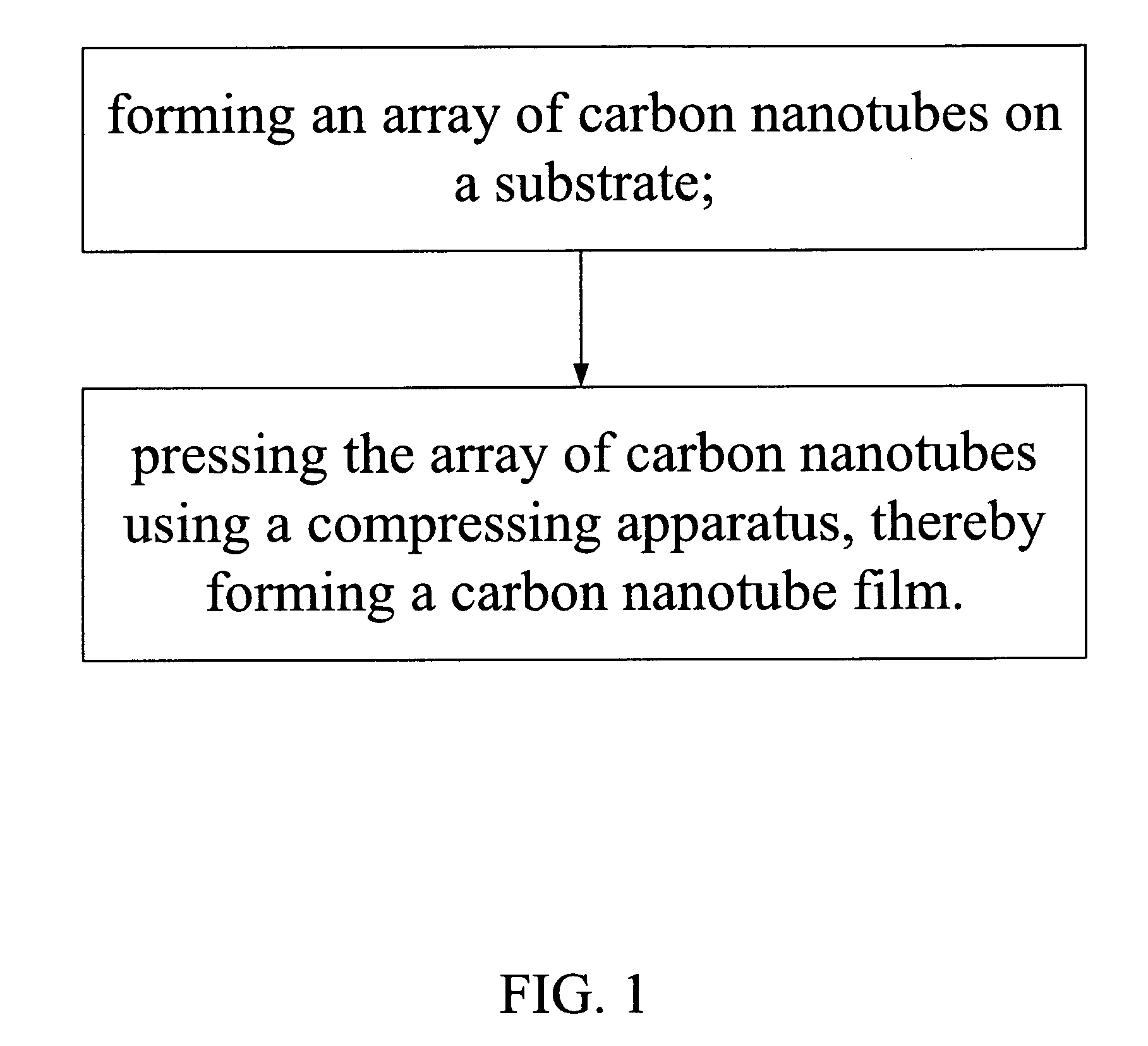

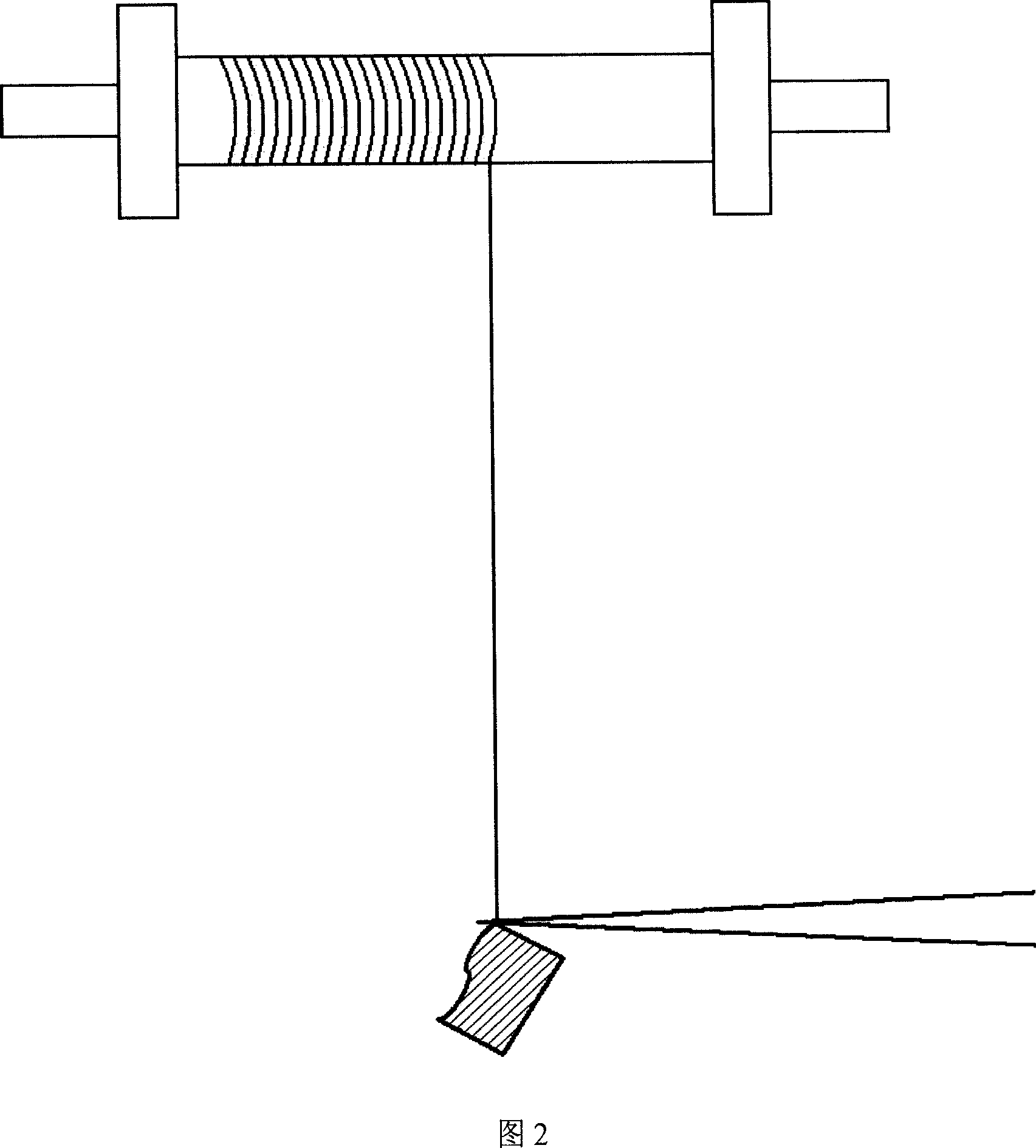

Method for making a carbon nanotube film

ActiveUS20080299031A1High strengthSimple methodMaterial nanotechnologyLayered productsCarbon nanotubeNanotube array

The present invention relates to a method for making a carbon nanotube film. The method includes the steps of: (a) forming an array of carbon nanotubes on a substrate; and (b) press the array of carbon nanotubes using a compressing apparatus, thereby forming a carbon nanotube film.

Owner:BEIJING FUNATE INNOVATION TECH +1

Carbon-Based Fine Structure Array, Aggregate of Carbon-Based Fine Structures, Use Thereof and Method for Preparation Thereof

ActiveUS20080095694A1Long and strong aggregateEasy alignmentMaterial nanotechnologyLayered productsFine structureStrong interaction

An aggregate of carbon-based fine structures in which a plurality of carbon-based fine structures are collected, wherein respective carbon-based fine structures are oriented in the same direction. The above aggregate of carbon-based fine structures is an aggregate of a plurality of carbon-based fine structures in a state they are pulled by one another with strong interaction, and has such a length that allows the improvement of the handleability and workability thereof.

Owner:NIPPON SANSO CORP

Continuous Process for the Production of Nanostructures Including Nanotubes

The present invention provides methods for uniform growth of nanostructures such as nanotubes (e.g., carbon nanotubes) on the surface of a substrate, wherein the long axes of the nanostructures may be substantially aligned. The nanostructures may be further processed for use in various applications, such as composite materials. For example, a set of aligned nanostructures may be formed and transferred, either in bulk or to another surface, to another material to enhance the properties of the material. In some cases, the nanostructures may enhance the mechanical properties of a material, for example, providing mechanical reinforcement at an interface between two materials or plies. In some cases, the nanostructures may enhance thermal and / or electronic properties of a material. The present invention also provides systems and methods for growth of nanostructures, including batch processes and continuous processes.

Owner:MASSACHUSETTS INST OF TECH

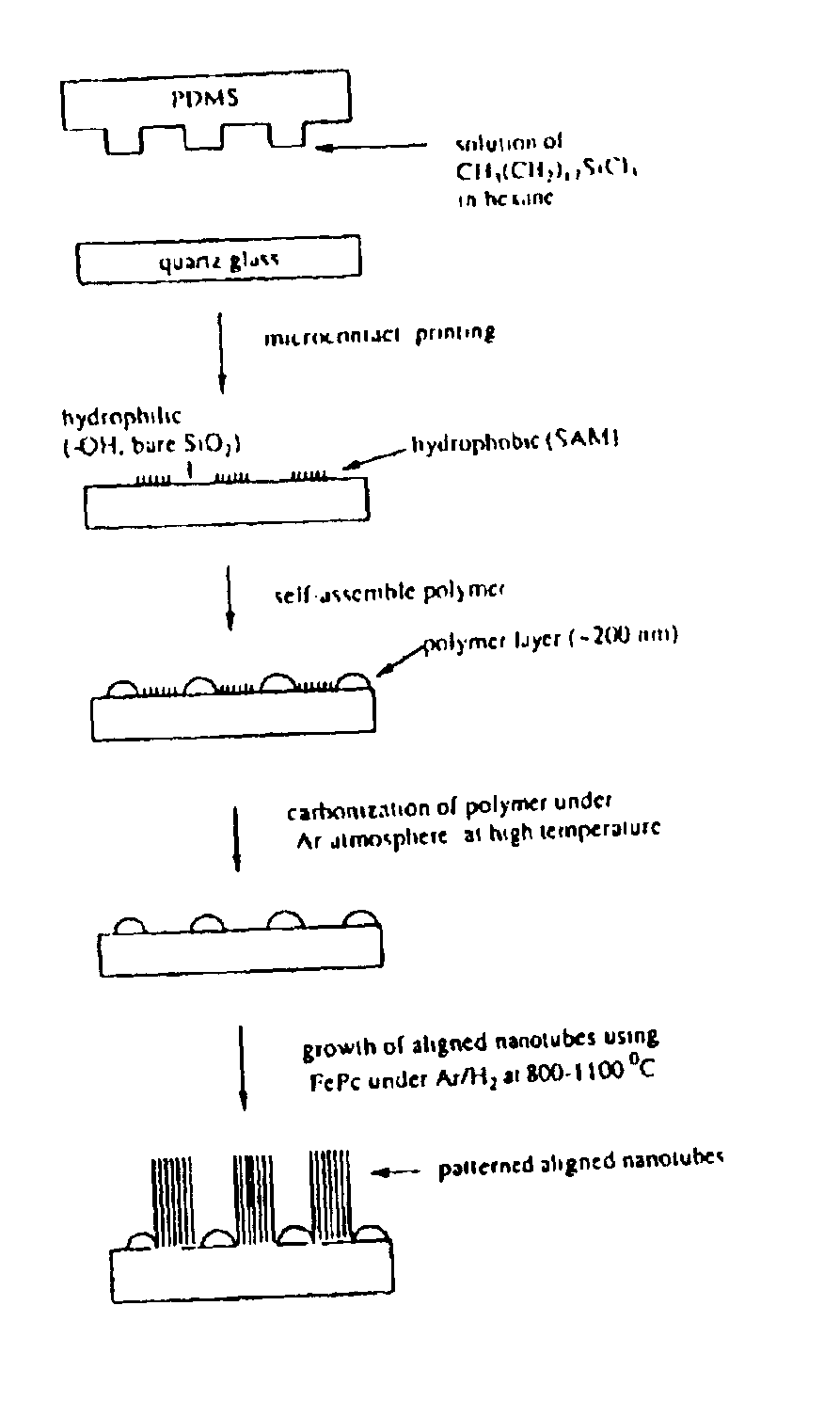

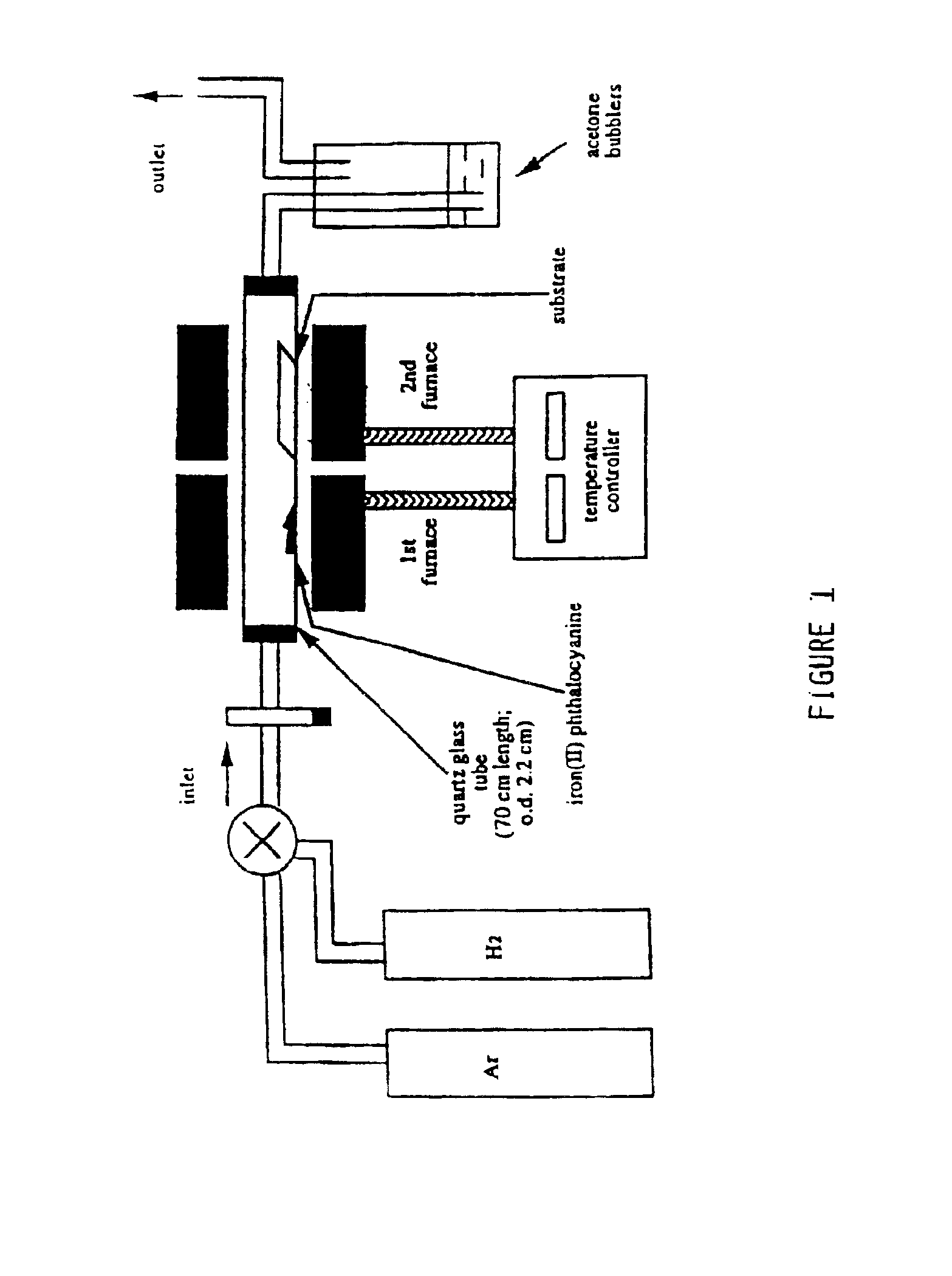

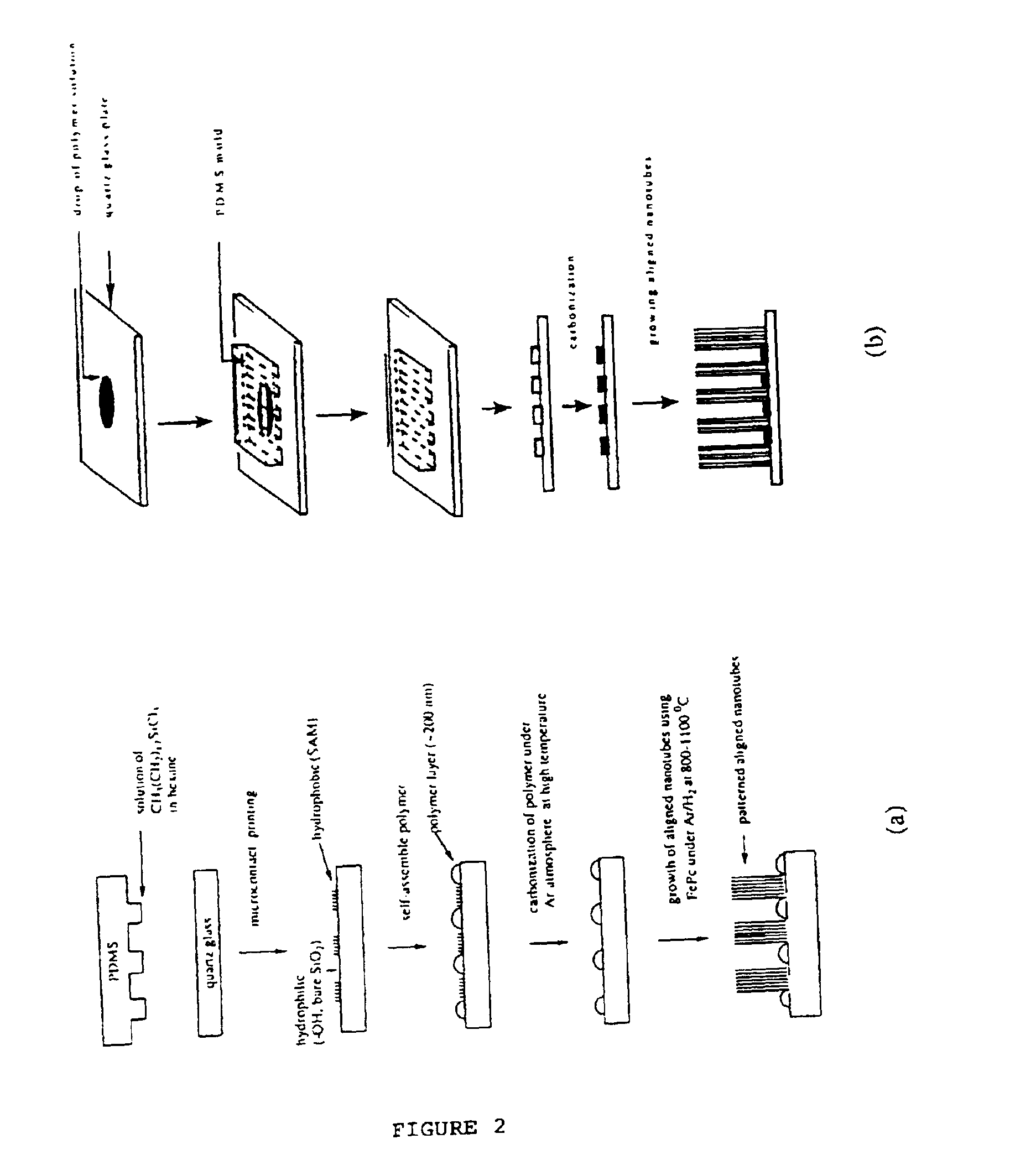

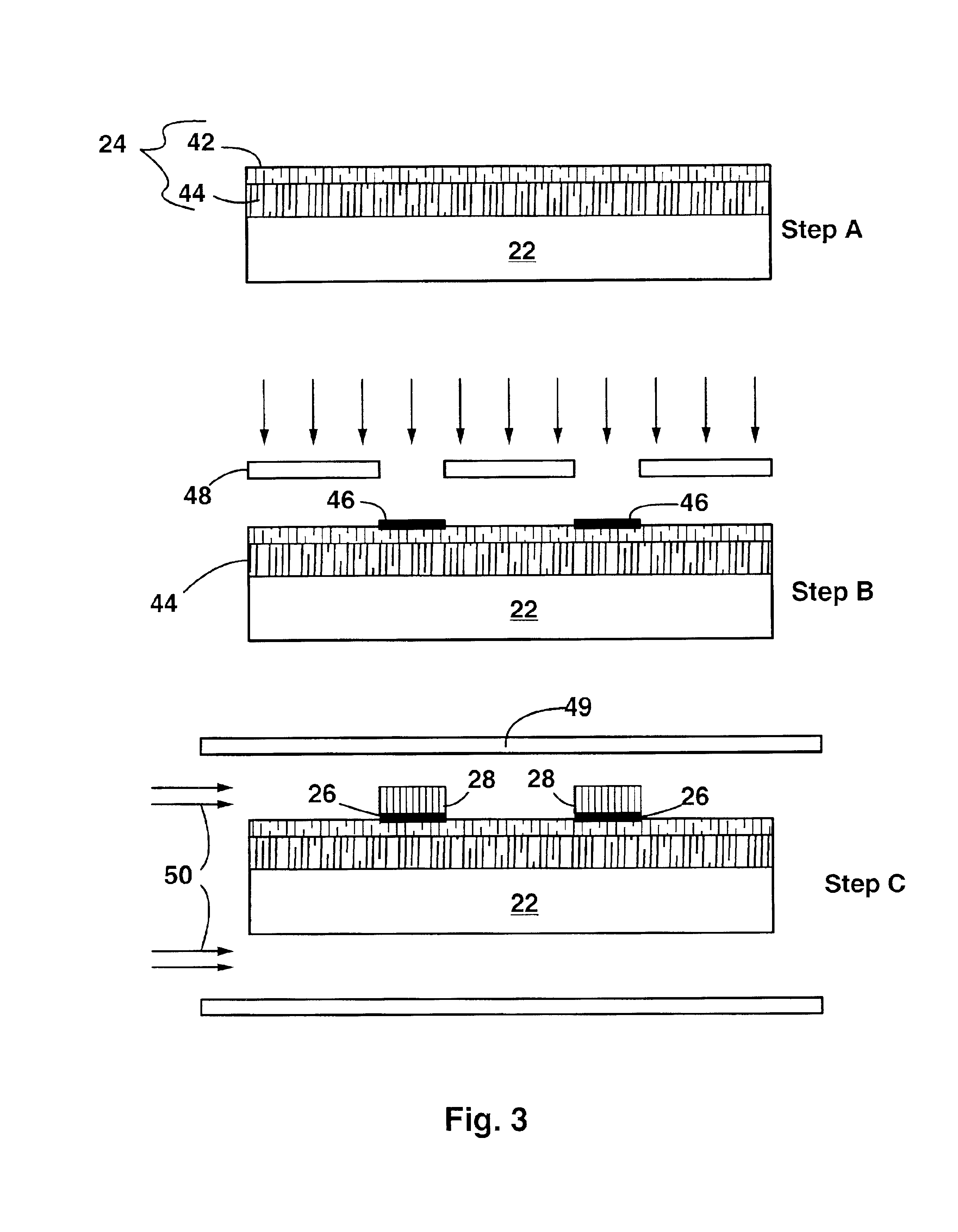

Process for making aligned carbon nanotubes

A process for preparing a patterned layer of aligned carbon nanotubes on a substrate including: applying a pattern of polymeric material to the surface of a substrate capable of supporting nanotube growth using a soft-lithographic technique; subjecting said polymeric material to carbonization to form a patterned layer of carbonized polymer on the surface of the substrate; synthesising a layer of aligned carbon nanotubes on regions of said substrate to which carbonized polymer is not attached to provide a patterned layer of aligned carbon nanotubes on said substrate.

Owner:UNIV OF DAYTON

Methods of chemically derivatizing single-wall carbon nanotubes

InactiveUS6841139B2Increase resistanceHigh yieldMaterial nanotechnologyPigmenting treatmentFiberLithium

This invention is directed to making chemical derivatives of carbon nanotubes and to uses for the derivatized nanotubes, including making arrays as a basis for synthesis of carbon fibers. In one embodiment, this invention also provides a method for preparing single wall carbon nanotubes having substituents attached to the side wall of the nanotube by reacting single wall carbon nanotubes with fluorine gas and recovering fluorine derivatized carbon nanotubes, then reacting fluorine derivatized carbon nanotubes with a nucleophile. Some of the fluorine substituents are replaced by nucleophilic substitution. If desired, the remaining fluorine can be completely or partially eliminated to produce single wall carbon nanotubes having substituents attached to the side wall of the nanotube. The substituents will, of course, be dependent on the nucleophile, and preferred nucleophiles include alkyl lithium species such as methyl lithium. Alternatively, fluorine may be fully or partially removed from fluorine derivatized carbon nanotubes by reacting the fluorine derivatized carbon nanotubes with various amounts of hydrazine, substituted hydrazine or alkyl amine. The present invention also provides seed materials for growth of single wall carbon nanotubes comprising a plurality of single wall carbon nanotubes or short tubular molecules having a catalyst precursor moiety covalently bound or physisorbed on the outer surface of the sidewall to provide the optimum metal cluster size under conditions that result in migration of the metal moiety to the tube end.

Owner:RICE UNIV

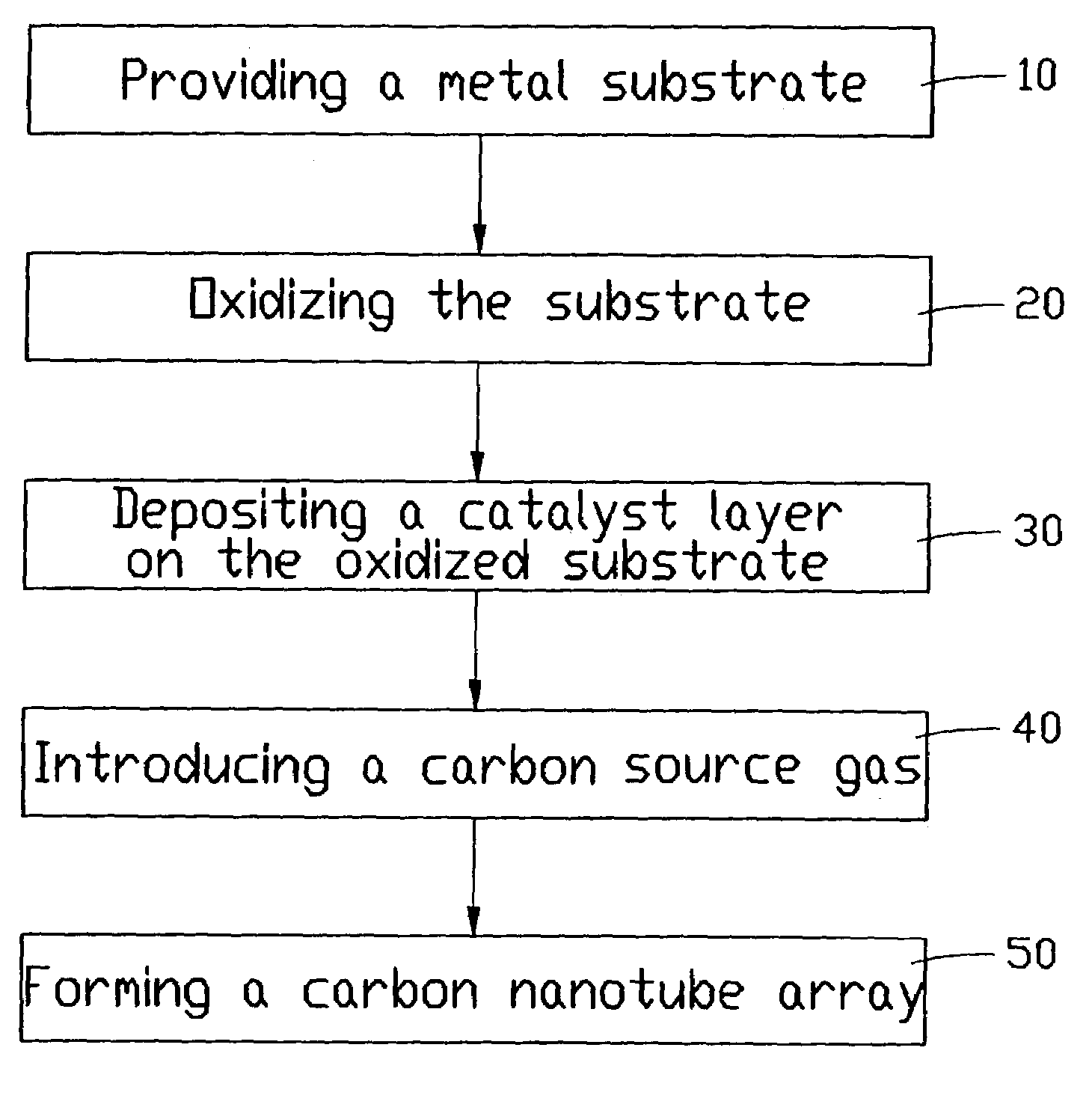

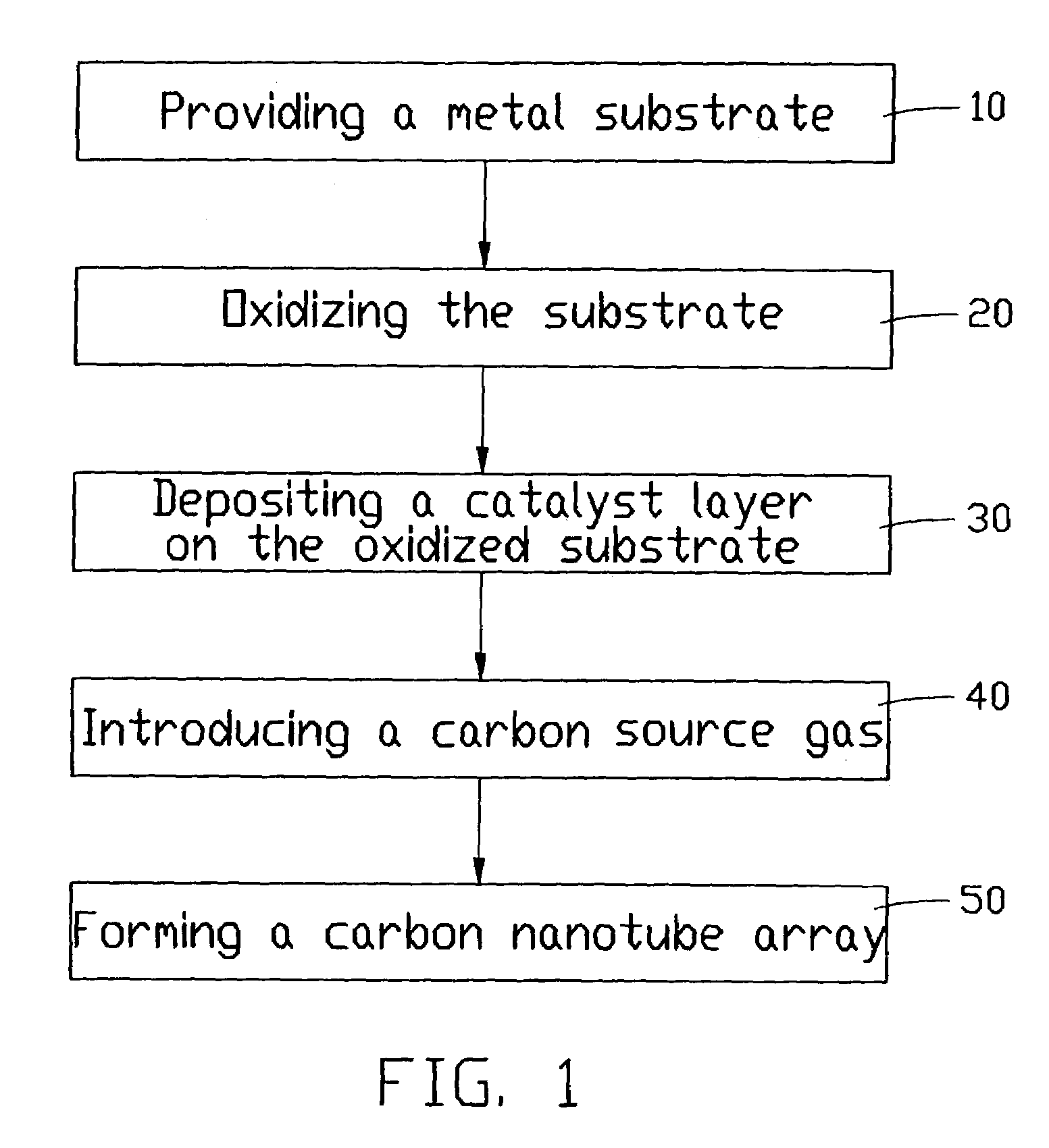

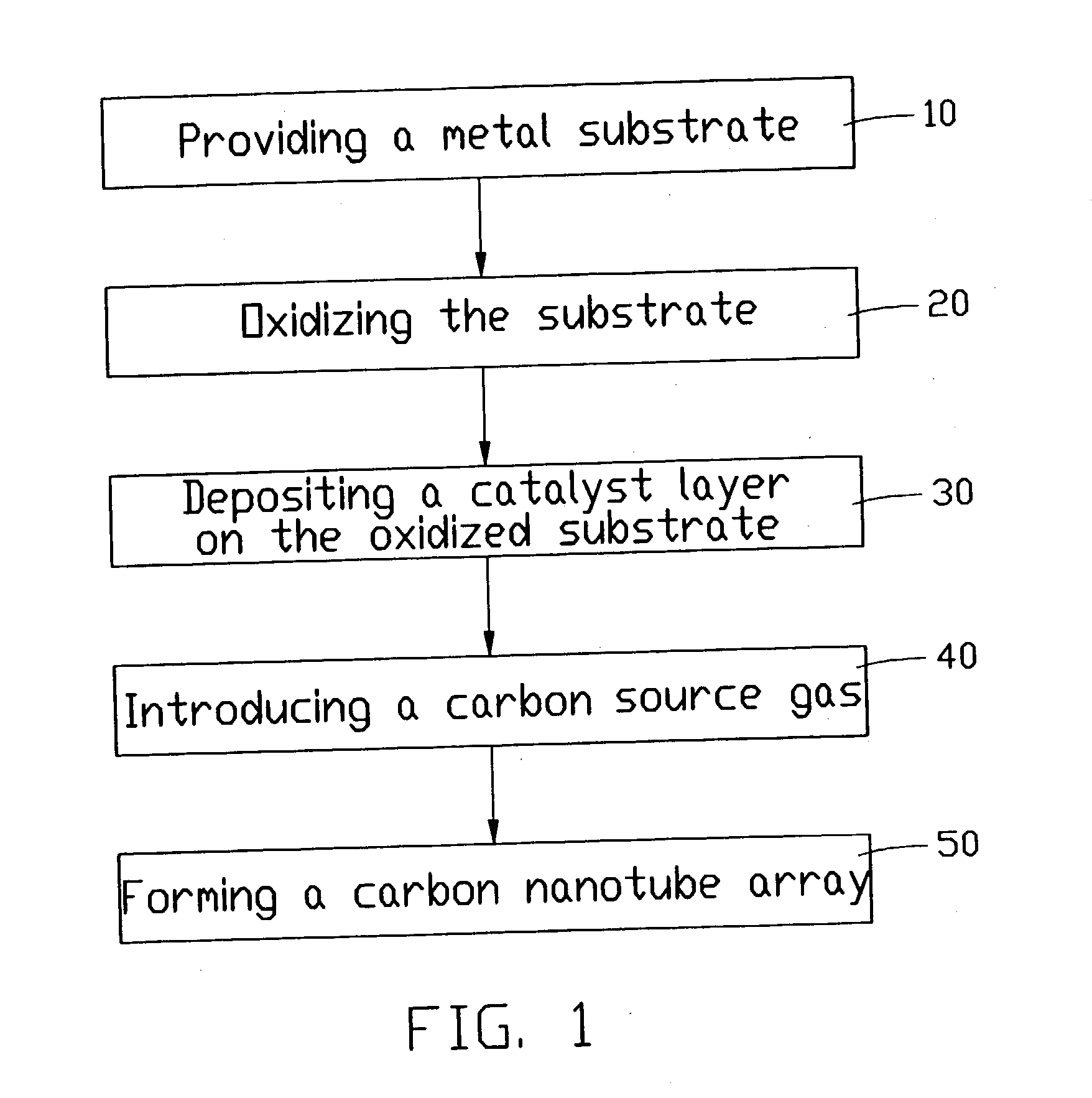

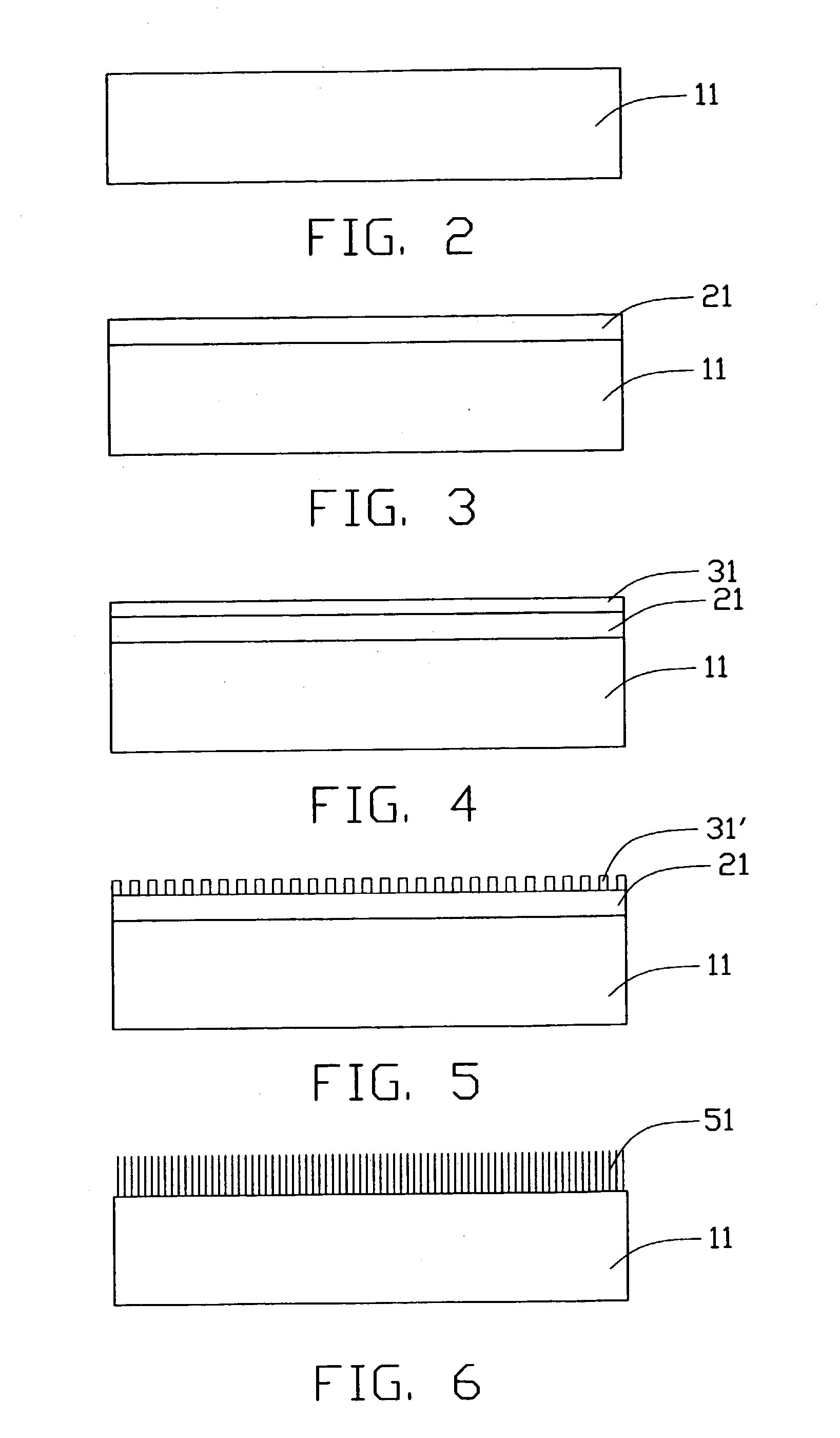

Carbon nanotube array and method for forming same

ActiveUS7160532B2Damage formationInhibition formationMaterial nanotechnologyFibre chemical featuresField emission deviceCarbon nanotube

A method for forming a carbon nanotube array using a metal substrate includes the following steps: providing a metal substrate (11); oxidizing the metal substrate to form an oxidized layer (21) thereon; depositing a catalyst layer (31) on the oxidized layer; introducing a carbon source gas; and thus forming a carbon nanotube array (61) extending from the metal substrate. Generally, any metallic material can be used as the metal substrate. Various carbon nanotube arrays formed using various metal substrates can be incorporated into a wide variety of high power electronic device applications such as field emission devices (FEDs), electron guns, and so on. Carbon nanotubes formed using any of a variety of metal substrates are well aligned, and uniformly extend in a direction substantially perpendicular to the metal substrate.

Owner:TSINGHUA UNIV +1

Directed assembly of highly-organized carbon nanotube architectures

A method of controllably aligning carbon nanotubes to a template structure to fabricate a variety of carbon nanotube containing structures and devices having desired characteristics is provided. The method allows simultaneous, selective growth of both vertically and horizontally controllably aligned nanotubes on the template structure but not on a substrate in a single process step.

Owner:RENESSELAER POLYTECHNIC INST

Chemically modifying single wall carbon nanotubes to facilitate dispersal in solvents

InactiveUS6875412B2High yieldIncrease resistanceMaterial nanotechnologyIndividual molecule manipulationFiberCarbon fibers

Owner:RICE UNIV

Cnt-based resistive heating for deicing composite structures

ActiveUS20110024409A1Prevent freezingInhibition formationMaterial nanotechnologyLayered productsFiberCarbon nanotube

A composite structure includes a matrix material and a carbon nanotube (CNT)-infused fiber material that includes a plurality of carbon nanotubes (CNTs) infused to a fiber material. The CNT-infused fiber material is disposed throughout a portion of the matrix material. The composite structure is adapted for application of a current through the CNT-infused fiber material to provide heating of the composite structure. A heating element includes a CNT-infused fiber material includes a plurality of CNTs infused to a fiber material. The CNT-infused fiber material is of sufficient proportions to provide heating to a structure in need thereof.

Owner:APPL NANOSTRUCTURED SOLUTIONS LLC

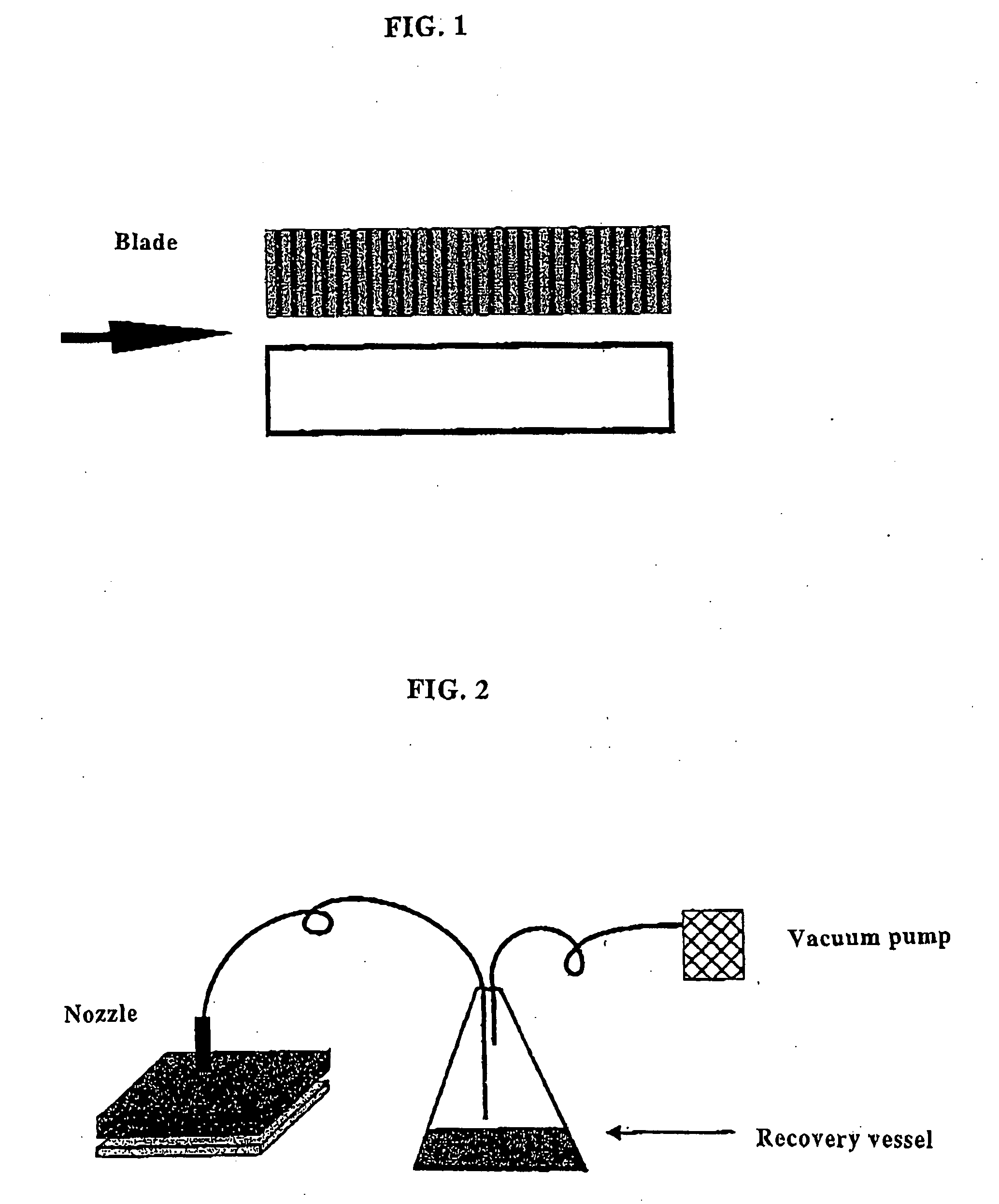

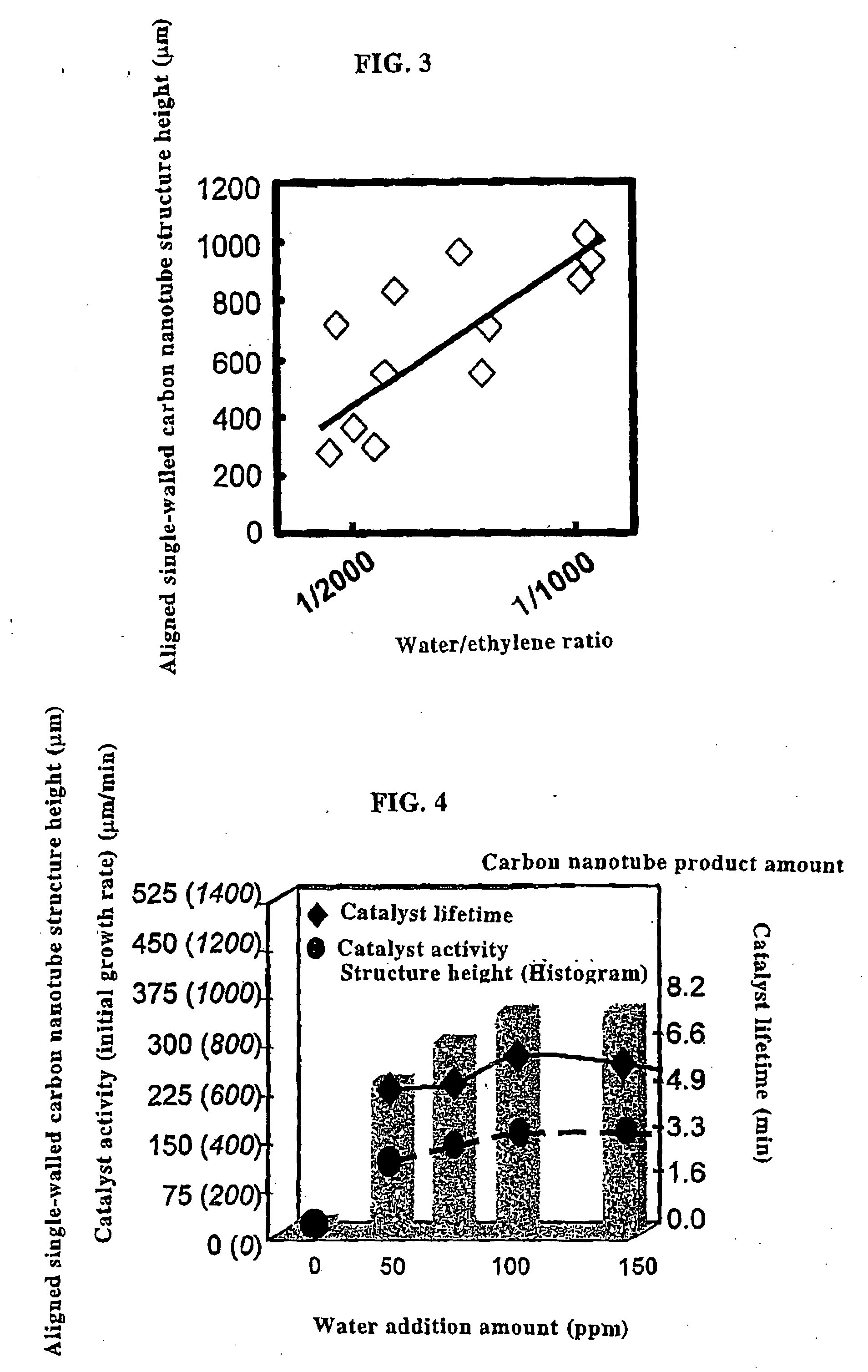

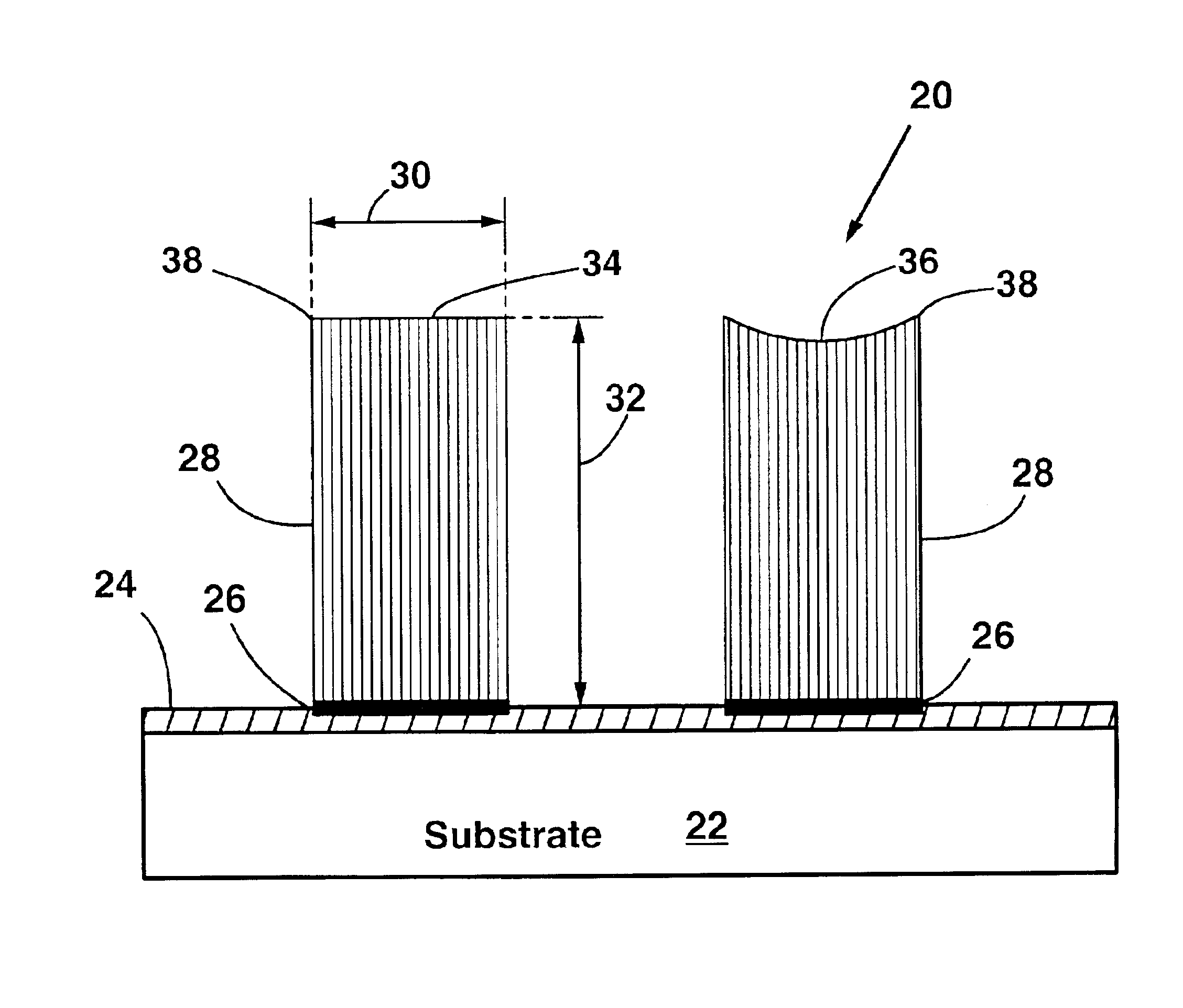

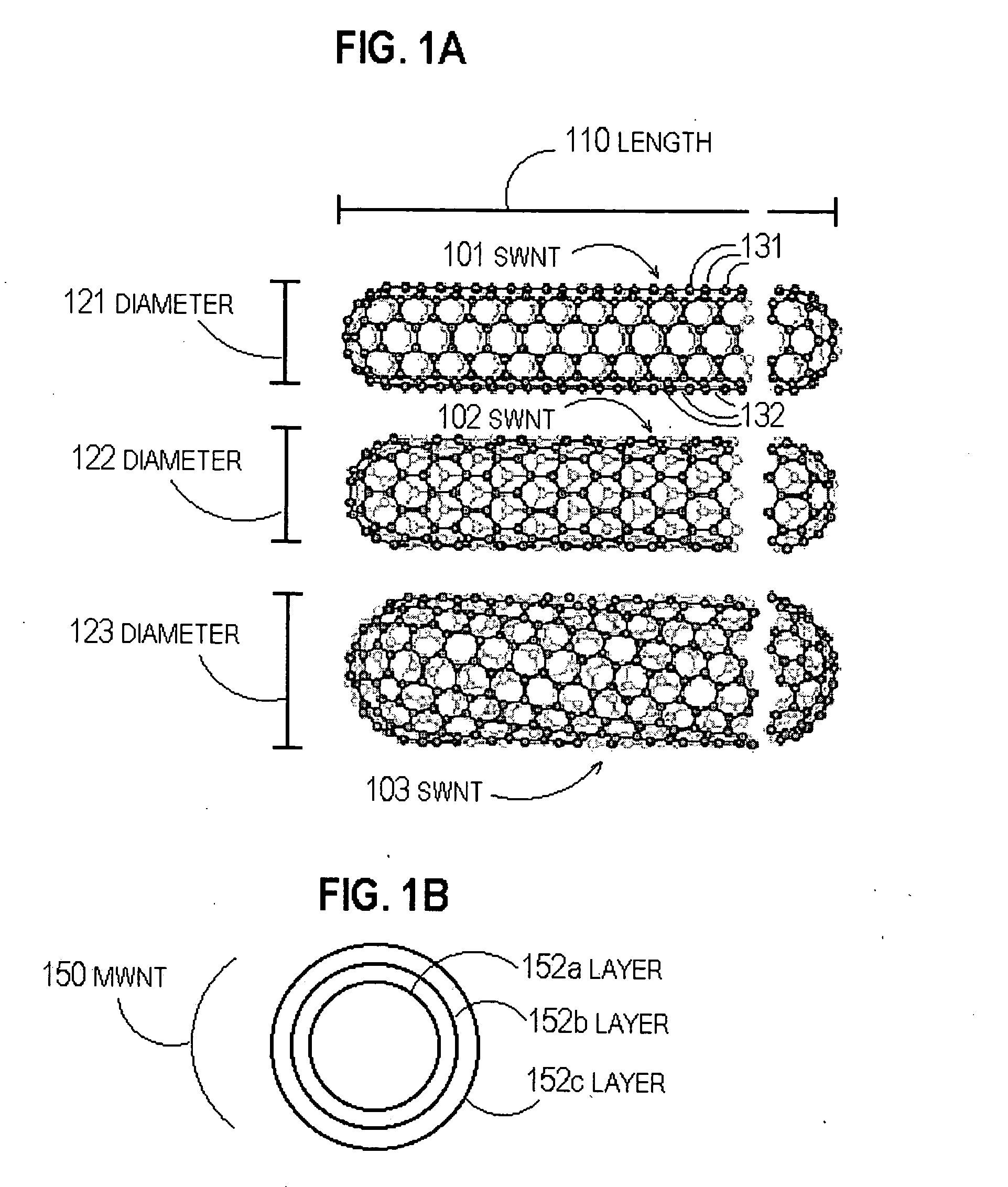

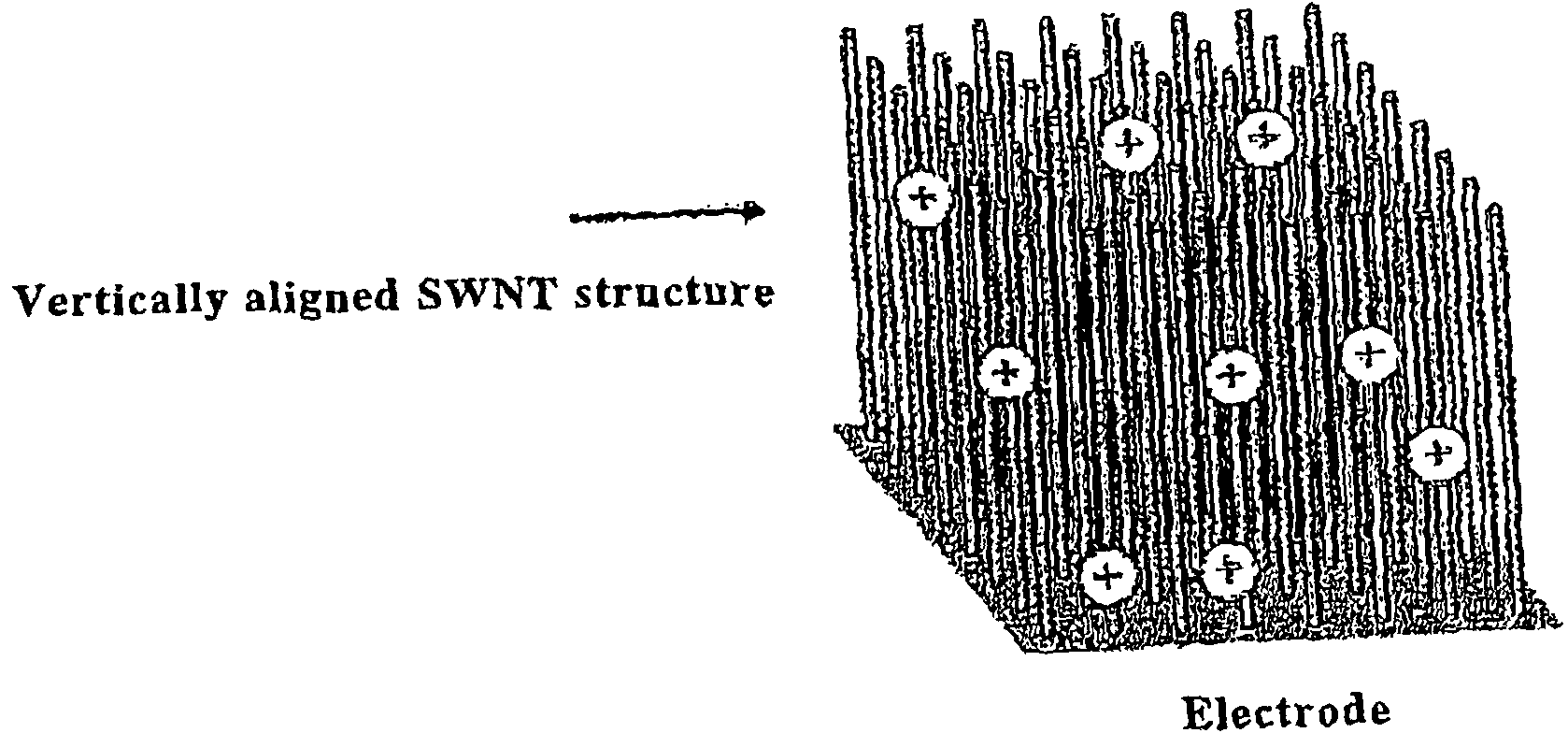

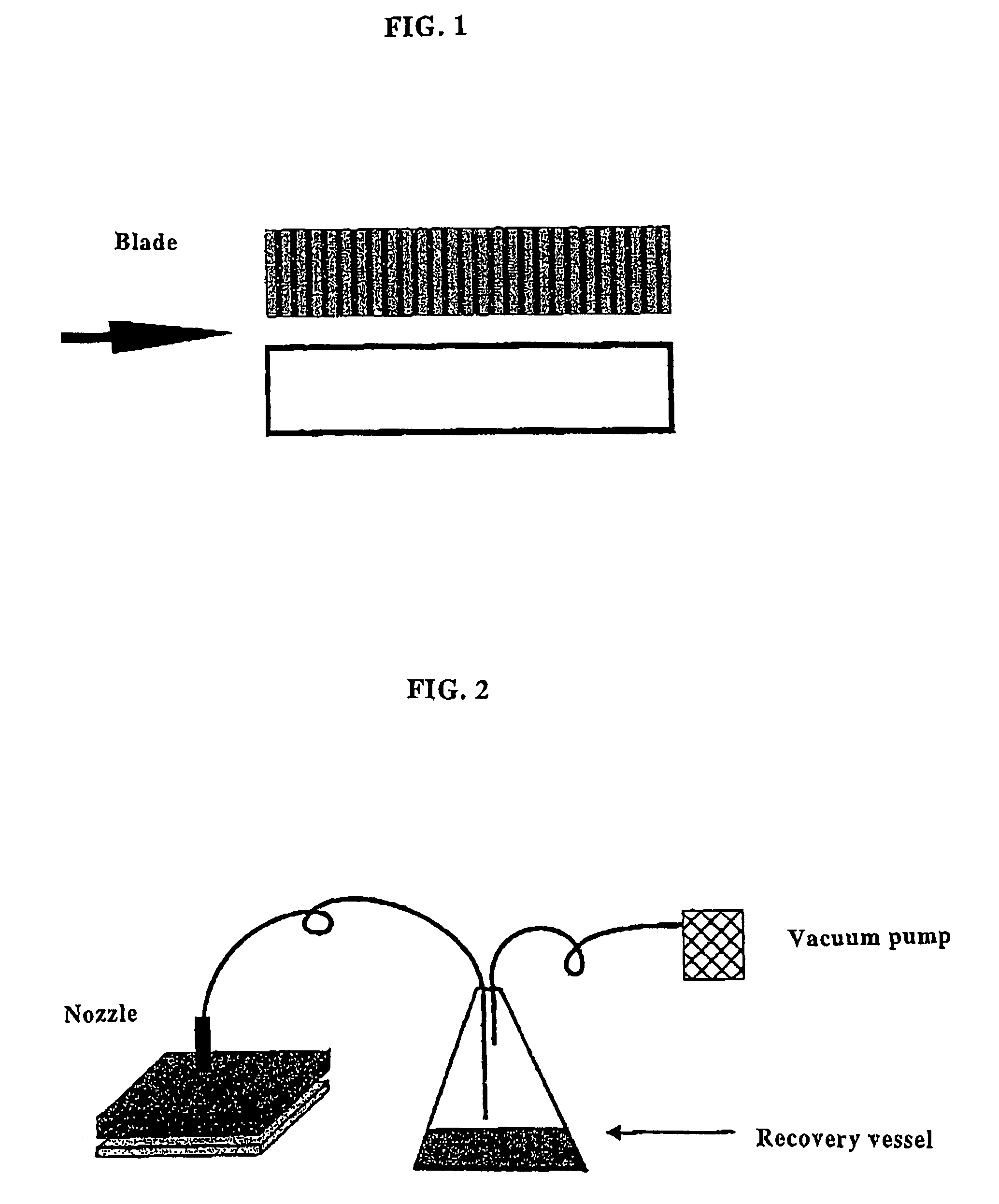

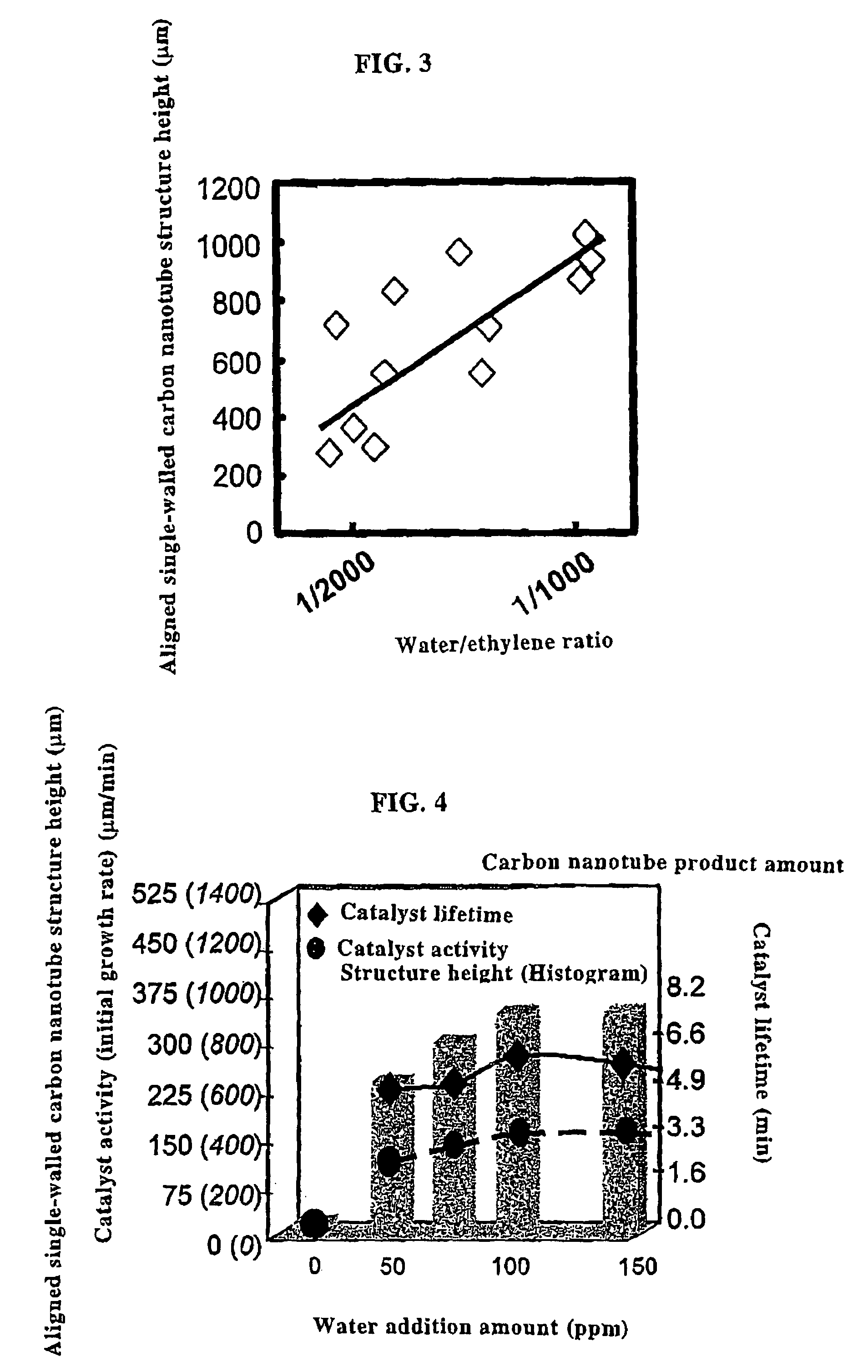

Single-Walled Carbon Nanotube and Aligned Single-Walled Carbon Nanotube Bulk Structure, and Their Production Process, Production Apparatus and Application Use

ActiveUS20080318049A1Efficient productionIncrease freedomMaterial nanotechnologyCell electrodesMetal catalystCarbon nanotube

This invention provides an aligned single-layer carbon nanotube bulk structure, which comprises an assembly of a plurality of aligned single-layer carbon nanotube and has a height of not less than 10 μm, and an aligned single-layer carbon nanotube bulk structure which comprises an assembly of a plurality of aligned single-layer carbon nanotubes and has been patterned in a predetermined form. This structure is produced by chemical vapor deposition (CVD) of carbon nanotubes in the presence of a metal catalyst in a reaction atmosphere with an oxidizing agent, preferably water, added thereto. An aligned single-layer carbon nanotube bulk structure, which has realized high purify and significantly large scaled length or height, its production process and apparatus, and its applied products are provided.

Owner:NAT INST OF ADVANCED IND SCI & TECH

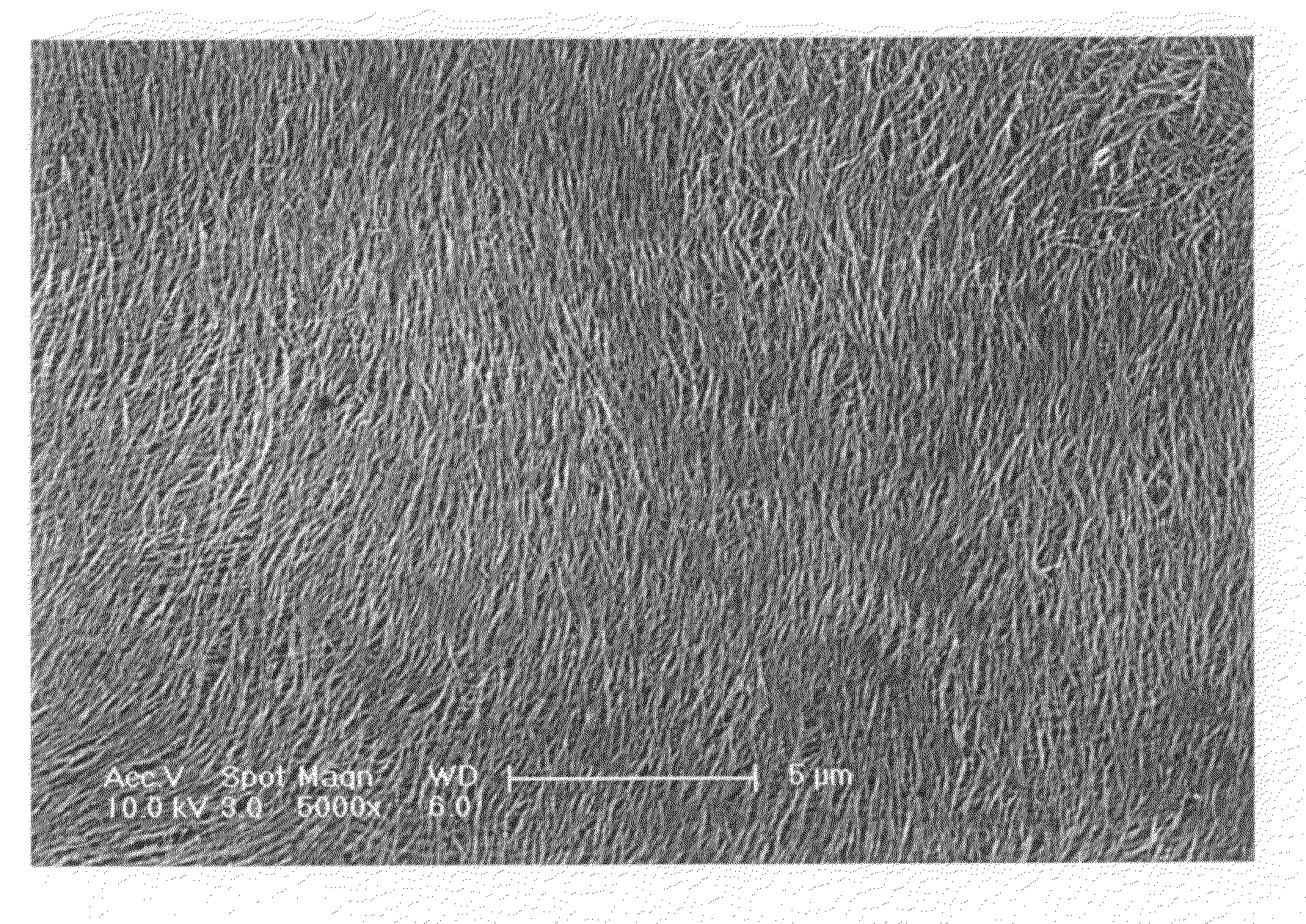

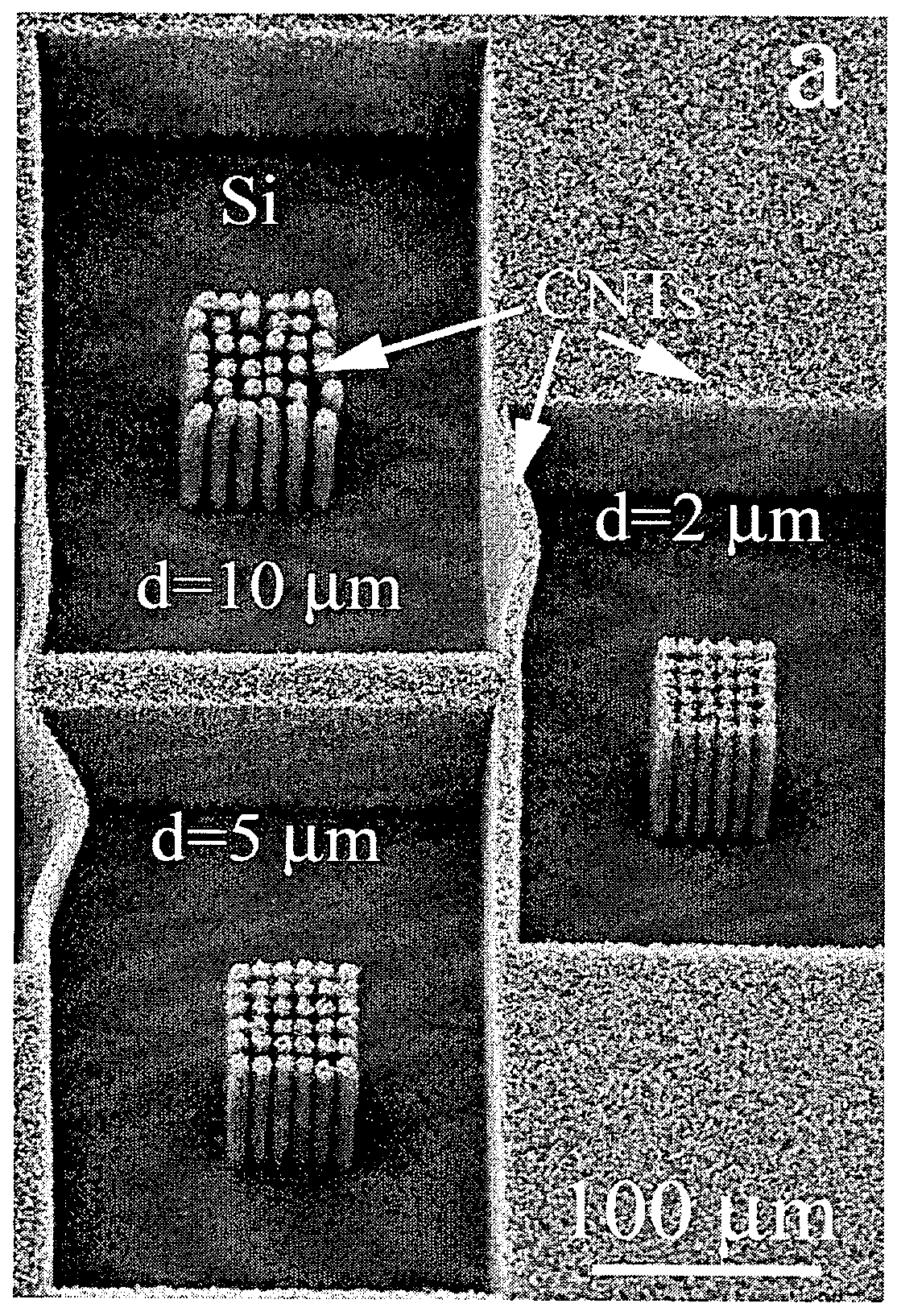

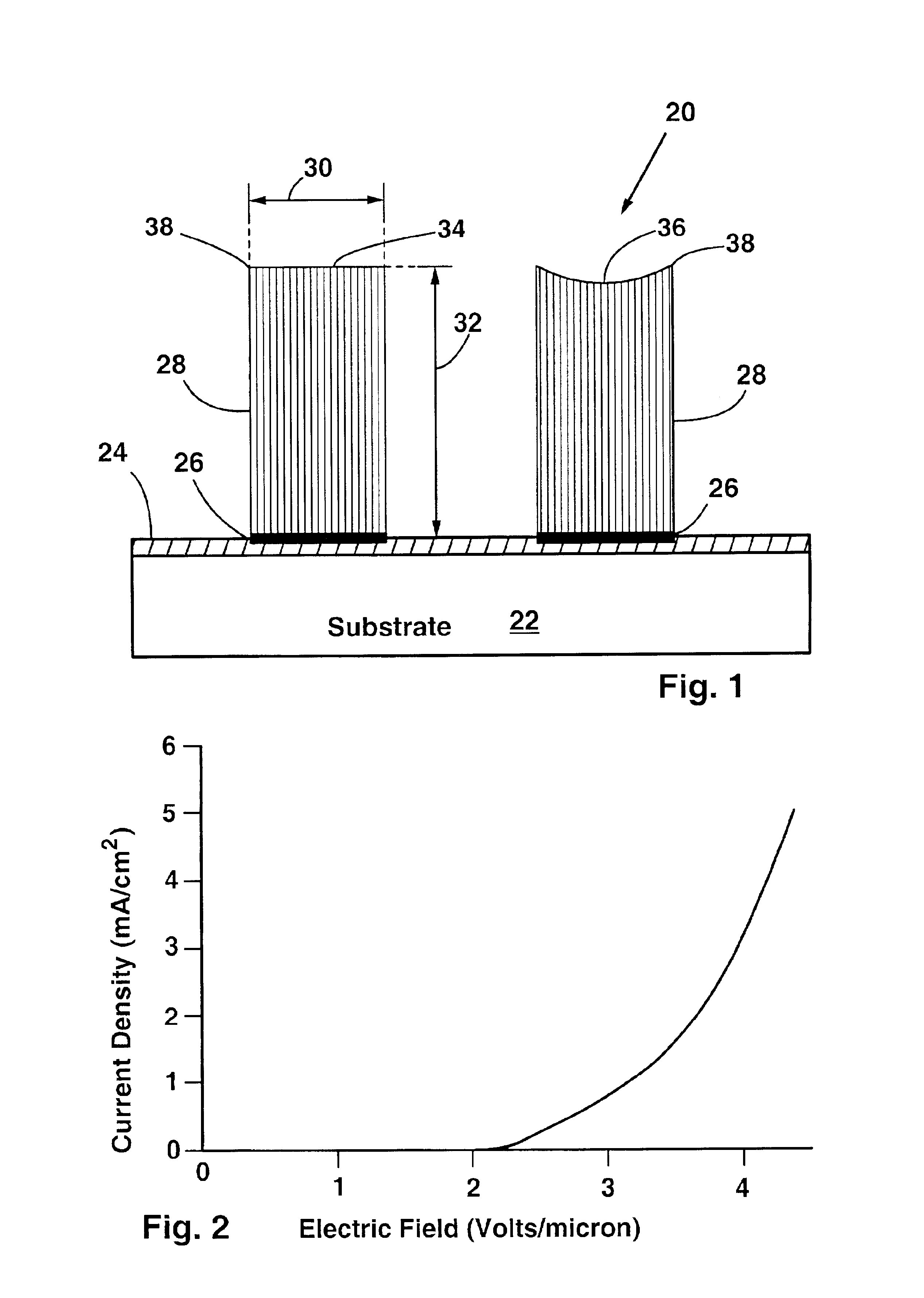

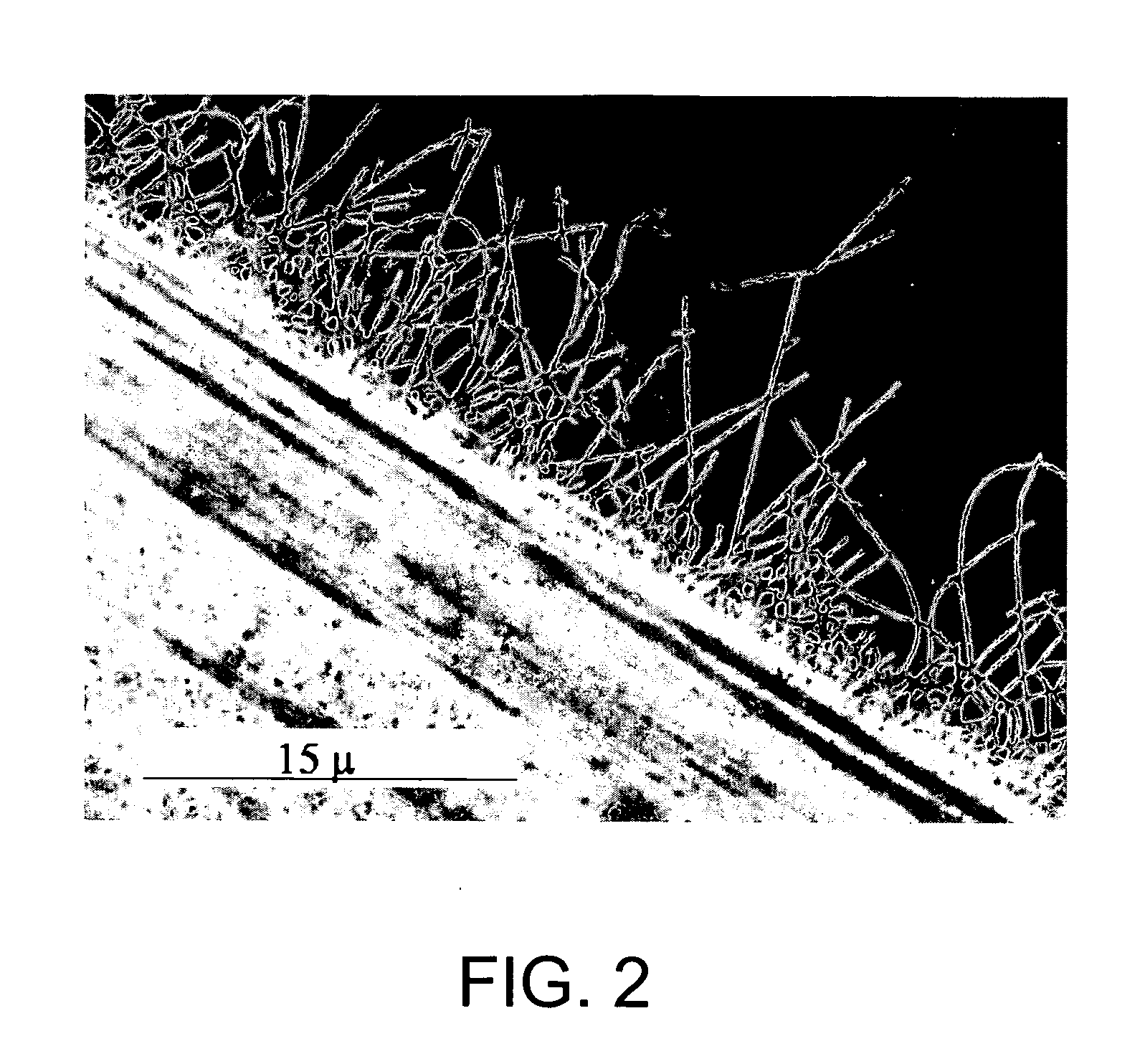

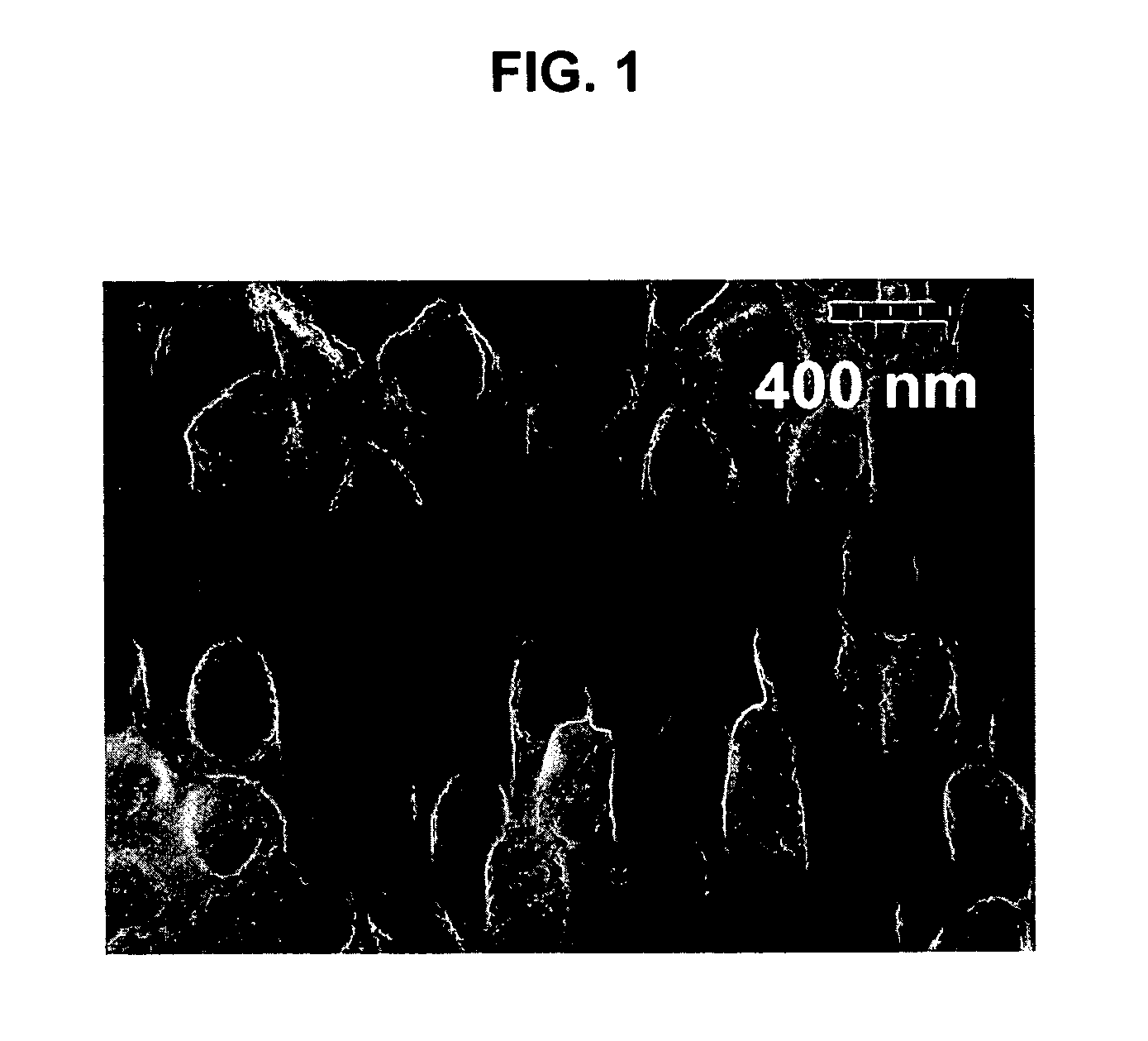

Self-oriented bundles of carbon nanotubes and method of making same

A field emission device having bundles of aligned parallel carbon nanotubes on a substrate. The carbon nanotubes are oriented perpendicular to the substrate. The carbon nanotube bundles may be up to 300 microns tall, for example. The bundles of carbon nanotubes extend only from regions of the substrate patterned with a catalyst material. Preferably, the catalyst material is iron oxide. The substrate is preferably porous silicon, as this produces the highest quality, most well-aligned nanotubes. Smooth, nonporous silicon or quartz can also be used as the substrate. The method of the invention starts with forming a porous layer on a silicon substrate by electrochemical etching. Then, a thin layer of iron is deposited on the porous layer in patterned regions. The iron is then oxidized into iron oxide, and then the substrate is exposed to ethylene gas at elevated temperature. The iron oxide catalyzes the formation of bundles of aligned parallel carbon nanotubes which grow perpendicular to the substrate surface. The height of the nanotube bundles above the substrate is determined by the duration of the catalysis step. The nanotube bundles only grow from the patterned regions.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Directed assembly of highly-organized carbon nanotube architectures

A method of controllably aligning carbon nanotubes to a template structure to fabricate a variety of carbon nanotube containing structures and devices having desired characteristics is provided. The method allows simultaneous, selective growth of both vertically and horizontally controllably aligned nanotubes on the template structure but not on a substrate in a single process step.

Owner:RENESSELAER POLYTECHNIC INST

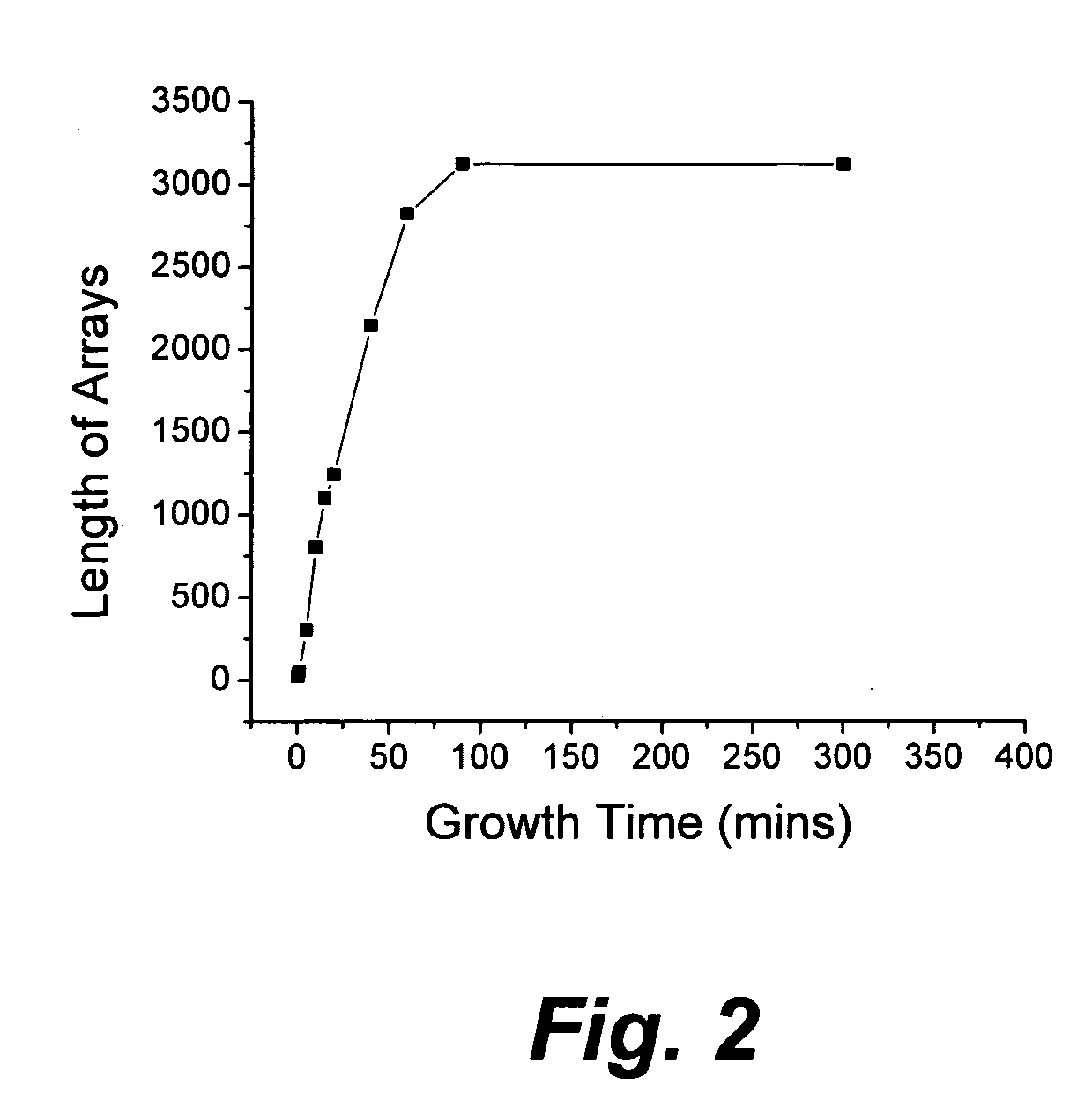

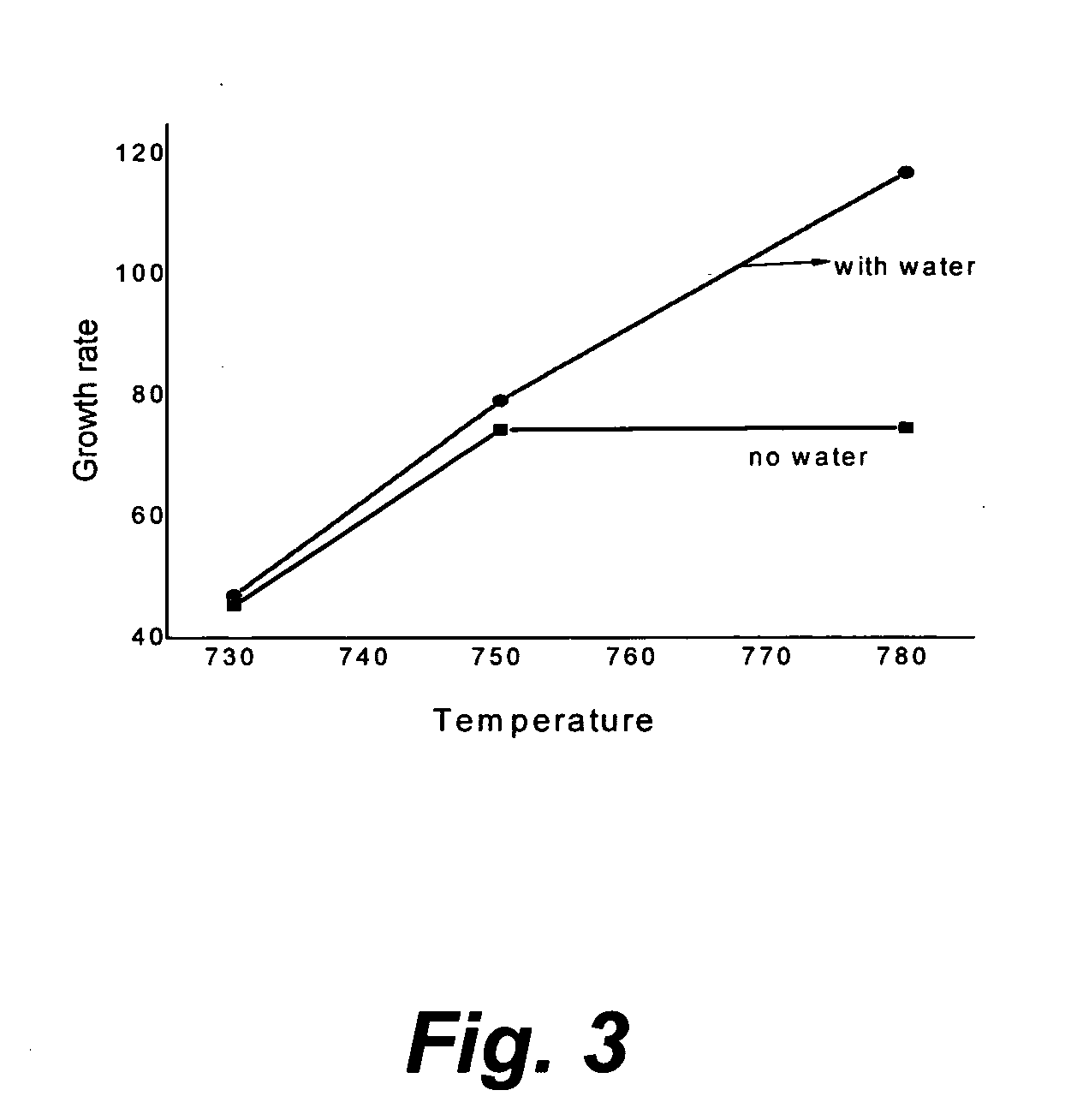

Arrays of long carbon nanotubes for fiber spinning

InactiveUS20070116631A1Material nanotechnologyPhysical/chemical process catalystsHydrogenWater vapor

An array of long carbon nanotubes (i.e. an array where the average length of the nanotubes is greater than 0.5 millimeters) is prepared by exposing a supported catalyst at elevated temperature to a gas mixture of hydrocarbon, inert gas, and a relatively low percentage of hydrogen. Addition of water vapor to the gas mixture may result in an increase in the length of the nanotubes, an increase the rate of growth, and a decrease in contamination of the array by amorphous carbon. The temperature and growth time are also chosen to minimize the amount of amorphous carbon that forms on the array. Fibers spun from the array have a higher tensile strength compared to known CNT fibers.

Owner:RGT UNIV OF CALIFORNIA

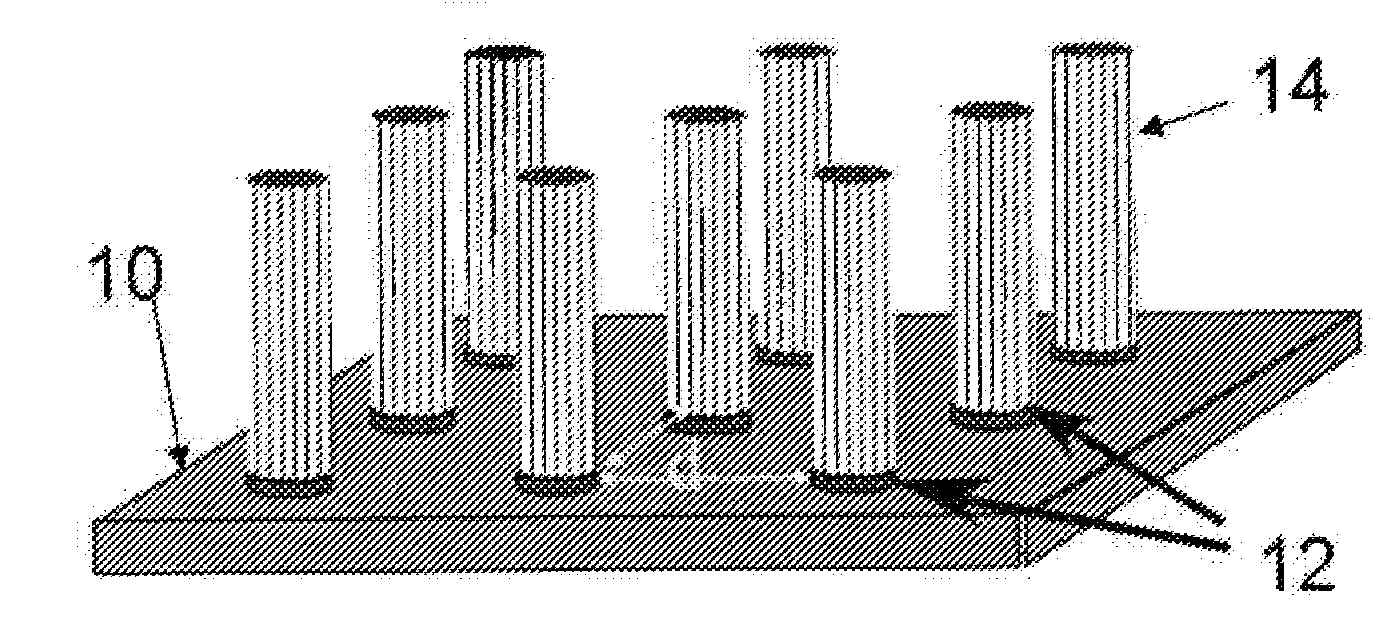

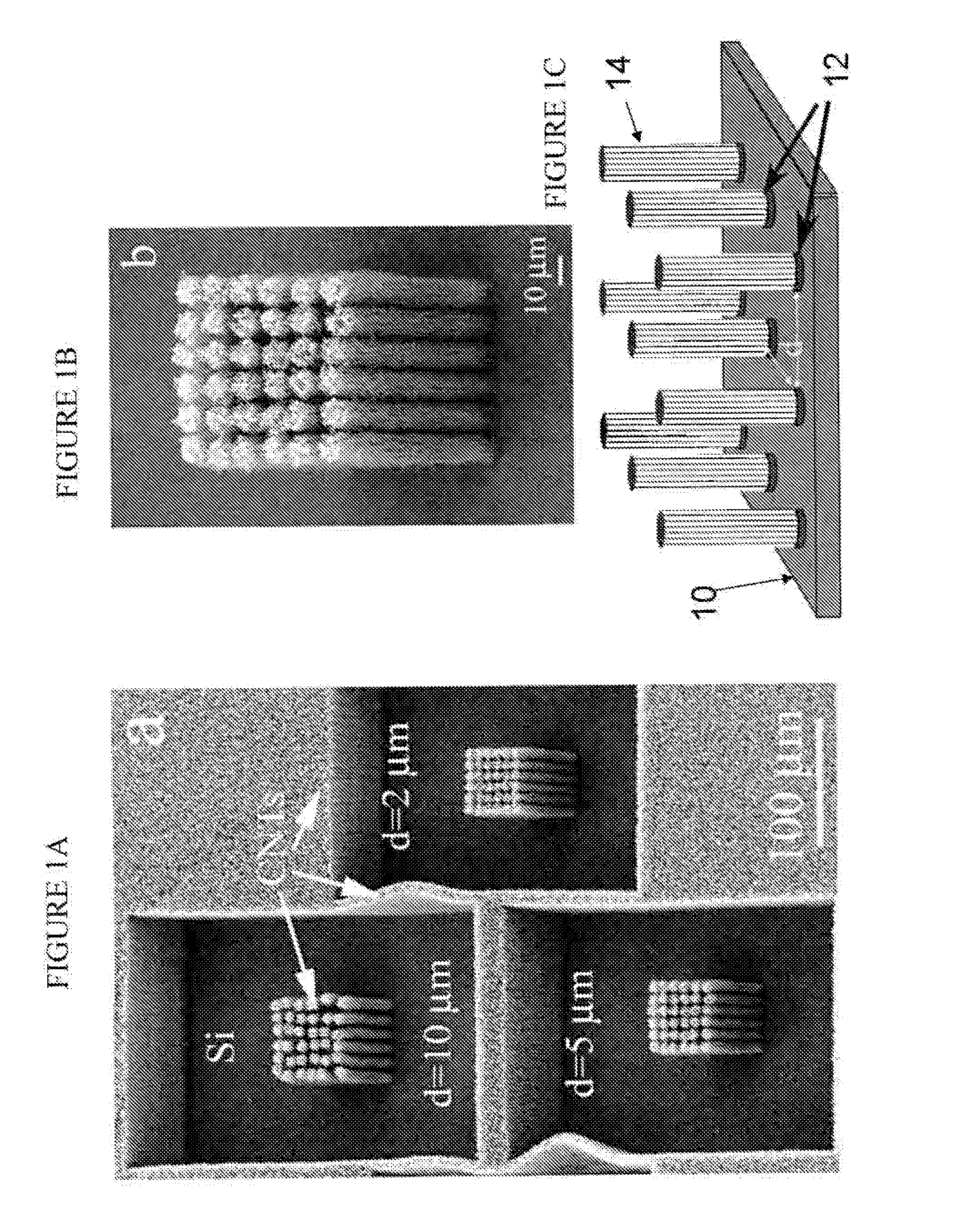

Methods of making spatially aligned nanotubes and nanotube arrays

ActiveUS8367035B2Easily integrated into functional deviceGood electronic behavior (and/or optical properties)Material nanotechnologyNanoinformaticsElectronNanotube array

The present invention provides arrays of longitudinally aligned carbon nanotubes having specified positions, nanotube densities and orientations, and corresponding methods of making nanotube arrays using guided growth and guided deposition methods. Also provided are electronic devices and device arrays comprising one or more arrays of longitudinally aligned carbon nanotubes including multilayer nanotube array structures and devices.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

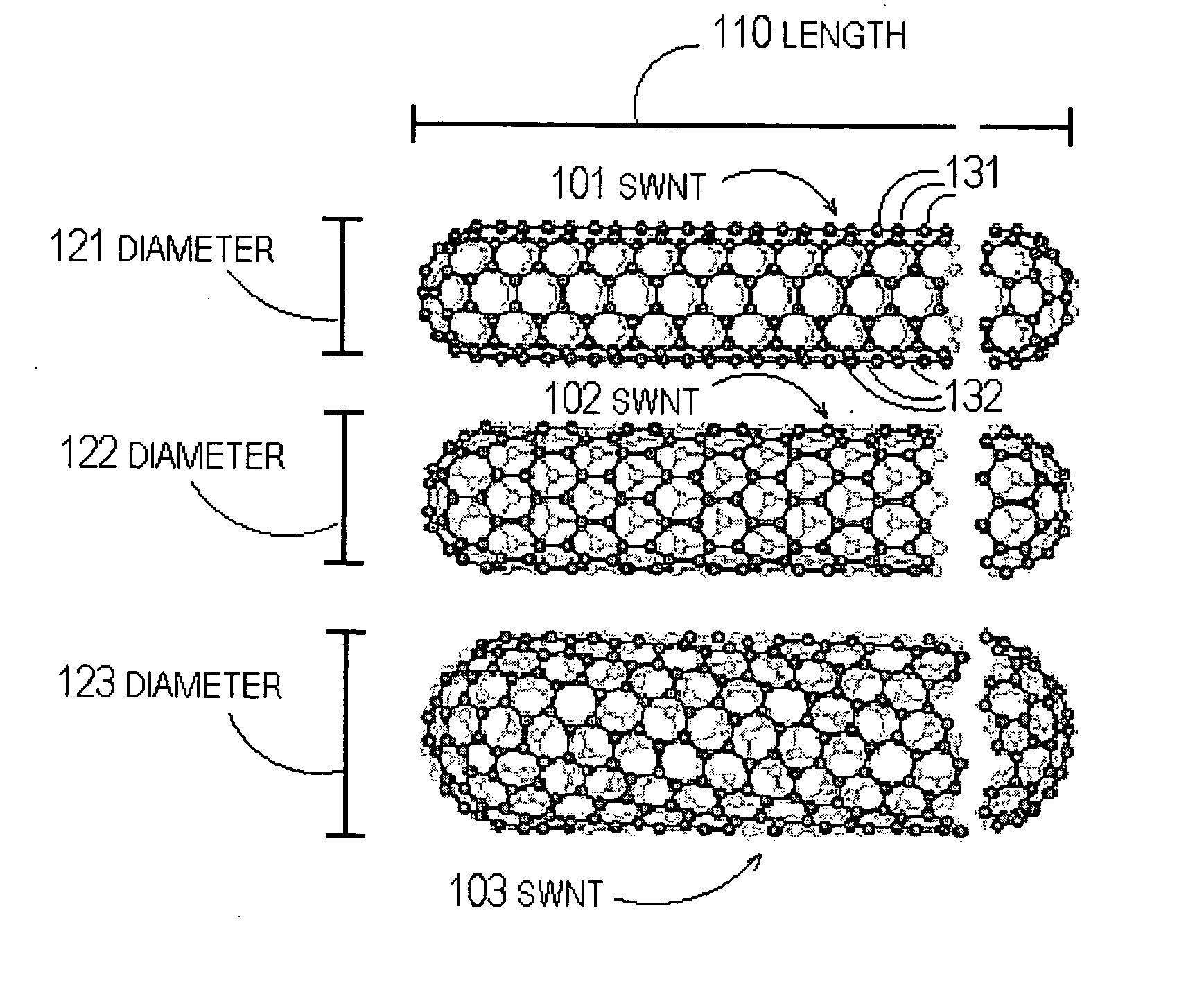

Systems and methods for producing single-walled carbon nanotubes (SWNTS) on a substrate

According to one embodiment, a method of fabricating a nanotube on a substrate is provided. The method can include a step for attaching a catalyst to a substrate. The method can also include a step for heating the catalyst to a predetermined temperature such that a nanotube grows from the catalyst. Further, the method can include a step for directing a feeding gas over the catalyst in a predetermined direction such that the nanotube grows in the predetermined direction.

Owner:DUKE UNIV

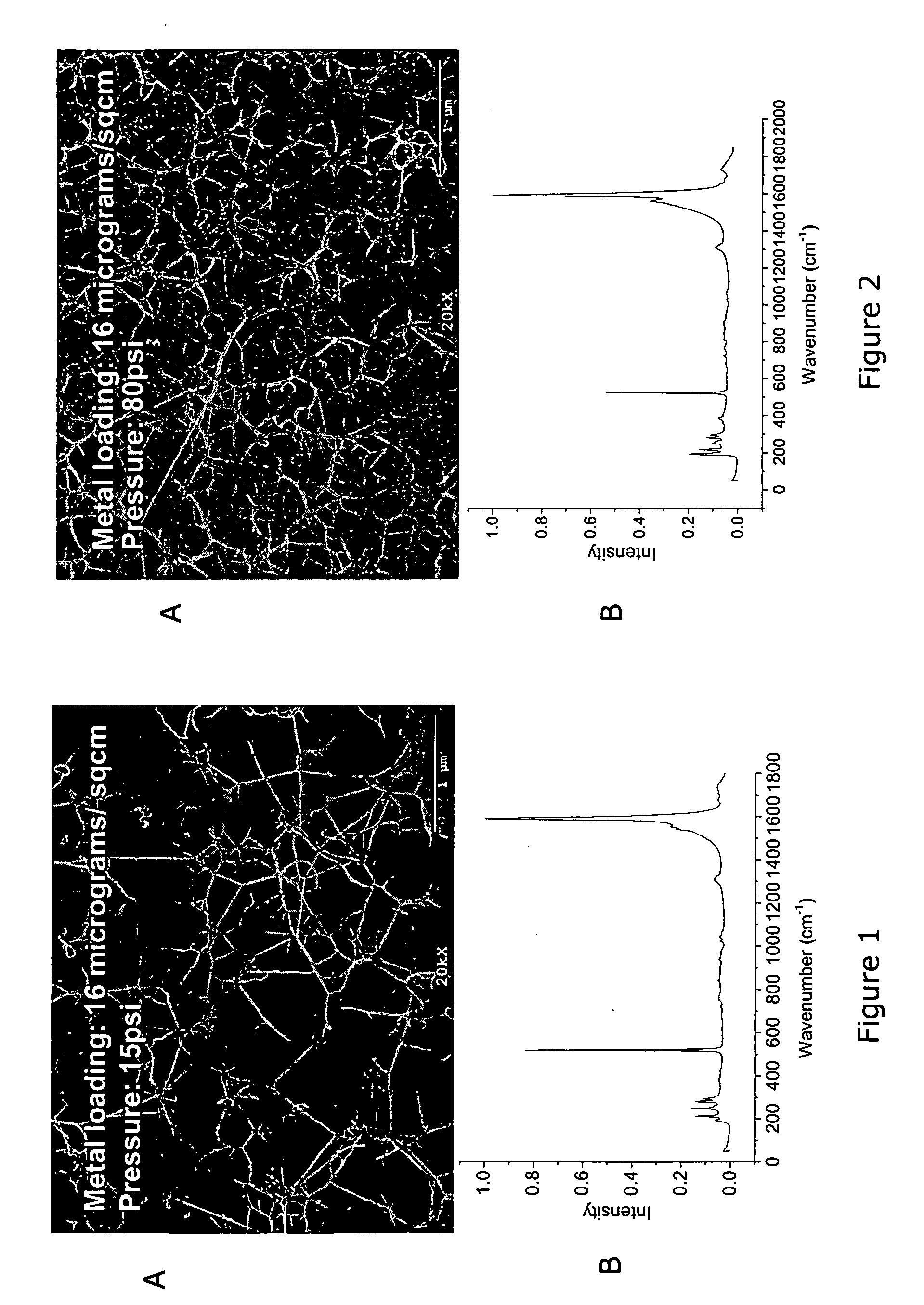

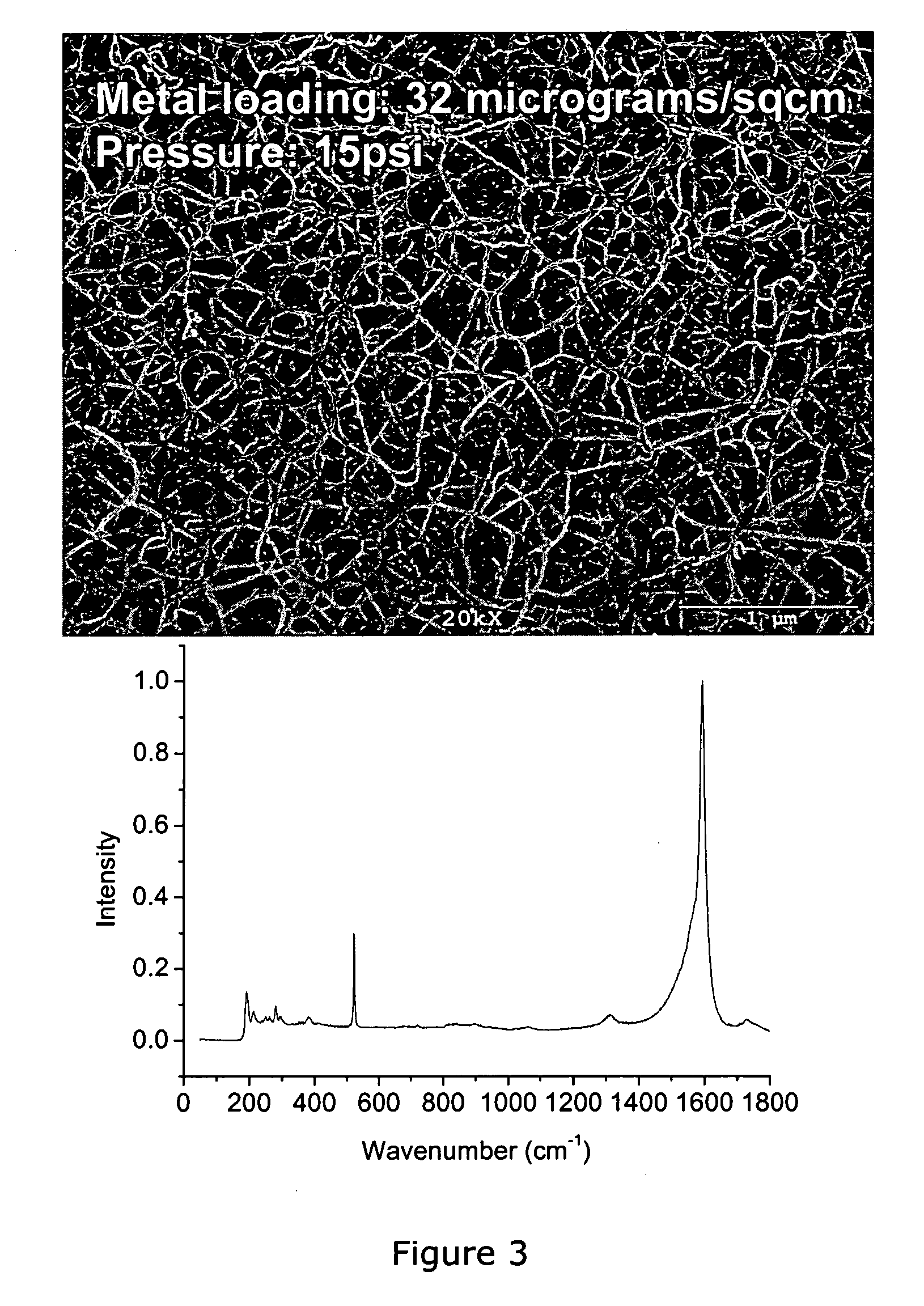

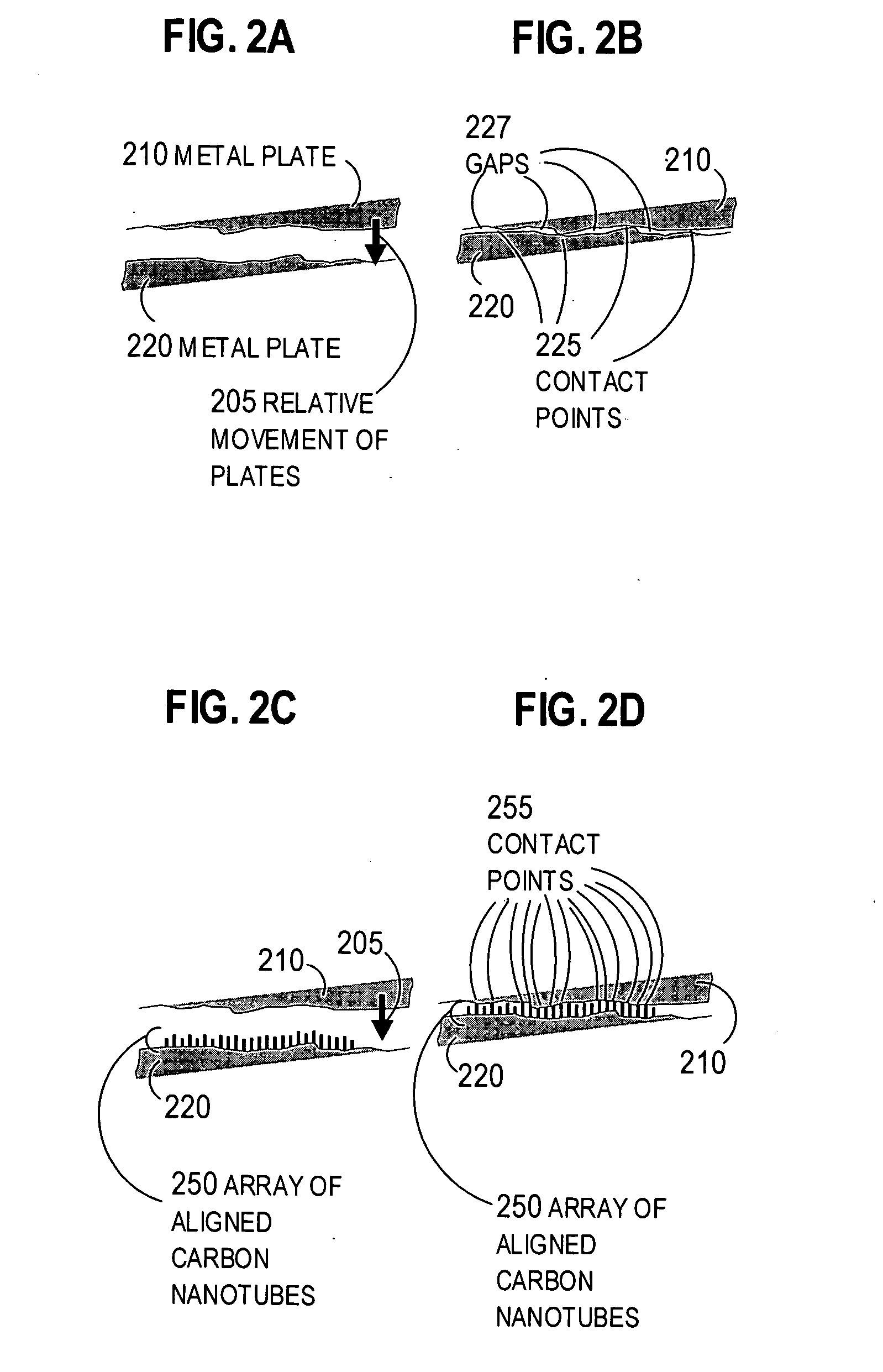

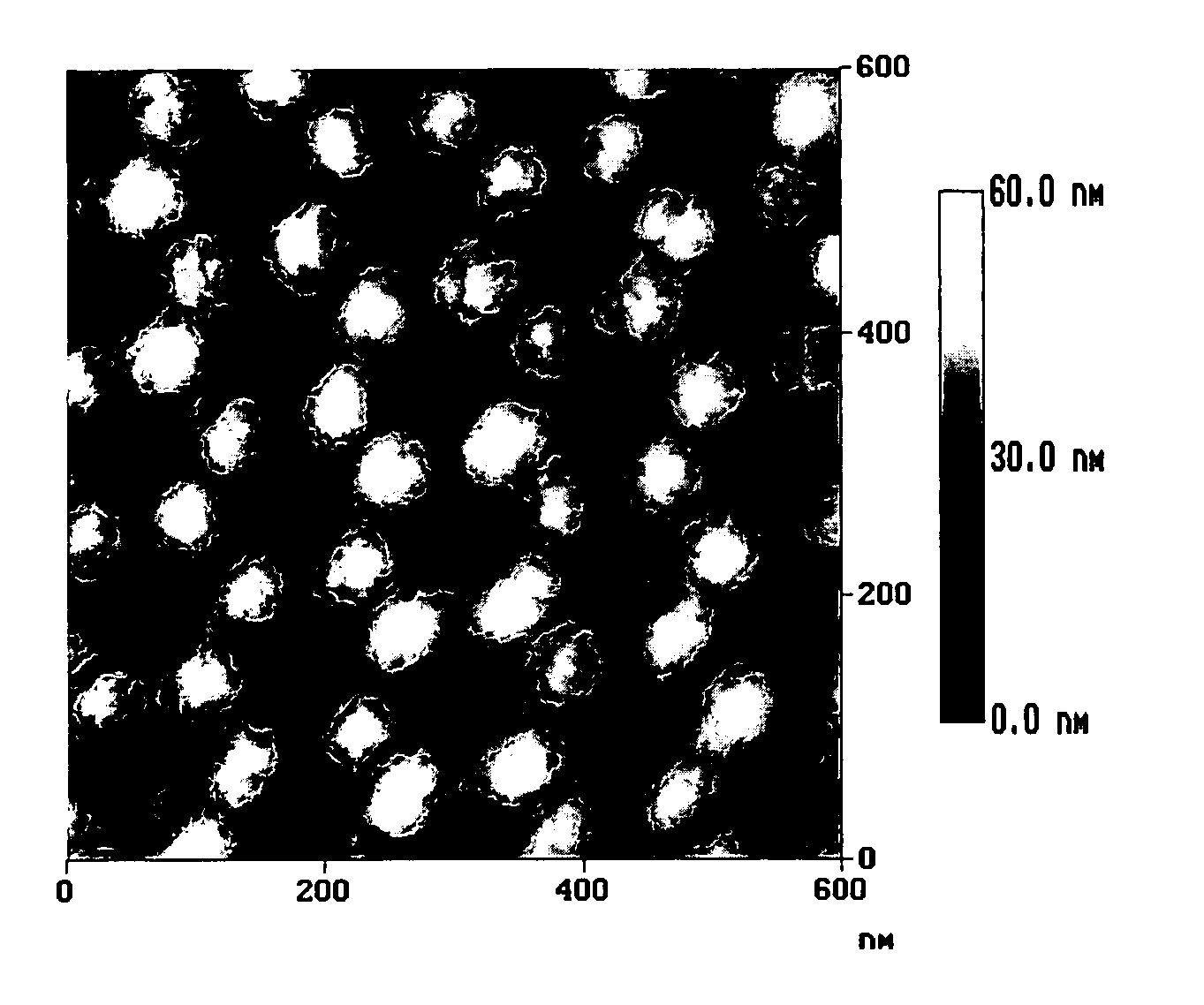

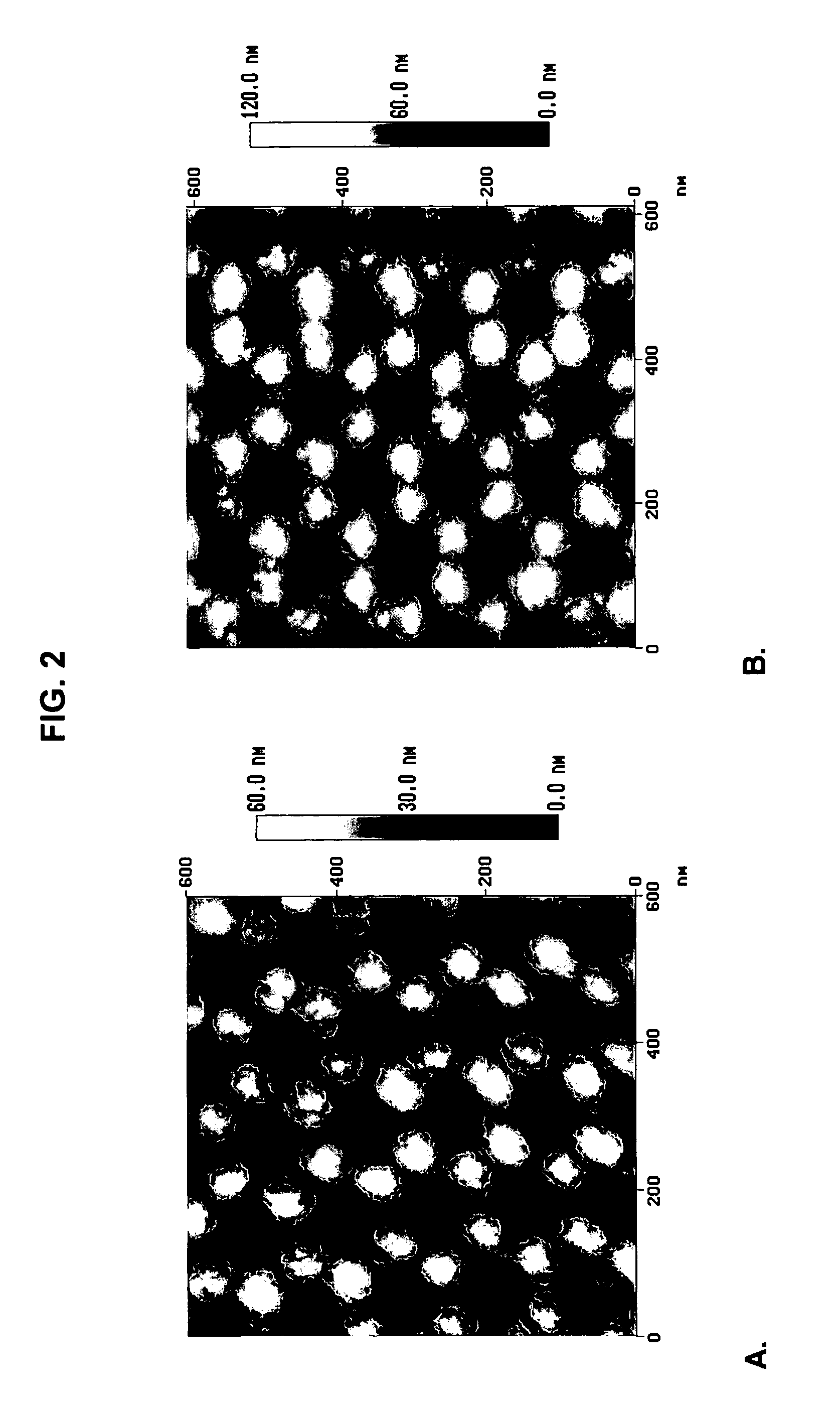

Method of making carbon nanotube arrays, and thermal interfaces using same

Thermal interfaces and methods include an array of carbon nanotubes aligned substantively perpendicularly from a substrate. One method includes arranging metal catalyst particles with a particular ligand on a fluid surface of a Langmuir-Blodgett trough. This forms uniformly spaced particles with spacing based on the particular ligand. The uniformly spaced metal catalyst particles are deposited on a substrate and carbon nanotubes are grown on the particles using chemical vapor deposition. A highly efficient thermal interface can be produced with a carbon nanotube packing ratio greater than fifty percent and used in a thermal switch or other device. In some methods, commercially available nanotubes are condensed on a substrate using carbon nanotubes with terminal carboxylic acids in solution and an amine monolayer on the substrate. Pretreatment of the nanotubes in a switch by applying heavy pressure between two surfaces results in good thermal conductivity between those surfaces at smaller operating pressures.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

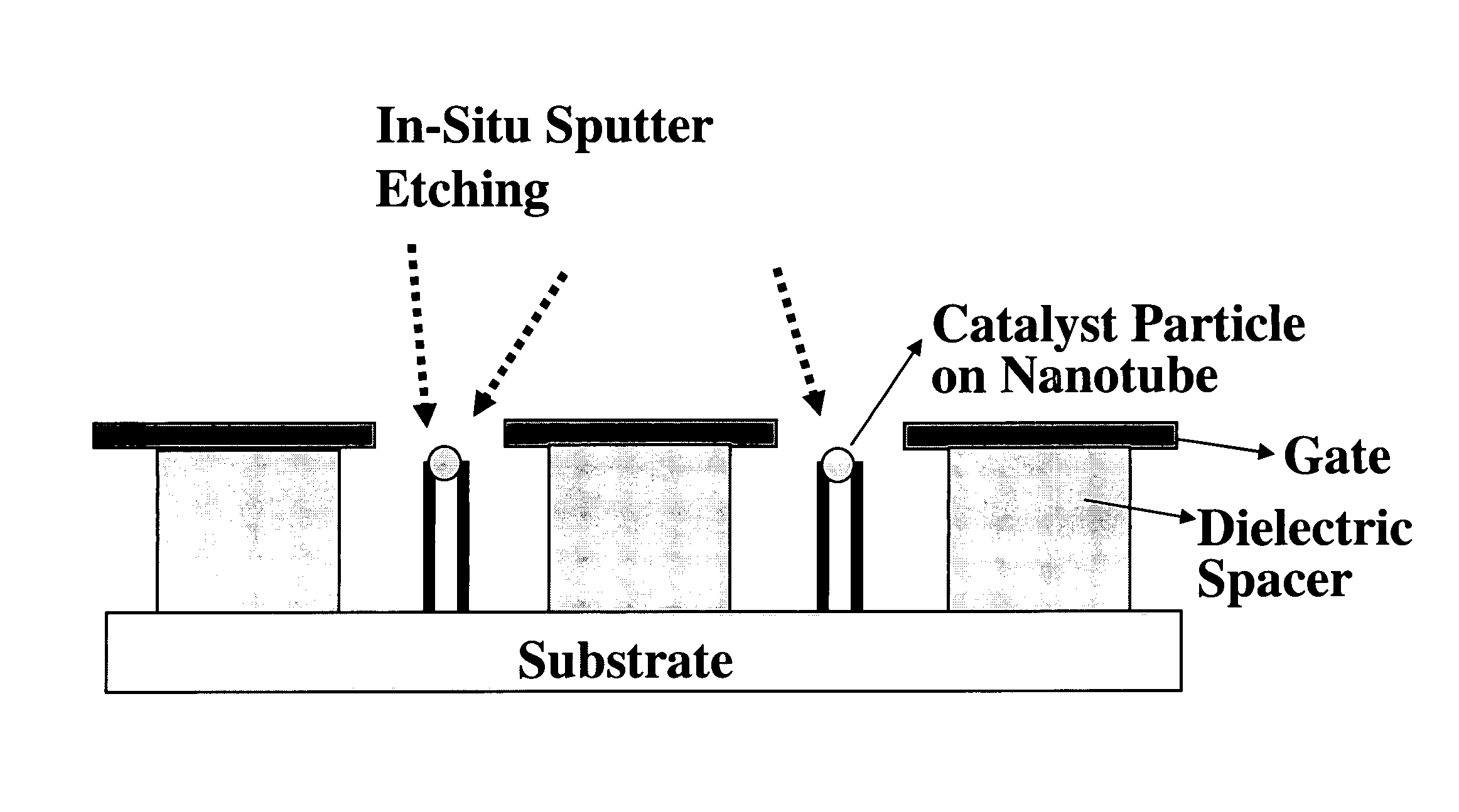

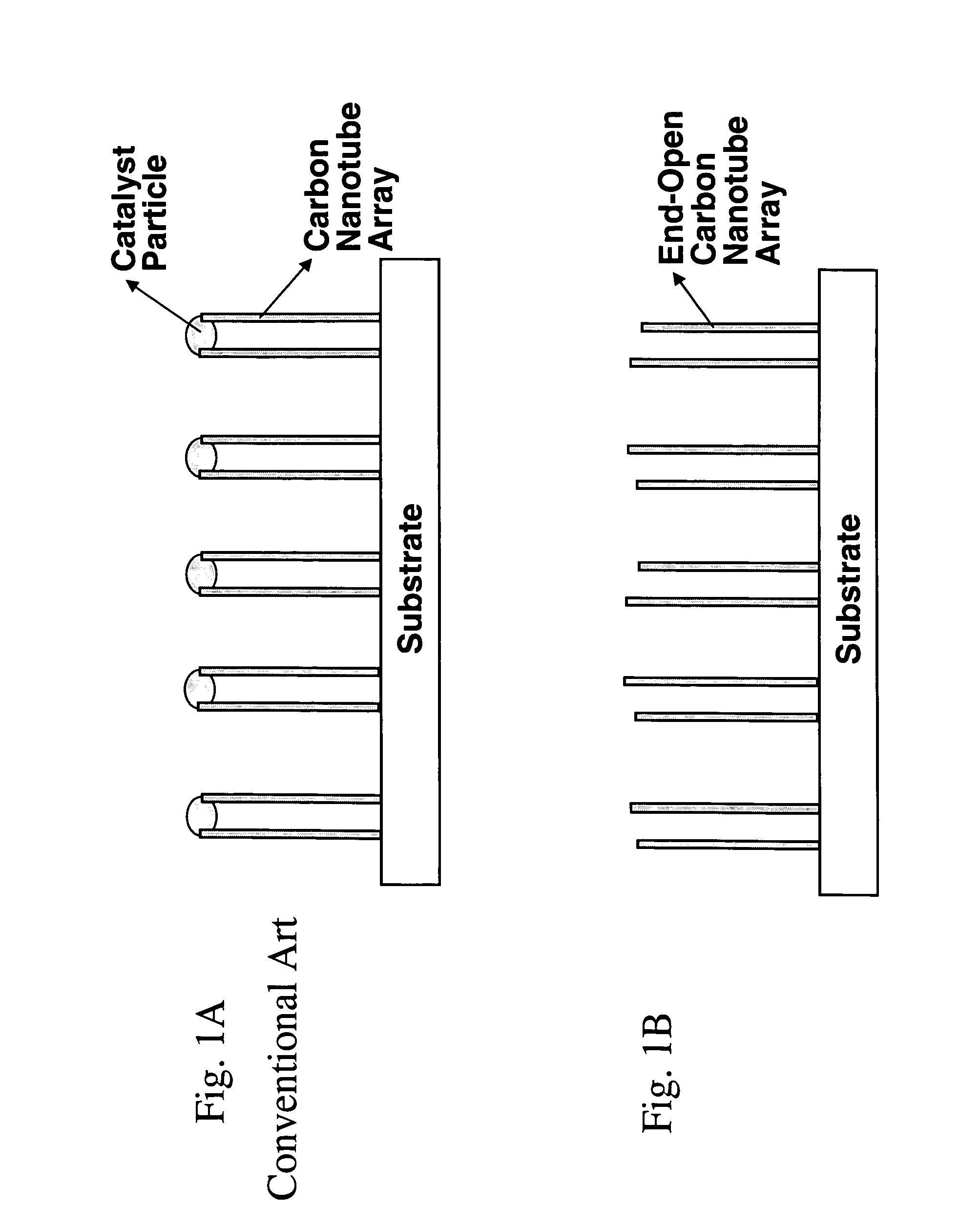

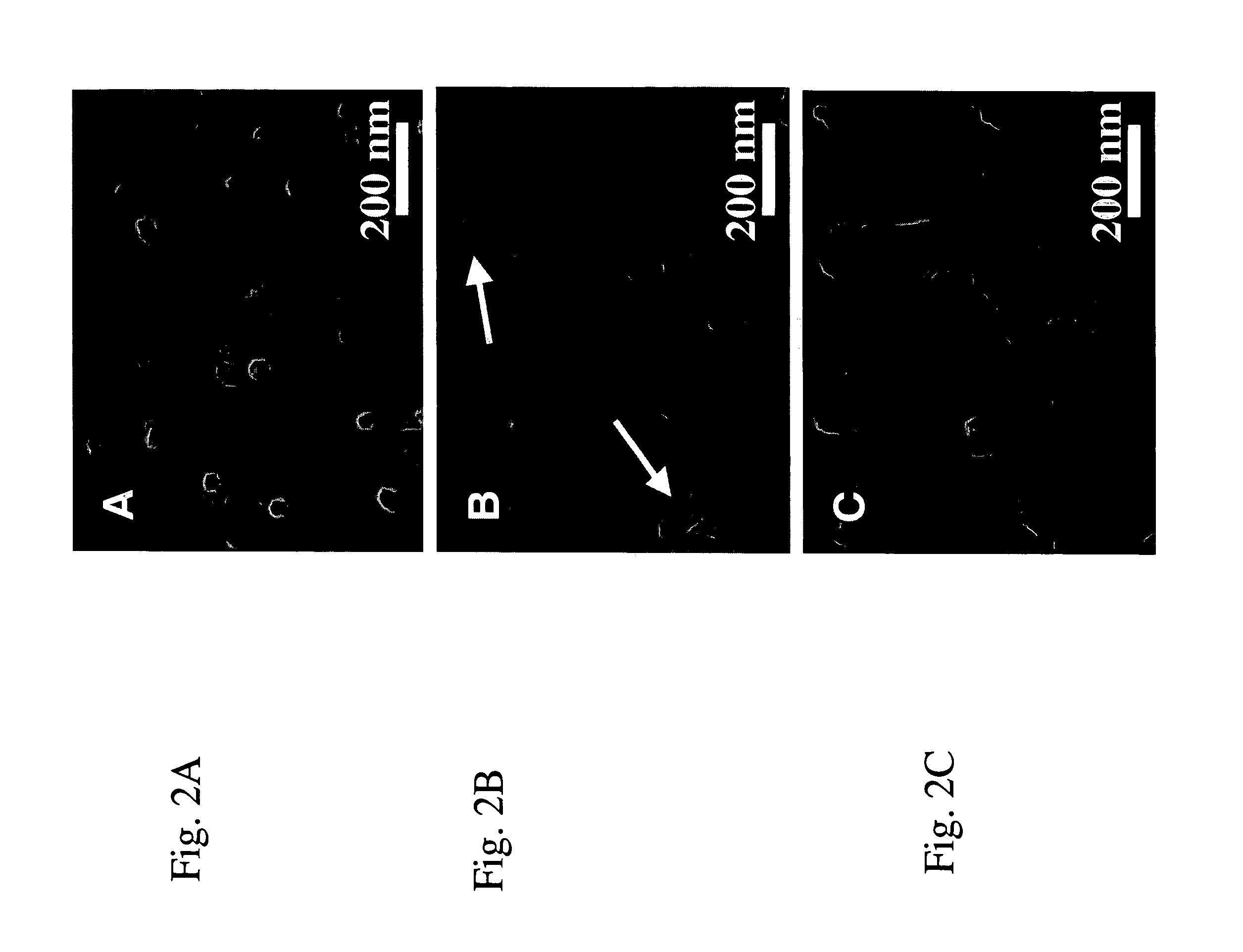

Aligned and open-ended nanotube structure and method for making the same

InactiveUS20060057388A1Improve performanceApplied fieldMaterial nanotechnologyNanostructure manufacturePolymer chemistryNanotube

Aligned and open-ended nanotube structures, methods for making the same, and devices including open-ended nanotubes. An aligned and open-ended nanotube structure which is free of catalyst particles at top ends, the aligned and open-ended nanotube structure having an uneven open-end height with local protruding portions. A method of opening an end of a nanotube including a catalyst particle including sputter etching the nanotube to remove an amorphous layer, bend the nanotube to one side, open a hole in the nanotube, and cause detachment of the catalyst particle.

Owner:SAMSUNG ELECTRONICS CO LTD +1

Single-walled carbon nanotube and aligned single-walled carbon nanotube bulk structure, and their production process, production apparatus and application use

ActiveUS7854991B2Prolong lifeIncrease probabilityMaterial nanotechnologyCell electrodesMetal catalystCarbon nanotube

This invention provides an aligned single-layer carbon nanotube bulk structure, which comprises an assembly of a plurality of aligned single-layer carbon nanotube and has a height of not less than 10 μm, and an aligned single-layer carbon nanotube bulk structure which comprises an assembly of a plurality of aligned single-layer carbon nanotubes and has been patterned in a predetermined form. This structure is produced by chemical vapor deposition (CVD) of carbon nanotubes in the presence of a metal catalyst in a reaction atmosphere with an oxidizing agent, preferably water, added thereto. An aligned single-layer carbon nanotube bulk structure, which has realized high purify and significantly large scaled length or height, its production process and apparatus, and its applied products are provided.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Ultralong orientational carbon nano-tube filament/film and its preparation method

ActiveCN1948144ASolve the problem of high-volume preparationMaterial nanotechnologyIndividual molecule manipulationMicrometerCarbon nanotube

Owner:TSINGHUA UNIV

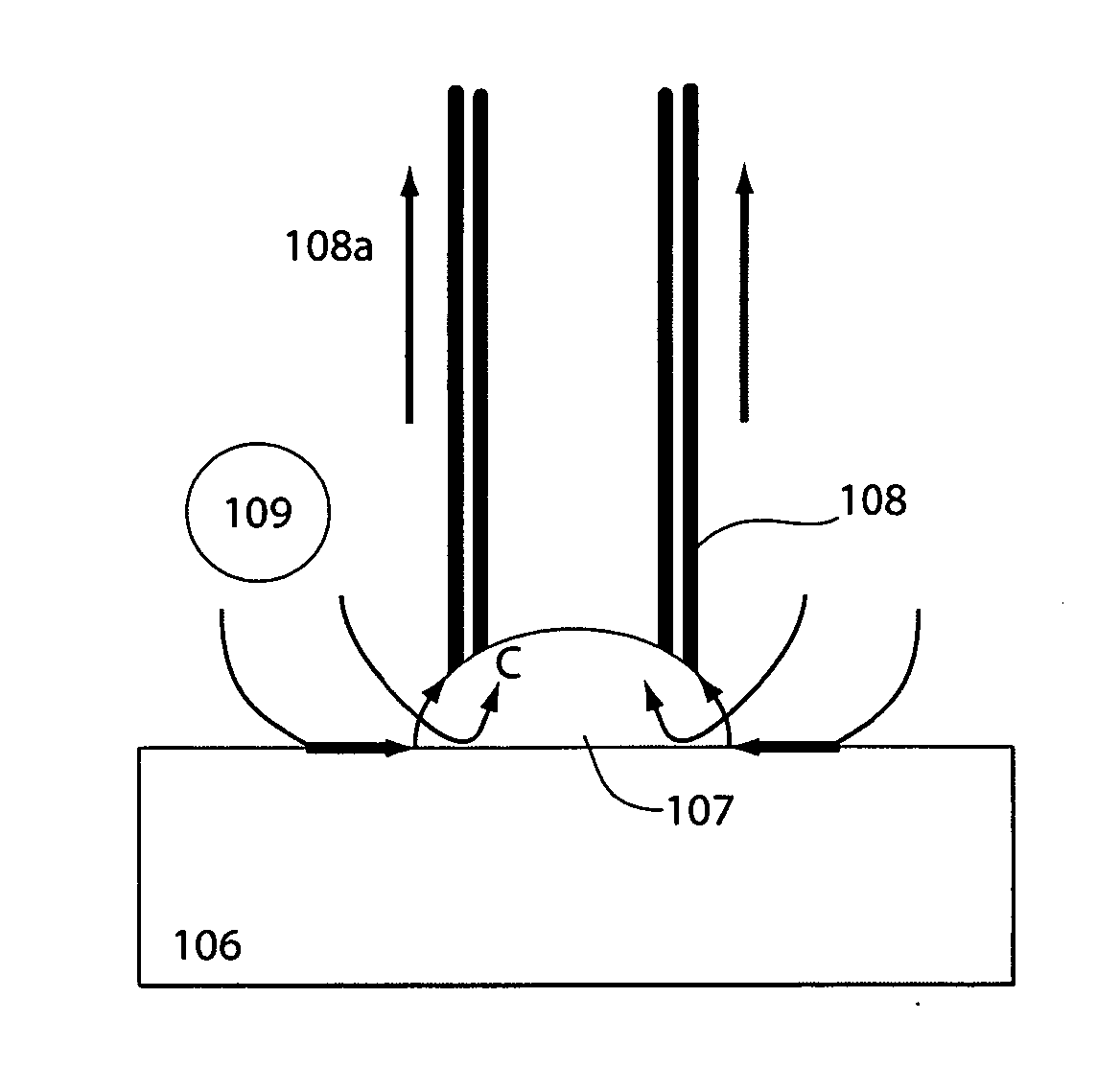

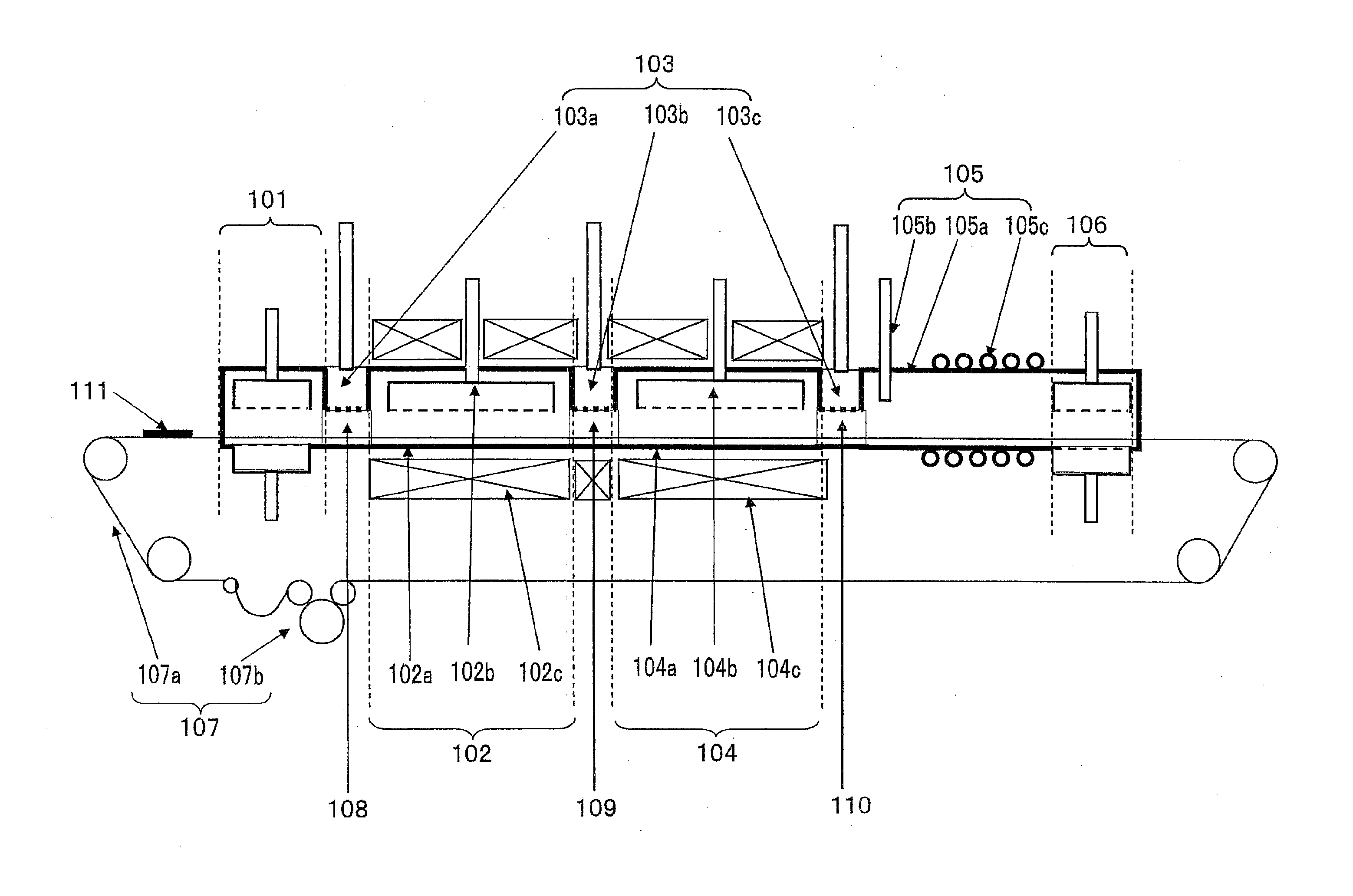

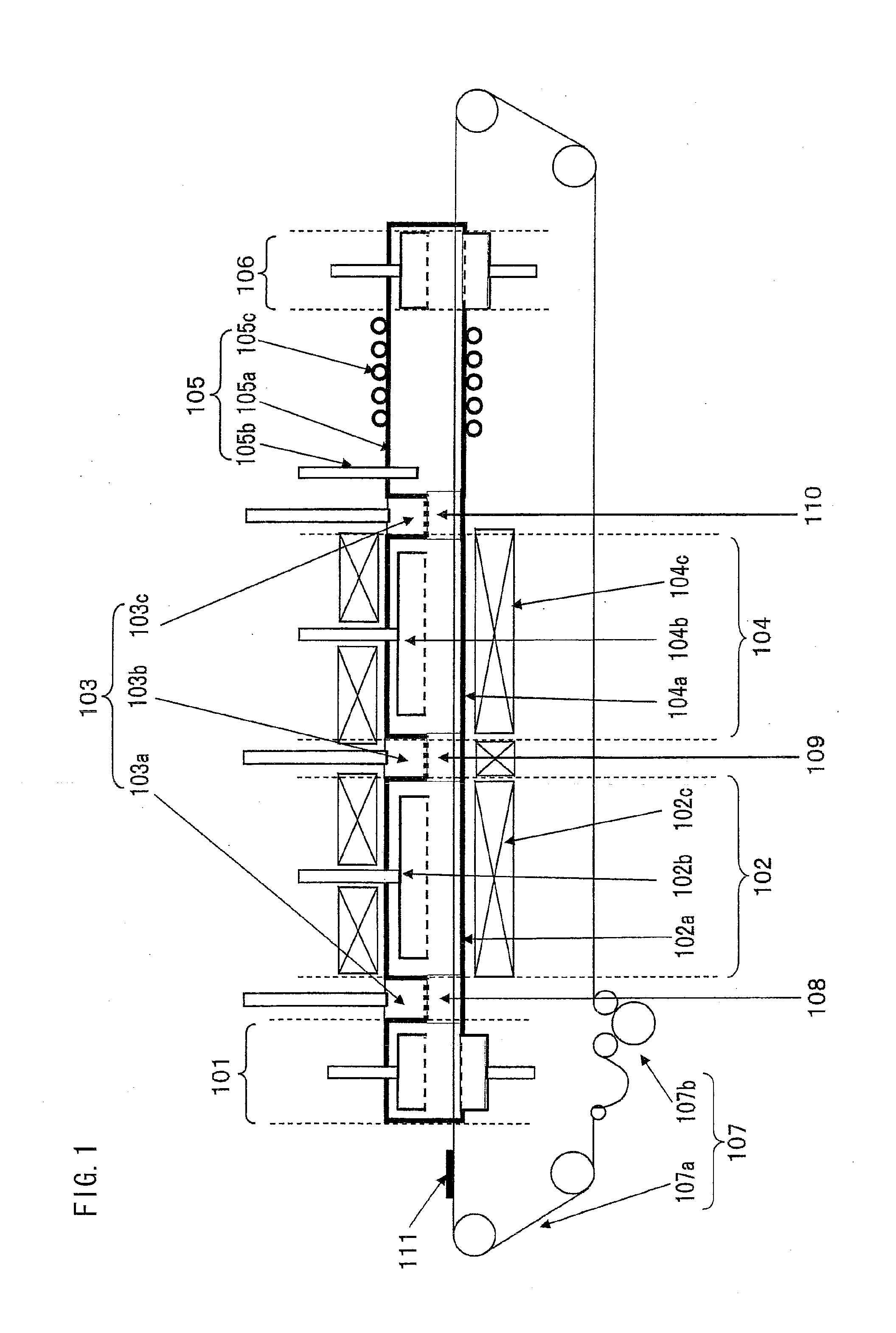

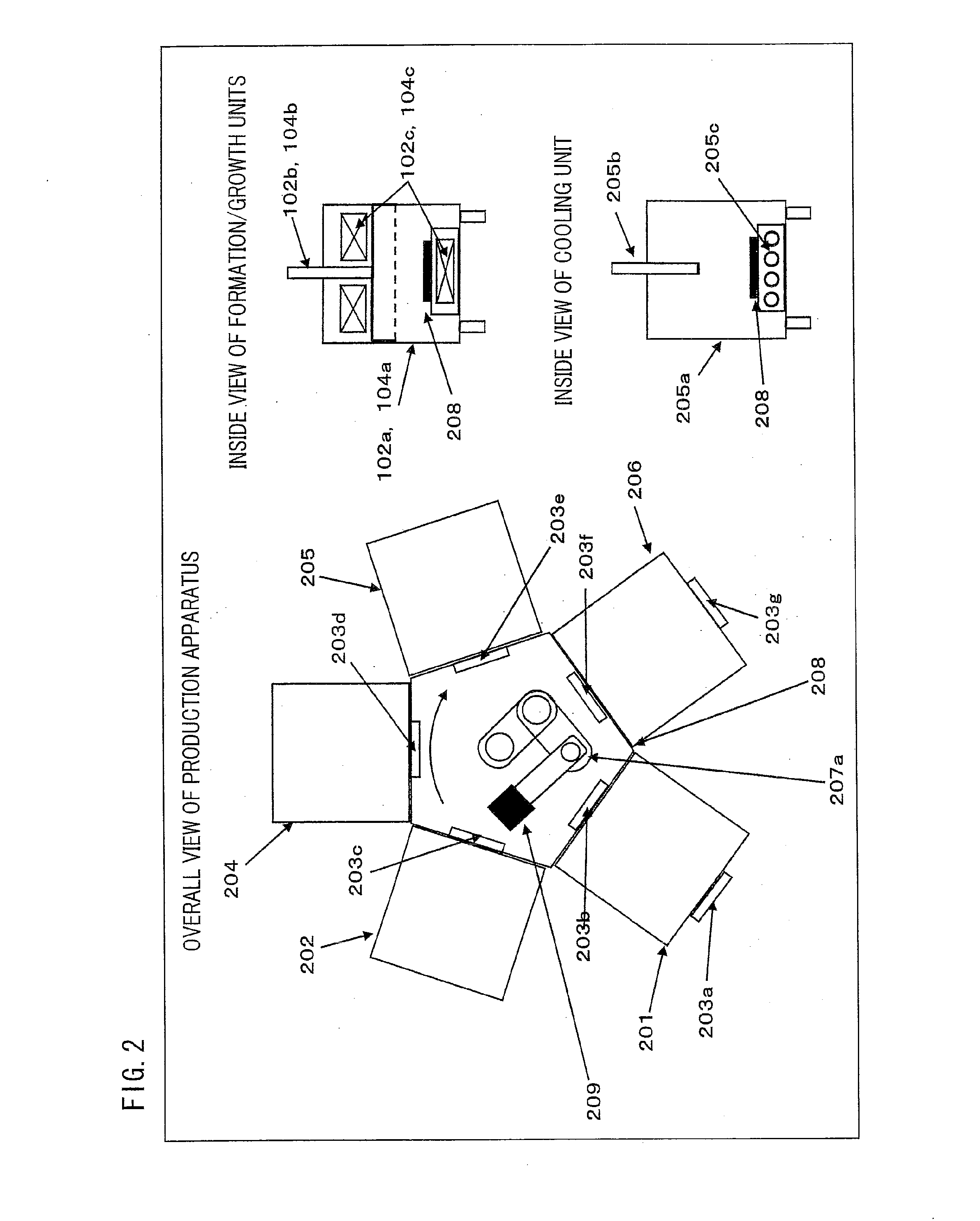

Apparatus and method for producing aligned carbon-nanotube aggregates

ActiveUS20100196600A1Deterioration in quality can be preventedAvoid stickingSpecific nanostructure formationMaterial nanotechnologyCarbon nanotubeProduct gas

An apparatus of the present invention for producing an aligned carbon-nanotube aggregate is an apparatus for producing an aligned carbon-nanotube aggregate by synthesizing the aligned carbon-nanotube aggregate on a base material having a catalyst on a surface thereof, the apparatus including: a formation unit that processes a formation step of causing an environment surrounding the catalyst to be an environment of a reducing gas and heating at least either the catalyst or the reducing gas; a growth unit that processes a growth step of synthesizing the aligned carbon-nanotube aggregate by causing the environment surrounding the catalyst to be an environment of a raw material gas and by heating at least either the catalyst or the raw material gas; and a transfer unit that transfers the base material at least from the formation unit to the growth unit. Thus provided is a production apparatus and a production method that are capable of improving efficiency in the production of aligned CNT aggregates by preventing a decrease in production volume and deterioration in quality of aligned CNT aggregates in serial production and by making it easy to increase the size of the apparatus.

Owner:ZEON CORP +1

Carbon nanotube array and method for forming same

ActiveUS20040184981A1Damage formationInhibition formationMaterial nanotechnologyFibre chemical featuresField emission deviceMetallic materials

A method for forming a carbon nanotube array using a metal substrate includes the following steps: providing a metal substrate (11); oxidizing the metal substrate to form an oxidized layer (21) thereon; depositing a catalyst layer (31) on the oxidized layer; introducing a carbon source gas; and thus forming a carbon nanotube array (61) extending from the metal substrate. Generally, any metallic material can be used as the metal substrate. Various carbon nanotube arrays formed using various metal substrates can be incorporated into a wide variety of high power electronic device applications such as field emission devices (FEDs), electron guns, and so on. Carbon nanotubes formed using any of a variety of metal substrates are well aligned, and uniformly extend in a direction substantially perpendicular to the metal substrate.

Owner:TSINGHUA UNIV +1

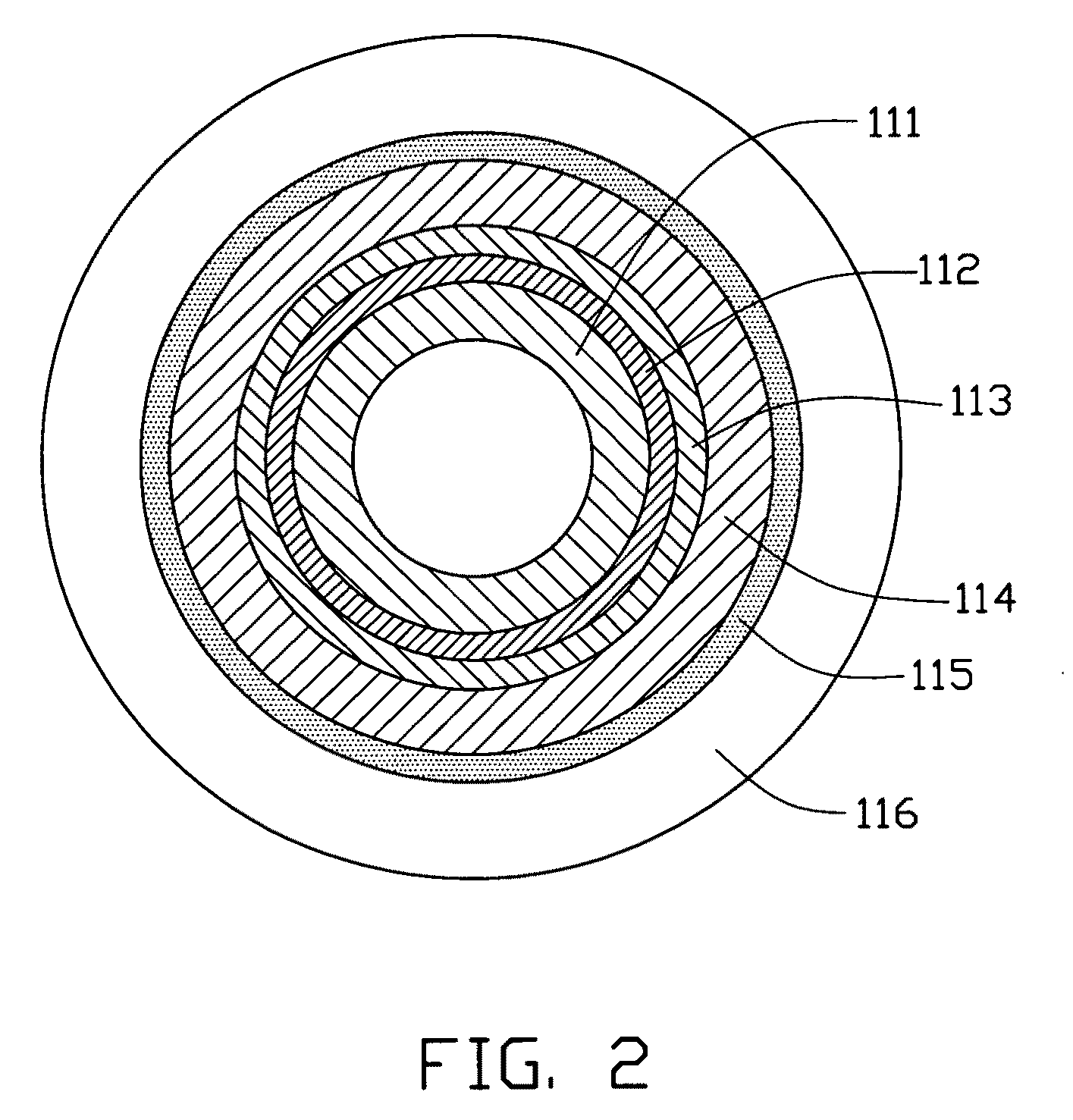

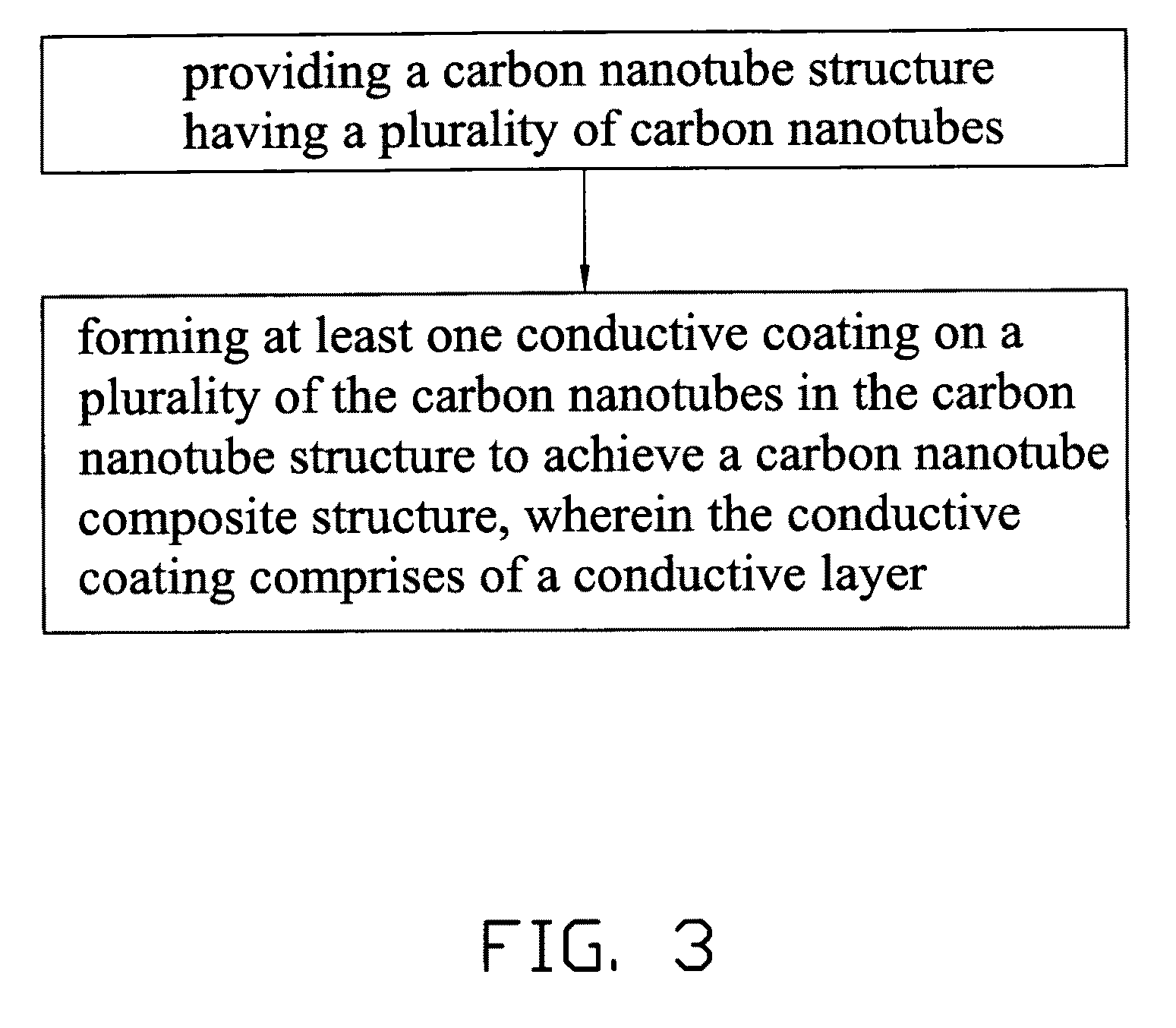

Method for making carbon nanotube composite structure

ActiveUS20090196981A1Highly structuredMaterial nanotechnologyConductive materialConductive coatingCarbon nanotube

A method for making a carbon nanotube composite structure, the method comprising the steps of: providing a carbon nanotube structure having a plurality of carbon nanotubes; and forming at least one conductive coating on a plurality of the carbon nanotubes in the carbon nanotube structure to achieve a carbon nanotube composite structure, wherein the conductive coating comprises of a conductive layer.

Owner:TSINGHUA UNIV +1

Nanostructures synthesized using anodic aluminum oxide

InactiveUS20060289351A1Simple methodEasy to makeMaterial nanotechnologyCoatingsHydrogen sensorNanostructure

This invention provides ways to fabricate nanotubes and nanobead arrays by utilizing nanopores in anodic aluminum oxide (AAO) membranes. Nanotubes of bismuth and other low melting point metals with controlled diameters and lengths can be fabricated by sintering AAO coated with appropriate metals at temperatures above their melting points. Carbon nanotubes may also be readily formed by carbonizing a polymer on the interior walls of the nanopores in AAO membranes. Palladium nanobead arrays which can be used as ultrafast hydrogen sensors are fabricated by coating the flat surface of AAO membranes with controlled pore-wall ratios.

Owner:UCHICAGO ARGONNE LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com