Arrays of long carbon nanotubes for fiber spinning

a carbon nanotube and fiber spinning technology, applied in the field of carbon nanotubes, can solve the problems of tensile strength, carbon nanotubes do not have perfect structures, and can be dangerous, and achieve the effects of reducing the tensile strength, and improving the tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

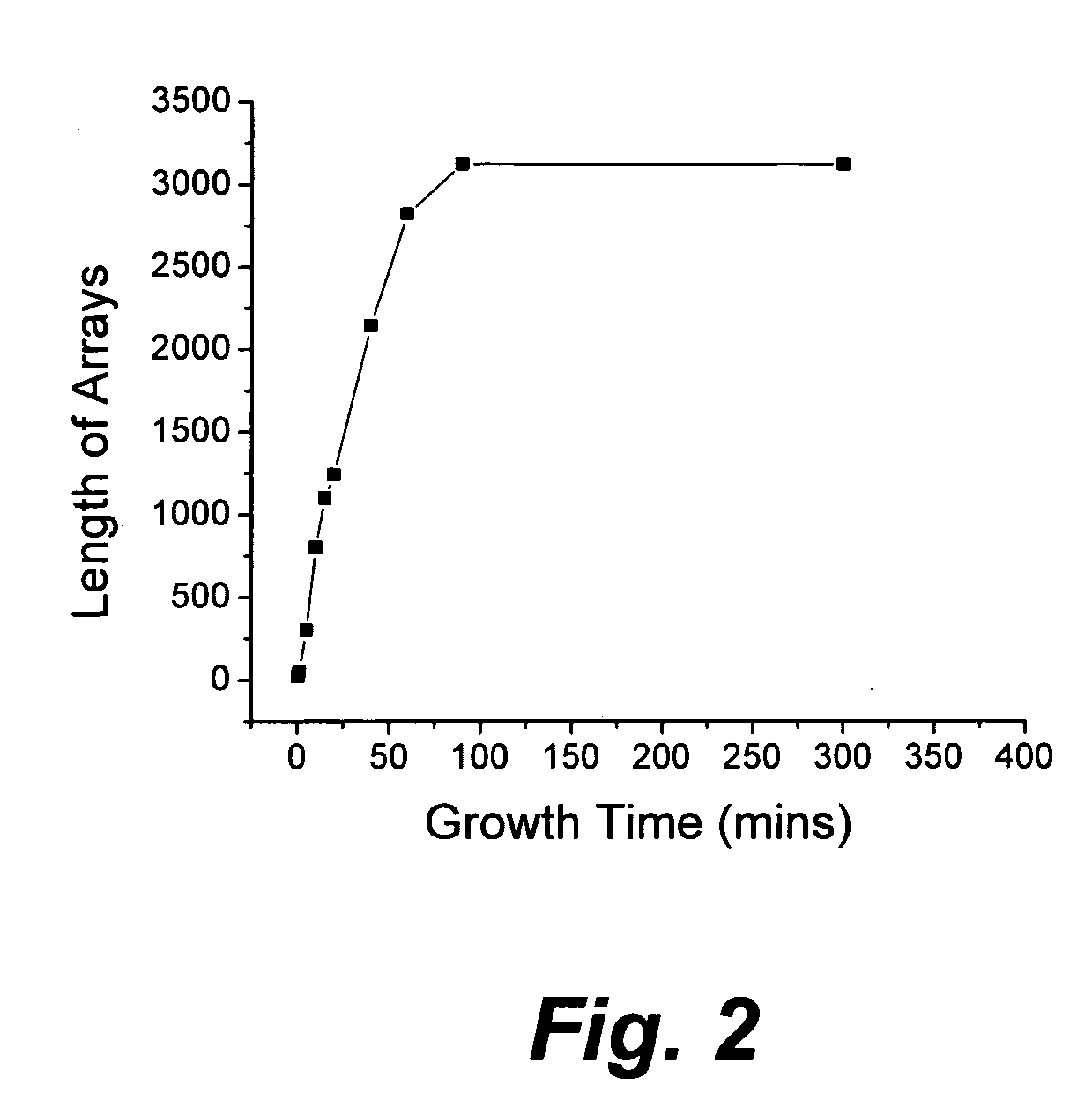

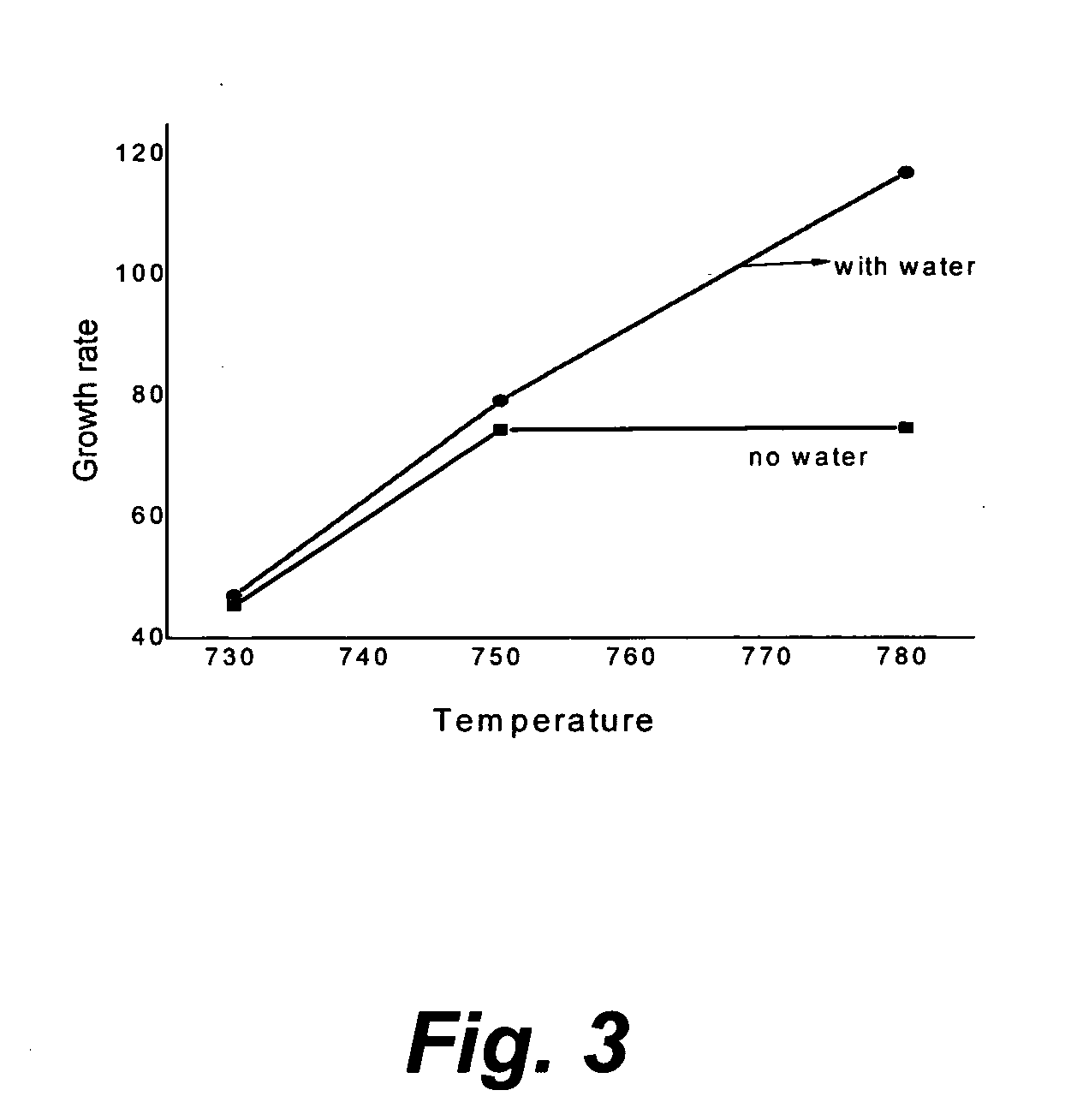

[0027] Briefly, the invention is concerned with the preparation of an array of long (greater than 0.5 millimeters), substantially straight and aligned carbon nanotubes (CNTs). The invention is also concerned with a catalyst useful for preparing the array, and with fibers that are spun from the array. A very efficient, relatively long-lived catalyst useful for preparing a high purity, well-aligned array of multi-walled, long CNTs was prepared by depositing a thin film of iron (Fe) on a layer of aluminum oxide (Al2O3). An array of long CNTs was prepared by exposing the catalyst to a gaseous mixture of hydrocarbon, inert gas, and a relatively low percentage of hydrogen at an elevated temperature. The addition of water vapor to the gaseous mixture results in an increase in the final length of the CNTs in the array.

[0028] Arrays of long CNTs of this invention have been prepared with lengths of about 3 millimeters (mm), 3.5 mm, 4 mm, and 4.5 mm. A growth rate of about 120 μm / min was achi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com