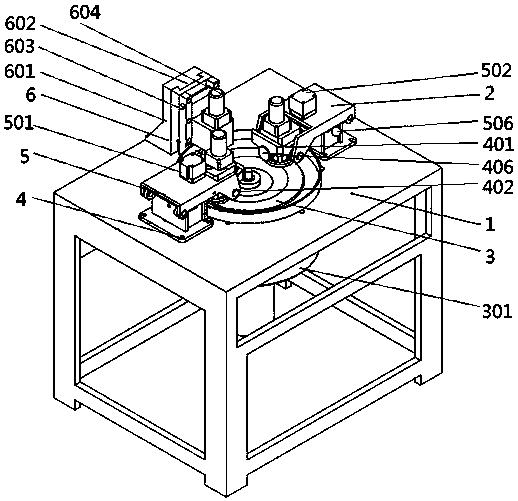

Two-workstation polycrystalline diamond compact polisher

A technology of polycrystalline diamond and composite sheet, which is applied in grinding/polishing equipment, grinding/polishing safety devices, manufacturing tools, etc. It can solve problems such as unreasonable structure, low polishing efficiency, and unreliable polishing quality, and achieve functional Practical, improve polishing efficiency, and ensure the effect of grinding and polishing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0026] Embodiment 2, a two-station polycrystalline diamond composite sheet polishing machine, the pressing mechanism 501 includes a two-way lead screw arranged on the swing arm 5, and the upper screw thread cooperating with the two-way lead screw is arranged on the swing arm 5 Hole, base 4 is provided with the lower threaded hole that cooperates with two-way leading screw. The two-way lead screw is set to cooperate with the upper threaded hole and the lower threaded hole, which not only can conveniently adjust the degree of compression between the driving seat assembly of the polycrystalline diamond composite sheet and the polishing wheel, but also has a simple structure and low manufacturing cost. Other structures of this embodiment are the same as those of Embodiment 1.

Embodiment 3

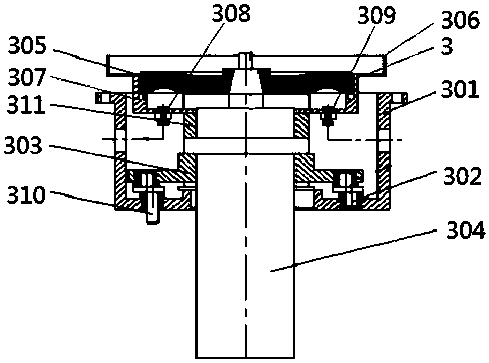

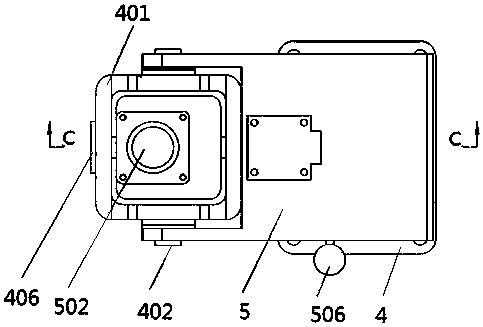

[0027]Embodiment 3, a two-station polycrystalline diamond composite sheet polishing machine, the polycrystalline diamond composite sheet driving seat assembly includes a turret 401, and the left and right sides of the turret 401 are provided with a rotating shaft 402 connected to the swing arm 5, A jig rotating sleeve 403 is arranged inside the turret 401 , and a jig 405 for installing a polycrystalline diamond composite sheet is arranged on the lower side of the jig rotating sleeve 403 . A rotating shaft 402 is provided to connect the turret 401 and the swing arm 5, and the jig 405 can swing left and right relative to the swing arm 5, so that the polycrystalline diamond composite sheet can be rotated relative to the polishing wheel 305 for self-adaptive polishing.

[0028] Further, the turret 401 is a universal bracket, and the clamp rotating sleeve 403 is movably connected with the front and rear sides of the turret 401 through a short shaft 406 . The short shaft 406 is set ...

Embodiment 4

[0029] Embodiment 4, a two-station polycrystalline diamond composite sheet polishing machine, the inside of the fixture rotating sleeve 403 is provided with a central hole 407, the center hole 407 is provided with a fixture rotating shaft 408, and the fixture rotating sleeve 403 is provided above There is a drive motor 409 for driving the gripper shaft 408 .

[0030] Further, a water inlet channel 410 and a water outlet channel 411 communicating with the upper side of the clamp 405 are provided in the clamp shaft 408, a water inlet 412 and a water outlet 413 are provided on the clamp rotating sleeve 403, and the water inlet channel 410 is provided with There is a water inlet annular groove 414 communicating with the water inlet 412 , and the water outlet channel 411 is provided with a water outlet annular groove 415 communicating with the water outlet 413 . The waterproof cooling shell matched with the polishing wheel can directly cool the polishing wheel. At the same time, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com