Nickel powder and production method thereof

A manufacturing method, micropowder technology, applied in the direction of transportation and packaging, metal processing equipment, etc., can solve the problems of shrinkage characteristics without any disclosure, thick oxide film thickness, difficult to form thickness, etc., to prevent discontinuity or peeling, crystallinity Excellent, prevent cracking or peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

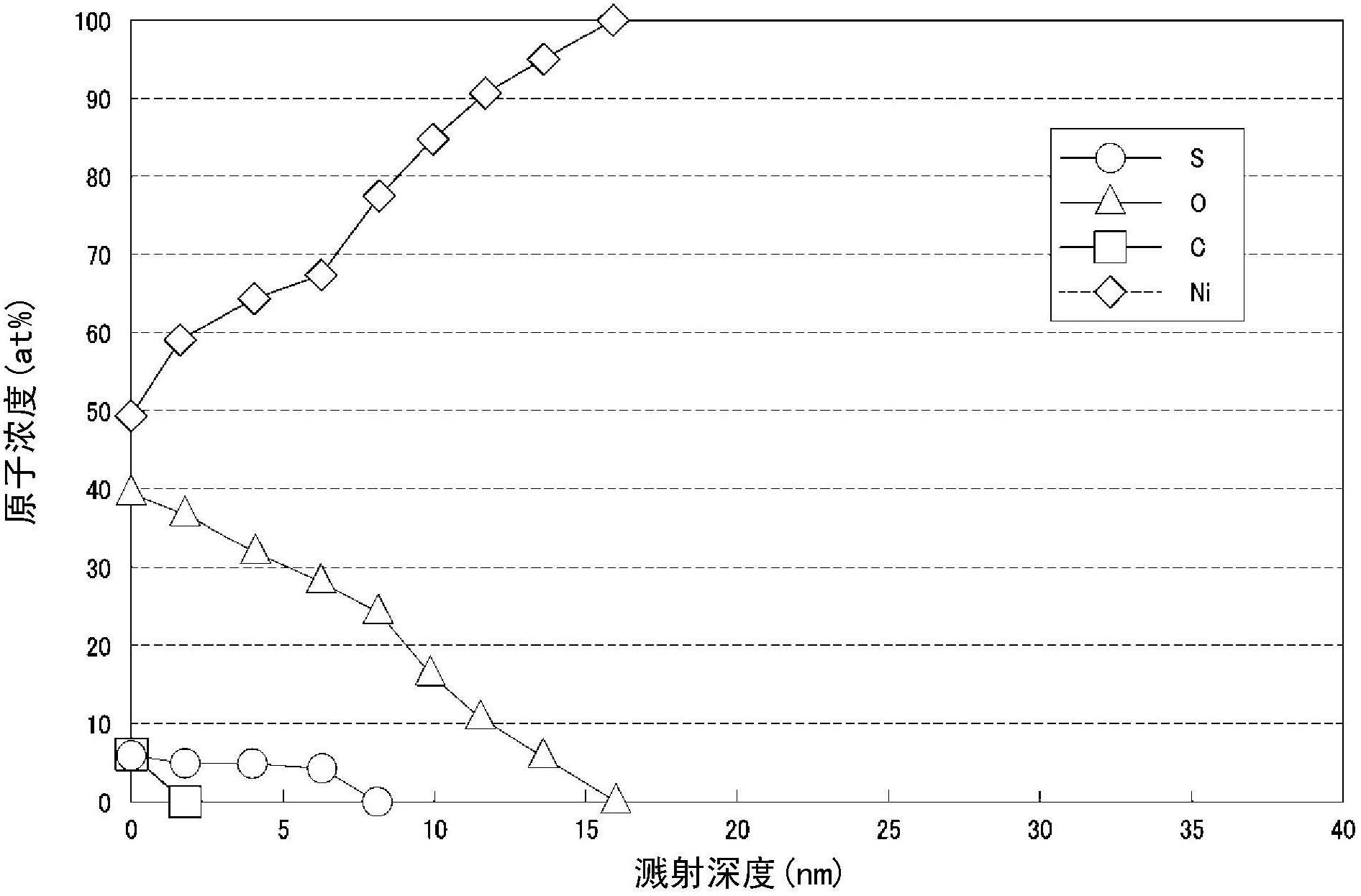

[0137] Ignite the high-frequency plasma with the plasma input power of about 60kW, adjust the total amount of argon to 209L / min, hydrogen to 45L / min, and ambient gas pressure to 60kPa to obtain a stable plasma flame. A nickel raw material was supplied to the inside of the plasma flame at 1 kg / hr by carrying gas (argon 10 liters / minute) to prepare fine powder.

[0138] In addition, as a nickel raw material, 90 mass % of nickel powder (nickel, Type 255, average particle diameter of 2.2 to 2.8 μm, manufactured by Inco Special Products and Inco Limited) was mixed with 10 mass % of nickel oxide (approximately 2 mass % sulfur) nickel raw material. The sulfur content in the nickel raw material was 0.2% by mass, and the oxygen content was 2% by mass.

[0139] The temperature of the plasma is 10000° C. or higher, so the nickel raw material powder evaporates and gasifies instantaneously, and then condenses in the low-temperature plasma tail flame to be pulverized. The obtained microni...

Embodiment 2

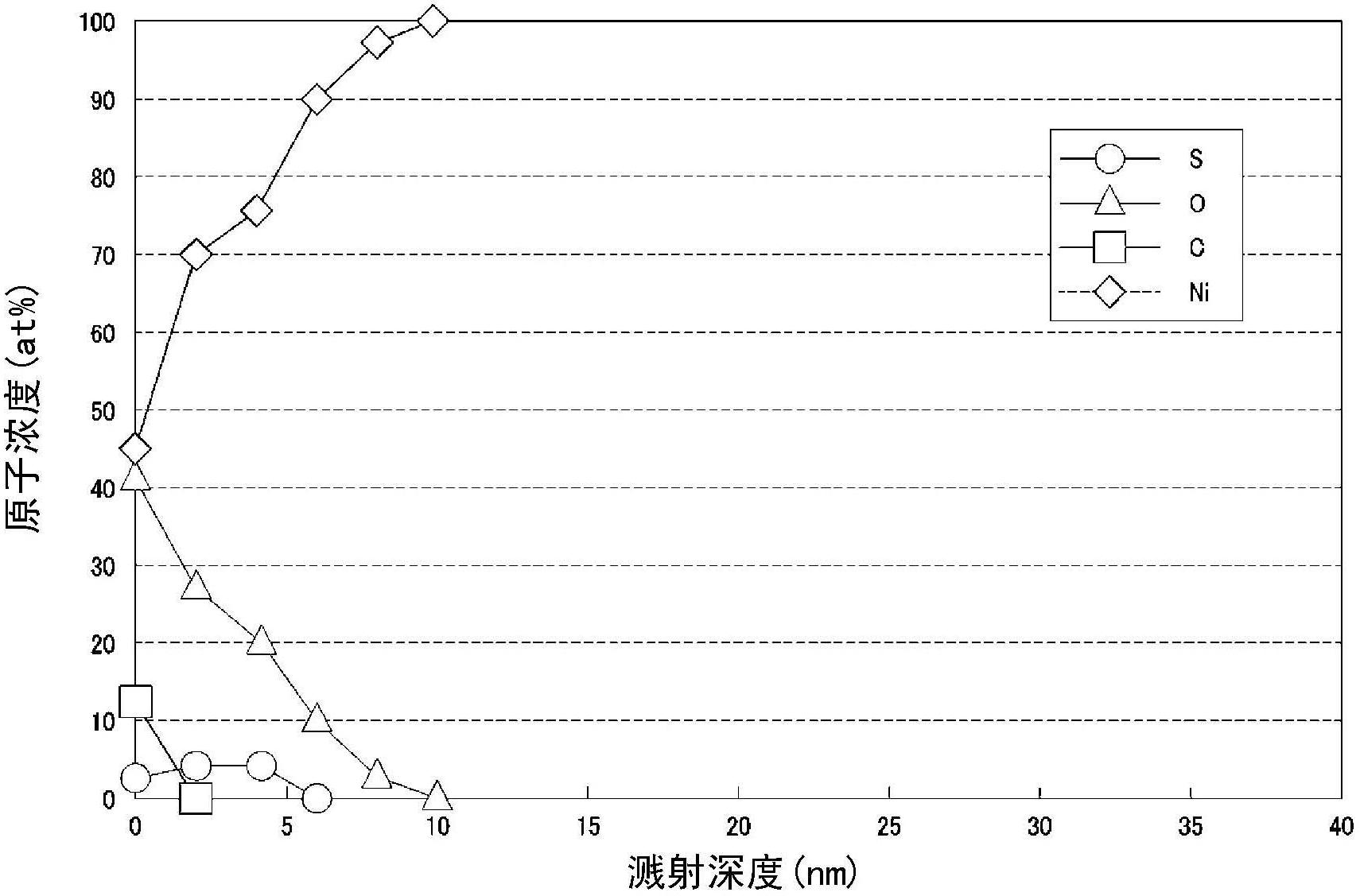

[0143] Except having changed the hydrogen gas supplied to the plasma to 9 L / min, it carried out similarly to Example 1, obtained nickel fine powder, and evaluated it. The BET diameter of nickel fine powder is 152nm. Analyze this nickel micropowder by XRD, adopt the grain size that Scherrer method obtains to be The crystal grain size was 85% of the BET diameter, and it was found that nickel fine powder having a crystallinity close to a single crystal was formed. The sulfur and oxygen contents were 0.24% by mass and 1.0% by mass, respectively. Based on the measurement results of TMA, the shrinkage initiation temperature was about 360° C., and the shrinkage rate was 7.9%. Each evaluation result is shown in Table 1 together with other examples.

[0144] Furthermore, as a result of FE-AES analysis, the thickness of the oxygen-containing coating layer was as thin as 14 nm. Also, the thickness of the sulfur-containing layer was 8 nm. The thickness of each layer is shown togethe...

Embodiment 3

[0146] Except having used the following nickel powder as nickel powder, it carried out similarly to Example 1, obtained the nickel fine powder, and evaluated it. Add 4kg of nickel powder (nickel, Type255, average particle size 2.2-2.8μm, manufactured by Inco Special Products and Inco Limited) to 16L of pure water adjusted to 50°C, add 18g of sodium hydrosulfide hydrate (Sodium hydrosulfide n- hydrate), stirred for 30 minutes. Then, repulp (Repulp) was performed once, and after filtering and vacuum-drying (36 hours), it crushed and was used as a nickel raw material. The sulfur content in the nickel raw material was 0.2% by mass, and the oxygen content was 0.4% by mass.

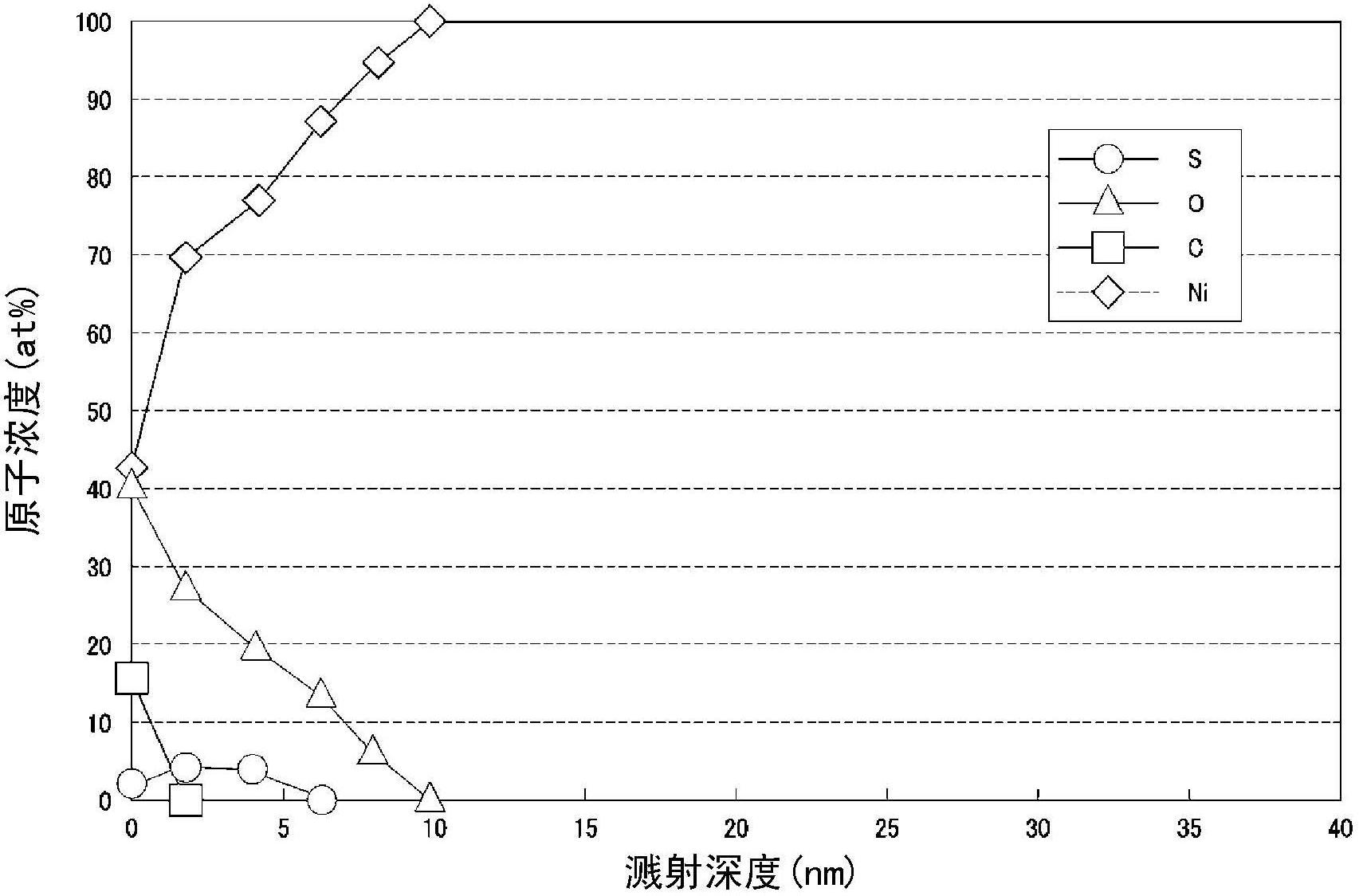

[0147] The BET diameter of nickel micropowder is 125nm. Analyze this nickel micropowder by XRD, adopt the grain size that Scherrer method obtains to be The crystal grain size was 75% of the BET diameter, and it was found that nickel fine powder having a crystallinity close to a single crystal was formed. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com