Cabbage weighing device used for cabbage harvester

A weighing device and harvester technology, applied in the field of agricultural machinery, can solve the problems of high technical requirements for parts, no weighing device for fruits and vegetables, complex mechanical structure, etc., to avoid collision and interference, improve the degree of automation, and ensure independence. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing and example.

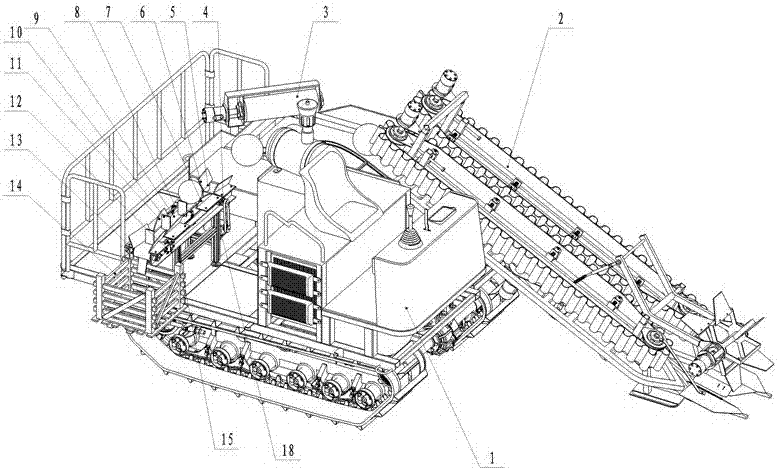

[0018] Such as figure 1 , figure 2 As shown, a cabbage weighing device for a cabbage harvester includes a power chassis 1, a harvesting platform assembly 2, a leaf stripping device 3, a system platform, a conveying assembly, a weighing platform, a weighing module, and a collection box 14 , the power chassis 1 is a crawler self-propelled type, which supplies the power of the whole machine; the harvesting platform assembly 2 and the leaf stripping device 3 are assembled on the power chassis 1, the harvesting platform assembly 2 is used for harvesting cabbage, and the leaf stripping device 3 is used for removing The loose outsourcing leaf of cabbage; Collection box 14 is positioned at system platform outlet, is used for collecting the cabbage that weighs;

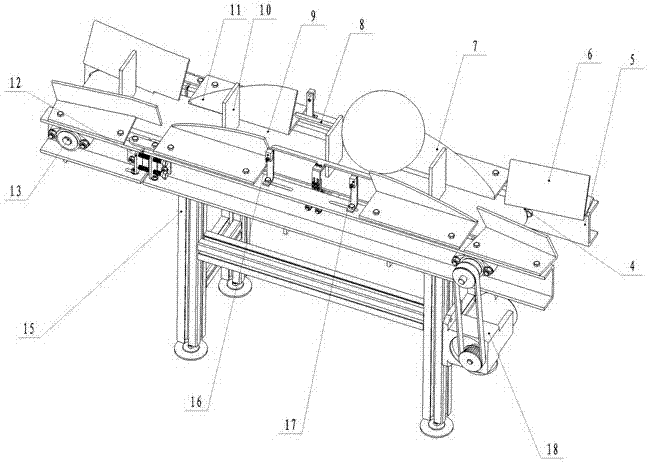

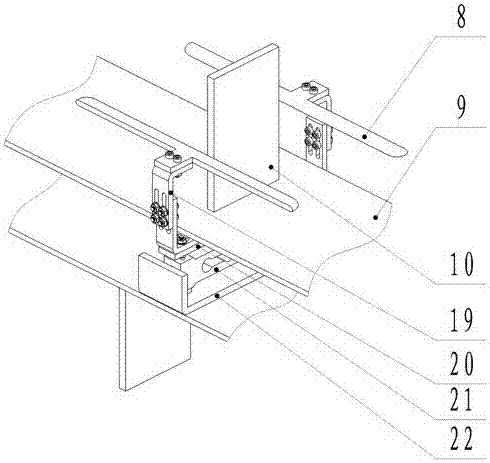

[0019] The system stand is located at the exit of the leaf stripping device 3 and is the physical support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com