Driving device for switch operation interlocking mechanism

A technology of interlocking mechanism and driving device, applied in the direction of air switch components, etc., can solve problems such as large operating force, sliding teeth or mechanism deformation, interlock failure, etc., to achieve the effect of convenient operation and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

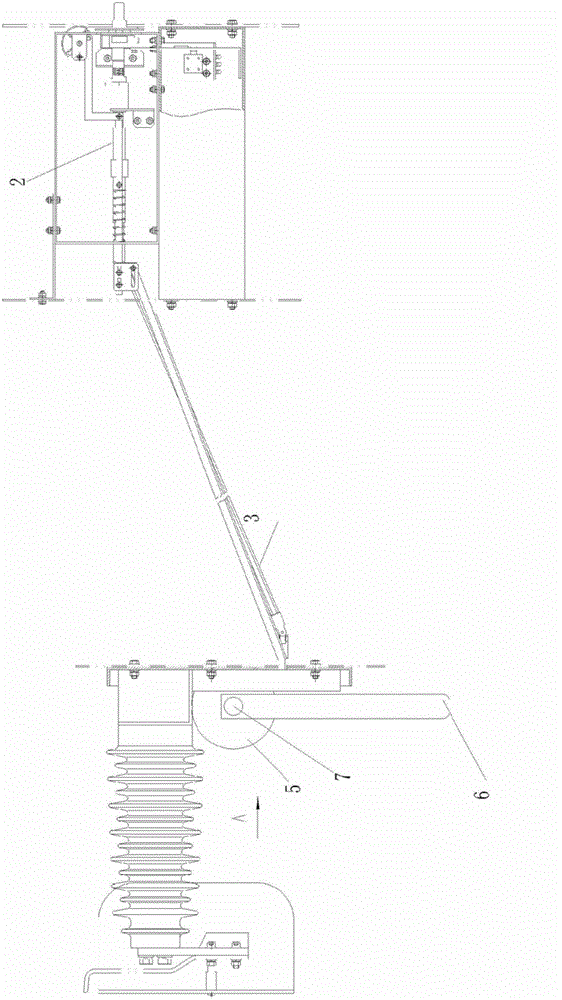

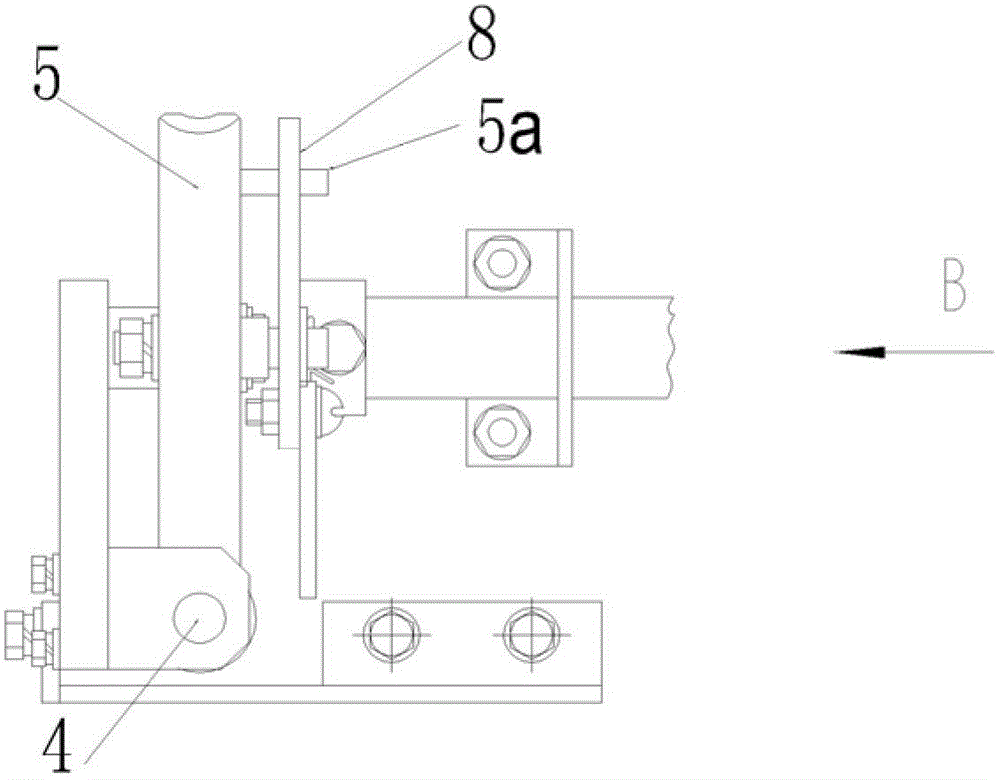

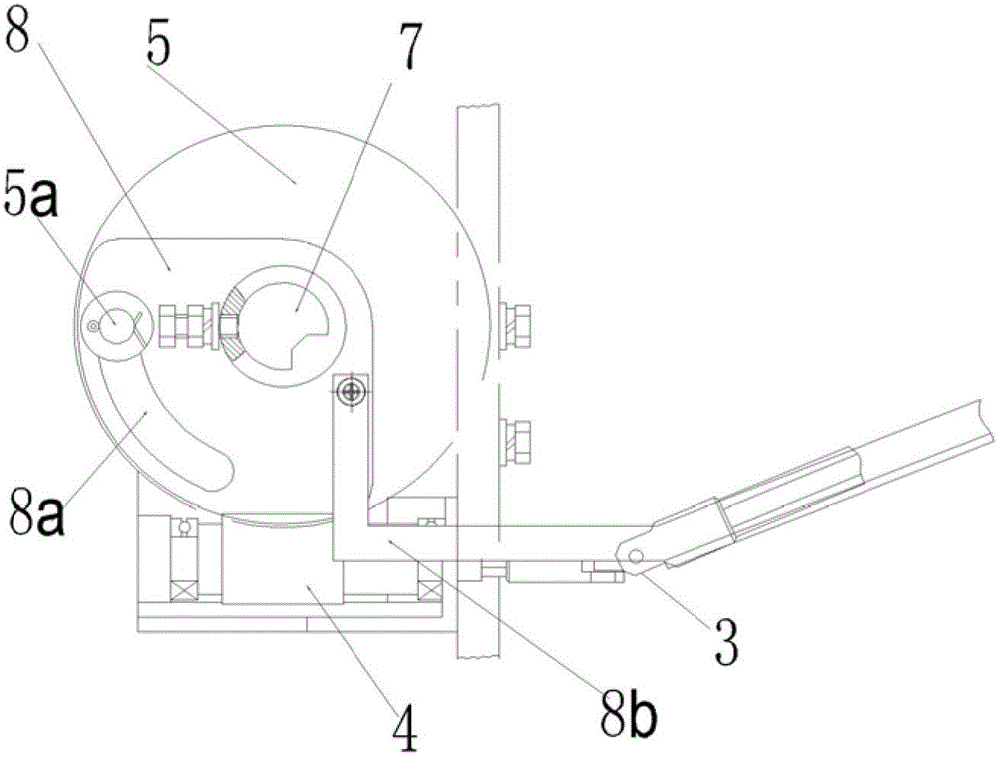

[0015] Such as figure 1 As shown, the drive device of the switch operation interlock mechanism, which includes a rotating mechanism located in the mechanism box 1, a worm wheel 5, a worm 4 and a stroke plate 8, the stroke plate 8 is fixed on the main shaft 7 of the grounding switch, and the main shaft 7 is connected to the grounding switch. The gate plate 6 on the grounding switch mechanism is connected, and the rotating mechanism is connected with the worm 4 through a universal joint. 5a is inserted into the stroke space 8a; wherein the rotating mechanism includes a rotating rod 2 and a transmission rod 3, the rotating rod 2 and the transmission rod 3 are connected through a transmission universal joint, and the transmission rod 3 is connected with the said worm 4 through the said universal joint ; Wherein, the stroke space 8a is an arc-shaped hollow groove on the stroke plate, and it can also be an arc-shaped guide groove.

[0016] Rotate the rotating rod 2, and then drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com