Processing process of screw pipe bending machine

A processing technology and pipe bending machine technology, which is applied in the processing technology field of screw pipe bending machines, can solve the problems of high labor intensity, waste, and low yield, and achieve the effects of reducing production costs, improving forming rate, and stabilizing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

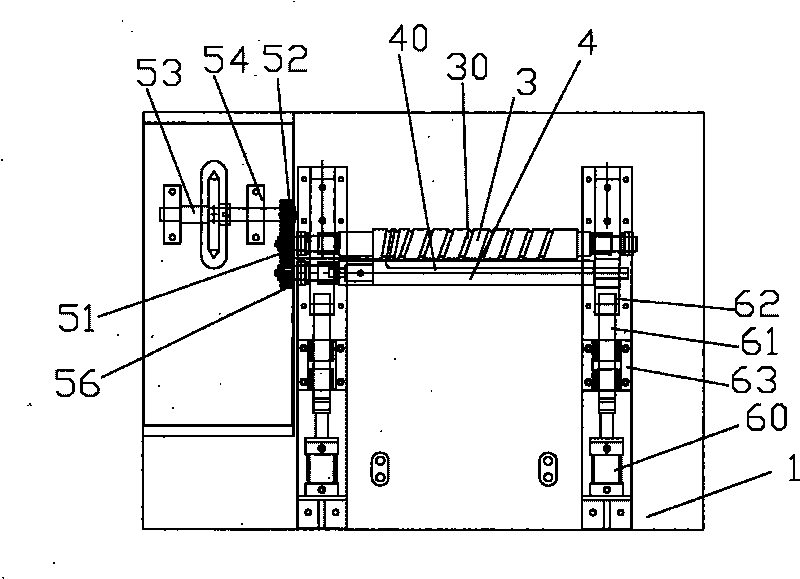

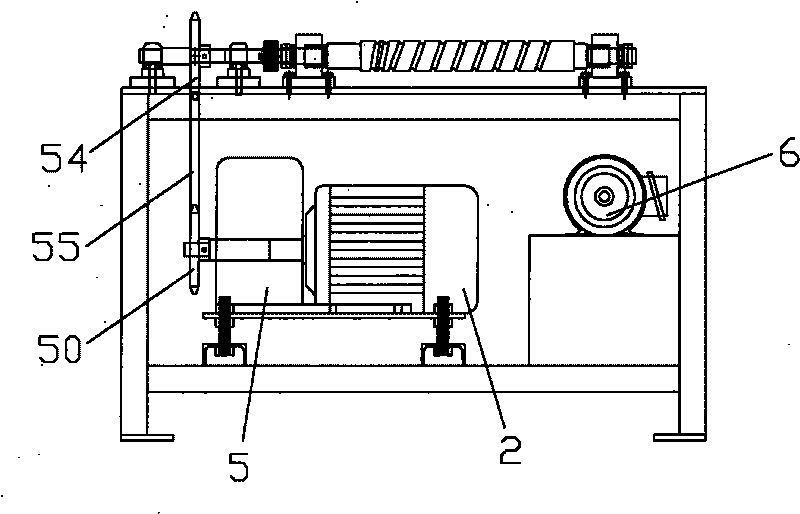

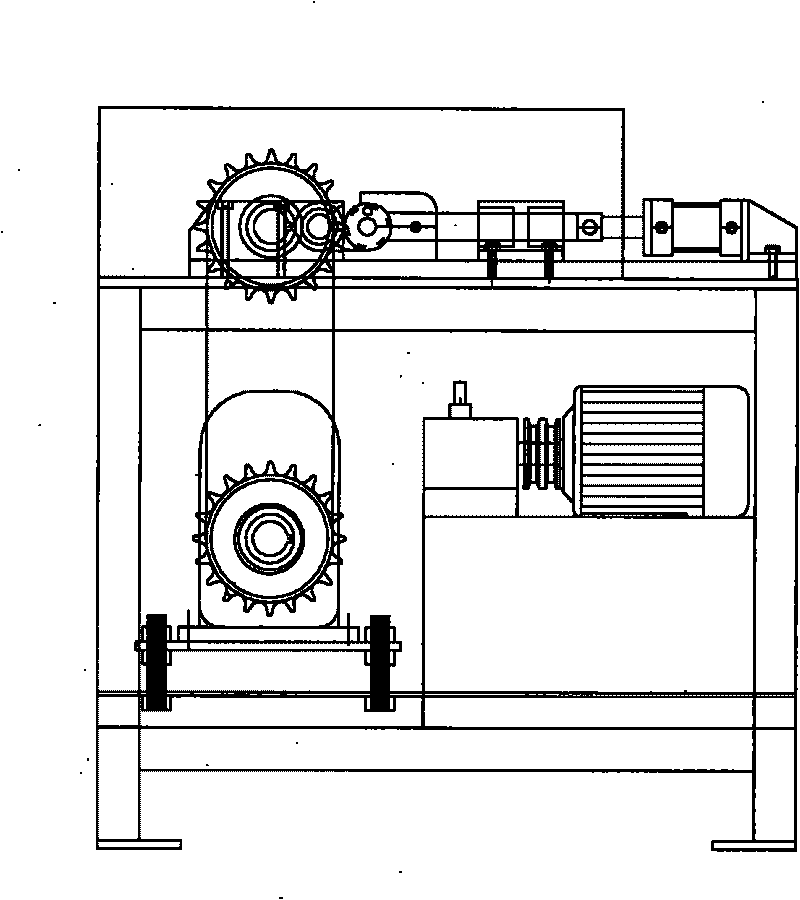

[0015] Such as Figure 1 to Figure 3 As shown, the processing technology of a screw pipe bending machine of the present invention is used for bending hollow steel pipes. The pipe bending machine includes a machine base 1, a motor 2 arranged on the machine base 1, and a motor driven by the The main shaft 3, and the transmission mechanism for connecting the motor 2 and the main shaft 3, and the auxiliary shaft 4 synchronously rotating with the main shaft 3, and the advance and retreat mechanism for driving the auxiliary shaft 4 to move back and forth; the main shaft 3 is provided with a thread groove 30 , the auxiliary shaft 4 is provided with an installation groove 40 for installing steel pipes; the steel pipes are automatically bent by the machine without too much manpower, so that the production cost is reduced, the efficiency is improved, and the quality is stable.

[0016] Wherein, the transmission mechanism includes a gearbox 5 arranged on the motor 2, a first sprocket 50 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com