Making process of Mongol stringed instrument box

A production process, the technology of matouqin, applied to instruments, stringed instruments, musical instruments, etc., can solve the problems of loose piano case, waste of time and energy, and lack of sound, and achieve the effect of improving bending performance, saving time, and not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

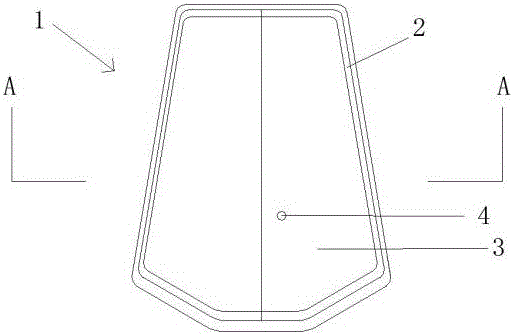

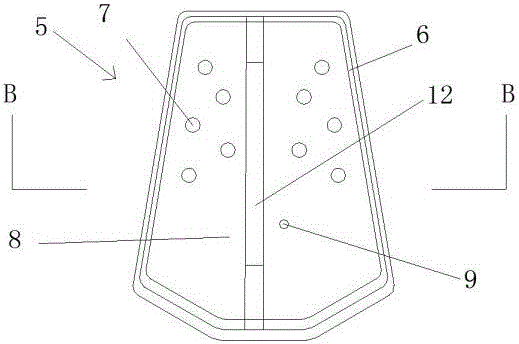

[0047] see Figure 1-7 , the present invention provides a kind of technical scheme: a kind of manufacturing process of matouqin box, comprising the following steps:

[0048] The first step is to make the bottom plate and panel of the piano box;

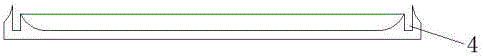

[0049] 1) Process a whole piece of wood into a hexagonal bottom plate 1, and grind the six corners of the bottom plate 1 into an arc shape, and process a groove a2 at the edge of one side of the bottom plate 1, and the treble on the bottom plate 1 Groove b4 is processed on side 3; the production of the whole board makes the resonance effect of the bottom plate better, and the six corners are polished into arcs, which will not accidentally hurt people, and the design is humanized;

[0050] 2) Process a whole piece of wood into a hexagonal board panel 5, and polish the six corners of the panel 5 into an arc shape, process a groove c6 at the edge of one side of the panel 5, and open a groove on the panel 5 The sound hole 7 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com