Machining method for assembling surface of dehumidifying blade

A blade assembly and surface processing technology, applied in the field of mechanical processing, can solve the problems of poor blade profile, easy bowing, and affecting welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

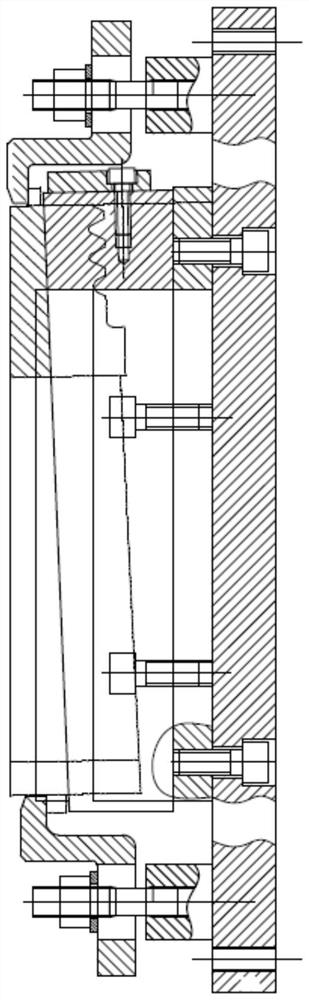

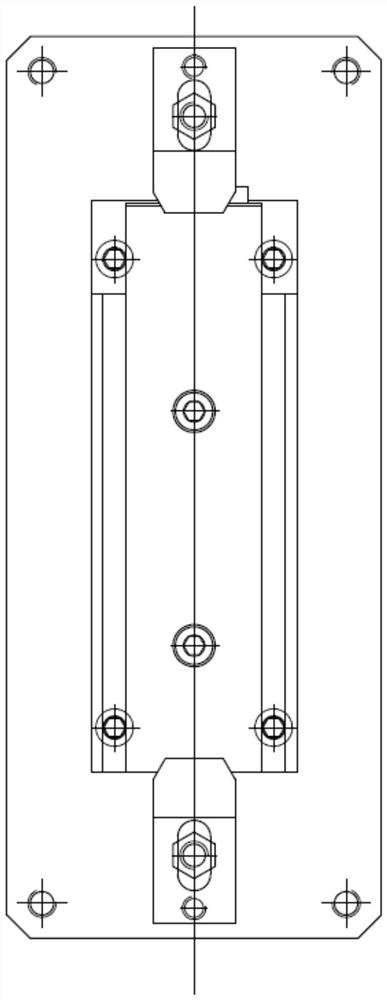

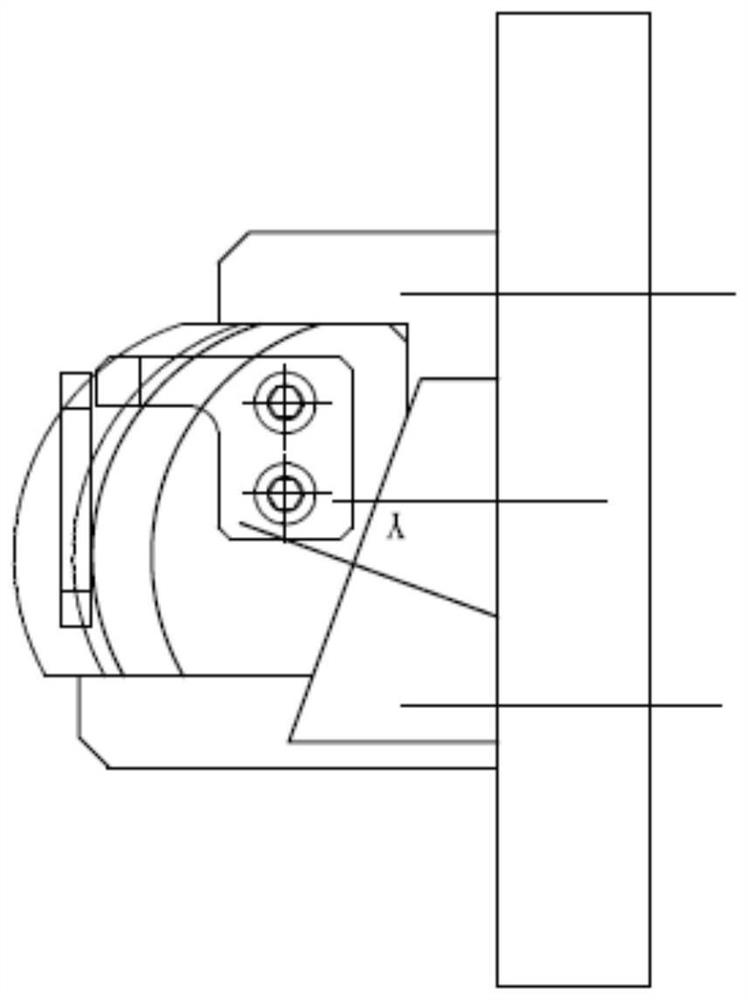

Image

Examples

specific Embodiment approach 1

[0039] Specific Embodiment 1: This embodiment provides a method for processing the assembly surface of a dehumidification blade, which is characterized in that: the method is realized through the following steps:

[0040] Step 1: Select the blank: Compared with the ordinary blank, the selected blank has a 7mm process head margin at the root of the blade, and a 5mm process head margin at the end face of the blade crown;

[0041] Step 2: Machining reference plane: use horizontal milling machine and flat grinding machine to process; first use horizontal milling machine to correct the blank selected in step 1, and process the blank with deviation in size into a cuboid blank, and then use flat grinding machine to grind To cut the six surfaces of the cuboid blank, the parallelism of both sides is required to be 0.02mm, and the dimensional tolerance is -0.03~0mm. The parallelism of the other two sides is 0.05 / 100, and the perpendicularity to both sides is 0.03 / 100. The perpendicular...

specific Embodiment approach 2

[0052] Specific embodiment 2: This embodiment is to further limit the step 2 described in the specific embodiment 1. In this embodiment, the cutting parameters of the horizontal milling machine tool used to correct the milling in the step 2 are: spindle speed: 800r / min , Feed speed: 40mm / min, depth of cut: 1-2mm, cutting parameters processed by flat grinding machine tools are: spindle speed: 26m / s, feed speed: 600mm / min; other components and connection methods and specific implementation methods One is the same.

specific Embodiment approach 3

[0053] Specific embodiment 3: This embodiment is to further limit the step 4 described in the specific embodiment 1. In this embodiment, in the step 4, a powerful grinding machine is used to finish the inner arc of the assembly, and the processing parameters of the fine milling are selected. :

[0054] Cutting depth 0.1mm 6 cutters, spindle speed 26m / s, feed speed 600mm / min;

[0055] Cutting depth 0.05mm 6 knives, spindle speed 26m / s, feed speed 600mm / min;

[0056] Cutting depth 0.02mm2 cutter, spindle speed 26m / s, feed speed 600mm / min;

[0057] Cutting depth 0.02mm 2 knives, spindle speed 26m / s, feed speed 600mm / min;

[0058] The depth of cut is 0.01mm, 2 knives, the spindle speed is 26m / s, and the feed rate is 600mm / min.

[0059] Other compositions and connection methods are the same as those in the second embodiment.

[0060] This embodiment adopts multi-feed grinding, and the single grinding amount is 0.1mm, 0.05mm, 0.02mm, 0.02mm, 0.1mm respectively. The cutting amoun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com